Moose R. Basin: Cretaceous Deposits

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Letters F and T Refer to Figures Or Tables Respectively

INDEX The letters f and t refer to figures or tables respectively "A" Marker, 312f, 313f Amherstberg Formation, 664f, 728f, 733,736f, Ashville Formation, 368f, 397, 400f, 412, 416, Abitibi River, 680,683, 706 741f, 765, 796 685 Acadian Orogeny, 686, 725, 727, 727f, 728, Amica-Bear Rock Formation, 544 Asiak Thrust Belt, 60, 82f 767, 771, 807 Amisk lowlands, 604 Askin Group, 259f Active Formation, 128f, 132f, 133, 139, 140f, ammolite see aragonite Assiniboia valley system, 393 145 Amsden Group, 244 Assiniboine Member, 412, 418 Adam Creek, Ont., 693,705f Amundsen Basin, 60, 69, 70f Assiniboine River, 44, 609, 637 Adam Till, 690f, 691, 6911,693 Amundsen Gulf, 476, 477, 478 Athabasca, Alta., 17,18,20f, 387,442,551,552 Adanac Mines, 339 ancestral North America miogeocline, 259f Athabasca Basin, 70f, 494 Adel Mountains, 415 Ancient Innuitian Margin, 51 Athabasca mobile zone see Athabasca Adel Mountains Volcanics, 455 Ancient Wall Complex, 184 polymetamorphic terrane Adirondack Dome, 714, 765 Anderdon Formation, 736f Athabasca oil sands see also oil and gas fields, Adirondack Inlier, 711 Anderdon Member, 664f 19, 21, 22, 386, 392, 507, 553, 606, 607 Adirondack Mountains, 719, 729,743 Anderson Basin, 50f, 52f, 359f, 360, 374, 381, Athabasca Plain, 617f Aftonian Interglacial, 773 382, 398, 399, 400, 401, 417, 477f, 478 Athabasca polymetamorphic terrane, 70f, Aguathuna Formation, 735f, 738f, 743 Anderson Member, 765 71-72,73 Aida Formation, 84,104, 614 Anderson Plain, 38, 106, 116, 122, 146, 325, Athabasca River, 15, 20f, 35, 43, 273f, 287f, Aklak -

Current Research in the Geological Sciences in Canada, May 1980-April 1981 Projets De Recherche En Cours D'execution Au Canada - Sciences Geologiques

GEOLOGICAL SURVEY PAPER 81-5 COMMISION GEOLOGIOUE ETUDE 81-5 CANADIAN GEOSCIENCE COUNCIL LE CONSEIL CANADIEN DES SCIENCES DE LA TERRE CURRENT RESEARCH IN THE GEOLOGICAL SCIENCES IN CANADA, MAY 1980-APRIL 1981 PROJETS DE RECHERCHE EN COURS D'EXECUTION AU CANADA - SCIENCES GEOLOGIQUES. MAI 1980-AVRIL 1981 Compiled by/Prepare par THOMAS E. BOLTON 1981 © Minister of Supply and Services Canada 1981 Available in Canada through authorized bookstore agents and other bookstores or by mail from Canadian Government Publishing Centre Supply and Services Canada Hull, Quebec, Canada KIA OS9 and from Geological Survey of Canada 60 l Booth Street Ottawa, Canada Kl A OE8 A deposit copy of this publication is also available for reference in public libraries across Canada Cat. No. M44-8 l/ 5E Canada: $4.00 ISBN 0-660-11003-2 Other countries: $4.80 Price subject to change without notice CONTENTS/TABLE DES MA TIERES v INTRODUCTION AREAL MAPPING, 1:50 OOO OR MORE DETAILED/ l CARTOGRAPHIE, 1:50 OOO OU A PLUS GRANDE ECHELLE l Alberta/ Alberta l British Columbia/Colombie-Britannique l Manitoba/Manitoba l New Brunswick/Nouveau-Brunswick 2 Newfoundland/Labrador /Terre-Neuve/Labrador 2 Northwest Territories/Territoires du Nord-Ouest 2 Nova Scotia/Nouvelle-Ecosse 2 Ontario/Ontario 3 Quebec 3 Saskatchewan/Saskatchewan 3 Yukon Territory/Territoire du Yukon AREAL MAPPING, LESS DETAILED THAN 1:50 OOO/ 3 CARTOGRAPHIE, A PLUS PETITE EC HELLE QU'AU 1:50 OOO 3 British Columbia/Colombie-Britannique 3 Manitoba/Manitoba 3 New Brunswick/Nouveau-Brunswick 3 Newfoundland/Labrador -

