Luossavaara-Kiirunavaara Aktiebolag (LKAB )

Total Page:16

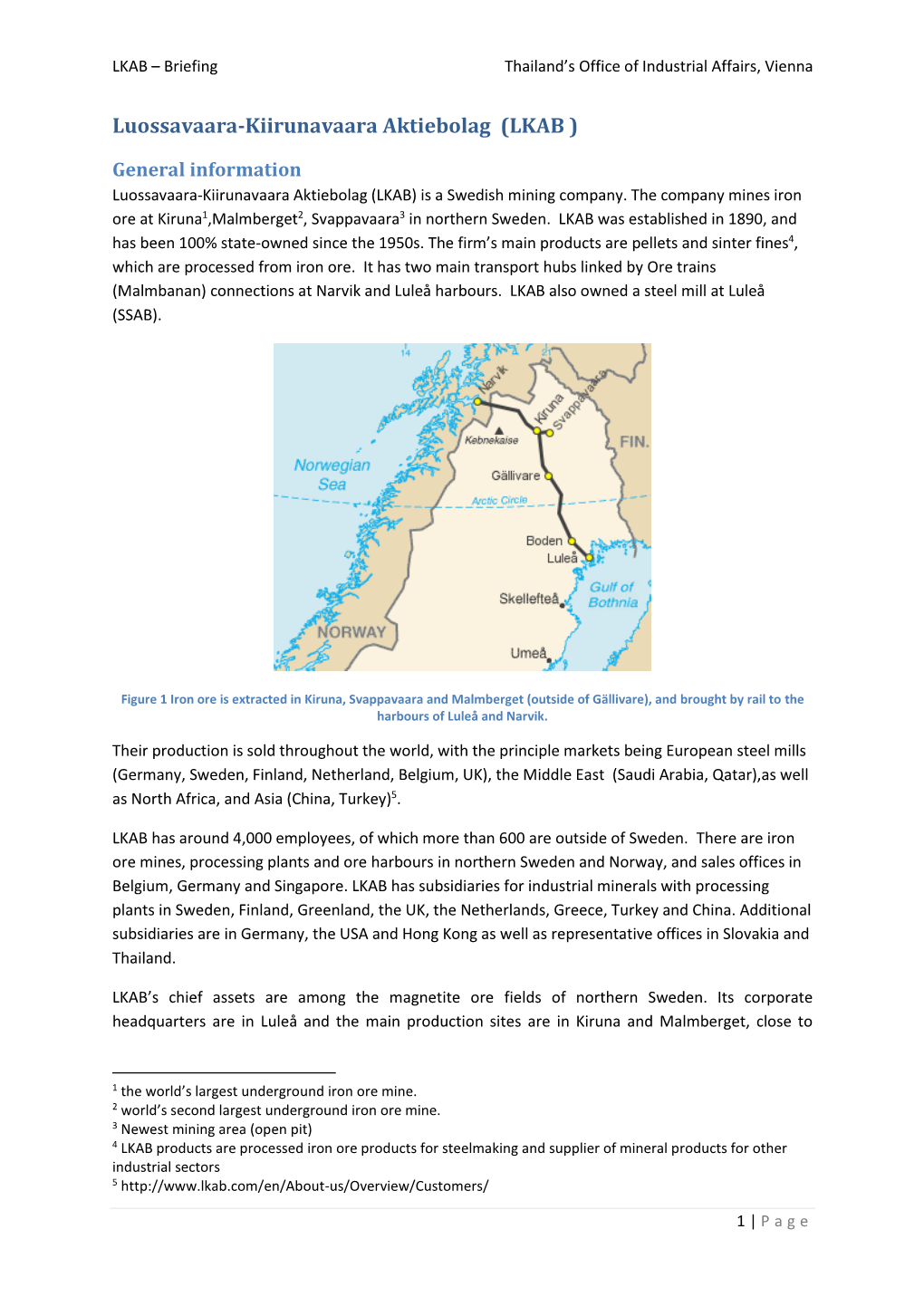

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Fire and Smoke Spread in Underground Mines

