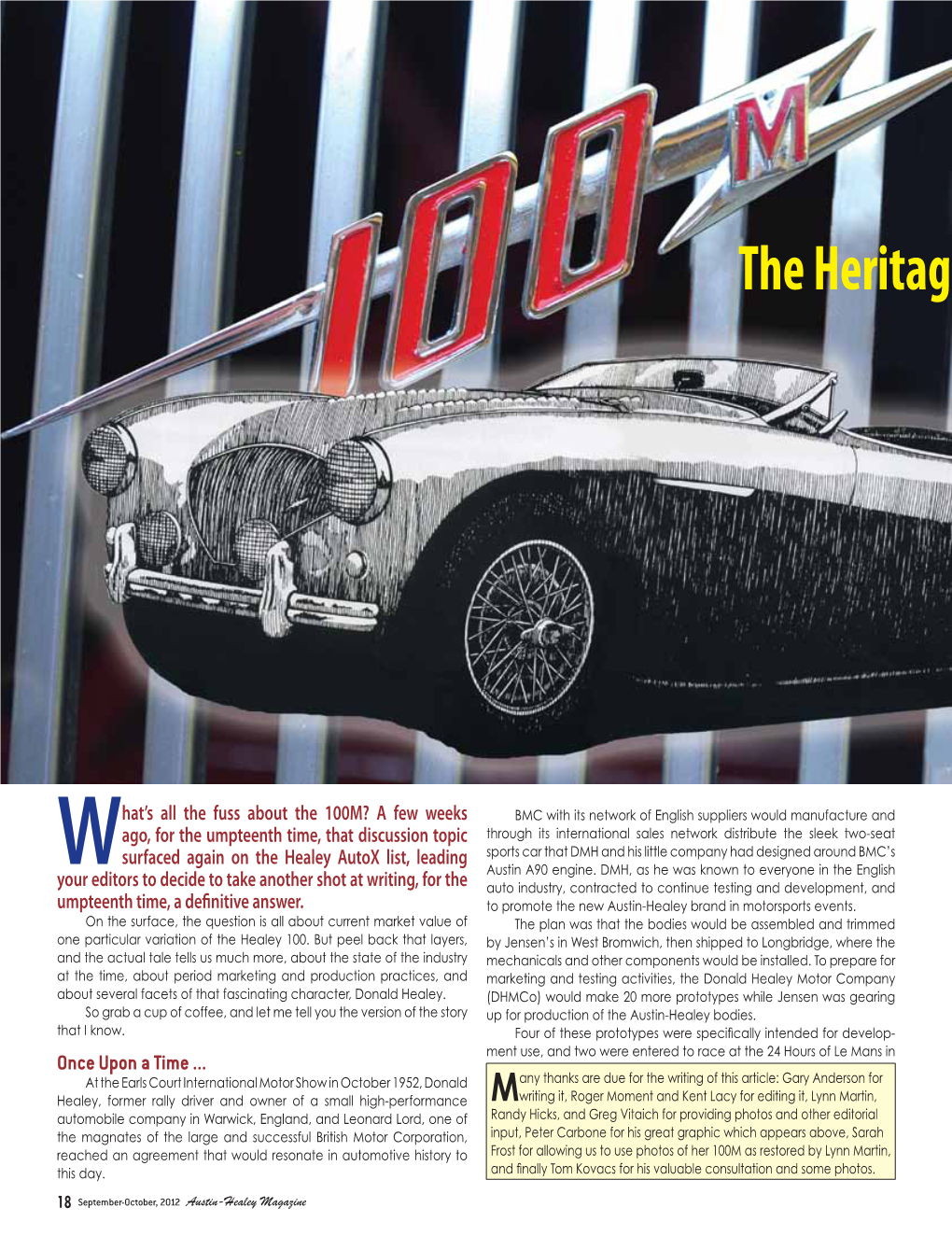

The Heritage of the Austin-Healey 100M

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Alan and Richard Jensen Produced Their First Car in 1928 When They

