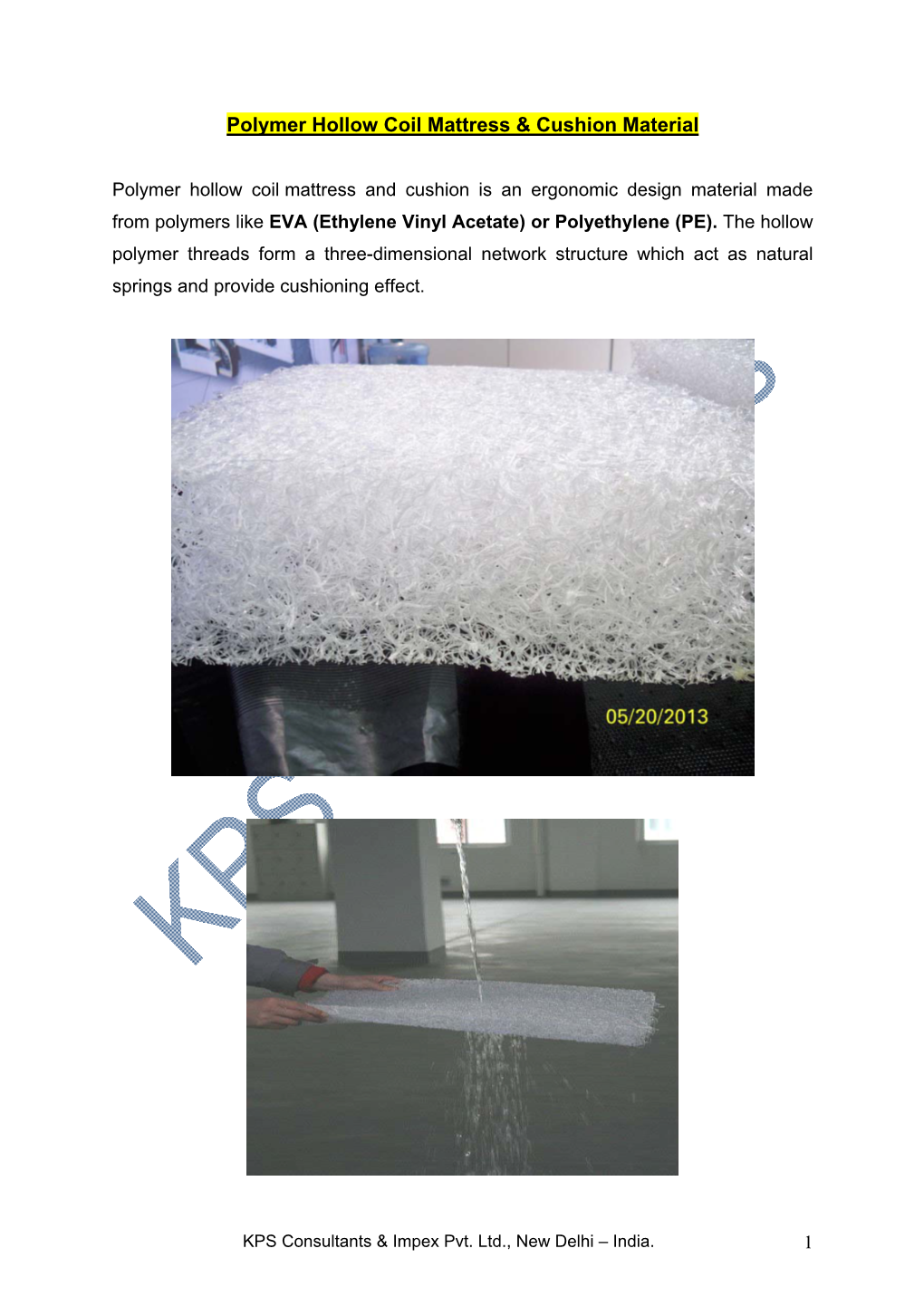

Polymer Hollow Coil Mattress & Cushion Material

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Average Weight of Common Household Furniture

