Do Concrete Shells Deserve Another Look? Industry Professionals Give Mixed Opinions

Total Page:16

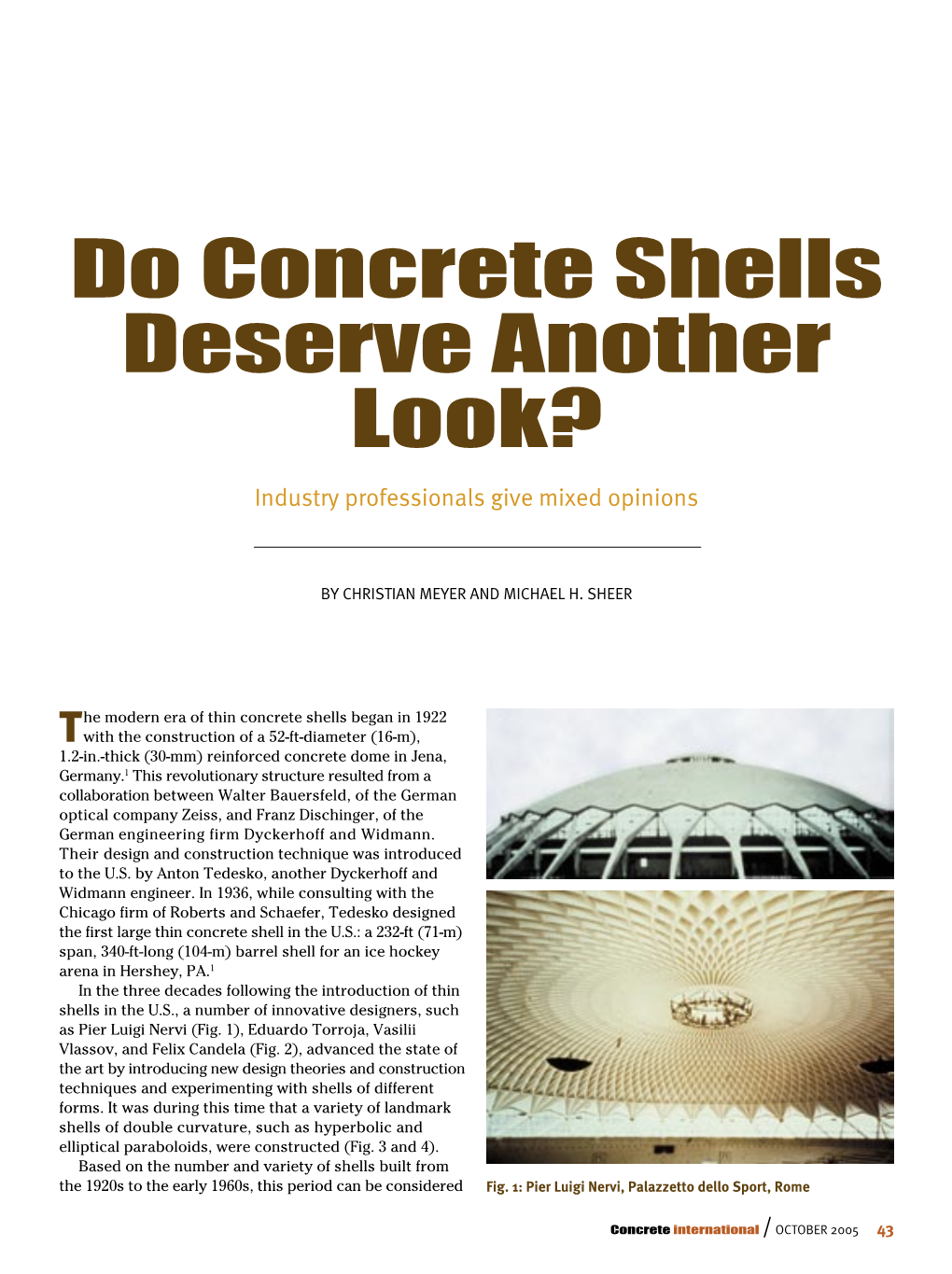

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

1960 National Gold Medal Exhibition of the Building Arts

EtSm „ NA 2340 A7 Digitized by the Internet Archive in 2012 with funding from LYRASIS Members and Sloan Foundation http://archive.org/details/nationalgoldOOarch The Architectural League of Yew York 1960 National Gold Medal Exhibition of the Building Arts ichievement in the Building Arts : sponsored by: The Architectural League of New York in collaboration with: The American Craftsmen's Council held at: The Museum of Contemporary Crafts 29 West 53rd Street, New York 19, N.Y. February 25 through May 15, i960 circulated by The American Federation of Arts September i960 through September 1962 © iy6o by The Architectural League of New York. Printed by Clarke & Way, Inc., in New York. The Architectural League of New York, a national organization, was founded in 1881 "to quicken and encourage the development of the art of architecture, the arts and crafts, and to unite in fellowship the practitioners of these arts and crafts, to the end that ever-improving leadership may be developed for the nation's service." Since then it has held sixtv notable National Gold Medal Exhibitions that have symbolized achievement in the building arts. The creative work of designers throughout the country has been shown and the high qual- ity of their work, together with the unique character of The League's membership, composed of architects, engineers, muralists, sculptors, landscape architects, interior designers, craftsmen and other practi- tioners of the building arts, have made these exhibitions events of outstanding importance. The League is privileged to collaborate on The i960 National Gold Medal Exhibition of The Building Arts with The American Crafts- men's Council, the only non-profit national organization working for the benefit of the handcrafts through exhibitions, conferences, pro- duction and marketing, education and research, publications and information services. -

