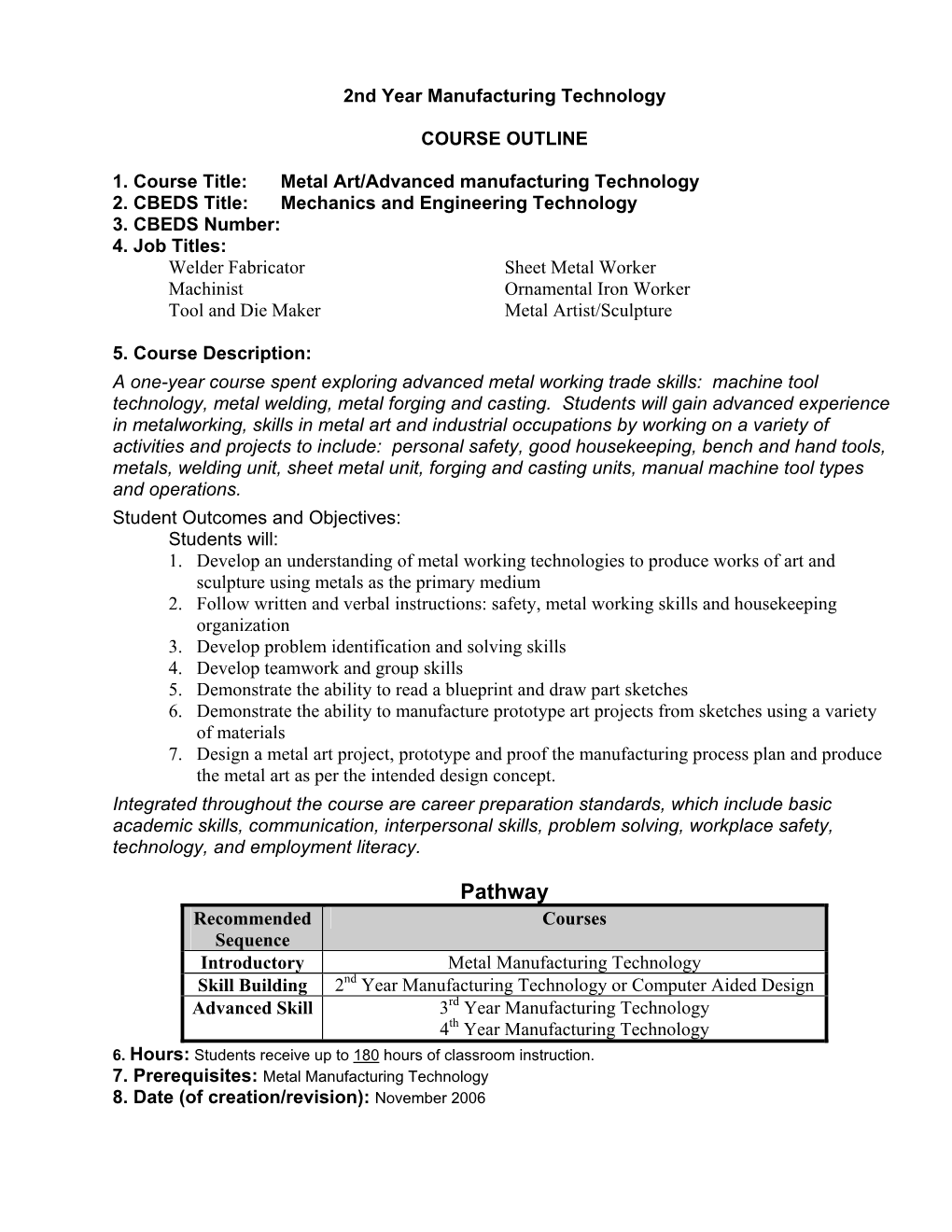

2Nd Year Manufacturing Technology

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Tool and Die Maker Level 1

Tool and Die Maker Level 1 Rev. March, 2013 Tool and Die Maker Unit: A1 Safety in the Machine Shop Level: One Duration: 7 hours Theory: 7 hours Practical: 0 hours Overview: This unit of instruction is designed to introduce safety requirements and Workplace Hazardous Materials Information System, WHMIS, identification and compliance with machine shop (basic) safety, and safe procedures used in erecting and securing block and tackle equipment according to manufacturer’s guidelines. Material covered includes: Safety requirements and WHMIS Machine shop (basic) safety Block and tackle fundamentals Percent of Objectives and Content: Unit Mark (%) 1. Identify the safety requirements as they apply to WHMIS with 25% emphasis on a. Positive perspective regarding accident prevention and job site safety b. WHMIS defined and the format used to convey information about hazardous materials in the workplace c. Information found on supplier and workplace labeling using WHMIS d. Information from Manitoba Labour, Workplace and Safety and Health Division - Workplace Bulletins e. Hazardous materials in accordance with WHMIS f. Compliance with government safety standards and regulations 2. Identifies and complies with machine shop (basic) safety: 50% a. General safety precautions b. Housekeeping, personal protective equipment, clothing c. Guards d. Grinding e. Block and tackle f. Specific health hazards and associated precautions Fumes and skin-contact with toxic substances Mechanical vibration Noise g. Fire prevention controls Types of fire-fighting equipment Types of fires Personal protective clothing h. Installation, maintenance and inspection of safety equipment Fire extinguishers 1 Rev. March, 2013 i. Personal Protective equipment Dust mask Respirator Hearing protection Safety glasses Protective clothing 3. -