Alan and Richard Jensen produced their first car in 1928 when they converted a five year old Austin 7 Chummy Saloon into a very stylish two seater with cycle guards, louvred bonnet and boat-tail. This was soon sold and replaced with another Austin 7. Then came a car produced on a Standard chassis followed by a series of specials based on the Wolseley Hornet, a popular sporting small car of the time. The early 1930s saw the brothers becoming joint managing directors of commercial coachbuilders W J Smith & Sons and within three years the name of the company was changed to Jensen Motors Limited. Soon bodywork conversions followed on readily available chassis from Morris, Singer, Standard and Wolseley. Jensen’s work did not go unnoticed as they received a commission from actor Clark Gable to produced a car on a US Ford V8 chassis. This stylish car led to an arrangement with Edsel Ford for the production of a range of sports cars using a Jensen designed chassis and powered by Ford V8 engines equipped with three speed Ford transmissions. Next came a series of sporting cars powered by the twin-ignition straight eight Nash engine or the Lincoln V12 unit. On the commercial side of the business Jensen’s were the leaders in the field of the design and construction of high-strength light alloys in commercial vehicles and produced a range of alloy bodied trucks and busses powered by either four-cylinder Ford engines, Ford V8s, or Perkins diesels. World War Two saw sports car production put aside and attentions were turned to more appropriate activities such as producing revolving tank gun turrets, explosives and converting the Sherman Tank for amphibious use in the D-Day invasion of Europe. -

Your Reference

MINI United Kingdom Corporate Communications Media Information 8 March 2013 A CENTURY OF CAR-MAKING IN OXFORD Plant’s first car was a Bullnose Morris Oxford, produced on 28 March 1913 Total car production to date stands at 11,655,000 and counting Over 2,250,000 new MINIs built so far, plus 600,000 classic Minis manufactured at Plant Oxford Scores of models under 14 car brands have been produced at the plant Grew to 28,000 employees in the 1960s As well as cars, produced iron lungs, Tiger Moth aircraft, parachutes, gliders and jerry cans, besides completing 80,000 repairs on Spitfires and Hurricanes Principle part of BMW Group £750m investment for the next generation MINI will be spent on new facilities at Oxford The MINI Plant will lead the celebrations of a centenary of car-making in Oxford, on 28 March 2013 – 100 years to the day when the first “Bullnose” Morris Oxford was built by William Morris, a few hundred metres from where the modern plant stands today. Twenty cars were built each week at the start, but the business grew rapidly and over the century 11.65 million cars were produced. Today, Plant Oxford employs 3,700 associates who manufacture up to 900 MINIs every day, and has contributed over 2.25 million MINIs to the total tally. Major investment is currently under way at the plant to create new facilities for the next generation MINI. BMW Group Company Postal Address BMW (UK) Ltd. Ellesfield Avenue Bracknell Berks RG12 8TA Telephone 01344 480320 Fax 01344 480306 Internet www.bmw.co.uk 0 MINI United Kingdom Corporate Communications Media Information Date Subject A CENTURY OF CAR-MAKING IN OXFORD Page 2 Over the decades that followed the emergence of the Bullnose Morris Oxford in 1913, came cars from a wide range of famous British brands – and one Japanese - including MG, Wolseley, Riley, Austin, Austin Healey, Mini, Vanden Plas, Princess, Triumph, Rover, Sterling and Honda, besides founding marque Morris - and MINI. -

B R a N D D E

BRAND DECK PREPARED BY LICENSING MANAGEMENT INTERNATIONAL HISTORY British Motor Heritage represents the classic marques of Austin, Morris, Wolseley and Rover together with the iconic British sports cars of MG and Austin-Healey. All are available for worldwide license. The BMH licensed products and designs have been inspired by the original sales brochures and advertising material held in the BMH archive. 1 THE BMH LOGO BRAND ATTRIBUTES ! Elegant ! Refined ! Sophisticated ! Masculine ! A rich British legacy and roots ! Traditional ! Adventurous ! Classic BMC, Nuffield and the Heritage logo are ! Nostalgic/Vintage trademarks of British Motor Heritage. ! Attention to detail ! Style British Motor Heritage and its logos are the registered The British Motor Heritage Brand encompasses a trademarks of British Motor Heritage Limited. The trademarks collection of classic car marques representing the golden were commissioned by the company in 1983 and have been in era of British car manufacturing. continual use ever since. The British Motor Heritage collection of licensed products Over the years, the Heritage trademarks have become the sign utilising the approved marques is targeted at men over 21 for quality of service and manufacture. The use of the logos has who may have fond sentimental memories of owning their been identified with Specialist Approval which is the Quality own MGs, Morris Minors or Austin-Healeys in their youth. Benchmark for the Classic Car Industry and with Quality Original Equipment product. We believe that collectors of fine wine, memorabilia and classic cars would be a key target for this Brand. The BMH Brand offers a prime opportunity for gift giving. 2 BMH MARQUES THE BMH MARQUES ARE AS FOLLOWS 3 BMH MARQUES - AUSTIN Registered in 1909, the Austin Word form was used on cars and literature well into the late 1930s. -

