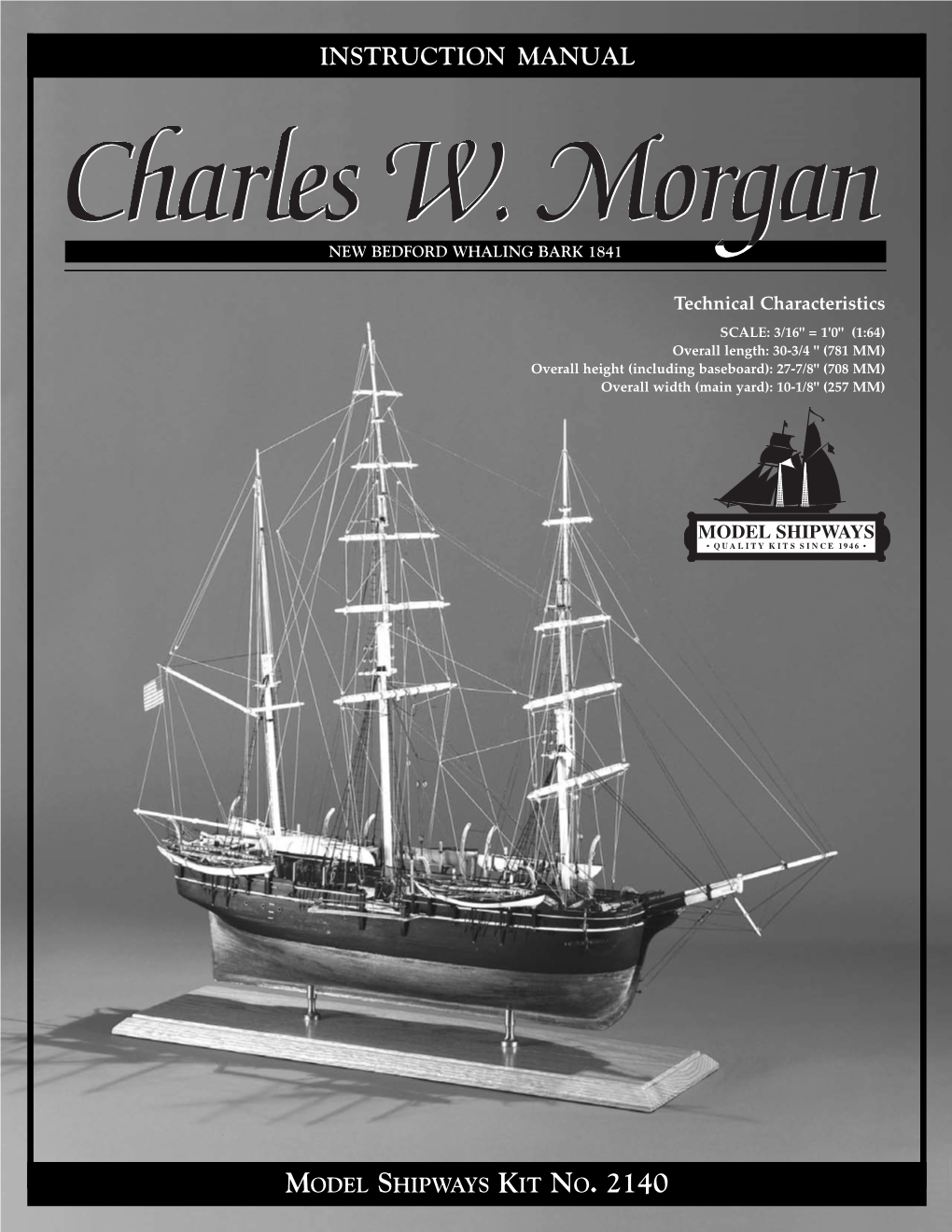

Model Shipways Charles Morgan Whale Bark Instructions

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Armed Sloop Welcome Crew Training Manual