Tool & Die Maker

Tool & Die Maker (Press Tools, Jigs & Fixtures) GOVERNMENT OF INDIA MINISTRY OF SKILL DEVELOPMENT & ENTREPRENEURSHIP DIRECTORATE GENERAL OF TRAINING COMPETENCY BASED CURRICULUM TOOL & DIE MAKER (PRESS TOOLS, JIGS & FIXTURES) (Duration: Two Years) CRAFTSMEN TRAINING SCHEME (CTS) NSQF LEVEL- 5 SECTOR – CAPITAL GOODS AND MANUFACTURING Tool & Die Maker (Press Tools, Jigs & Fixtures) TOOL & DIE MAKER (Press Tool, Jigs & Fixture) (Engineering Trade) (Revised in 2018) Version: 1.1 CRAFTSMEN TRAINING SCHEME (CTS) NSQF LEVEL - 5 Developed By Ministry of Skill Development and Entrepreneurship Directorate General of Training CENTRAL STAFF TRAINING AND RESEARCH INSTITUTE EN-81, Sector-V, Salt Lake City, Kolkata – 700 091 Tool & Die Maker (Press Tools, Jigs & Fixtures) ACKNOWLEDGEMENT The DGT sincerely acknowledges contributions of the Industries, State Directorates, Trade Experts, Domain Experts and all others who contributed in revising the curriculum. Special acknowledgement is extended by DGT to the following expert members who had contributed immensely in this curriculum. List of Expert members contributed/ participated for finalizing the course curriculum of TDM (Press Tools, Jigs & Fixtures) trade held on 16.05.17 at Govt. ITI- Aundh, Pune Name & Designation S No. Organization Remarks Shri/Mr./Ms. Industry Experts 1. Dr. K C Vora, Sr. Dy. Director & The Automotive Research Chairman Head, Arai Academy Association of India, S.No.102, Vetal Hill, Off Paud Road, Kothrud, Pune 2. Jayanta Patra, Sr. Manager Micromatic Machine Tools (P) Ltd. Member 240/241,11th Main, 3rd Phase, Peenya Industrial Area, Bangalore 3. Kashinath M. Patnasetty, Head Ace Designers Ltd. Plot No. 7&8, II Member - Application Support Group Phase Peenya Industrial Area, Bangalore 4. -

Smart Contracts for Machine-To-Machine Communication: Possibilities and Limitations