Are214b Building Structures Ib

ARE214B BUILDING STRUCTURES I B CHENG HO YIU REX 193401515 B.Sc. Yr2 May 27, 2020 LIST OF BUILDING STRUCTURES LECTURE 1 – INTRODUCTION Portuguese National Pavilion Expo 98, Lisbon, Portugal. 1998 | Alvaro Siza | Cecil Balmond (Engineer) A minimalistic pavilion with a wide-spanning curved concrete canopy, fastened between the roofs of two rolls of vertical columns by steel cables embedded inside the thin layers of concrete, HSBC Headquarters, Central, Hong Kong. 1985 | Norman Forster | Ove Arup & Partners (Engineer) High-rise office with exoskeleton structure with steel trusses and floors suspended by tension columns that supported by eight main clustered columns, each composed of 4 connected steel tubes, to create the large column free atrium. Pont du Gard Roman Aqueduct, Nimes, France. 40-60 AD Three tier semi-circular arch structure built with stone using only friction and gravity to transfer water in ancient times. Exchange House Office Building, Dockland, London. 1996 | Skidmore, Owings & Merrill (SOM) The 10-story office building is supported by external steel frame structure that is hold up primarily by four parabolic arches, two internal and two external, to provide a column-free and flexible open office design. Statue of Liberty, New York City, USA. 1886 | Gustave Eiffel | Frédéric Auguste Bartholdi (Sculptor) Structure ≠ Form | The neoclassical copper statue is sectioned into sheets of metal claddings which are attached to steel frames supported by four steel columns, is a gift from France to USA as a memorial to their independence. Greater Columbus Convention Center, Columbus, Ohio, USA. 1993 | Peter Eisenman Structure ≠ Form | The organic and irregular exterior is supported by convoluted structural frame that creates a strong juxtaposition with the convention centre’s large open interior. -