North American Geology

DEPARTMENT OF THE INTERIOR Hubert Work, Secretary U. S. GEOLOGICAL SURVEY George Otis Smith, Director Bulletin 802 BIBLIOGRAPHY OF NORTH AMERICAN GEOLOGY FOR 1925 AND 1926 BY JOHN M. NICKLES UNITED STATES GOVERNMENT PRINTING OFFICE WASHINGTON 1928 ADDITIONAL COPIES OF THIS PUBLICATION MAT BE PROCURED FROM THE SUPERINTENDENT OF DOCUMENTS U. S. GOVERNMENT PRINTING OFFICE WASHINGTON, D. C. AT 40 CENTS PER COPY CONTENTS Page Introduction. __ ______!____ _ _____________. 1 Serials examined_______________________________.. 3 Bibliography____________________________________ 9 Index______________________________________. 187 Lists________________________________________. 274 Chemical analyses______________________ ___ . 274 Mineral analyses_______________i_________________ . 276 Minerals described_____________________________. 276 Rocks described _______ _ . 278 Geologic formations described . 279 in BIBLIOGRAPHY OF NORTH AMERICAN GEOLOGY FOE 1925 AND 1926 By JOHN M. NICKLES INTRODUCTION The bibliography of North American geology, including paleon tology, petrology, and mineralogy, for the years 1925 and 1926 con tains publications on the geology of the Continent of North America and adjacent islands and on Panama and the Hawaiian Islands. It includes textbooks and papers of general character by American au thors, but not those by foreign authors, except papers that appear in American publications. The papers, with full title and medium of publication are listed under the names of their authors, which are arranged in alphabetic order. The author list is followed by an index to the literature listed. The bibliography of North American geology is comprised in the following bulletins of the United States Geological Survey: No. 127 (1732-1892); Nos. 188 and 189 (1892-1900); No. 301 (1901-1905); No. 372 (1906-7); No. 409 (1908); No. 444 (1909); No. 495 (1910); No. -