The MG Car Club Geelong Inc

The MG Car Club Geelong Inc. Selected Indexes of articles in indexed magazines. Many of these magazines are missing from our Library, please return if you have them. The Index is not complete but is a 'work in progress' and will be updated regularly. Only articles of on-going historical or technical interest are indexed. I have included any articles about the history of the MG Company, MG cars, or the people who were involved in either. I have not listed articles about Club Runs, Competition Events, or non-technical reports of Club Members' MGs as many of these are only relevant to Members in the UK. Use <Ctrl><f> to open the pdf search box to find keywords from articles, or to jump to the latest indexed edition of the magazines. To go to latest:- BMC Experience, insert text "latestbmc" in the search box MGCC G-Torque, insert text "latestgtorque" in the search box Octane, insert text "latestoctane" in the search box MG Octagon CC Bulletin, insert text 'latestoctagonbulletin' in the search box Librarian - The MGCC Geelong Inc. Index of Technical Articles from G-Torque - MGCC Geelong Magazine Edition Article Title EDITION ARTICLE PAGES 1990 Believe it or Not - This article is a personal account of installing an Austin 1800 engine in an MGB. It has good February 1990 basic information and tips on how to install the engine and some pitfalls.Barry Arthur Bits and Pieces - A brief description outlining the factors of MG handling and what may fix it. For example front March 1990 sway bar, ride height tyre pressure. -

The Healey Oral History Project Warwickshire County Record Office Would Like to Record Your Healey Memories for the Archive

The Healey Oral History Project Warwickshire County Record Office would like to record your Healey memories for the archive. Warwickshire County Record Office has purchased, catalogued and conserved the Warwick Healey Motor Company archive. This amounts to 28 rolls and portfolios of plans, 30 boxes of papers including 8 containing photographs; in total there are 850 items including many files and also an additional 300 items donated separately since the project began. There is also a small amount of cinefilm, previously unseen. The collection is available for everybody to view at the record office during our opening hours. As well as the written archive we are creating an oral history archive to keep with the collection. We have set a challenging target to create 60 hours of interview material. We want to record and transcribe the memories of individuals with long-standing connections to the Donald Healey Motor Company or to car m a n u f a c t u r e r s s u c h a s A u s t i n a n d J e n s e n t h a t h e l p e d b u i l d t h e c a r s . S o naturally we want to hear from you if you are a former mechanic, driver, constructor, engineer, or office worker. Maybe you have memories of Healey family members such as Donald and his sons Geoff and Brian (‘Bic’). We also want to talk to Healey owners and enthusiasts so they can share their memories. -

Austin Motor Company

Austin Motor Company Few names in British motoring history are better known than that of Austin. For many years the company claimed that ‘You buy a car but you invest in an Austin’. A young Herbert Austin (1866–1941) travelled to Australia in 1884 seeking his fortune. In mid 1886 he began working for Frederick Wolseley’s Sheep Shearing Machine Company in Sydney. Austin returned to England with Wolseley in 1889 to establish a new factory in Birmingham, where he became Works Manager. Austin built himself a car in 1895/6 followed a few months later by a second for Wolseley, a production model followed in 1899. A new company, backed by Vickers, bought the car making interests of the Wolseley Company in 1901 with Austin taking a leading role. Following a disagreement over engine design in 1905 Austin left, setting up his own Austin Motor Company in a disused printing works at Longbridge in December of that year. The first Austin was a 4 cylinder 5182cc 25/30hp model which became available in the spring of 1906. This was replaced by the 4396cc 18/24 in 1907. 5838cc 40hp and 6 cylinder 8757cc 60hp models were also produced. The 6 cylinder engine also formed the basis for a 9657cc 100hp engine used in cars for the 1908 Grand Prix. A 7hp single cylinder car was marketed in 1910/11. The company expanded rapidly, output growing from 200 cars in 1910 to 1100 in 1912. By 1914 there was a three model line-up of Ten, Twenty and Thirty. The Austin Company underwent a massive expansion during World War I with the workforce growing from 2,600 to more than 22,000. -