AVERAGE WEIGHT OF COMMON HOUSEHOLD FURNITURE Average Weight Average Weight FURNITURE TYPE (EMPTY) FURNITURE TYPE (EMPTY) Armoire (Large) 200 Bed Headboard (Full) 40 Armoire (Medium) 150 Bed Headboard (King) 55 Armoire (Small) 100 Bed Headboard (Queen) 45 Baby Changing Table 50 Bed Headboard (Twin) 20 Baby Crib (Frame) 40 Bed Rails 10 Baby Crib (Mattress) 15 Bench (Wooden) 75 Baby High Chair 30 Bicycle 25 Baby Play Pen 60 Book Case (Large) 100 Baby Stroller 25 Book Case (Medium) 75 Bar 175 Book Case (Small) 25 Bar Stool 15 Boxes 40 Bed - Double (Box Spring) 60 Boxspring (Full Size) 60 Bed - Double (Footboard) 25 Boxspring (Queen Size) 75 Bed - Double (Headboard) 40 Boxspring (Twin Size) 50 Bed - Double (Mattress/Pillow Top) 75 Breakfront 200 Bed - Double (Mattress/Standard) 60 Buffet 125 Bed - Double (Set of Rails) 10 Cabinet (Curio) 150 Bed - Queen Size (Boxspring) 75 Cabinet (w/ Glass) 100 Bed - Queen Size (Footboard) 35 Cabinet (Wooden) 125 Bed - Queen Size (Headboard) 45 Carpet (Rolled) 125 Bed - Queen Size (Mattress/Pillow Top) 100 Chair ( Recliner) 125 Bed - Queen Size (Mattress/Standard) 75 Chair (Desk) 35 Bed - Queen Size (Set Rails) 10 Chair (Dining/Arms) 20 Bed - Twin Size (Boxspring) 50 Chair (Dining/No Arms) 15 Bed - Twin Size (Footboard) 15 Chair (Glider) 85 Bed - Twin Size (Headboard) 20 Chair (Occasional) 75 Bed - Twin Size (Mattress/Pillow Top) 75 Chair (Open Arm) 15 Bed - Twin Size (Mattress/Standard) 50 Chair (Overstuffed) 85 Bed - Twin Size (Set of Rails) 10 Chair (Papasan) 50 Bed Footboard (Full) 25 Chair (Rocker) 20 Bed Footboard (King) 45 Chair (Straight Back) 35 Bed Footboard (Queen) 35 Chair (Wing) 75 Bed Footboard (Twin) 15 Chaise Lounge 100 Bed Frame (Metal) 25 Chest 75 CONTINUED . -

Fill Your Products with Confidence. Insideinside Beautiful

insideinside beautiful... beautiful... Fill your products with confidence. insideinside beautiful... beautiful... American Down & Feather: designed to deliver. A second generation family business that are experts in custom manufacturing of high quality products for the Interior Design, Sleep, Hospitality, Upholstery and Workroom industries. With over 20 years of experience, you can count on us for the finest in pillows, cut foam, comforters, bed toppers, fills, bulk materials and more. Plus, most importantly, a great vendor relationship designed to deliver. All our products are Made in the U.S.A. at our facility in Henderson, Colorado. americandownandfeather.com WHY AMERICAN DOWN & FEATHER? • Offering the best in personalized service is one of the top • We use 230 thread count for all our down proof ticking and reasons our customers keep coming back. products vs. more widely used 180 thread count. • We work directly with interior • We offer upholstery supplies designers and industry “Great product, and bulk materials at professionals but can also wholesale prices. drop ship to your clients. great price, and • No minimum order • We specialize in Custom prompt shipping! quantities are required; 5 day and Standard Cushions, You can be sure turnaround on most orders. Comforters, Throw Pillows, Sleep you will have Pillows, Mattress Toppers, Cut • Our products are featured Foam and more. my business inside beautiful homes, lodges, hotels and B&B’s throughout Colorado and the USA. • Choose from diverse types in the future” of fill and blends including, -Sam Stubbs organic and allergy resistant No minimum materials, Polyester, Polysilk™ and Kapok. • We offer designer quality down and 2-4 centimeter feathers order quantities sourced primarily in the USA; ethically harvested and often are required! cleansed as many as 7x’s. -