HMAS WELCOME ARMED SLOOP WELCOME CREW TRAINING MANUAL Discovery Center ~ Great Lakes 13268 S. West Bayshore Drive Traverse City, Michigan 49684 231-946-2647 [email protected] (c) Maritime Heritage Alliance 2011 1 1770's WELCOME History of the 1770's British Armed Sloop, WELCOME About mid 1700’s John Askin came over from Ireland to fight for the British in the American Colonies during the French and Indian War (in Europe known as the Seven Years War). When the war ended he had an opportunity to go back to Ireland, but stayed here and set up his own business. He and a partner formed a trading company that eventually went bankrupt and Askin spent over 10 years paying off his debt. He then formed a new company called the Southwest Fur Trading Company; his territory was from Montreal on the east to Minnesota on the west including all of the Northern Great Lakes. He had three boats built: Welcome, Felicity and Archange. Welcome is believed to be the first vessel he had constructed for his fur trade. Felicity and Archange were named after his daughter and wife. The origin of Welcome’s name is not known. He had two wives, a European wife in Detroit and an Indian wife up in the Straits. His wife in Detroit knew about the Indian wife and had accepted this and in turn she also made sure that all the children of his Indian wife received schooling. Felicity married a man by the name of Brush (Brush Street in Detroit is named after him). -

Sound Explorations Educator Packet 2017.Pub

Sound Explorations Educator Packet (360) 379-0438 PO Box 1390 Port Townsend, WA 98368 Email: [email protected] Fax: (360) 379-0439 www.soundexp.org Dear Educator, Thank you for choosing Sound Experience for a fun and exciting, hands- on learning experience aboard Adventuress for your group! This is an active learning and working voyage designed to enhance the curriculum in your classroom and build community through experiential programming aboard the schooner Adventuress. This pre-trip packet contains important information about your upcoming voyage. Please read it over thoroughly and utilize the checklist to ensure all required documents are turned in prior to the trip. Included is an overview of curriculum for the Sound Explorations program, history and information about the ship, required paperwork, and reference and resource lists you may use with your class before or after the trip to enhance the learning experience. You may visit http:// www.soundexp.org/index.php?page=teacherinfo for a few suggested activities for before and after your voyage. I will contact you approximately three weeks before your trip to cover any last minute details and gather any additional information about your group and program interests relevant to this trip. We do our best to tailor the experience within our ability. Please do not hesitate to call if you have any questions or concerns. Sincerely, Amy Kovacs Education Director Sound Experience P.O. Box 1390 Port Townsend, WA 98368 (360) 379-0438, ext. 2 (Phone) (360) 379-0439 (FAX) E-mail: [email protected] Website: www. soundexp. org Welcome! Sound Experience welcomes you to the historic schooner Adventuress for a voyage of exploration on Puget Sound. -

December 2007 Crew Journal of the Barque James Craig

December 2007 Crew journal of the barque James Craig Full & By December 2007 Full & By The crew journal of the barque James Craig http://www.australianheritagefleet.com.au/JCraig/JCraig.html Compiled by Peter Davey [email protected] Production and photos by John Spiers All crew and others associated with the James Craig are very welcome to submit material. The opinions expressed in this journal may not necessarily be the viewpoint of the Sydney Maritime Museum, the Sydney Heritage Fleet or the crew of the James Craig or its officers. 2 December 2007 Full & By APEC parade of sail - Windeward Bound, New Endeavour, James Craig, Endeavour replica, One and All Full & By December 2007 December 2007 Full & By Full & By December 2007 December 2007 Full & By Full & By December 2007 7 Radio procedures on James Craig adio procedures being used onboard discomfort. Effective communication Rare from professional to appalling relies on message being concise and clear. - mostly on the appalling side. The radio Consider carefully what is to be said before intercoms are not mobile phones. beginning to transmit. Other operators may The ship, and the ship’s company are be waiting to use the network. judged by our appearance and our radio procedures. Remember you may have Some standard words and phases. to justify your transmission to a marine Affirm - Yes, or correct, or that is cor- court of inquiry. All radio transmissions rect. or I agree on VHF Port working frequencies are Negative - No, or this is incorrect or monitored and tape recorded by the Port Permission not granted. -