Site inventory of operational mines– fire and smoke spread in underground mines. Rickard Hansen Studies in Sustainable Technology 2010:01 Mälardalen University Summary This report is part of the research project “Concept for fire and smoke spread prevention in mines”, conducted by a research group at Mälardalen University. The project is aimed at improving fire safety in mines in order to obtain a safer working environment for the people working for the mining companies in Sweden or for visitors in mines open to the public. This report deals with the second step in the project: the site inventory in operational mines. The main purposes of the inventory are: - To get a clear picture of the risks in the different mines. - To get a clear picture of the protective measures of each mine. - Optimize the choice of design fires for each mine. To find out what the present situation was at the operational mines, a site inventory was conducted at the two LKAB mines. The site inventories were conducted through actual visits to the specific sites and through e-mail correspondence with LKAB personnel responsible for the different sections and areas. During the inventories, predefined forms for each type of item were used in order to facilitate the work. The following items were examined: - Combustible materials in general, for example large amounts of wood. - Vehicles - Cables - Fire barriers - Ventilation systems - Extinguishing systems Besides the above items, earlier fires and fire incidents were also examined. As the two LKAB mines are tremendously large with a large amount of equipment etc, only the most common vehicles were listed and examined further. -

Year-End Report 2019: Strong Earnings in an Uncertain Market

PRESS RELEASE Attachments: Date: 1 (3) 11/02/2020 Contact: Bo Krogvig, Senior Vice President Communications and Climate, LKAB Telephone: +46 (0)8 429 3445 Email: [email protected] Year-end report 2019: Strong earnings in an uncertain market Stable production and favourable market conditions enabled LKAB to increase its operating profit both for the quarter and for the full year, this despite lower delivery volumes. The market remains uncertain, however. Sales for full-year 2019 increased to MSEK 31,260 (25,892) and operating profit strengthened to MSEK 11,788 (6,869), an increase of 72 percent. The improved earnings are mainly due to higher iron ore prices and a stronger dollar exchange rate. Lower sales had an adverse effect. Operating cash flow for the full year increased to MSEK 6,981 (3,386). The improvement is mainly due to the increase in profits and to lower levels of capital expenditure. Higher expenditure on urban transformation had a negative impact. Profit for the year amounted to MSEK 10,173 (5,274) and the Board is proposing to the Annual General Meeting an ordinary dividend amounting to MSEK 6,104 (3,164). For the fourth quarter sales increased to MSEK 6,947 (6,911) and operating profit increased to MSEK 2,047 (1,900). The improved earnings are mainly a result of a stronger dollar exchange rate and lower costs for urban transformation provisions. Lower prices for highly upgraded iron ore products and lower delivery volumes during the quarter had an adverse effect. “I am pleased that we are delivering strong earnings despite an uncertain market and despite making significant investments in both the ongoing urban transformation and our projects for the future. -

Eighth Annual Market Monitoring Working Document March 2020

Eighth Annual Market Monitoring Working Document March 2020 List of contents List of country abbreviations and regulatory bodies .................................................. 6 List of figures ............................................................................................................ 7 1. Introduction .............................................................................................. 9 2. Network characteristics of the railway market ........................................ 11 2.1. Total route length ..................................................................................................... 12 2.2. Electrified route length ............................................................................................. 12 2.3. High-speed route length ........................................................................................... 13 2.4. Main infrastructure manager’s share of route length .............................................. 14 2.5. Network usage intensity ........................................................................................... 15 3. Track access charges paid by railway undertakings for the Minimum Access Package .................................................................................................. 17 4. Railway undertakings and global rail traffic ............................................. 23 4.1. Railway undertakings ................................................................................................ 24 4.2. Total rail traffic ......................................................................................................... -