Structural Health Monitoring of Artemio Franchi Stadium In

Structural health monitoring of “Artemio Franchi” Stadium in Florence, Italy: measurement using interferometric radar Lapo MICCINESI 1, Massimiliano PIERACCINI 1, Gloria TERENZI 2, Iacopo COSTOLI 3, Paolo SPINELLI 2, Giulia MAZZIERI 2 1 Department of Information Engineering, University of Florence, Florence, Italy http://www.ndt.net/?id=24901 2 Department of Civil and Environmental Engineering, University of Florence, Florence, Italy 3 Polytechnic Department of Engineering and Architecture, University of Udine, Udine, Italy Contact e-mail: [email protected] More info about this article: ABSTRACT: The “Artemio Franchi” Stadium in Florence, Italy, designed by Pier Luigi Nervi in 1929, was built from 1930 to 1932. The stadium has a reinforced concrete structure and it is composed by 24 stands, a 50-meter tower (“Maratona” tower) and a cantilever roof. In occasion of the World Cup in 1990 the stadium was renovated by adding seats at the ground level as retrofit. A study for seismic requalification is in progress and an interferometric radar was used for monitoring the architectural complex. In particular, the radar monitored the “Maratona” tower and some stands. In this paper, the preliminary results of this measurement campaign are reported. The wind action was exploited to test the “Maratona” tower and the measurement was performed both with an interferometric radar and a seismic accelerometer. Natural frequencies measured with both instruments substantially match. The stands are too rigid to be appreciably excited by wind or vehicular traffic, hence the measurements were performed during football matches. The supporters’ movements were used as input action to measure the dynamic properties of stands. -

FORM and FORCE 7-10 October 2019, Barcelona, Spain

60th Anniversary Symposium of the International Association for Shell and Spatial Structures IASS Symposium 2019 9th International Conference on Textile Composites and Inflatable Structures Structural Membranes 2019 FORM and FORCE 7-10 October 2019, Barcelona, Spain Carlos Lázaro, Kai-Uwe Bletzinger and Eugenio Oñate (Eds.) IASS Symposium 2019 60th Anniversary Symposium of the International Association for Shell and Spatial Structures Structural Membranes 2019 9th International Conference on Textile Composites and Inflatable Structures FORM and FORCE Barcelona, Spain October 7 - 10, 2019 A publication of: International Centre for Numerical Methods in Engineering (CIMNE) Barcelona, Spain ISBN: 978-84-121101-0-4 Printed by: Artes Gráficas Torres S.L., Huelva 9, 08940 Cornellà de Llobregat, Spain SUMMARY SUMMARY INVITED SESSIONS IS - Actual Structural Behavior of Thin Shells (IASS WG 5) ...................................... 45 IS - Adaptive Lightweight Structures .................................................................. 68 IS - Additive Manufacturing of Architectural Components........................................ 87 IS - Analysis and Design of Adaptive Structures ...................................................121 IS - Bio-inspiration for Structural Forms + Fractal and Form ...................................129 IS - Celebrating the Work of Mike Barnes ............................................................145 IS - Constructive Geometry for Structural Design (IASS WG 15) ...............................175 IS - Contemporary -

Mid 20Th Century Architecture in NH: 1945-1975

Mid 20th Century Architecture in NH: 1945-1975 Prepared by Lisa Mausolf, Preservation Consultant for NH Employment Security December 2012 Table of Contents Page I. Introduction 3 II. Methodology 4 III. Historic Context, Architecture in NH, 1945‐1975 5 IV. Design Trends in New Hampshire, 1945‐1975 43 Changes in the Post‐World War II Building Industry 44 Architectural Trends, 1945‐1975 61 Styles 63 V. Recommendations for Future Study 85 VI. Bibliography 86 Appendix A Examples of Resource Types 90 Appendix B Lists of NH Architects 1956, 1962, 1970 111 Appendix C Brief Biographies of Architects 118 2 I. Introduction The Mid 20th Century Architecture in New Hampshire Context: 1945‐1975 was prepared by Lisa Mausolf, Preservation Consultant, under contract for the New Hampshire Department of Employment Security. The context was prepared as mitigation for the sale of the Employment Security building at 32 South Main Street in Concord. The modern curtain wall structure was designed by Manchester architects Koehler & Isaak in 1958. A colorful landmark on South Main Street, discussion of the architectural significance of the building draws commentary ranging from praise “as an excellent example of mid‐ century Modern architecture and ideals of space, form, and function”1 to derision, calling it one of the ugliest buildings in Concord. NH Department of Employment Security, 32 South Main Street, Concord (1958) The Mid 20th Century Architecture in New Hampshire Context was prepared in order to begin work on a framework to better understand the state’s modern architectural resources. The report focuses primarily on high‐style buildings, designed by architects, and excludes residential structures. -