Healey Duncan Sports Saloon

Healey Duncan Sports Saloon Patrick Quinn New South Wales, Australia healey marque Correspondent etween late 1945 and early 1954, a total of 1,287 Heal- ey cars were produced by the Donald Healey Motor Company. The chassis fitted to all Healey cars were basically the same, however there were derivations Bthroughout the production period. Engines used for these cars were the 2.4-litre twin-cam Riley four-cylinder, the Alvis 3-litre six-cylinder, and the Nash 3.8/4.1-litre six-cylinder. Each Healey car features the unique trailing link front suspen- sion and coils at the rear that is found on no other car and is nothing like that fitted to Austin-Healeys. In total there were 781 Healey cars built with Riley drivetrains and these were in the main fitted with a number of differing body styles. To start with, the Donald Healey Motor Company offered an open body called a Westland and the saloon was called the Elliott. Later Riley-engined cars included the Silverstone, Sportsmobile, Abbott and Tickford. At the early days of Healey car production a partnership was also formed with Duncan Industries (Engineers) Ltd. for the supply of rolling chassis to be fitted with differing body styles. In total, 40 Healeys were supplied to Duncan Industries from 1946 to 1948 and two were fitted with roadster bodywork, 15 received “drone” bodywork (cheap bodies to avoid UK tax), and 23 were built with saloon coach-built bodywork. The saloon became known as the Healey Duncan Sports Saloon. Like all Healey cars the Healey Duncan Sports Saloon was capable of 100 MPH and for a time a Healey car wore the distinction of being the fastest saloon in the world. -

Proprietors and Managers: Structure and Technique in Large British Enterprise 1890 to 1939

PROPRIETORS AND MANAGERS: STRUCTURE AND TECHNIQUE IN LARGE BRITISH ENTERPRISE 1890 TO 1939. JOHN MICHAEL QUAIL Submitted in accordance with the requirements for the degree of PhD, The University of Leeds School of Business and Economic Studies January 1996 The candidate confirms that the work submitted is his own and that appropriate credit has been given where reference has been made to the work of others Abstract. The model of the managerial modern business enterprise set out by A D Chandler defines a specific organisational structure and specific techniques of corporate control which are presented as the most effective form of governance for large enterprise. It is generally accepted, however, that this form of governance remained largely unadopted by large UK enterprise before World War Two. This thesis offers an explanation based on the particular role and function of directors in UK firms. Part One of the thesis examines the structure and control technique of large UK enterprise before World War One and the theory of the firm that underpinned them. It is shown that the favoured form of joint stock company structure, here called `proprietorial', was the consequence of the perceived role of company directors as shareholders' representatives rather than managers of the business. Much flowed from this. The legitimation of directors powers through property rights impelled them to retain centralised control despite their customary part-time status. This restricted the growth of top management, fragmented management and business professions into narrow departmental structures and restricted the development of control techniques. Under these circumstances the development of firms of the Chandler type was unlikely. -

New Additions to the Healey Museum

New Additions AUSTIN-HEALEY 100-6 RALLY CAR Since January 12, 2019, the Healey Museum has had this heavily-campaigned rally car on display, pictured above and below. Not only is it the only Austin-Healey to win the to the Healey International Historic Tulpenrallye, but it has done so three times, with owner Rinus Sinke as the driver and Bart den Museum Hartog as the navigator. Recently, two Austin-Healeys have been added to the Healey Museum—a beautiful BN7 and the only Austin-Healey to ever win the Tulpenrallye. Museum director Hans van de Kerkhof has shared some information and pictures of these exciting additions to the collection. Reprinted with permission from the Austin-Healey Magazine SPECIFICATIONS • Complete aluminum body including full aluminum doors, Works-style front wing vents, and shroud cut out for Webers • Full rally specification engine including steel billet crank, steel rods, forged pistons, aluminum cylinder head, super damper, alternator, high torque pre-engaged starter motor, triple Weber carburators, engine oil-cooler, and a DWR rally exhaust manifold with silencer in the door • Full race rear axle including 4.1 ratio crown wheels and pinions and a clutch-type limited-slip differential • Balance bar adjustable dual brake system with disc brakes all around • Twin facet red top fuel pumps in boot • Original hard top with side screens • Full roll cage with door bars • High ratio steering box with safety steering column • Fully rated suspension including up-rated shocks, springs, anti-roll bar, and stub axles in front and adjustable rear shocks and up-rated panhard rod in rear • Two-speed wipers • 51/2" 72 spoke tires • Heated wind screen • Twinmaster and Brantz 3Pro +Driver display tripmeter Specifications created by Dennis Welch Motorsport and provided to this magazine by the Healey Museum. -

