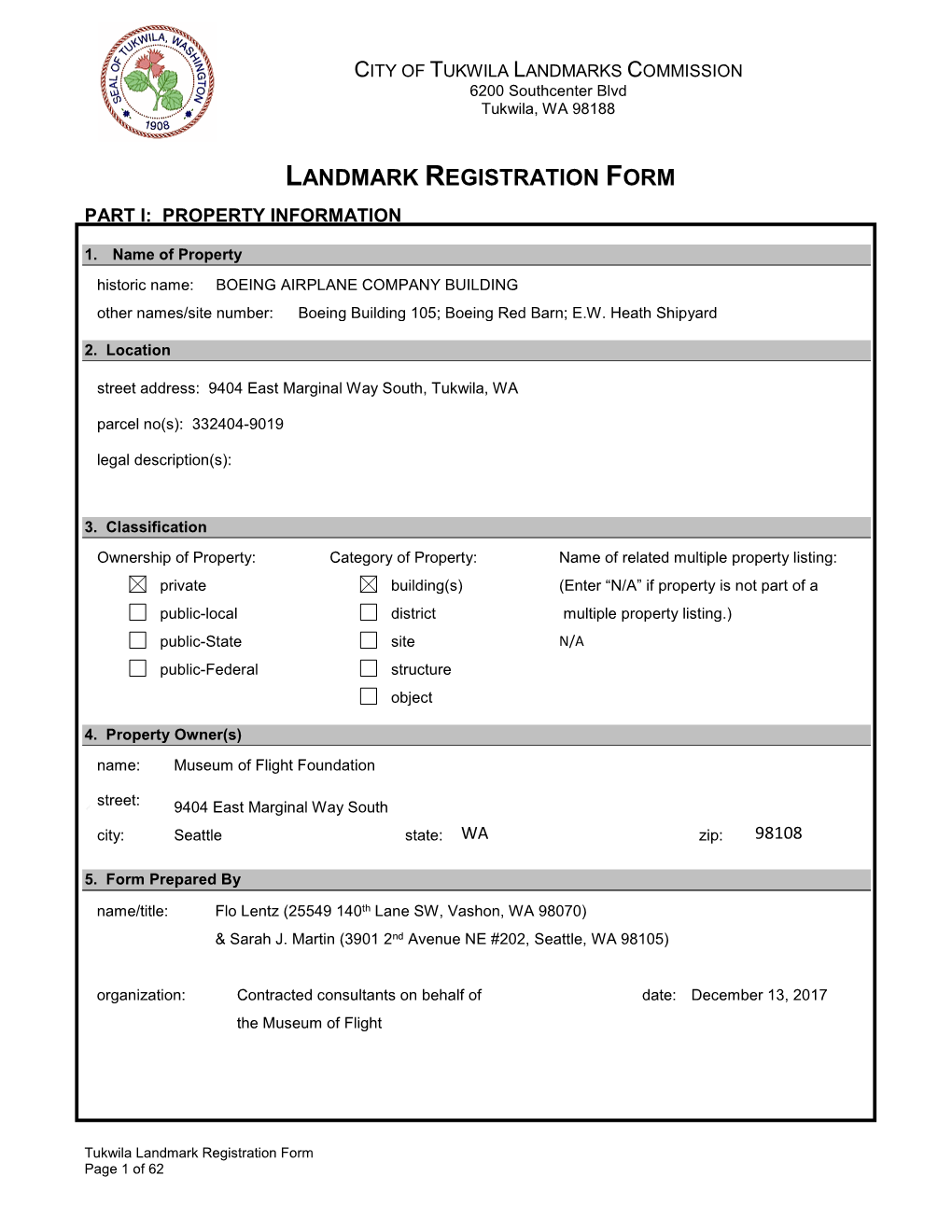

Tukwila's Boeing Red Barn

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Comments to Paine Field Airport; They Have Been Noted