Smart Contracts for Machine-to-Machine Communication: Possibilities and Limitations Yuichi Hanada Luke Hsiao Philip Levis Stanford University Stanford University Stanford University [email protected] [email protected] [email protected] Abstract—Blockchain technologies, such as smart contracts, present a unique interface for machine-to-machine communication that provides a secure, append-only record that can be shared without trust and without a central administrator. We study the possibilities and limitations of using smart contracts for machine-to-machine communication by designing, implementing, and evaluating AGasP, an application for automated gasoline purchases. We find that using smart contracts allows us to directly address the challenges of transparency, longevity, and Figure 1. A traditional IoT application that stores a user’s credit card trust in IoT applications. However, real-world applications using information and is installed in a smart vehicle and smart gasoline pump. smart contracts must address their important trade-offs, such Before refueling, the vehicle and pump communicate directly using short-range as performance, privacy, and the challenge of ensuring they are wireless communication, such as Bluetooth, to identify the vehicle and pump written correctly. involved in the transaction. Then, the credit card stored by the cloud service Index Terms—Internet of Things, IoT, Machine-to-Machine is charged after the user refuels. Note that each piece of the application is Communication, Blockchain, Smart Contracts, Ethereum controlled by a single entity. I. INTRODUCTION centralized entity manages application state and communication protocols—they cannot function without the cloud services of The Internet of Things (IoT) refers broadly to interconnected their vendors [11], [12]. -

Tool and Die Makers, Turret and Engine Lathe Operators, Sheet Metal

DO CU M E N T R ES U ME ED 025 582 VT 000 415 A Survey of Demand in Selected MetalworkingOccupations for Major Areas of Idaho. Idaho State Dept. of Employment, Boise. Pub Date Oct 66 Note- 34p. EDRS Price MF-$0.25 HC-$1.80 Descriptors-*Educational Needs, Employer Attitudes, *EmploymentOpportunities, *Employment Projections, Employment Statistics, Labor Supply, Metal WorkingOccupations, Occupational Information,*Occupational Surveys, Questionnaires, Skilled Occupations, Trade andIndustrial Education Identifiers- Idaho To determine the state and area impactof occupational shortages inthe metal working,skills in Idaho and to provide abasis for planningeffective vocational education programs, the IdahoDepartment of Employmentconducted a sample survey of 68 employers in the metal workingoccupations. The occupations wereselected from a national list of hard-to-findmetal workers and ihcludedmachinists, welders, tool and die makers, turret and enginelathe operators, sheetmetal workers, structural steel workers, andboilermakers. The study,conducted inApril1966, .encompasses the ninemost populous counties inIdaho including 55 percentof the (1) The lack of qualified metalworkers has population. Some weneral conclusions were: of the not caused curtailmentof operation, (2) More welderswill be needed than any other survey occupations, (3)The demand for qualifiedmachinists should remain at a high level and (4) Seasonality inthe total employment ofworkers was implied bythe survey for the occupationsof welders, structural steelworkers, sheet metal workers, machinists, and. boilermakers.Statistical data is presented intable form and the interview questionnaire is included inthe appendix. (DM) 4 Ow. 111111111111111 11111111higill U.S. DEPARTMENT OF HEALTH, EDUCATION & WELFARE OFFICE OF EDUCATION THIS DOCUMENT HAS BEEN REPRODUCED EXACTLY AS RECEIVED FROM THE PERSON OR ORGLNIZATION ORIGINATING IT.POINTS OF VIEW OR OPINIONS STATED DO NOT NECESSARILY REPRESENT OFFICIAL Of FICE OF EDUCATION POSITION OR POLICY. -

TOOL & DIE MAKER (Press Tool, Jigs & Fixture) (Dual Mode)