Nervi's Cantilevering Stadium Roofs

Proceedings of the International Association for Shell and Spatial Structures (IASS) Symposium 2013 „BEYOND THE LIMITS OF MAN” 23-27 September, Wroclaw University of Technology, Poland J.B. Obrębski and R. Tarczewski (eds.) Nervi’s cantilevering stadium roofs: discipline of economy leads to inspiration Sigrid Adriaenssens1, David P. Billington2 1Assistant Professor, Form Finding Lab, Princeton University, Princeton, USA, [email protected] 2 Professor Emeritus, Department of Civil and Environmental Engineering, Princeton University, NJ 08544, USA [email protected] Summary: Although he came from a tradition that built magnificent palaces and churches, the Italian master builder Pier Luigi Nervi is arguably mostly known for his sports infrastructure. In this paper, we focus on his first (Giovanni Berta Stadium, Florence, 1930-1932) and last (Olympic Flaminio Stadium, Rome, 1957-1959) internationally widely recognized stadium with cantilevering roof. Through literature studies and structural analyses, we compare and contrast these two stadia on the basis of their structural and constructional efficiency, economy and design intent within the specific social-political context of the interbellum and post-World War II era in Italy. The interpretation of these studies shows Nervi’s clear progression from imitation, innovation to inspiration in his stadium design. More specifically shortage of construction materials and skilled labor did not constrain his projects but drove Nervi to design and build great structures. Keywords: Nervi, ferro-cement, prefabrication, stadium, cantilever, grandstand 1. INTRODUCTION 2. IMITATION: ARCHITECTURAL FORMS AND IDEAS ABOUT REINFORCED CONCRETE Although he came from a tradition that built magnificent palaces and churches, the Italian master builder Pier Luigi Nervi (1891-1979) is Nervi’s life has been intrinsically linked to concrete. -

The Evolution of Concrete Shells; Innovations by Ildefonso Sánchez Del Río La Evolución De Las Estructuras Laminares; Innovaciones De Ildefonso Sánchez Del Río

Informes de la Construcción Vol. 65, 530, 147-154, abril-junio 2013 ISSN: 0020-0883 eISSN: 1988-3234 doi: 10.3989/ic.12.051 The evolution of concrete shells; innovations by Ildefonso Sánchez del Río La evolución de las estructuras laminares; innovaciones de Ildefonso Sánchez del Río P. Cassinello(*) SUMMARY RESUMEN The legacy of Ildefonso Sánchez del Río El legado de Ildefonso Sánchez del Río Pisón (1898-1980) contains some of the Pisón (1898-1980) contiene algunas de most pioneer Spanish concrete shells. las más pioneras estructuras laminares It’s a fact that the “Modern Architec- españolas. Es un hecho que la “Aventura ture‘s Thin Shells Adventure” had just Laminar de la Arquitectura Moderna” start when he designed and built his empezó cuando él proyectó y construyó first work in Spain (1924). In the inter- sus primeros trabajos en España (1924). national context prevailing in the twen- En el contexto internacional de la década ties, the reinforced concrete was still de los años veinte, el hormigón armado evolving. The first Thin Concrete Shells estaba todavía en desarrollo. La primera was built by Dyckerhoff and Widman in estructura laminar fue construida por Jena, Germany (1922-1925). Ildefonso Dy ckerhoff and Widman en Jena. Alema- Sánchez was looking for a system to nia (1922-1925). Ildefonso Sánchez buscó design concrete shells in a simple way. un método sencillo de diseño. Finalmente, Finally, he founded his own and inno- encontró su propio e innovador sistema, vate system based in a similar method que estaba basado en un método similar to the ribbed Gothic Vault. -