Things You Should Know About Your Chainsaw

Things You Should Know About Your Chainsaw Having a sharp blade on a chainsaw the chain link. The curve of the file should not only saves effort and wear on your fit the curve of the face of the cutting tip, Tips equipment, but makes using it more safe. and the top of the file should be nearly Here are some tips for sharpening your flush with the top of the tooth. • Buy the correct size file for your saw. own saw. Hold the file at the same angle that the • It is recommended that after a chain has been hand sharpened five times, it should be 1) Determine the size or gauge of your cutter is ground or filed to begin with. The ground by a chainsaw shop to correct any saw's chain. You will need to buy either a standard angle is about 25 degrees on variations in tooth pitch that occurred during rotary grindstone or chainsaw file/rattail most saws. Special "ripping" chains may filing. file that matches your blade. Since there • Use a chainsaw file guide to maintain have a flatter angle, and it is essential to the correct angle of your file stroke when fil- are several sizes of chainsaw teeth, the match the angle the chain is originally ing your blade. grindstone or file you choose must be the machined to. • Look for wear on the drive links, the correct diameter for your saw. Typical 7) Slide the file across the face of the blade groove, and sprocket often. Chains can break and cause serious injury or death when sizes are 3/16, 5/32 and 7/32 inches in cutter, using a moderate twisting motion operated with worn or damaged parts. -

Dualmaster 3000 Manual

DUALMASTER 3000 MANUAL DUALMASTER 3000 Precision Reel/Cylinder Spin & Relief Grinder ISSUE ONE — Serial No. 22110 – on User’s Guide & Instruction Manual Please read this manual carefully before using the Dual Master. This manual should be kept in a safe place so that it can be used for future reference. DUAL MASTER 3000 NOTES ..................................................................................................................................................................................................................................................................... ..................................................................................................................................................................................................................................................................... ..................................................................................................................................................................................................................................................................... ..................................................................................................................................................................................................................................................................... .................................................................................................................................................................................................................................................................... -

Chapter Twelve Have Used the Serv-O-Matic Available at Syren Ship Model Company

Chapter Twelve have used the Serv-o-matic available at Syren Ship Model Company. It’s a simple device and you Starting the rigging process… could no doubt make one similar should you want to. Before I begin describing the rigging process, I must remind folks that it would be a great time to slip that traveler ring onto the bowsprit. I forgot to mention this in the previous chapter. Traveler rings are also available for this model at SSMC. They are made already blackened and simply need to be slid onto the bowsprit before we begin rigging. A served rope basically has a thinner line wrapped around it as shown above. It can be needed for a ropes entire length. The serving machine allows you to wrap a standard rope with a thin thread for an unlimited length. See below for a photo showing a served line …bottom…in comparison to a non-served length of rope. I will be rigging the model in a specific order that I find comfortable to work in. I am assuming that this is probably not your first model and you may have developed a different order to rig your model that has become comfortable for you. But even so, I will describe the different tasks to rig the Cheerful in the order I proceeded in. Thimbles- Whenever a thimble is needed I will show this detail. This is yet another optional detail. Before I start, let me describe a few things that you You can create a thimble very easily. I will be may not have detailed on your earlier models that I using thin wall brass tube from Albion. -

Lumber and Related Products; a Base Syllabus on Wood Technology. Eastern Kentucky Univ., Richmond

4-f,r ' DOCUMENT RESUME ED 031 558 VT 007 859 Lumber and Related Products; A Base Syllabus on Wood Technology. Eastern Kentucky Univ., Richmond. Pub Date Aug 68 Note-108p.; From NDEA Inst. on Wood Technology (Eastern Kentucky UM, June 10-Aug. 2, 1968). EDRS Price MF-$0.50 HC-$5.50 Descriptors-*Building Materials, Curriculum Development, *Curriculum Guides, *Industrial Arts, Instructional Improvement, Lumber Industry, *Resource Materials, Summer Institutes, Teacher Developed Materials, Teacher Education, *Woodworking Identifiers-*National Defense Education Act Title XI Institute, NDEA Title XI Institute Prepared by participants in the 1%8 National Defense Education Act Institute on Wood Technology, this syllabus is one of a seriesof basic outlines designed to aid college level industrial arts instructors in improving and broadening the scope and .content of their programs. The primary objective of this course outhne is to point out the importance and the many uses of wood and wood products. Topics covered are: (1 )Lumber Grades and Sizes,(2)Plywood,(3)Veneer,(4)Fiberboard,(5) Particleboard,(6)Sheetboard,(7)InsulationBoard,(8)StructuralSandwich Construction,(9)Shingles,(10)Pulp and Paper,(11) Wood Flour,and (12) Cellulose-DerivedProducts.Mostunitscontain 'informationonmanufacturing processes, properties,types and grades, and uses of the products. Selected bibliographies are listed for each unit. The final section provides instructional aids, suggested projects and student activities, and materials and equipment needed for specific prolects. The document is &strafed with drawings, charts, and photographs. Related documents are available as VT 007 857, VT 007 858, and VT 007 861: (AW) ft; LUMBER BAS YLLABUS ON WOOD CHNOLOGY .:'Pre,pare4 by INSTITUTE. -