CURRICULUM FOR THE TRADE OF TOOL & DIE MAKER (Press Tool, Jigs & Fixture) (Dual Mode) UNDER DUAL TRAINING SYSTEM BY GOVERNMENT OF INDIA MINISTRY OF SKILL DEVELOPMENT & ENTREPRENEURSHIP DIRECTORATE GENERAL OF TRAINING 1 PROPOSED TIME DISTRIBUTION FOR TOOL & DIE MAKER (PRESS TOOL JIGS & FIXTURE) TRADE UNDER INDUSTRY INSTITUTE - TRAINING SCHEME BLOCK THEORY PRAC. WSC/ ENGG. EMP. ECA, REM. WITH CAL DRG. SKILL LIB. & DURATION OTHERS BLOCK – I 510 hrs. 830 hrs. 170 250 110 50 hrs. 160 hrs. (12 hrs. hrs. hrs. Revision months/52 & Test Weeks duration ) Institute level trg. BLOCK – II --- 1560 HRS. --- --- --- --- --- (09 months /39 weeks duration) Industry level trg. BLOCK – III 100 hrs. 210 hrs. 50 60 hrs. --- 20 hrs. Last 2 (3 months/ (Practical hrs. weeks 13 Weeks practice and revision duration) submission of & exam. Institute report related level trg. to industry training) GRAND 610 2600 HRS. 220 310 110 70 HRS. 240 TOTAL HRS. HRS. HRS. HRS. HRS. Total duration of training inclusive of Industry & Institute is 2 years (4160 HRS.) 2 GENERAL INFORMATION FOR INSTITUTE (ITI) 1. Name of the Trade : Tool & Die Maker (Press Tool, Jigs & Fixture ) (Dual mode) 2. NCO Code No. : 7222.0200, 7222.0300, 7223.0200 3. Duration of Craftsmen Training : Two years (Three Blocks) 4. Power norms : 20 KW 5. Space norms : 166 Sq. mt. 6. Entry qualification : Passed 10th Class with Science and Mathematics under 10+2 system of Education or its equivalent 7. Trainees per unit : 16 (Supernumeraries/Ex-Trainee allowed:5) 8 a. Qualification for Instructor : Degree in Mechanical Engineering from recognized Engineering College/university with minimum two-year experience in the relevant field. -

Occupational Standard/ Qualification Pack – Under Industry Validation

Occupational Standard/ Qualification Pack – Under Industry Validation 1. Qualification Pack - Draughtsman - Civil 2. Qualification Pack - Draughtsman - Piping 3. Qualification Pack - Electroplating Operator 4. Qualification Pack - Flux Cored Arc Welder (Semi-Automatic) 5. Qualification Pack - Forger 6. Qualification Pack - Lab Technician - Metal Testing 7. Qualification Pack - Lab Technician - Radiographic Testing 8. Qualification Pack - Manual Metal Arc Welder Level 2 9. Qualification Pack - Manual Metal Arc Welder Level 3 10. Qualification Pack - Manual Metal Arc Welder Level 4 11. Qualification Pack - Operator - Broaching Machine 12. Qualification Pack - Operator - Plate Bending Machine 13. Qualification Pack - Operator - Shot Blasting and Grit Blasting 14. Qualification Pack - CNC Operator - Electric Discharge Machine (Spark Erosion) 15. Qualification Pack - CNC Setter cum operator - Electric Discharge (Spark Erosion) Machine 16. Qualification Pack - Operator - Electric Discharge Machine (Spark Erosion) (Non-Conventional) 17. Qualification Pack - Setter cum Operator - Electric Discharge (Spark Erosion) (Non-Conventional) 18. Qualification Pack - Oxy fuel gas cutter Level 2 19. Qualification Pack - Oxy fuel gas cutter Level 3 20. Qualification Pack - Plasma Cutter Manual 21. Qualification Pack - Resistance Spot Welding Machine operator 22. Qualification Pack - Stud welding operator 23. Qualification Pack - Submerged Arc Welder 24. Qualification Pack - Tool and Die Maker 25. Qualification Pack - Tungsten Inert Gas Welder Level 4 Please click here to visit the Latest Updated Draft of Qualification Packs. (Link it to http://jmp.sh/beQNnVm) If you are from the Capital Goods Sector and want to become part of draft Qualification Pack validation. Please feel free to write to us on [email protected] for details. . -

Microscope Systems and Their Application in Machine Vision

Microscope Systems And Their Application in Machine Vision 1 1 Agenda • What is a microscope system? • Basic setup of a microscope • Differences to standard lenses • Parameters of microscope systems • Illumination options in a microscope setup • Special contrast enhancement techniques • Zoom components • Real-world examples What is a microscope systems? Greek: μικρός mikrós „small“; σκοπεῖν skopeín „observe“ Microscopes help us to look at small things, by enlarging them until we can see them with bare eyes or an image sensor. A microscope system is a system that consists of compatible components which can be combined into different configurations We only look at visible light microscopes We only look at digial microscopes no eyepiece but an image sensor in the object plane The optical magnification is ≥1 Basic setup of a microscope microscopes always show the same basic configuration: Sensor Tube lens: - Images onto the sensor - Defines the maximum sensor size Collimated beam path (infinity conjugated) Objective: - Images to infinity - Holds the system aperture - Defines the resolution of the system Object Differences to standard lenses microscope Finite-finite lens Sensor Sensor Collimated beam path (infinity conjugate) EnthältSystem apertureSystemblende Object Object Differences to standard lenses • Collimated beam path offers several options - Distance between objective and tube lens can be changed . Focusing by moving the objective without changing any optical parameter . Integration of filters, mirrors and beam splitters . Beam -