080515 Lindahl Bukarest II

Sustainable Mining in Europe – The Nordic experience Lars-Åke Lindahl SveMin (Swedish Association of mines, mineral and metal producers) Non-energy mining industry in Europe Bucharest, 15 May 2008 Outline • Introduction • The three pillars of sustainable development/sustainable mining – Economic – Social – Ecology/Environment • Concluding comments Health & Safety Energy Environment Exploration Metalprod. access to land Swedish Association of Mines, issues Mineral and Metal Producers EU- Competence Treaties monitoring with unions The three pillars of Sustainable development • Economic • Social • Ecology/Environment Source: SGU Source: SGU Mines in Sweden Swedish mine production 2006 Metal Production Part of EU Place production Iron 23.3 Mt 89.6 % 1st Gold 6.8 t 32.8 % 1st Silver 292 t 16.9 % 2nd Iron (Poland) Sulphide Gold Zinc 210 Kt 25.4 % 2nd Industrial Minerals (Ireland) Operating Planned Lead 55.6 Kt 30.8 % 2nd (Ireland) Copper 86.7 Kt 12.4 % 2nd (Poland) Source: SGU (Swedish Geological Survey) KIRUNA MINE (LKAB) Automated drillrig, Kiruna mine Remote Controlled Electrical Loader, Kiruna mine THE AITIK MINE (Boliden) Source: SGU Source: SGU The three pillars of Sustainable development • Economic • Social • Ecology/Environment 70 60 Swedish Mining and Mineral Industry (all employees) Lost Day Injury Frequency Rate 1988-2007 50 Occupational Accidents 40 30 20 No. per 1 million worked hours 10 0 1988 1989 1990 1991 1992 Under ground 1993 Surface Total 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 Mining Industry -

Representing the SPANISH RAILWAY INDUSTRY

Mafex corporate magazine Spanish Railway Association Issue 20. September 2019 MAFEX Anniversary years representing the SPANISH RAILWAY INDUSTRY SPECIAL INNOVATION DESTINATION Special feature on the Mafex 7th Mafex will spearhead the European Nordic countries invest in railway International Railway Convention. Project entitled H2020 RailActivation. innovation. IN DEPT MAFEX ◗ Table of Contents MAFEX 15TH ANNIVERSARY / EDITORIAL Mafex reaches 15 years of intense 05 activity as a benchmark association for an innovative, cutting-edge industry 06 / MAFEX INFORMS with an increasingly marked presence ANNUAL PARTNERS’ MEETING: throughout the world. MAFEX EXPANDS THE NUMBER OF ASSOCIATES AND BOLSTERS ITS BALANCE APPRAISAL OF THE 7TH ACTIVITIES FOR 2019 INTERNATIONAL RAILWAY CONVENTION The Association informed the Annual Once again, the industry welcomed this Partners’ Meeting of the progress made biennial event in a very positive manner in the previous year, the incorporation which brought together delegates from 30 of new companies and the evolution of countries and more than 120 senior official activities for the 2019-2020 timeframe. from Spanish companies and bodies. MEMBERS NEWS MAFEX UNVEILS THE 26 / RAILACTIVACTION PROJECT The RailActivation project was unveiled at the Kick-Off Meeting of the 38 / DESTINATION European Commission. SCANDINAVIAN COUNTRIES Denmark, Norway and Sweden have MAFEX PARTICIPTES IN THE investment plans underway to modernise ENTREPRENEURIAL ENCOUNTER the railway network and digitise services. With the Minister of Infrastructure The three countries advance towards an Development of the United Arab innovative transport model. Emirates, Abdullah Belhaif Alnuami held in the office of CEOE. 61 / INTERVIEW Jan Schneider-Tilli, AGREEMENT BETWEEN BCIE AND Programme Director of Banedanmark. MAFEX To promote and support internationalisation in the Spanish railway sector. -