SnohoniLt 1) • 17’ 1 J ,4$~ic~ Comments Countvkitport u amer len ~F Environtuental Assessinen~ ~~S4LW, LOft. 9~t7f NSCtEwJ cn~, cc~c i2~k ~u u~ COMMENTS: A~ 4o~i-c ~M ~—Tw*~ C Ia Dave Waggoner Cayla Morgan Director Environmental Protection Spedalist Snohomish County Airport Seattle Airports District Office Comments to 3220 100th Street Southwest or Federal Aviation Administration Everett, Washington 98204 1601 Lind Avenue, SW Barnard Dunkelberg >? Company Email. [email protected] Renton, Washington 98057-3356 BridgeNet International Email. [email protected] Synergy Consultants Gibson Traffic Consultants Thank You! D.1 Response to Comment Dear Jeanne and George Dalton: Thank you for your comments to Paine Field Airport; they have been noted. D.2 -Original Message— From: [email protected] [mailto:[email protected]] Sent: Wednesday, January 20, 2010 5:40 PM To: Waggoner, Dave; Dolan, Bill; Ryk Dunkelberg; Ryan Hayes Cc: [email protected]; [email protected]; Roland. J.McKee@faa . gov Subject: Fw: Paine Field review Cayla Morgan Environmental Protection Specialist Seattle Airports District Office Federal Aviation Administration 425—227—2653 Forwarded by Cayla Morgan/ANM/FAA on 01/20/2010 04:38 PM I > From: I I > I > IStephen Dana <[email protected]> > > I To: I > I > Cayla Morgan/ANM/FAA@FAA I > > Date: I > > 101/20/2010 03:22 PM > > Subject: I > > IPaine Field review > D.3 January 19, 2010 Cayla Morgan Environmental Protection Specialist Seattle Airport District Office, FAA 1601 Lind Ave SW Renton, WA 98057 Ms. Morgan, The matter of commercial air service at Paine field is up for environmental review before your office in the coming weeks. -

NOVEMBER 3, 1980 I WASHINGTON, D.C

THE whl7”c hci;Sg 1 TiiE OAiLY DIARY OF PREStDENt JIMMY CARSER 1 SF--.- ! Loc.xrIoN 3AsE &to.. Day. Yt.1 me. f THE WHITE HOUSE NOVEMBER 3, 1980 i WASHINGTON, D.C. TIX E DAY . -*: L 5:00 a.m. MONDAY I R I The President received a wake up call from the White House f signal board operator. I 5:18 i R The President talked on a conference line with: , I Edmund S. Muskie, Secretary of State I warren M. Christopher, Deputy Secretary of State 5 :*20 597 P‘ The President talked with his Press Secretary, Joseph L. "Jody" iI Powell. 5 = 31 5 = 35 P The President talked with Hamilton Jordan, Deputy Campaign Chairman, Carter Mondale Presidential Committee, Inc. 5:50 f The President went to the Oval Office. 5:50 5:51 P The President talked with Charles H. Kirbo, partner with King I t and Spalding law firm, Atlanta, Georgia. i 6~26 ; P The President telephoned the First Lady. The call was not I I completed. I I I 7:02 / 7:Og R 1 The President talked with the First Lady. I ; The President met with: 8:oo 1 8:18 Mr. Powell 8:oo 1 8:18 Gerald M. Rafshoon, President, Rafshoon Communications, ! I I I Washington, D.C. 8:oo 1 8:18 Patrick J. Caddell, President, Cambridge Survey, I I Cambridge, Massachusetts Mr. Kirbo Jack H. Watson, Jr., Chief of Staff Mr. Jordan a:18 The President went to the Cabinet Room. He was accompanied by: Mr. Watson Mr. -

The Seattle Foundation Annual Report Donors & Contributors 3

2008 The Seattle Foundation Annual Report Donors & Contributors 3 Grantees 13 Fiscal Sponsorships 28 Financial Highlights 30 Trustees and Staff 33 Committees 34 www.seattlefoundation.org | (206) 622-2294 While the 2008 financial crisis created greater needs in our community, it also gave us reason for hope. 2008 Foundation donors have risen to the challenges that face King County today by generously supporting the organizations effectively working to improve the well-being of our community. The Seattle Foundation’s commitment to building a healthy community for all King County residents remains as strong as ever. In 2008, with our donors, we granted more than $63 million to over 2000 organizations and promising initiatives in King County and beyond. Though our assets declined like most investments nationwide, The Seattle Foundation’s portfolio performed well when benchmarked against comparable endowments. In the longer term, The Seattle Foundation has outperformed portfolios comprised of traditional stocks and bonds due to prudent and responsible stewardship of charitable funds that has been the basis of our investment strategy for decades. The Seattle Foundation is also leading efforts to respond to increasing need in our community. Late last year The Seattle Foundation joined forces with the United Way of King County and other local funders to create the Building Resilience Fund—a three-year, $6 million effort to help local people who have been hardest hit by the economic downturn. Through this fund, we are bolstering the capacity of selected nonprofits to meet increasing basic needs and providing a network of services to put people on the road on self-reliance. -

Informational Handout: King County International Airport-Boeing Field Seattle, Washington