Build the USS CONSTITUTION the World’S Oldest Commissioned Naval Vessel Afloat 12 Build the USS CONSTITUTION Contents STAGE PAGE 111 Sails 245

Build the USS CONSTITUTION The world’s oldest commissioned naval vessel afloat 12 Build the USS CONSTITUTION Contents STAGE PAGE 111 Sails 245 112 Sails and flags 247 113 Sails 249 114 Sails 251 115 Sails 253 116 Sails 255 117 Sails 257 118 Sails 259 119 Sails 261 120 Sails 263 Editorial and design by Continuo Creative, 39-41 North Road, London N7 9DP. Published in the UK by De Agostini UK Ltd, Battersea Studios 2, 82 Silverthorne Road, London SW8 3HE. Published in the USA by De Agostini Publishing USA, Inc.,121 E. Calhoun Street, Woodstock, IL 60098. All rights reserved © 2017 Warning: Not suitable for children under the age of 14. This product is not a toy and is not designed or intended for use in play. Items may vary from those shown. USS CONSTITUTION STAGE: 111 C 79 Sails 75 68 V3. Fore topmast staysail V4. Main topmast staysail 57 V4 V3 111C Following the plan, attach the four yards (57, 68, 75 and 79) to the front of the foremast. 111D Now prepare the three sections of the mainmast, following the plan. The mainmast (81) with fittings and top, the main topmast (106) and the main topgallant mast (112) following the same process as with the foremast. 111A Retrieve the spritsail A D yard (20) and secure it to the 81 bowsprit with the parrel (23). Tie the parrel to the yard, then pass it over the bowsprit and secure the free end to the yard. 20 112 106 B E 64 111B Retrieve the foremast yards (57, 68, 75 and 79) prepared in Stage 110 and paint them with wood stain. -

Boats Built at Toledo, Ohio Including Monroe, Michigan

Boats Built at Toledo, Ohio Including Monroe, Michigan A Comprehensive Listing of the Vessels Built from Schooners to Steamers from 1810 to the Present Written and Compiled by: Matthew J. Weisman and Paula Shorf National Museum of the Great Lakes 1701 Front Street, Toledo, Ohio 43605 Welcome, The Great Lakes are not only the most important natural resource in the world, they represent thousands of years of history. The lakes have dramatically impacted the social, economic and political history of the North American continent. The National Museum of the Great Lakes tells the incredible story of our Great Lakes through over 300 genuine artifacts, a number of powerful audiovisual displays and 40 hands-on interactive exhibits including the Col. James M. Schoonmaker Museum Ship. The tales told here span hundreds of years, from the fur traders in the 1600s to the Underground Railroad operators in the 1800s, the rum runners in the 1900s, to the sailors on the thousand-footers sailing today. The theme of the Great Lakes as a Powerful Force runs through all of these stories and will create a lifelong interest in all who visit from 5 – 95 years old. Toledo and the surrounding area are full of early American History and great places to visit. The Battle of Fallen Timbers, the War of 1812, Fort Meigs and the early shipbuilding cities of Perrysburg and Maumee promise to please those who have an interest in local history. A visit to the world-class Toledo Art Museum, the fine dining along the river, with brew pubs and the world famous Tony Packo’s restaurant, will make for a great visit. -

1 Joseph Conrad (1857-1924) Youth (1902) This Could Have Occurred

1 Joseph Conrad (1857-1924) Youth (1902) This could have occurred nowhere but in England, where men and sea interpenetrate, so to speak—the sea entering into the life of most men, and the men knowing something or everything about the sea, in the way of amusement, of travel, or of bread-winning. We were sitting round a mahogany table that reflected the bottle, the claret-glasses, and our faces as we leaned on our elbows. There was a director of companies, an accountant, a lawyer, Marlow, and myself. The director had been a Conway boy, the accountant had served four years at sea, the lawyer—a fine crusted Tory, High Churchman, the best of old fellows, the soul of honor— had been chief officer in the P. & O. service in the good old days when mail- boats were square-rigged at least on two masts, and used to come down the China Sea before a fair monsoon with stun'-sails set alow and aloft. We all began life in the merchant service. Between the five of us there was the strong bond of the sea, and also the fellowship of the craft, which no amount of enthusiasm for yachting, cruising, and so on can give, since one is only the amusement of life and the other is life itself. Marlow (at least I think that is how he spelt his name) told the story, or rather the chronicle, of a voyage: “Yes, I have seen a little of the Eastern seas; but what I remember best is my first voyage there. -