Heavy Mineral Indicators in Gravels

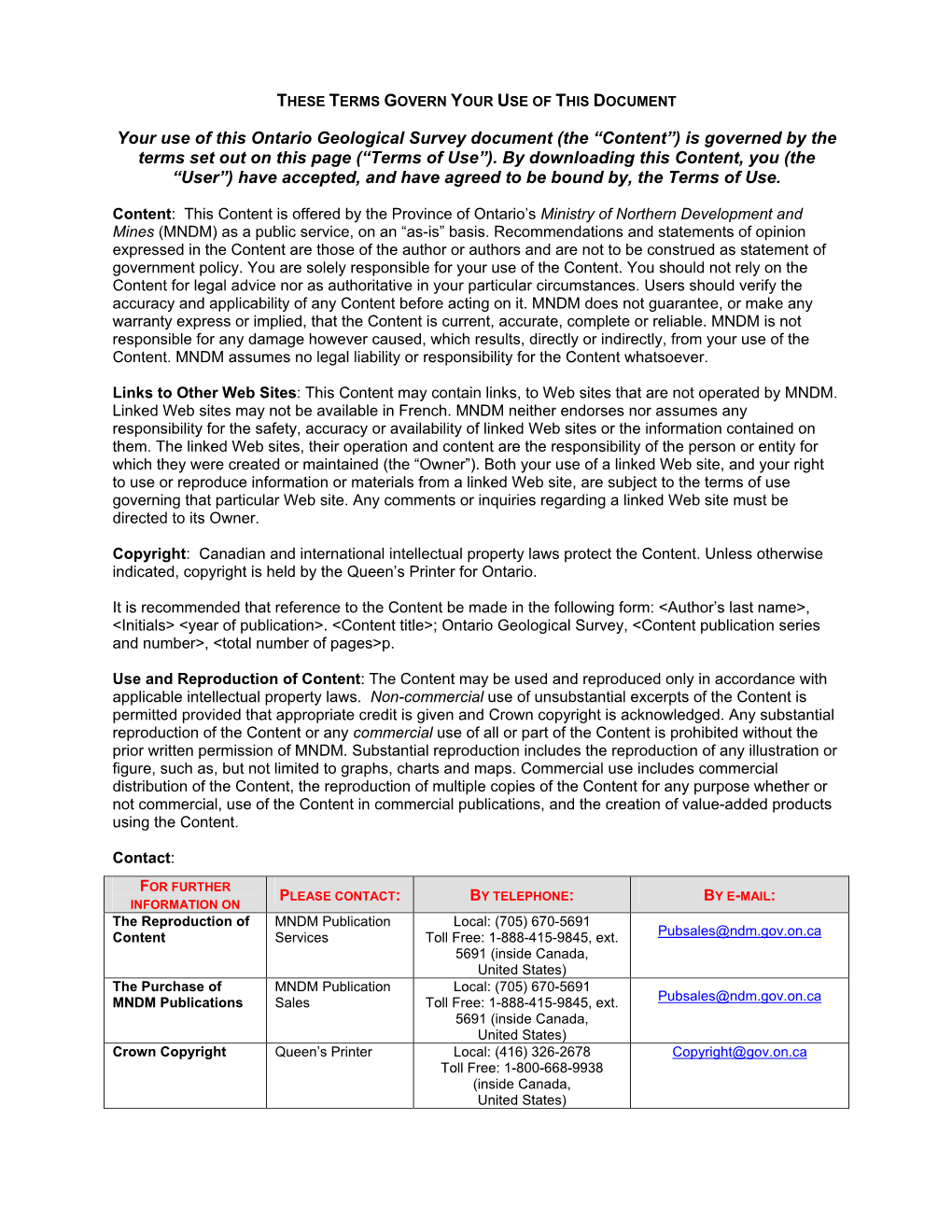

THESE TERMS GOVERN YOUR USE OF THIS DOCUMENT Your use of this Ontario Geological Survey document (the “Content”) is governed by the terms set out on this page (“Terms of Use”). By downloading this Content, you (the “User”) have accepted, and have agreed to be bound by, the Terms of Use. Content: This Content is offered by the Province of Ontario’s Ministry of Northern Development and Mines (MNDM) as a public service, on an “as-is” basis. Recommendations and statements of opinion expressed in the Content are those of the author or authors and are not to be construed as statement of government policy. You are solely responsible for your use of the Content. You should not rely on the Content for legal advice nor as authoritative in your particular circumstances. Users should verify the accuracy and applicability of any Content before acting on it. MNDM does not guarantee, or make any warranty express or implied, that the Content is current, accurate, complete or reliable. MNDM is not responsible for any damage however caused, which results, directly or indirectly, from your use of the Content. MNDM assumes no legal liability or responsibility for the Content whatsoever. Links to Other Web Sites: This Content may contain links, to Web sites that are not operated by MNDM. Linked Web sites may not be available in French. MNDM neither endorses nor assumes any responsibility for the safety, accuracy or availability of linked Web sites or the information contained on them. The linked Web sites, their operation and content are the responsibility of the person or entity for which they were created or maintained (the “Owner”). -

Devo INTR ODUCTIO on P Eozoic Atf Erlie a Vast Are Million 2 Son Bay. T

CA NADA G. TELFOR A BSTR RACT The M ose Riv er Basin is an in tracrat onic Paleoz oic sedim enta ry basi n un derlyin g th e Ja mes Bay L owland of n or theas tern Onta rio and containing strata rangin g from Ord dovicia n to Uppe r Devon ian age. Exce pt alo ng g th e mildly defo rmed d easte ern m argin st rata a re gene ra lly flat-lyi ing. Devonian carbon ates, sha les, evapori tes and mino ssic a nd Cretac eous clastic sediments o ve rlies the D evonian rocks inthe sout heastern pa rt of t he basin and the en tire region is blankete d by Pleist ocene glacial d eposits and Rec ent mari ne clays. Th e Devon ian suc cession com pris es, in asce nding order: Lower Devo nian Kenogam i R ver (upper part only; dolom mitic lim estone), St ooping River (mainly lim estone ) and Sextan s), M urray Islan d (lime tone) and W lli ams Island (s hal , carbo nates) Formation ; and the Up per Devoni n Long Ra pids Form ation (b lack shale, mudstone minor carbo nate s). The apparently s mple s tratigrap hy s com mpli cated by lateral fa cies variations, including a co ntinental to marine tr ansition am ong t he Low wer Devo INTR ODUCTIO ON P eozoic atf erlie a vast are million 2 son Bay. T ibute d amon r m ain te ctonic e lem viz. -