FOAM OR FIBER? a Comparison of Fill Material for Outdoor Cushioning

FOAM OR FIBER? A Comparison of Fill Material for Outdoor Cushioning INTRODUCTION For the average consumer and retail furniture buyer, navigating the world of cushion materials can be a confusing proposition. With a technical community that continues to innovate, it is sometimes difficult to differentiate which innovations create real value in terms of performance and customer experience and which are just enhanced marketing. Polyurethane foam and polyester fiber remain the industry stand- ards, yet the variety of choices that exist within these two options create a decision-making process that is significantly more complex. KEY PARAMETERS IN CHOOSING POLYURETHANE FOAM1,2,3 Polyurethane foam has long been a staple of the cushion industry. Its excellent performance over extended use coupled with a variety of types that can be tailored to specific applications allow retailers to customize their offerings to individual markets. When discussing the material in terms of outdoor performance, there are a few characteristics that require some consideration. All flexible polyurethane foams have an open cellular structure which, when applied in an outdoor setting, means that moisture can penetrate the body of the foam. While polyurethane foam itself has antimicrobial properties, additional additives are often preferred for use in outdoor applications in order to further protect against the effects of exposure to moisture. The other two main performance elements to consider when reviewing foam are density and indentation force deflection (IFD). Density, typically measured in pounds per cubic foot or kilograms per cubic meter, is one of the key determining characteristics of a foam’s durability. A higher density rating will in most cases equate to longer-term durability in the finished product. -

Get the Look! HOME STUDIO Curly Shag Rug • 5'X 7' 129.99

F A L L 2 0 1 0 Get the look! HOmE stuDIO Curly shag rug • 5'x 7' 129.99 lInEns-n-tHIngs Red ottoman with castors 59.99 Chenille cushion 29.99 Throw 29.99 HOmE stuDIO Bonded leather dining chair, red fieryfinds 99.99 Red hot. Fire hot. There’s nothing quiet about red. When it comes to adding colour look no further than our hot red accents. Perfect for that added shock of colour that adds drama to any home décor. Cotton velvet floor Oblong vases umBRa cushion 29.99 • 7" - 12" Mosh frames Accent 19.99 7.99 - 9.99 24.99 HOmE stuDIO Fiesta tab-top window • 52" x 84" ea 63.99 2pk Wamsutta T300 Bamboo stripe duvet cover with 2 shams 2 STYLICIOUSFall2010 Queen set 129.99 STYLICIOUSFall2010 3 Buffalo check throw 29.99 Coordinating cushion 19.99 HOmE stuDIO Flannel plaid Wood bench sheet set 30"x17½"x9" 19.99 89.99 umBRa Starburst clock 149.99 Wood single candle holder 16.99 Wood triple candle holder naturalBring the beauty that is mother nature indoors to accent designyour home. Introduce warm, 29.99 smooth accent pieces to any room décor! gluCKstEInHOmE Wood table Flannel plaid bedding lamp Queen Duvet Cover 49.99 99.99 Multi check rug • 2’x3’ – 7’11”x10’4” 39.99 - 379.99 HOmE stuDIO Faux leather storage ottoman 129.99 Wood bowl 39.99 Curly willow branches 19.99 4 STYLICIOUSFall2010 STYLICIOUSFall2010 5 Add luxury and “elegance to your feel bedroom with the Prestige Collection. With refi ned pleating texture Prestige coordinate bedding detail punctuated by new Set includes duvet cover and 2 shams thoughtfully selected colours, the Prestige Queen or King duvet cover set . -

Alex Pillow Collection 2017

Alex Pillow Collection 2017 www.alexorthopedic.com TABLE OF CONTENTS Cervical.......................................................3-8 Lumbar........................................................9-12 Seating Cushions........................................13-14 Wheelchair Cushions..................................15-17 Seating........................................................18-21 Back Wedge................................................22-25 Leg Wedge..................................................26-27 Knee Wedge................................................28 Wedge Systems..........................................29-30 Positions / Rollers........................................31-32 Specialty Foam............................................33-35 Bed Rails.....................................................36 Pillow Cases................................................37 Alex Retail...................................................38 1 Other Alex Orthopedic Products VISIT OUR VIRTUAL SHOWROOM Google: Alex Orthopedic Inc Click on the image, and move the mouse around for the full showroom ALEX FAMILY OF PRODUCT LINES 2 Cervical Pillows Cervical Pillow • Circular fiber pillow • Covered in poly cotton blend 1001 7” x 17” Cervical Pillow Case Poly Cotton: • Available in assorted colors • Polyurethane foam • Removable washable cover Blue Burgundy Navy Sand White Satin: 1002-S Satin Covers 1002 Poly-Cotton Covers Beige Blue Pink White Yellow Cervical Pillow with Cover • Same as 1001 above • Pillow Case included Poly Cotton: -