Interim Report Q2

2015 INTERIM REPORT Q2 Luossavaara-Kiirunavaara AB (publ) Corp. ID no. 556001-5835 Financial information from LKAB is available in Swedish and English and can be obtained from: LKAB Communications, Box 952, SE–971 28 Luleå, Sweden. Tel +46 (0)771 76 00 00, Fax +46 (0)771 76 00 01. Financial information is also available on lkab.com APRIL – june JANUARy – june • NET salES TOTALLED MSEK 3,567 (4,957). • NET salES TOTALLED MSEK 7,745 (10,963). • OPERATING LOSS was MSEK -228 (-417). • OPERATING PROFIT was MSEK 147 (1,530). • OPERATING PROFIT BEFORE COSTS FOR URbaN • OPERATING PROFIT BEFORE COSTS FOR URbaN TRANSFORMATION PROVISIONS was MSEK 23 (859). TRANSFORMATION PROVISIONS was MSEK 622 (2,883). • LOSS BEFORE TAX TOTALLED MSEK -548 (-319). • PROFIT BEFORE TAX TOTALLED MSEK 188 (1,707). • LOSS FOR THE PERIOD was MSEK -416 (-247). • PROFIT FOR THE PERIOD was MSEK 190 (1,343). • OPERATING CASH FLOW was MSEK -1,488 (643). • OPERATING CASH FLOW was MSEK -1,195 (2,764). • DELIVERIES OF IRON ORE TOTALLED 5.3 (6.0) MT. • DELIVERIES OF IRON ORE TOTALLED 11.2 (12.6) MT. NET SALES AND OPERATING PROFIT COMMENTS BY THE PRESIDENT AND CEO Net sales Q2 2015 Net sales Operating profit MSEK COSTS IN FOCUS AS PRICE 8000 7000 PRESSURE CONTINUES IN THE 6000 MARKET 5000 4000 3000 Low iron ore prices and fewer deliveries planned to begin as early as the summer of 2015. 2000 are putting pressure on LKAB’s profitability. Full production should be reached in Q2 2016 as 1000 Meanwhile, efforts to reduce costs are having previously announced. -

Jukkasjärvi Socken

Arkiv nr Arkivnamn Serie 1:1 NORRBOTTENS MUSEUM FO AH Rubrik HANDLINGAR OM JUKKASJÄRVI SOCKEN Placering Volymnr Tid Anmärkningar Volym 1-5 Fornfynd, fornminnen, fornlämningar. Volym 6 Sjöregleringar, Historia, uppteckningar. Volym 7-8 Byggnadsinventering längs Malmbanan. Volym 9 Jukkasjärvi samhälle. Volym 10 Kyrkor, Kyrkogårdar. Volym 11 Hembygdsgården och hembygdsföreningen. Volym 12-19 Byar och gårdar. Volym 20 Övrigt. 1 1931-2001 FORNFYND, FORNMINNEN, FORNLÄMNINGAR Rapport över arkeologiska undersökningar i Jukkasjärvi socken 1954. Historik - kulturhistoriskt skyddsvärde (från olika byar och platser i Jukkasjärvi sn) Fyndförteckningar från SHM, utan år. Uppgift om fynd av pilspets, utan år. Handlingar om Jukkasjärviexpeditionen 1931-1932. 0138/34 Ang. Lapplandsundersökningen (med 0192/34). 0043/37 Ang. mejsel av skiffer. 0674/38 Skiss av pilspets funnen vid Vuoskajärvi. 0492/40 Ang. stenformation vid Vaikkojärvi, Vaikkolombolo. Ang. fynd av skida 1943. 0014/47 Ang. mynt från Övre Soppero. 0267/47 Ang. fynd av stenåldersverktyg i Vittangi. Inv. nr. 5014 (med 0300/47). 0167/48 Ang. fynd av spikar m.m. från Svappavaara. 0125/48 Ang. bidrag till undersökning. Ang. sten från Pjeskenjarka 1948. 0231/48 Ang. stort fångstgropsystem (med 0034/54). 0234/48 Ang. skelettdelar på Jeprinsuolo, Torneträsk. 0101/51 Ang. kvarnstenar i Kurravaara. 0033/53 Ang. fynd av sten, troligen i Kuoksu. Pm om ev. fornlämning nedanför Tuollavaara. 0202/60 Ang. Jukkasjärviundersökningen. 0115/54 Ang. förmodad plats för Jukkasjärvi gamla kyrka och undersökning av skelettdelar (med 0136/54). 0089/54 Ang. fynd av människoben från Altavaara, ev. gamla begravningsplatsen i Jukkasjärvi (med 0105/54). Uppteckning om avrättad same vid Altavaara 1841, 1943. Pm om undersökning av kåtatomt vid Bergfors, 1956. -