Glacial Stratigraphy of the Ridge River Area, Northern Ontario: Refining Wisconsinan Glacial History and Evidence for Laurentide Ice Streaming

Western University Scholarship@Western Electronic Thesis and Dissertation Repository 9-15-2014 12:00 AM Glacial Stratigraphy of the Ridge River Area, Northern Ontario: Refining Wisconsinan Glacial History and Evidence for Laurentide Ice Streaming Maurice Nguyen The University of Western Ontario Supervisor Dr. Stephen Hicock The University of Western Ontario Graduate Program in Geology A thesis submitted in partial fulfillment of the equirr ements for the degree in Master of Science © Maurice Nguyen 2014 Follow this and additional works at: https://ir.lib.uwo.ca/etd Part of the Geology Commons Recommended Citation Nguyen, Maurice, "Glacial Stratigraphy of the Ridge River Area, Northern Ontario: Refining Wisconsinan Glacial History and Evidence for Laurentide Ice Streaming" (2014). Electronic Thesis and Dissertation Repository. 2470. https://ir.lib.uwo.ca/etd/2470 This Dissertation/Thesis is brought to you for free and open access by Scholarship@Western. It has been accepted for inclusion in Electronic Thesis and Dissertation Repository by an authorized administrator of Scholarship@Western. For more information, please contact [email protected]. Glacial Stratigraphy of the Ridge River Area, Northern Ontario: Refining Wisconsinan Glacial History and Evidence for Laurentide Ice Streaming Thesis format: Monograph by Maurice Nguyen Graduate Program in Geology A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science The School of Graduate and Postdoctoral Studies Western University London, Ontario, Canada © Maurice Nguyen 2014 Abstract Detailed field studies of Quaternary sediments were undertaken during the summer of 2012 in the remote Ridge River area of the Hudson Bay Lowland. Grain size, carbonate content, stone lithologic analyses and stratigraphy of 31 sites were compiled, and revealed two main till units likely deposited by the advance and retreat of the Laurentide Ice Sheet. -

PDF Linkchapter

Index [Italic page numbers indicate major references] Abbott Formation, Illinois, 251 Michigan, 287 beetle borrows, Nebraska, 11 Acadian belt, 429 Archean rocks beetles, Manitoba, 45 Acadian orogeny Michigan, 273, 275 Belfast Member, Brassfield Illinois, 243 Minnesota, 47, 49, 53 Formation, Ohio, 420, 421 Indiana, 359 Wisconsin, 189 Bellepoint Member, Columbus Acrophyllum oneidaense, 287 Arikaree Group, Nebraska, 13, 14, Limestone, Ohio, 396 Adams County, Ohio, 420, 431 15, 25, 28 Belleview Valley, Missouri, 160 Adams County, Wisconsin, 183 Arikareean age, Nebraska, 3 Bellevue Limestone, Indiana, 366, Admire Group, Nebraska, 37 arthropods 367 Aglaspis, 83 Iowa, 83 Bennett Member, Red Eagle Ainsworth Table, Nebraska, 5 Missouri, 137 Formation, Nebraska, 37 Alexander County, Illinois, 247, 257 Ash Hollow Creek, Nebraska, 31 Benton County, Indiana, 344 algae Ash Hollow Formation, Nebraska, 1, Benzie County, Michigan, 303 Indian, 333 2, 5, 26, 29 Berea Sandstone, Ohio, 404, 405, Michigan, 282 Ash Hollow State Historical Park, 406, 427, 428 Missouri, 137 Nebraska, 29 Berne Conglomerate, Logan Ohio, 428 asphalt, Illinois, 211 Formation, Ohio, 411, 412, 413 Alger County, Michigan, 277 Asphalting, 246 Bethany Falls Limestone Member, Algonquin age, Michigan, 286, 287 Asterobillingsa, 114 Swope Formation, Missouri, Allamakee County, Iowa, 81, 83, 84 Astrohippus, 26 135, 138 Allegheny Group, Ohio, 407 Atherton Formation, Indiana, 352 Bethany Falls Limestone, Iowa, 123 Allen County, Indiana, 328, 329, 330 athyrids, Iowa, 111 Betula, 401 Allensville -