Cotton Canvas Shoddy Blankets Catatlogue

COTTON CANVAS SHODDY BLANKETS CATATLOGUE Product name: GEMINI Size: 160x220cms Code: GEM-SHO-16X Quality: Premium Shoddy Blanket Minimum quantity-1 carton (60pieces) Price-360+(5%gst) Product name: ESQUIRE Size: 160x220cms Code: EQ-SHO-16X Quality: Shoddy Blanket Minimum quantity-1 carton (60pieces) Price-300+(5%gst) COTTON CANVAS SHODDY BLANKETS CATATLOGUE Product name: MARINO Size: 160x220cms Code: MAR-SHO-16X Quality: Style Shoddy Blanket Minimum quantity-1 carton (60pieces) Price-280+(5%gst) Product name: RAYMOND Size: 160x220cms Code: RAY-SHO-16X Quality: Plus Shoddy Blanket Minimum quantity-1 carton (60pieces) Price-180+(5%gst) COTTON CANVAS SHODDY BLANKETS CATATLOGUE Product name: MARUTI Size: 160x220cms Code: MAR-SHO-16X Quality: Super Shoddy Blanket Minimum quantity-1 carton (60pieces) Price-150+(5%gst) Product name: SAFARI Size: 160x220cms Code: SAF-SHO-16X Quality: Ref Shoddy Blanket Minimum quantity-1 carton (60pieces) Price-130+(5%gst) COTTON CANVAS SHODDY BLANKETS CATATLOGUE Product name: SIMPLEX Size: 160x220cms Code: SIM-SHO-16X Quality: Donate Shoddy Blanket Minimum quantity-1 carton (60pieces) Price-115+(5%gst) Product name: POLAR BLANKET Size: 160x220cms Code: POL-16X Quality: Polar Blanket Minimum quantity-1 carton (60pieces) Price starts from 85+gst Available in 5 other qualities i.e @ 105,125, 155,`200,280 COTTON CANVAS SHODDY BLANKETS CATATLOGUE Product name: MINK BLANKET Size: 160x220cms, 220X240cms Code: MINK Quality: Mink Blanket Minimum quantity-1 carton (60pieces) Price starts from 300+gst Available in many -

Futon Cover - Yates - Birch - 20" Cushion EW-FC-Birch-Cush20

September 29, 2021 4502 Main Street 604-875-1881 Vancouver, V5V 3R5 [email protected] Futon Cover - Yates - Birch - 20" Cushion EW-FC-Birch-Cush20 $68 Plus tax and shipping General info Futon Cover Cover is the last piece you need to choose in order to complete your futon sofa bed set which consists of a mattress, a frame and a futon cover. Mattress gives you comfort and frame gives structure to yoursofa bed. Futon cover is there to protect your mattress against wear and tear since the cover usually is made of thick fabric. Covers usually come in many colors and patterns so they add character to your room. Since the cover is removable and washable, it can also act as a slipcover. Yates offers refined textures in sun-kissed tones. With its light feel and soft hand, this pattern is very versatile. Yates can bring elegance to traditional homes, or a relaxed air to more modern designs. The adaptability of Yates makes it easy to incorporate into any home. Material Most often, our futon covers are 100% polyester and sometimes they are from a blend of few materials. Abrasion: > 350 k. Majority of our covers are thick and sofa style so you can turn your mattress into a sofa. Polyester, for better or worse, is a very durable material. It lasts long and washes easy. Fabric you see, we use on the top surface as well as all four sides. Back of the cover where it rests on a futon frame is a different material and often in black cover. -

CUSTOM UPHOLSTERY an Exceptional Eye for Design and Detail in Our Bench Made Products Is the Signature of Theodore Alexander