2016 Affinity Tool Works Dealer Price Book Rev 20 Xlsx

2016 PRODUCT CATALOG Prices Effective January 1, 2016 Supersedes all previously dated price lists. No. 20 Prices subject to change without notice. Affinity Tool Works, LLC • 1161 Rankin • Troy, Michigan 48083 Ph(248) 588-0395 • Fax(248) 588-0623 • [email protected] • www.affinitytool.com Pkg www.boratool.com Stock No. Description Part No. List Price Qty BORA Clamps & Vises 540445 4.5" Micro Bar Clamp (2-Pack) 6$ 10.91 540606-S 6" Midi Pistol Grip Clamp 6$ 12.64 540606 6" Midi Pistol Grip Clamp (2-Pack) 6$ 23.64 540612-S 12" Midi Pistol Grip Clamp 6$ 15.45 540612 12" Midi Pistol Grip Clamp (2-Pack) 6$ 30.00 540806 6" Pistol Grip Bar Clamp 6$ 19.09 540812 12" Pistol Grip Bar Clamp 6$ 20.91 540818 18" Pistol Grip Bar Clamp 6$ 28.18 540824 24" Pistol Grip Bar Clamp 6$ 30.00 BORA Specialized Clamps & Vises 540520 20 Piece Mini Spring Clamp Set 1$ 10.00 551025 Corner Clamp 6$ 30.00 551027 Large Vise 6$ 30.00 BORA Angle Master Miter Duplicator for Mitersaws 530301 Angle Master - Miter Duplicator 3$ 65.45 BORA Sharpening Stones 501057 Sharpening Stone-Aluminum Oxide 6" x 2" x 1" 30$ 4.47 501098 Sharpening Stone-Green Silicon Oxide 6" x 2" x 1" 30$ 8.73 501060 Sharpening Stone-Aluminum Oxide 8" x 2" x 1" 30 $ 8.90 Page 2 © 2016 Affinity Tool Works, LLC Pkg Stock No. Description List Price Qty BORA Modular Clamp Edge & Accessories 543100 100" WTX Clamp Edge (50" + 50") 6$ 99.00 543050 50" WTX Clamp Edge 6$ 53.00 543036 36" WTX Clamp Edge 6$ 46.00 543024 24" WTX Clamp Edge 6$ 40.00 Kits: 543300 3 pc Clamp Edge Set, 24, 36, 50" 4$ 134.00 543400 -

Download LYDE 05 FIFE RAILS YO PUMP

Euromodel – Lyde(1787).05. fife rails to pump. January 2021 TRANSLATION LINKS 1. type into your browser ... english+italian+glossary+nautical terms 2. utilise the translation dictionary ‘Nautical Terms & Expressions’ from Euromodel website An interpretive build of the Lyde English Schooner 1787 Scale 1:80 Checked the Resource File ? 05.FIFE RAIL to PUMP January 2021 My interpretive build is based on the supplied drawings, the kit material – and an amount of extra mater ial. This work only illustrates how this ship might be built.The level of complexity chosen is up to the individual This resource information was based on the original text supplied by Euromodel and then expanded in detail as the actual ship was constructed by the author, Peter Coward. Neither the author or Euromodel have any commercial interest in this information and it is published on the Euromodel web site in good faith for other persons who may wish to build this ship. Euromodel does not accept any responsibility for the contents that follow. 1 Euromodel – Lyde(1787).05. fife rails to pump. January 2021 [To navigate through the contents – use ‘control + click’] Contents CHAPTER 1: DECK ACCESSORIES ...................................................................................... 4 Hatchways .............................................................................................................................. 6 Quarter Deck: 1 & 2 ........................................................................................................... 6 Coaming Construction