Abstracts / Résumés

Kingston, Ontario Abstracts / Résumés Volume May Contents Abstract Titles / Titres Des Résumés i Abstracts / Résumés l Author Index / Index des Auteurs 438 Abstract Titles / Titres Des Résumés 1 Reduction of AMD generation and availability of metals from sulfidic mine tailings through biochar application: A laboratory scale study Abedin, J., Labrador Institute of Memorial University, 219 Hamilton River Road, Happy Valley-Goose Bay, NL A0P 1E0, [email protected] 2 An investigation of apatite as an indicator mineral that recorded hydrothermal fluid chemistry at the Cantung tungsten skarn deposit, NWT, Canada Adlakha, E.E., [email protected], Hanley, J.J., Saint Mary’s University, 901 Robie St., Halifax, NS B3H 3C3, and Falck, H., NWT Geological Survey, 5310 44 St., Yellowknife, NT X1A 1K3 3 Early Cenozoic evolution of the Gurla Mandhata core complex, NW Nepal Himalaya Ahenda, M., [email protected], Godin, L., Queen’s University, Kingston, ON K7L 3N6, Grujic, D., Dal- housie University, PO Box 15000, Halifax, NS B3H 4R2, and Stevenson, R., Université du Québec à Montréal, CP 8888, Succursale Centre-Ville, Montréal, QC H3C 3P8 4 Diffusion research: Lab scale to field scale – recent advances Al, T.A., Department of Earth & Environmental Sciences, University of Ottawa, [email protected] 5 The zircon record of granitic continental crust subjected to tectonic burial, from 0 to ≥ 60 km, the Eastern Segment, Sveconorwegian orogen Andersson, J.1, [email protected], Moller, C.2, Lundqvist, L.3, Hellström, F.3, Johansson, L.2, and Claeson, D.4, 1Geological Survey of Sweden, Box 670, SE75128 Uppsala, Sweden; 2Lund Univ., Lund, Sweden; 3SGU, Up- psala, Sweden; 4SGU, Lund, Sweden 6 Mineralogical and geochemical characterization of spilled tailings from the Mount Polley Mine: Im- plications for remediation and rehabilitation Anglin, C.D., Imperial Metals Corporation, 200-580 Hornby St, Vancouver, BC V6C 3B6, langlin@imperialmetals. -

Moose River Basin: Geology and Mineral Potential

THESE TERMS GOVERN YOUR USE OF THIS DOCUMENT Your use of this Ontario Geological Survey document (the “Content”) is governed by the terms set out on this page (“Terms of Use”). By downloading this Content, you (the “User”) have accepted, and have agreed to be bound by, the Terms of Use. Content: This Content is offered by the Province of Ontario’s Ministry of Northern Development and Mines (MNDM) as a public service, on an “as-is” basis. Recommendations and statements of opinion expressed in the Content are those of the author or authors and are not to be construed as statement of government policy. You are solely responsible for your use of the Content. You should not rely on the Content for legal advice nor as authoritative in your particular circumstances. Users should verify the accuracy and applicability of any Content before acting on it. MNDM does not guarantee, or make any warranty express or implied, that the Content is current, accurate, complete or reliable. MNDM is not responsible for any damage however caused, which results, directly or indirectly, from your use of the Content. MNDM assumes no legal liability or responsibility for the Content whatsoever. Links to Other Web Sites: This Content may contain links, to Web sites that are not operated by MNDM. Linked Web sites may not be available in French. MNDM neither endorses nor assumes any responsibility for the safety, accuracy or availability of linked Web sites or the information contained on them. The linked Web sites, their operation and content are the responsibility of the person or entity for which they were created or maintained (the “Owner”). -