CUSTOM UPHOLSTERY An exceptional eye for design and detail in our bench made products is the signature of Theodore Alexander. Our signature forms are available for you to create your own sofas, chairs, sectionals and loveseats, customized to your own personal style. FRONT COVER IMAGE: (Clockwise from top left) C324-93-JT-BEB, 93” Sofa, Jensen Arm, T Cushion, Boxed Back Pillow, Turner’s London (3002-099), Lindridge Accent (5029-061), Hayward Exposed Leg Base, Medium Block Foot. (4402-064) 1. Choose a Silhouette and Depth CHAIR OTTOMAN CHAIR AND A HALF OTTOMAN AND A HALF LEFT ARM LOVESEAT RIGHT ARM LOVESEAT C301/C401 C311/C411 C305/C405 C315/C415 C363/C463 C364/C464 C300 SERIES LOVESEAT LONG LOVESEAT MID SIZE SOFA SOFA LEFT ARM LONG LOVESEAT RIGHT ARM LONG LOVESEAT STANDARD DEPTH 37” C320/C420 C321/C421 C322/C422 C323/C423 C365/C465 C366/C466 LONG SOFA GRAND SOFA ARMLESS CHAIR ARMLESS LOVESEAT LEFT ARM SOFA RIGHT ARM SOFA C324/C424 C325/C425 C330/C430 C331/C431 C367/C467 C368/C468 ARMLESS SOFA LEFT ARM CHAISE RIGHT ARM CHAISE TWO ARM CHAISE SQUARE CORNER CURVED CORNER C400 SERIES C332/C432 C341/C441 C342/C442 C302/C402 C375/C475 C376/C476 RELAXED DEPTH 40” The length of most silhouettes available by the inch. Please see the price list for details. LEFT ARM CORNER SOFA RIGHT ARM CORNER SOFA LEFT ARM CHAIR RIGHT ARM CHAIR ANGLE CORNER C353/C453 C354/C454 C361/C461 C362/C462 C377/C477 • 20” X 20” THROW PILLOWS STANDARD AS SHOWN ON ILLUSTRATIONS ABOVE. 2 3 2. -

The Sand Society

The sand society ITALY ITALY 2 3 The sand society Desert-inspired fabrics and furniture for a glamorous lifestyle. A sophisticated approach to a sunny life. The elegance of The Sand Society capsule draws inspiration from the rarefied atmosphere of a secretly rich environment, the desert. With a modern and light imprinting, the capsule captures the vibes of a cosmopolitan, dynamic and innovative lifestyle. KOHRO is an Italian manufacturer and editor of high-quality textiles for interior decoration. An expression of Made-in-Italy excellence, taste and savoir vivre developed over seventy years of expertise, KOHRO’s products are made with the best raw materials through a tightly controlled textile supply chain. KOHRO collections - which in addition to fabrics include bespoke bedding products, home furnishings and fabric wallcoverings - leverage a rich Italian cultural heritage and combine art, design, craftsmanship and service. 4 5 INTERIORS OVERLOOKING LANDSCAPES FLOODED WITH LIGHT 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 ABSTRACTION, TEXTURE, LIGHT AND SHADOWS 26 27 28 29 30 31 32 33 34 35 36 37 38 39 Rising Desert is the first abstract subject in The Grand Design Wallcovering Collection. A creation with an extraordinary decorative effect that evokes a desert environment, where the styles of historical abstraction meet the natural inspiration found in the volumes of rocks and sands worked by the wind. Rising Desert goes beyond the traditional idea of wallcovering, getting closer to the concept of art. 40 41 FURNITURE, FABRICS AND COLORS 42 43 Pag. -