Informational Handout: King County International Airport-Boeing Field Seattle, Washington Published Visual Flight Rules (VFR) routes for arrivals and departures. Project Background The Federal Aviation Administration (FAA) cancelled two existing VFR routes for aircraft landing and departing King County International Airport-Boeing Field (KBFI) and replaced them with newly defined routes (retaining some of the existing names). The term “routes” can best be described in this instance as a “set of pre-coordinated instructions” that is given to VFR pilots. The routes enhance safety by increasing separation between arrival and departure flows into KBFI, Seattle-Tacoma International Airport (KSEA), and Renton Municipal Airport (KRNT). Purpose of Changes There have been Traffic Alert and Collision Avoidance System (TCAS) events involving VFR aircraft arriving and departing KBFI, and these routes are intended to reduce TCAS events and enhance safety. TCAS monitors the airspace around an aircraft for other aircraft equipped with proper equipment, independent of air traffic control, and warns pilots of the presence of other properly equipped aircraft in the immediate area. Project Description The project results in a change to past operating procedures by publishing several existing routes for VFR aircraft to use when arriving and departing from either runway configuration at KBFI. KBFI Airport Traffic Control Tower (BFI ATCT) now has the ability to assign published routes rather than issuing tailored instructions. The new VFR routes provide better predictability, enhance safety, and improve the segregation of aircraft arriving and departing KBFI. What Changed The new VFR routes follow pre-existing air traffic flight tracks that are assigned by BFI ATCT and no new areas will experience new air traffic overflights. -

Washington Funding Report: FY 2011 – 2016

Washington Institute of Museum and Library Services Funding Report: FY 2011 - 2016 The Institute of Museum and Library Services (IMLS) helps ensure that all Americans have access to museum, library, and information services. IMLS is an independent grantmaking agency and the primary source of federal support for the nation’s approximately 123,000 libraries and 35,000 museums. The agency supports innovation, lifelong learning, and entrepreneurship, enabling museums and libraries to deliver services that make it possible for communities and individuals to thrive. IMLS Investments IMLS Investments: FY 2011-2016 # Projects Federal % of Non-Federal Total $ or Awards Funding Federal $ Contribution $ Grants to States, Libraries 431 * $19,618,687 59% $12,830,000 * $32,448,687 Competitive Awards to Museums & Libraries 146 $13,378,884 41% $10,161,216 $23,540,100 Total 577 $32,997,571 100% $22,991,216 $55,988,787 * FY 2016 data for the Grants to States, Libraries count of projects and non-federal contribution are not yet available. Figures shown here only include FY 2011-2015. Grants to State Library Administrative Agencies The Library Grants to States Program, supported by the Library Grants to States Awards (LSTA): Services and Technology Act (LSTA), is IMLS's largest program and FY 2011-2016 provides grants to every state using a population-based formula. State Library Administrative Agencies (SLAAs) provide IMLS with a five-year FY 2016 $3.26 M plan and use subawards and statewide projects to improve library services. FY 2015 $3.30 M In FY 2014, IMLS’s $3.28 million grant to the SLAA leveraged FY 2014 $3.28 M approximately $2.27 million in support from the state that year for library services through the SLAA. -

PDF Download

August 2008 | Volume VII, Issue IV www.boeing.com/frontiers The Weapons Program team at Boeing is reinventing itself to better meet emerging warfighter needs. August 2008 Volume VII, Issue IV BOEING FRONTIERS ON THE COVER: Mike Dour performs final-assembly tasks on a Small Diameter Bomb in St. Charles, Mo. RICHARD RAU PHOTO COVER STORY RICHARD RAU PHOTO BULLSEYE | 12 Otis Stith uses ergonomic handling equipment to move a Joint Direct Attack Munition tailkit from the St. Charles, Mo., assembly line to the packaging area. He’s a member of the newly formed Weapons Programs organization, which is reinventing itself to better meet warfighter needs and deliver even greater capabilities to U.S. and allied forces. FEATURE STORY | 50 Rich history, strong future Turkey reveres its storied past as it moves confidently into a technologically capable, global future. With 65 percent of its population age 34 and under, the country is working to develop a tech-savvy work force. That’s important to Boeing, which is undertaking a cross-enterprise approach to doing business in this market—the home to customers in both the commercial and defense segments. BOEING FRONTIERS AUGUST 2008 3 Contents BOEING FRONTIERS A clean handoff | 22 In July, the first P-8A Poseidon achieved “factory complete” status as workers at the Boeing Commercial Airplanes factory in Renton, Wash., rolled it off the moving assembly line. Now, Integrated Defense Systems teammates will com- plete systems integration and functional checks. A load of assistance | 27 Boeing Commercial Airplanes’ structures engineer- ing team was spread thin supporting several development programs. -