Program and Abstracts

Program and Abstracts Peat Carbon Accumulation on Earth: An Integrated and Global Perspective — C-PEAT Launch and Integration Workshop Compiled and Edited by Zicheng Yu (Lehigh University, USA) Lamont-Doherty Earth Observatory, Columbia University, Palisades, New York, USA 11-13 October 2015 Sponsors: Department of Earth and Environmental Sciences C-PEAT Workshop 2015: Program and Abstracts 2 C-PEAT Workshop: Peats On Earth Through Time Overarching Questions and Focuses: 1. Controls on the formation, persistence and disappearance of peats under different climate and environmental conditions; 2. Changes in peat accumulation rates and C stocks during Earth history; and 3. Future trajectories of peat extent and C stocks, including fate of existing peats. Agenda and Program Participants arrival and check-in on Saturday (10 October) Day 1 (Sunday, 11 October 2015) 8:30-8:40 Jon Nichols Welcome and logistics 8:40-9:00 Zicheng Yu Introduction and workshop objectives Session I. Peatland processes (Chair: Zicheng Yu) 9:00 -9:15 Nigel Roulet Peatlands as complex system 9:15-9:30 Tim Moore Stoichiometry of peat formation 9:30-9:45 Charlie Harvey Geomorphology, hydrology & dynamics of tropical peatlands 9:45-10:00 René Dommain Peat accumulation in tropical swamp forests 10:00-10:15 Juan Benavides Peat initiation following glacier retreat in Colombia Andes 10:15-10:30 Thomas Kleinen Simulating global peatlands since the LGM 10:30-10:45 Discussion 10:45 -11:10 Break Session II. Peats through Earth's history (Chair: Jon Nichols) 11:10-11:25 Stephen Greb Peatlands through time 11:25-11:40 Chris Williams High-latitude Paleogene and Neogene peat forming forests 11:40-11:55 N. -

Atomic Energy &£& L'energie Atomique of Canada Limited ^B9 Du Canada, Limitee

— CA9200477 - CA9200493 AECL—7822 ATOMIC ENERGY &£& L'ENERGIE ATOMIQUE OF CANADA LIMITED ^B9 DU CANADA, LIMITEE WORKSHOP ON TRANSITIONAL PROCESSES" PROCEEDINGS COMPTE RENDU DE L'ATELIER SUR LES PROCEDES DE TRANSITION Compiled by/Redige par Werner F. Heinrich *held in Ottawa, 1982 November 4 and 5 *qu: a eu lieu a Ottawa les 4 et 5 novembre 1982. Whiteshell Nuclear Research Etablissement de recherches Establishment nucleaires de Whiteshell Pinawa, Manitoba ROE 1L0 May 1984 mai Copyright '-. Ator. Energy of Canada Limited, 1984 ATOMIC ENERGY OF CANADA LIMITED WORKSHOP ON TRANSITIONAL PROCESSES* PROCEEDINGS Compiled by Werner F. Heinrich *held In Ottawa, 1982 November 4 and 5. Whiteshell Nuclear Research Establishment Pinawa, Manitoba ROE 1LO 1984 May AECL-7822 COMPTE RENDU DE L'ATELIER SUR LES PROCEDES DE TRANSITION* Rédigé par Werner F. Heinrich RESUME Cet atelier a été organisé dans le cadre du Programme canadien de gestion des déchets de combustible nucléaire en vue d'examiner certains aspects historiques du bouclier canadien susceptibles d'influencer l'évacua- tion des déchets de combustible nucléaire en profondeur, dans la roche plu- tonique du bouclier canadien. L'atelier a porté en particulier sur les futurs processus climatiques et géologiques probables qui pourraient influ- encer le transport des radionuclldes à travers la géosphère qui constitue la barrière principale entre une enceinte d'évacuation et la biosphère. Le présent rapport contient les exposés qui ont été présentés au cours de l'a- telier et certaines des discussions qui ont eu lieu à la suite des présenta- tions. *qui a eu lieu à Ottawa les 4 et 5 novembre 1982.