Ubiquitous Mini Booklet 2

Unrest and Diversity TheThe UbiquitousUbiquitous MiniMini As BMC turned into British Leyland, poor management decisions and unhelpful union influences conspired to see the eventual downfall of the British motor industry. As British Leyland lurched through the 1970s, even the charismatic South African, Michael Edwards could not stop the strikes and company unrest. Nevertheless, through the entire trauma, upheavals and re-adjustments the company suffered, the evergreen Mini sailed on, with ever varying modifications and company changes. Eventually, on the 4th October 2000 the Rover Mini, as it was now called, ceased to be when MG Rover sold the rights to BMW. A new Mini was born that only slightly resembles the original model, but somehow the spark lives on with enthusiasts who covet this new Mini concept as strongly as their grandparents did back in 1959. INTERNATIONAL INTERNATIONAL HAYNES HAYNES INTERNATIONAL INTERNATIONAL MOTOR MUSEUM Haynes International Motor Museum MOTOR MUSEUM Haynes International Motor Museum INTERNATIONAL INTERNATIONAL Introduction Development and Variations What makes a car into a cult object and therefore successful and During its life, the Mini saw some real oddball developments from collectable is difficult to quantify, but there is no doubt that the Mini outside of the parent company. Harold Radford Ltd, suppliers of has achieved this status. During a 41 year life span the outer panels quality coachwork to the rich and famous, re-appointed Minis to of the Mini have changed little, many of them interchangeable with ape their much larger brother, the gargantuan Rolls Royce by fitting later units. From the 1980s on however, the modern Mini became a deep pile carpet, leather interiors very different animal. -

Gerry Coker Body Designer of the Austin-Healey 100

Celebrating the 90th Birthday of Gerry Coker Body Designer of the Austin-Healey 100 Bill Meade Founder & Registrar, Gerry Coker proudly Worldwide 100M “Le Mans” Registry standing with an example Contributi ng Editor, ������ ������ of the car he designed. The body style endured for 14 years spanning the original four-cylinder car and in the fi nal, six- cylinder big Healey. he 1950s were a time when automo- bile designs reached levels of beauty many feel have never been equaled. Car designs of that era had shapes that Twere simple yet elegant. Bodies had sensuous, organic curves that were full and rounded and almost begged to be caressed. Because of these fantastic designs, people today still lust after these cars and it’s why the Austin-Healey de- sign is still growing in fame and stature nearly 60 years later! The man Donald Healey hired to be Body Engineer for his Nash Healey, and later the Austin-Healey, was Gerry Coker. He was only twenty-eight years The Coker-designed Streamliner set records on the Bonneville old at the time he started to work at Donald Healey Motor Salt Flats in 1954. This photo is of the replica built and run in 2009 to celebrate the 55th anniversary of the 1954 eff ort. Company. After proving himself to Donald, Gerry was given the task of designing the body for the new Healey 100 that Donald was planning. with stretching the body for the rear jump-seats. The new six-cylinder car largely continued with the body shape of the original 100 (made from 1953 to 1956) from 1957 until 1967, a total of 14 years for one body style being produced, unheard of in today’s world of Donald Healey’s factory in the early 1950s, about the ti me Gerry Coker planned obsolescence for cars. -

Lord Nuffield Philanthropic Legacy.Pdf

A philanthropic legacy Lord Nuffield A philanthropic legacy arms of lord nuffield The background of the shield is ermine—the fur of a white weasel decorated with small black tails. The roses are said to represent England. The pears are taken from the arms of the City of Worcester, where Lord Nuffield was born. The scales or balance link up with the motto ‘Fiat Justitia’: let justice be done (part of the legal maxim ‘Fiat Justitia ruat coelum’: Let justice be done though the heavens fall.) The coronet is a Viscount’s coronet. The bull in the crest is taken from the arms of the City of Oxford, and the winged wheel that it holds represents the motor industry. The beavers are also taken from the arms of the City of Oxford (one of the City supporters is a beaver, the other an elephant). lord nuffield A philanthropic legacy nuffield college 2013 Published by Nuffield College, Oxford 2013 Nuffield College, Oxford OX1 1NF www.nuffield.ox.ac.uk Produced in partnership with the Nuffield Foundation Copyright © Nuffield College All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means—electronic, mechanical, photocopying, recording or otherwise—without prior written permission of the publisher. The publishers make no representation, express or implied, with regard to the accuracy of the information contained in this book and cannot accept responsibility for any errors or omissions that take place. isbn 978–0–9559055–4–4 Design & typesetting by Kim Vousden Set in Sina Nova and Sina Nova Italic Printed on Olin Regular Natural White, 120 gsm / cover: 300gsm Printed by Oxuniprint Ltd, Unit 10, Oxonian Park, Langford Locks, Kidlington, Oxford Cover image: Extracted from the photograph reproduced in full on page 23.