Second Machine Age Or Fifth Technological Revolution? Different

Second Machine Age or Fifth Technological Revolution? Different interpretations lead to different recommendations – Reflections on Erik Brynjolfsson and Andrew McAfee’s book The Second Machine Age (2014). Part 1 Introduction: the pitfalls of historical periodization Carlota Perez January 2017 Blog post: http://beyondthetechrevolution.com/blog/second-machine-age-or-fifth-technological- revolution/ This is the first instalment in a series of posts (and a Working Paper in progress) that reflect on aspects of Erik Brynjolfsson and Andrew McAfee’s influential book, The Second Machine Age (2014), in order to examine how different historical understandings of technological revolutions can influence policy recommendations in the present. Over the next few weeks, we will discuss the various criteria used for identifying a technological revolution, the nature of the current moment, and the different implications that stem from taking either the ‘machine ages’ or my ‘great surges’ point of view. We will look at what we see as the virtues and limits of Brynjolfsson and McAfee’s policy proposals, and why implementing policies appropriate to the stage of development of any technological revolution have been crucial to unleashing ‘Golden Ages’ in the past. 1 Introduction: the pitfalls of historical periodization Information technology has been such an obvious disrupter and game changer across our societies and economies that the past few years have seen a great revival of the notion of ‘technological revolutions’. Preparing for the next industrial revolution was the theme of the World Economic Forum at Davos in 2016; the European Union (EU) has strategies in place to cope with the changes that the current ‘revolution’ is bringing. -

DOCUMENT RESUME Machine Tool Advanced Skills Technology

DOCUMENT RESUME ED 401 445 CE 072 938 TITLE Machine Tool Advanced Skills Technology (MAST). Common Ground: Toward a Standards-Based Training System for the U.S. Machine Tool and Metal Related Industries. Volume 15: Administrative Information, of a 15-Volume Set of Skill Standards and Curriculum Training Materials for the Precision Manufacturing Industry. INSTITUTION Texas State Technical Coll., Waco. SPONS AGENCY Office of Vocational and Adult Education (ED), Washington, DC. PUB DATE Sep 96 CONTRACT V199J40008 NOTE 277p.; For other volumes in this set, see CE 072 924-937. AVAILABLE. FROM World Wide Web: http://machinetool.tstc.edu PUB TYPE Guides Classroom Use Teaching Guides (For Teacher) (052) EDRS PRICE MFO1 /PC12 Plus Postage. DESCRIPTORS Automation; Behavioral Objectives; Competency Based Education; Computer Assisted Design; Computer Assisted Manufacturing; Course Content; Course Descriptions; Course Objectives; Curriculum; Curriculum Development; Drafting; Job Skills; Machine Tool Operators; *Machine Tools; Manufacturing; Manufacturing Industry; *Metal Working; Postsecondary Education; Program Administration; Program Development; Program Evaluation; *Technical Education ABSTRACT This volume developed by the Machine Tool Advanced Skill Technology (MAST) program contains key administrative documents and provides additional sources for machine tool and precision manufacturing information and important points of contact in the industry. The document contains the following sections: a foreword; grant award letter; timeline for progress -