Tests for Heavier Transports on the Ore Railway

PRESS RELEASE Attachement: Date: 1 (2) 19/04/2021 Contact person: Anders Lindberg, Group Media Relations Manager Phone: +46 72 717 8355 E-Mail: [email protected] Tests for heavier transports on the Ore Railway Trafikverket (the Swedish Transport Administration), together with LKAB and Bane Nor, is conducting tests on the Swedish and Norwegian sections of the Ore Railway to enable heavier transports in future. Therefore, the axle load for ore cars is being increased from 30 tonnes to 31 tonnes. “The purpose of the tests is to determine which stretches of the railway must be upgraded to enable an increase in the payload weight of cars operating on the line and thereby create a more efficient and environmentally friendly transport system. Quite simply, through testing, we want to determine how higher axle load affects wear on rails and switches. Testing is beginning now and we will assess the results on an ongoing basis,” says Staffan Ökvist, maintenance manager for Trafikverket's northern region. Testing will be carried out on both the Swedish and Norwegian stretches of the railway that runs between Kiruna and Narvik (Malmbanan and Ofotbanan). For some time, testing has also been under way on the southern section of the line, between Malmberget and Luleå. In business and industry there is a great demand for increased capacity on the Ore Railway. By upgrading the railway, more freight can be hauled without increasing the number of trains operating on the line. The tests are part of a forward-thinking strategy, the ambition of which is to be able in future to operate trains with an axle load of 32.5 tonnes along the entire Ore Railway. -

2005-12 Fram-Baksida Kiruna VV FS.Indd

Förstudie Kirunaprojektet, Allmänna vägar i Kiruna 6 Planeringsförutsättningar 6.1 Trafi k och trafi kanter I detta avsnitt redovisas befi ntliga förutsättningar som främst har 6.1.1 MÅLPUNKTER 6.1.2 ARBETSPENDLING betydelse för planeringen av vägar på kort sikt. På lång sikt är förändringen av dessa förutsättningar av betydelse för långsiktigt Huvuddelen av de offentliga och kommersiella serviceinrätt- Trots långa avstånd förekommer arbetspendling mellan Kiruna och hållbara lösningar. ningarna är lokaliserade till stadsdelen Centrum. Av det totala anta- övriga kommuner inom Norrbottens län. De viktigaste pendlingsor- let arbetstillfällen inom Kiruna stad fi nns cirka 80% inom stadsde- terna redovisas i tabell 6.1. Det är cirka 70 personer fl er som pend- Konsekvenser och effekter redovisas i avsnitt 12. I förekommande larna Centrum, Bolaget, Järnvägen och Industrin. lar till Kiruna än som pendlar från Kiruna. fall har studerade korridorer som redovisas i avsnitt 11. Tänkbara åtgärder lagts in med konturlinjer på kartor för att underlätta förstå- Följande målpunkter bedöms vara av störst vikt: elsen av konsekvensbeskrivningar i avsnitt 12. Mål för turistresor: Mål för tjänsteresor: Stadscentrum LKAB Kyrkan Stadshuset Campingplatsen Sjukhuset Jukkasjärvi Mål för arbetsresor: Flygplatsen Stadscentrum Mål för besöksresor: Industriområden Bostadsområden Sjukhuset Skolor För redovisning av skolor som mål- punkter se avsnitt 6.1.7 Barriäreffek- ter. Loussajärvi Arbetspendling Arvids- Boden Gälli- Hapa- Jokk- Kalix Luleå Pajala Piteå Över- Summa Kiruna 2003 jaur vare randa mokk torneå Utpendling till: 34 24 85 2 12 21 140 26 9 1 Ut: 355 Inpendling från: 2 13 210 8 9 7 62 86 10 11 In: 428 9832 pers har Kiruna som både bostads- och arbetsställekommun Pendlingsnetto: 73 Tabell 6.1. -