10 Great Places to Savor the Wild Blue Yonder

As seen in USA TODAY, AUGUST 18, 2006 10 great places to savor the wild blue yonder Fasten your seat belt and soar back in restored them to pristine condition time to celebrate National Aviation using only original materials." A num- Day on August 19. From early stick- ber are flown regularly for visitors, and-canvas constructions to the including a North American P-51 Saturn V's 7.5 million pounds of Mustang and "a Curtiss Jenny from thrust, the exhibits at aviation muse- the barnstorming era." Oral histories ums are over the top. Pat Trenner, a from those who flew the aircraft give pilot and senior editor at Air and visitors the story behind the planes. Space magazine, shares her favorites 360-435-2172; flyingheritage.com with Kathy Baruffi for USA TODAY. National Museum of the United Old Rhinebeck Aerodrome States Air Force Rhinebeck, N.Y. Dayton, Ohio Some people plan their vacations The collection of Air Force Ones is a around the Aerodrome's 20-minute big draw here. Visitors can board and open-cockpit biplane tours above the "see the desks and beds in FDR, lush Hudson Valley. They also come Truman, Eisenhower and JFK presi- for the vast collection of early air- dential planes," Trenner says. Plus, planes and to watch air shows. "Every there's "an A-to-Z collection of inter- weekend from June to October, Old national airpower," from early bal- Rhinebeck re-creates a delightfully loons to modern-day craft. 937-255- Mike Tsukamoto, USA TODAY corny World War I air battle, com- Air history: Visitors to the Steven F. -

Washington State National Maritime Heritage Area Feasibility Study for Designation As a National Heritage Area

Washington State National Maritime Heritage Area Feasibility Study for Designation as a National Heritage Area WASHINGTON DEPARTMENT OF ARCHAEOLOGY AND HISTORIC PRESERVATION Washington State National Maritime Heritage Area Feasibility Study for Designation as a National Heritage Area WASHINGTON DEPARTMENT OF ARCHAEOLOGY AND HISTORIC PRESERVATION APRIL 2010 The National Maritime Heritage Area feasibility study was guided by the work of a steering committee assembled by the Washington State Department of Archaeology and Historic Preservation. Steering committee members included: • Dick Thompson (Chair), Principal, Thompson Consulting • Allyson Brooks, Ph.D., Department of Archaeology and Historic Preservation • Chris Endresen, Office of Maria Cantwell • Leonard Forsman, Chair, Suquamish Tribe • Chuck Fowler, President, Pacific Northwest Maritime Heritage Council • Senator Karen Fraser, Thurston County • Patricia Lantz, Member, Washington State Heritage Center Trust Board of Trustees • Flo Lentz, King County 4Culture • Jennifer Meisner, Washington Trust for Historic Preservation • Lita Dawn Stanton, Gig Harbor Historic Preservation Coordinator Prepared for the Washington State Department of Archaeology and Historic Preservation by Parametrix Berk & Associates March , 2010 Washington State NATIONAL MARITIME HERITAGE AREA Feasibility Study Preface National Heritage Areas are special places recognized by Congress as having nationally important heritage resources. The request to designate an area as a National Heritage Area is locally initiated, -

Flying the Line Flying the Line the First Half Century of the Air Line Pilots Association

Flying the Line Flying the Line The First Half Century of the Air Line Pilots Association By George E. Hopkins The Air Line Pilots Association Washington, DC International Standard Book Number: 0-9609708-1-9 Library of Congress Catalog Card Number: 82-073051 © 1982 by The Air Line Pilots Association, Int’l., Washington, DC 20036 All rights reserved Printed in the United States of America First Printing 1982 Second Printing 1986 Third Printing 1991 Fourth Printing 1996 Fifth Printing 2000 Sixth Printing 2007 Seventh Printing 2010 CONTENTS Chapter 1: What’s a Pilot Worth? ............................................................... 1 Chapter 2: Stepping on Toes ...................................................................... 9 Chapter 3: Pilot Pushing .......................................................................... 17 Chapter 4: The Airmail Pilots’ Strike of 1919 ........................................... 23 Chapter 5: The Livermore Affair .............................................................. 30 Chapter 6: The Trouble with E. L. Cord .................................................. 42 Chapter 7: The Perils of Washington ........................................................ 53 Chapter 8: Flying for a Rogue Airline ....................................................... 67 Chapter 9: The Rise and Fall of the TWA Pilots Association .................... 78 Chapter 10: Dave Behncke—An American Success Story ......................... 92 Chapter 11: Wartime............................................................................. -

Rock Solid Performance WHY Caterpillar?