2021-2022 College Catalog

Notice of Nondiscrimination 1 Admissions Office 724-925-4000 Athletics 724-925-4129 Academic Calendar 2 College Store 724-925-4174 Tutoring & Learning Services 724-925-4135 Accreditation 3 Continuing Education 724-925-4107 Westmoreland Profile 4 Counseling 724-925-4000 Disabled Student Services 724-925-4000 Education Centers 5 Admissions and Registration 7 Art, Humanities, Social Sciences & Public Service Transfer Information 13 724-925-4046 Business, Math, Science & Engineering 724-925-4004 Expenses, Financial Aid & Scholarships 15 Distance Education & Learning Resources 724-925-4177 Health Professions & Culinary Arts/Hospitality 724-925-4029 Academic Information 21 Planning, Assessment & Institutional Effectiveness Academic Programs 27 724-925-4000 Technology 724-925-8650 Programs of Study 29 Associate of Arts Degree 30 Westmoreland-Advanced Technology Center Associate of Science Degree 37 724-925-4269 Westmoreland-Fayette 724-437-3512 Associate of Fine Arts Degree 43 Westmoreland-Indiana 724-357-1404 Westmoreland-Latrobe 724-925-8473 Associate of Applied Science Degree 49 Westmoreland-Murrysville 724-327-8090 Course Descriptions 193 Westmoreland-New Kensington 724-335-8110 Westmoreland-Public Safety Training Center 724-872-2447 Personnel Directory 237 Financial Aid 724-925-4000 Library 724-925-4100 Majors 246 Placement Assessment 724-925-4000 Registration 724-925-4000 Student Life 724-925-4000 Student Records 724-925-4000 TDD 724-925-4297 Transfer Services 724-925-4000 Tutoring 724-925-4135 Veteran's Services 724-925-4000 For other Westmoreland offices, call 724-925-4000 Westmoreland County Community College will not discriminate in its educational programs, activities or employment practices based on race, color, national origin, sex, sexual orientation, disability, age, religion, ancestry, union membership or any other legally protected classification. -

The History of Computing in the History of Technology

The History of Computing in the History of Technology Michael S. Mahoney Program in History of Science Princeton University, Princeton, NJ (Annals of the History of Computing 10(1988), 113-125) After surveying the current state of the literature in the history of computing, this paper discusses some of the major issues addressed by recent work in the history of technology. It suggests aspects of the development of computing which are pertinent to those issues and hence for which that recent work could provide models of historical analysis. As a new scientific technology with unique features, computing in turn can provide new perspectives on the history of technology. Introduction record-keeping by a new industry of data processing. As a primary vehicle of Since World War II 'information' has emerged communication over both space and t ime, it as a fundamental scientific and technological has come to form the core of modern concept applied to phenomena ranging from information technolo gy. What the black holes to DNA, from the organization of English-speaking world refers to as "computer cells to the processes of human thought, and science" is known to the rest of western from the management of corporations to the Europe as informatique (or Informatik or allocation of global resources. In addition to informatica). Much of the concern over reshaping established disciplines, it has information as a commodity and as a natural stimulated the formation of a panoply of new resource derives from the computer and from subjects and areas of inquiry concerned with computer-based communications technolo gy. -

Tool, Dies and Moulds Report

TOOL, DIES AND MOULDS REPORT 1. WHAT IS TOOLING? The equipment required to convert raw material into a required shape is commonly referred to as tooling. The process of equipment manufacture that aids in the conversion of a raw material into a required shape is commonly referred to as tool, die and mould making. Materials converted include: • Metals • Aluminium • Polymers (Plastics) Tooling is found in almost all manufacturing industries including: • Automotive • Aerospace • Rail & Marine • Defense • Mining • Agro-processing • Mineral beneficiation • Leisure • Packaging (foodstuffs, consumer goods and electronics) The manufacturing industry is dependant on the availability of a good tool, die and mould making industry. Tools, dies and moulds directly contribute to: • Manufacturing output capacity, • Quality standard of a product produced, • Price competitiveness of the product produced, • Lifecycle cost of a product produced. 1 2. DEFINITION OF INDIVIDUAL AREAS OF TOOL, DIES AND MOULDS. I. WHAT IS A TOOL? A machine tool is a powered mechanical device, typically used to fabricate metal components of machines by machining, which is the selective removal of metal. The term machine tool is usually reserved for tools that used a power source other than human movement, but they can be powered by people if appropriately set up. Many historians of technology consider that the true machine tools were born when direct human involvement was removed from the shaping or stamping process of the different kinds of tools. Machine tools can be powered from a variety of sources. Human and animal power are options, as is energy captured through the use of waterwheels. However, machine tools really began to develop after the development of the steam engine, leading to the Industrial Revolution.