CIAB 8. VIII Congreso Internacional Arquitectura Blanca

210 CIAB 8 CÁTEDRA BLANCA VALENCIA · EDITORIAL UNIVERSITAT POLITÈCNICA DE VALÈNCIA 8º Congreso Internacional de Arquitectura Blanca, Valencia, 7, 8 y 9 de Marzo de 2018 Turning Point at the UNESCO Headquarters Crossed Influences Between Pier Luigi Nervi and Marcel Lajos Breuer Martín Fuentes, Javier BAU International Berlin University of Applied Sciences. [email protected] https://doi.org/10.4995/CIAB8.2018.7424 Abstract: The history of architecture is closely linked to the evolution Two men and one destiny and the use of materials. Concrete was the most important material of the 20th century, becoming the medium for a new architecture. The architect Marcel Breuer, born in Hungary in 1902, died as an Many different architects not only relied on the use of concrete as American citizen in 1981. Having been trained at the Bauhaus in their main mode of expression but also got involved in the quest for Weimar under the long-lasting patronage of Walter Gropius, he a new architectural language for the so-called new material. Pier immigrated to the United States in 1937 due to World War II, af- Luigi Nervi and Marcel Breuer are not only among the great archi- ter spending three years working in England. In the United States, tects of the last century, but above all, they are masters of concrete, he first lived in Cambridge, Massachusetts, where he taught at both developing extensive bodies of work based on the use of the the Graduate School of Design (GSD) at Harvard University from material. 1938 to 1946. He was at the GSD not by chance, but because at the time, the Department of Architecture was directed by Gropius. -

ENGINEERING and ARCHITECTURE Author(S): RICCARDO MORANDI Source: Journal of the Royal Society of Arts, Vol

ENGINEERING AND ARCHITECTURE Author(s): RICCARDO MORANDI Source: Journal of the Royal Society of Arts, Vol. 110, No. 5066 (JANUARY 1962), pp. 75- 92 Published by: Royal Society for the Encouragement of Arts, Manufactures and Commerce Stable URL: http://www.jstor.org/stable/41367048 Accessed: 24-09-2017 17:29 UTC JSTOR is a not-for-profit service that helps scholars, researchers, and students discover, use, and build upon a wide range of content in a trusted digital archive. We use information technology and tools to increase productivity and facilitate new forms of scholarship. For more information about JSTOR, please contact [email protected]. Your use of the JSTOR archive indicates your acceptance of the Terms & Conditions of Use, available at http://about.jstor.org/terms Royal Society for the Encouragement of Arts, Manufactures and Commerce is collaborating with JSTOR to digitize, preserve and extend access to Journal of the Royal Society of Arts This content downloaded from 132.174.254.12 on Sun, 24 Sep 2017 17:29:33 UTC All use subject to http://about.jstor.org/terms ENGINEERING AND ARCHITECTURE A paper by PROFESSOR ING. RICCARDO MORANDI read to the Society on Wednesday, 15 th November , 1 96 1, with Sir Herbert Manzoni , С. В. E., City Engineer and Surveyor , Birmingham , and Presidenty Institution of Civil Engineers , in the Chair chairman : Professor Riccardo Morandi has travelled from Italy especially to talk to us this evening. You might think that, having regard to the name of your Chairman tonight, there is some matter of collusion. But I assure you that that is not so, for indeed I find it quite impossible to speak to Professor Morandi in his own language - he speaks very well to me in mine. -

PIER LUIGI NERVI. Architecture for Sport

PIER LUIGI NERVI. Architecture for sport The experimentation, ideas, methods and expertise of the talented Italian engineer and constructor 5 February – 2 October 2016 www.fondazionemaxxi.it #PierLuigiNervi A new material and new themes necessarily lead to new architecture (Pier Luigi Nervi) Rome 4 February 2016 . Stadia with innovative structures, diving boards that have become icons, sports centres with lace-like concrete domes, in the long career of Pier Luigi Nervi (1891 – 1979) research into sports facilities was a continuous fil rouge. From the first stadium built in Florence in 1929 to the Kuwait Sports Centre from 1968, 22 projects and their stories make up the exhibition Pier Luigi Nervi. Architecture for Sport curated by Micaela Antonucci with Annalisa Trentin and Tomaso Trombetti of the University of Bologna at MAXXI from 5 February to 2 October 2016 . “This exhibition traces the constructional and formal genesis of Pier Luigi Nervi's architecture for sport - from the football stadia to the sports halls and the swimming pools - that in the collective imagination have been and still are remarkable settings for sporting events", says Margherita Guccione Director of MAXXI Architettura . “A model of success, one of the most important early expressions of the Made in Italy phenomenon and a fundamental point of reference for contemporary architecture and engineering.” The exhibition features over 100 photographs, original drawings and documents drawn from the rich heritage of the Archivio Pier Luigi Nervi, part of the MAXXI Architettura Archives Centre and presented together with four models of the stadia from Florence, Rome, Swindon and Kuwait made by LaMo and LaMoViDA (the Laboratorio Modelli di Architettura and the Laboratorio di Modellazione e Visualizzazione Digitale per l’Architettura) of the University of Bologna. -