2012 YEAR IN REVIEW ROCK SOLID Potential | Position | Plan | People | Performance In a global marketplace filled with shifting dynamics, our customers count on Caterpillar as a dependable source of products, services and solutions to meet their needs. This strategy is the stabilizing force behind our business. Today, we’re as confident of our rock solid strength as at any time in our history. ROCK SOLID 2012 Year in Review Forward-Looking Statements Certain statements in this 2012 Year in Review relate to future events and expectations and are forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Words such as “believe,” “estimate,” “will be,” “will,” “would,” “expect,” “anticipate,” “plan,” “project,” “intend,” “could,” “should” or other similar words or expressions often identify forward-looking statements. All statements other than statements of historical fact are forward-looking statements, including, without limitation, statements regarding our outlook, projections, forecasts or trend descriptions. These statements do not guarantee future performance, and we do not undertake to update our forward-looking statements. Caterpillar’s actual results may differ materially from those described or implied in our forward-looking statements based on a number of factors, including, but not limited to: (i) global economic conditions and economic conditions in the industries and markets we serve; (ii) government monetary or fiscal policies and infrastructure spending; (iii) commodity or component -

Boeing Reports Second-Quarter Results

Boeing Reports Second-Quarter Results ▪ Continued progress on global safe return to service of 737 MAX ▪ Revenue of $17.0 billion, GAAP earnings per share of $1.00 and core (non-GAAP)* earnings per share of $0.40 ▪ Operating cash flow of ($0.5) billion; cash and marketable securities of $21.3 billion ▪ Commercial Airplanes backlog grew to $285 billion and added 180 net orders Table 1. Summary Financial Results Second Quarter First Half (Dollars in Millions, except per share data) 2021 2020 Change 2021 2020 Change Revenues $16,998 $11,807 44% $32,215 $28,715 12% GAAP Earnings/(Loss) From Operations $1,023 ($2,964) NM $940 ($4,317) NM Operating Margin 6.0 % (25.1) % NM 2.9 % (15.0) % NM Net Earnings/(Loss) $567 ($2,395) NM $6 ($3,036) NM Earnings/(Loss) Per Share $1.00 ($4.20) NM $0.09 ($5.31) NM Operating Cash Flow ($483) ($5,280) NM ($3,870) ($9,582) NM Non-GAAP* Core Operating Earnings/(Loss) $755 ($3,319) NM $402 ($5,019) NM Core Operating Margin 4.4 % (28.1) % NM 1.2 % (17.5) % NM Core Earnings/(Loss) Per Share $0.40 ($4.79) NM ($1.12) ($6.49) NM *Non-GAAP measure; complete definitions of Boeing’s non-GAAP measures are on page 6, “Non-GAAP Measures Disclosures." CHICAGO, July 28, 2021 – The Boeing Company [NYSE: BA] reported second-quarter revenue of $17.0 billion, driven by higher commercial airplanes and services volume. GAAP earnings per share of $1.00 and core earnings per share (non-GAAP)* of $0.40 primarily reflects higher commercial volume and lower period costs (Table 1). -

Successor to Boeing 737 Likely to Be Built in State Page 1 of 3

The Seattle Times: Successor to Boeing 737 likely to be built in state Page 1 of 3 Friday, December 30, 2005 - 12:00 AM Permission to reprint or copy this article or photo, other than personal use, must be obtained from The Seattle Times. Call 206-464-3113 or e-mail [email protected] with your request. Successor to Boeing 737 likely to be built in state By Dominic Gates Seattle Times aerospace reporter Good news from Boeing Commercial Airplanes Chief MIKE SIEGEL / THE SEATTLE TIMES Executive Alan Mulally: The company's next airplane after In 2004, Boeing Commercial the 787 is likely to be assembled in Washington state. And Airplanes CEO Alan Mulally an announcement on that program could come soon after the applauds Everett workers after 787 enters service in 2008. announcing the launch order for the 787 from All Nippon Airways. Mulally says he sees no reason why At least one Boeing critic thought the next plane up — the a replacement for the 737 won't be replacement for the narrow-body 737 — might be assembled built here, too. in Japan. But it appears the state's $3.2 billion tax-incentive package passed in 2004 has secured more than the 787. Asked in a year-end interview if the 737 replacement would be built here, Mulally responded: "I don't see any reason why not. "I couldn't be more pleased with the response we all have had [from Washington state]. We have so many people that understand the importance of improving our competitiveness," he added.