Product Catalogue

tisser sareesHAND PAINTED Madhubani | Pattachitra | Warli | Kalamkari | Kerela Hand Painted CHANDERI Buti | Plain | Gold Zari | Shibori | Indigo | Block Print LINEN Pure Linen | Tussar by Linen | Linen Jamdani | Digital Print TUSSAR Moonga | Gidcha | Plain | Block Print HAND-EMBROIDERED Mirror work | Kasuti work | Applique | Kantha | Mangalgiri MAHESHWARI Resham Border | Temple Border | Chatai Border | Shatranj Diya leher | Badi leher | Choka COTTON - SILK Mahapore | Velvet | Gorod | Temple Border COTTON Bishnupur | Cut Shut | Bhagalpur Silk | Kosa Silk Kolkata Cotton Fusion | Khes | Khadi | Khes Pom-Pom BLOCK PRINTED Maddhamoni | Gamcha | Muslin | Tant Indigo | Shibori | Baug | Ajrakh | Pigment | Chuna patri IKAT Sinlge Ikat | Double Ikat CHANDERI - SHIBORI MAHESHWARI - HALF STRIPE COTTON SILK - MIRROR WORK KOSA SILK HAND PAINTED Madhubani | Pattachitra | Warli | Kalamkari Abstract | Orissa Handpainted | Warli Zaripalla CHANDERI Buti | Indigo | Shibori | Chanderi dupattas Block Print | Silk | Pigment | Bagroo HAND-EMBROIDERED Kutch | Applique | Chikan | Kasuti Dunkand | Crotchet | Kantha | Cotton MAHESHWARI Leheriya Border | Kosa Pallu | Zari Pallla | Zari Patta | Resham Border Chatai | Zigzag Border Diya Border | Missing Lines | Tissue IKAT Ikat Silk | Ikat Cotton | Missing Lines TUSSAR Dupion | Gidcha | Tapti| Silk TIE-DYE Bandhni | Batik | Patterned BLOCK PRINTED Bagroo | Pigment |Baug | Ajrakh | Indigo | Kalamkari COTTON Siri Giri | Wave Border | Temple Border | Silk Border | Semi Khadi | Plain KOTA Plain | Block Print | Embroidary -

Murasaki Fine Futon Shop Catalog 2008

Murasaki Fine Futon Shop Catalog 2008 Miwa Inc. Website: www.murasaki-rockridge.com All prices and item availabilities are subject to change without notice. Murasaki Fine Futon Shop 6050 College Ave Oakland, CA 94618 Phone: (510) 547-6252 NEW ~ Puneé Bed/Bench Frame and Table Set (One Size Only) Item No. 03050C Color: Antique Mahogany(6) and Honey Oak(5) Bed/Bench: 27" x 75" x 14"H Square Table: 35" x 35" x 23"H *Optional: Tatami Mats (27"x75") Print S02 as pictured here Punee Murasaki Fine Futon Shop 6050 College Ave Oakland, CA 94618 Phone: (510) 547-6252 NEW ~ Puneé Bed/Bench Frame and Table Set (One Size Only) Item No. 03050C Color: Antique Mahogany(6) and Honey Oak(5) Seat Cushion 6" cotton w/ 1" foam 27" x 75" Back Support (L) 6" cotton w/ 1" foam 18" x 75" Back Support (S) 6" cotton w/ 1" foam 18" x 38" *Optional Seat cushions and Back support Print T01/brown as pictured here *Optional: Tatami Mats (27"x75") Prices for cushions are for permanent sewn on covers in the prints as shown. For choice fabrics, add $10 for each cushion. Covers: Solid color covers will be $18 for seat, $15 for Long back support, and $12 for short back support Punee Murasaki Fine Futon Shop 6050 College Ave Oakland, CA 94618 Phone: (510) 547-6252 Bed Frame Item No. Size Color 030455 Twin (Single) Antique Mahogany 030456 Twin (Single) Honey Oak 030465 Full (Double) Antique Mahogany 030466 Full (Double) Honey Oak 030485 Queen Antique Mahogany 030486 Queen Honey Oak 030495 Cal King Antique Mahogany 030496 Cal King Honey Oak 030475 Eastern King Antique Mahogany 030476 Eastern King Honey Oak *Additional Options: Tatami Mat - SEE TATAMI MAT SECTION FOR SIZE AND PRICING INFORMATION Murasaki Fine Futon Shop 6050 College Ave Oakland, CA 94618 Phone: (510) 547-6252 Metal Bi-Fold Frame and Wooden Arm Item No. -

Bedding Report

1 1 A report by Made Safe September 2018 Written and researched by Sydney Cook, MS Environmental Studies, with writing by Cassidy Randall, MS Environmental Studies. Content and review provided by Amy Ziff, MA Journalism. Scientific review provided by Summer Streets, MS, Environmental Chemist, Minnesota Pollution Control Agency; and Ecology Center. Design by Susan Cann. Thank you to Naturepedic and Coyuchi who helped sponsor the design and release of this report. Funding and content decisions for this report were the sole undertaking of Made Safe. 2 Table of Contents Overview ...............................................................................................................................................................................................................................5 How Our Bodies Heal & Detox During Sleep ......................................................................................................................................6 Our Brains...................................................................................................................................................................................................... 6 Our Hormones .............................................................................................................................................................................................6 Our Skin ...........................................................................................................................................................................................................6