Annual Report and Sustainability Report

ANNUAL REPORT AND LKAB SUSTAINABILITY REPORT ANNUAL REPORT AND SUSTAINABILITY REPORT AND SUSTAINABILITY ANNUAL REPORT CONTENTS Events in brief 2 The LKAB Manifesto 3 Overview of the past year 4 President’s report 6 Group strategies 9 LKAB 2009 11 Economic trends, market 13 Steel demands iron ore 16 International trade 17 The iron ore mines 18 Prospecting, ore reserves 19 From iron ore to pellets 20 Production 2009 21 Research and development 22 Human resources 23 Investments 24 The industrial minerals business 25 Subsidiaries 26 2009 SUSTAINABILITY REPORT 27 Stakeholders and sustainability issues 28 Value creation 29 Control of sustainability activities 30 Urban transformation 31 Environment 34 Co-workers 44 Involvement in local communities 49 About LKAB’s Sustainability Report for 2009 106 GRI index 106 Auditors’ statement of assurance 108 CORPORATE GOVERNANCE REPORT 50 Board of Directors and Group Management 55 FINANCE 58 Group overview 58 Contents, financial statements 59 Report of the Directors 60 Financial reports and notes 68 LKAB, BOX 952, SE-971 28 LULEÅ, SWEDEN Proposed disposition of unappropriated earnings 104 www.lkab.com Auditors’ Report 105 Glossary 109 Addresses 110 Annual General Meeting 20092009 and financial information 111 ANNUAL REPORT AND LKAB SUSTAINABILITY REPORT ANNUAL REPORT AND SUSTAINABILITY REPORT AND SUSTAINABILITY ANNUAL REPORT CONTENTS Events in brief 2 The LKAB Manifesto 3 Overview of the past year 4 President’s report 6 Group strategies 9 LKAB 2009 11 Economic trends, market 13 Steel demands iron ore 16 -

Geology of the Northern Norrbotten Ore Province, Northern Sweden Paper 3 (13) Editor: Stefan Bergman

Rapporter och meddelanden 141 Geology of the Northern Norrbotten ore province, northern Sweden Paper 3 (13) Editor: Stefan Bergman Rapporter och meddelanden 141 Geology of the Northern Norrbotten ore province, northern Sweden Editor: Stefan Bergman Sveriges geologiska undersökning 2018 ISSN 0349-2176 ISBN 978-91-7403-393-9 Cover photos: Upper left: View of Torneälven, looking north from Sakkara vaara, northeast of Kiruna. Photographer: Stefan Bergman. Upper right: View (looking north-northwest) of the open pit at the Aitik Cu-Au-Ag mine, close to Gällivare. The Nautanen area is seen in the back- ground. Photographer: Edward Lynch. Lower left: Iron oxide-apatite mineralisation occurring close to the Malmberget Fe-mine. Photographer: Edward Lynch. Lower right: View towards the town of Kiruna and Mt. Luossavaara, standing on the footwall of the Kiruna apatite iron ore on Mt. Kiirunavaara, looking north. Photographer: Stefan Bergman. Head of department, Mineral Resources: Kaj Lax Editor: Stefan Bergman Layout: Tone Gellerstedt och Johan Sporrong, SGU Print: Elanders Sverige AB Geological Survey of Sweden Box 670, 751 28 Uppsala phone: 018-17 90 00 fax: 018-17 92 10 e-mail: [email protected] www.sgu.se Table of Contents Introduktion (in Swedish) .................................................................................................................................................. 6 Introduction .............................................................................................................................................................................. -

Bilaga 2 Anläggningar

Bilaga 2 Anläggningar 2 (12) Innehåll 1 FYSISK PLANERING FÖR ANLÄGGNINGAR OCH AVFALLSLÖSNINGAR ................ 4 2 ÅVC............................................................................................................. 5 2.1 Kiruna ÅVC ........................................................................................ 5 2.2 ÅVC i byarna ...................................................................................... 5 3 KIRUNA AVFALLSANLÄGGNING ..................................................................... 5 4 KIRUNA VÄRMEVERK .................................................................................... 7 5 SLAMLAGUNER ............................................................................................ 8 5.1 Frys-/torkbädd i Lainio ..................................................................... 8 5.2 Frys-/torkbädd Karesuando .............................................................. 9 5.3 Frys-/torkbädd i Soppero (Soppero avfallsupplag enl. Mk lista) ...... 9 5.4 Frys-/torkbädd i Saivomuotka .......................................................... 9 5.5 Frys-/torkbädd Vittangi avloppsreningsverk .................................. 10 6 TILLSTÅNDSPLIKTIGA ANLÄGGNINGAR MED PRIVATA VERKSAMHETSUTÖVARE ............................................................................. 10 6.1 Svevias anläggning, Svappavaara .................................................... 10 6.2 Kuusakoski Sverige AB ..................................................................... 11 6.3 Stena Miljö