PIER LUIGI NERVI Art and Science of Building • the TRAVELING EXHIBITION •

PIER LUIGI NERVI Art and Science of Building • THE TRAVELING EXHIBITION • a project by Comunicarch Associates with PLN project Who is Pier Luigi Nervi? Why an exhibition For whom? The international exhibition on Pier Luigi Nervi? After the successes of previous “Pier Luigi Nervi. Art and Internationally esteemed and editions, the exhibition was Science of Building” celebrates praised during his lifetime, after transformed in 2014 in a light the life and work of one of the his death in 1979 the work of format and it will embark in a greatest and most inventive Pier Luigi Nervi fell into a period wide international tour towards structural engineers of the 20th of oblivion and it is only in recent other prospective locations in century, the Italian Pier Luigi years that extensive research Asia, North America and other Nervi (1891-1979). into his work has recommenced. parts of the world to celebrate With his masterpieces, In 2010, to commemorate the not only the genius and scattered the world over, Nervi thirtieth anniversary of Nervi’s inventiveness of Pier Luigi Nervi, contributed to create a glorious death, an international itinerant but also his genuine period for structural exhibition was developed. This international spirit, as a architecture. Nikolaus Pevsner, work marks the outcome of a designer, builder and educator. the distinguished historian of multifaceted research project Such an extended analysis and architecture, described him as that assembled a vast team of critical appraisal of Nervi’s “the most brilliant artist in scholars, with the aim of work is expected to offer a reinforced concrete of our time”. -

Pier Luigi Nervi's Works for the 1960 Rome Olympics

Actas del Cuarto Congreso Nacional de Historia de la Construcción, Cádiz, 27-29 enero 2005, ed. S. Huerta, Madrid: I. Juan de Herrera, SEdHC, Arquitectos de Cádiz, COAAT Cádiz, 2005. Pier Luigi Nervi’s Works for the 1960 Rome Olympics Tullia Iori, Sergio Poretti Pier Luigi Nervi designed and constructed four struc- varying width pillars —the sections change tures for the 1960 Rome Olympic games: three sports from rectangular to cross-shaped and the facilities and a viaduct serving the Athlete’s residential transitional surface from one to the other in a quarter, the Villaggio Olimpico. These are considered hypar surface, formed by straight lines— and some of his most famous international works. by the V-shaped beams, precast and pre- stressed. – The Palazzetto dello Sport (Small Sports Palace; 1956–57; with Annibale Vitellozzi) in The works erected for the 1960 Olympic games the Flaminio area of Rome is characterized by represented a crucial milestone in Pier Luigi Nervi’s its sixty-meter diameter dome, which is held career. They are the best examples of his experimen- up —or better, held down— by 48 radial Y- tation on statics, construction and architecture, and shaped struts whose divergent upper arms de- guaranteed his international fame. However, the ob- velop the rim «decoration». The externally smooth dome only reveals its large rhomboidal ribbing internally. – The Palazzo dello Sport (Sports Palace; 1956–59; with Marcello Piacentini) in the EUR area is also dome-shaped, but with a hun- dred-meter diameter. The internal surface is characterized by minute pleated V-shaped «waves». Externally, the dome is concealed by a high glass cylinder, which only partially re- veals the structure of the perimetral stands.