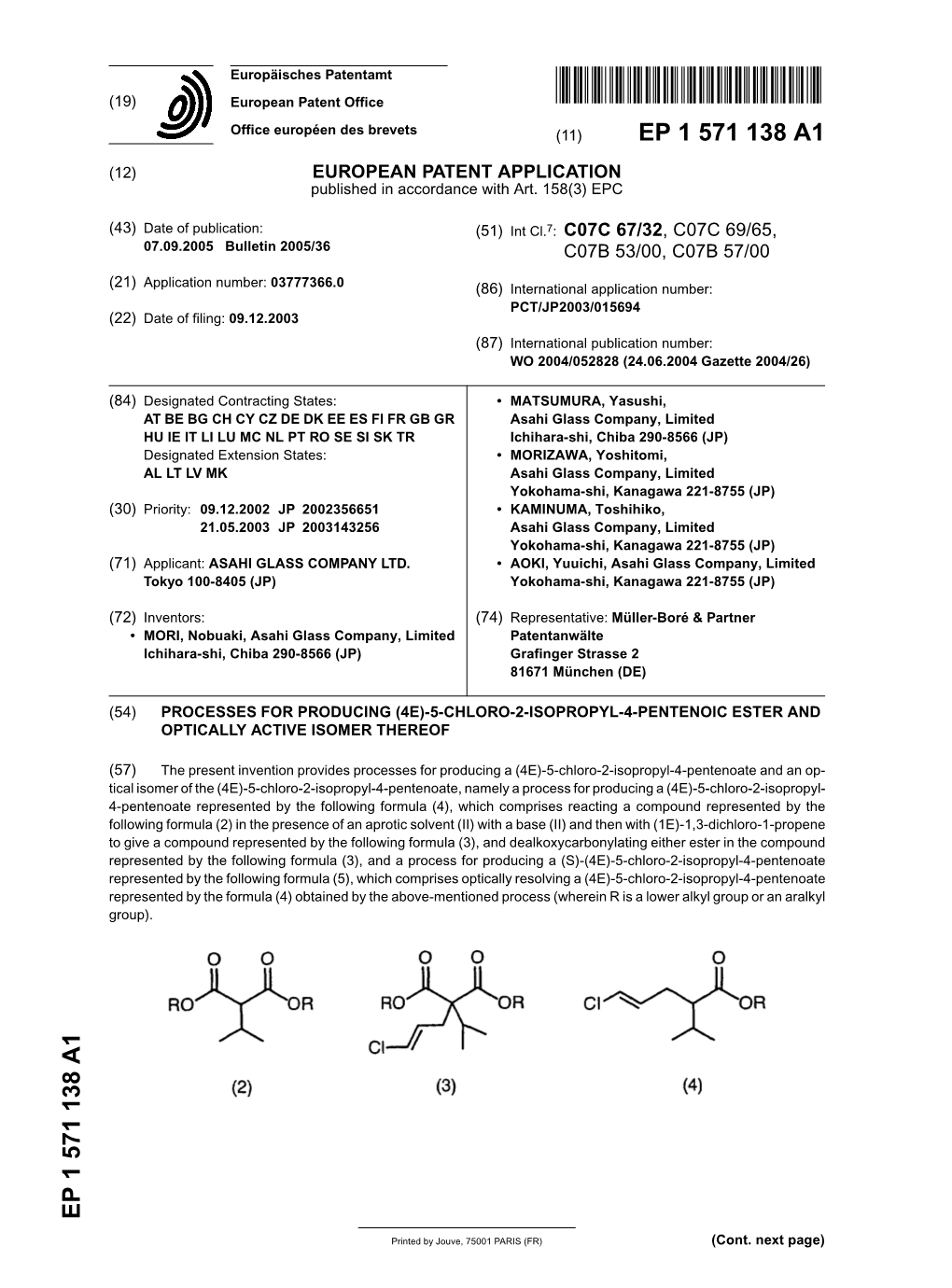

Processes for Producing (4E)-5-Chloro-2-Isopropyl-4-Pentenoic Ester and Optically Active Isomer Thereof

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Wo 2009/082437 A9

(12) INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT) CORRECTED VERSION (19) World Intellectual Property Organization International Bureau (10) International Publication Number (43) International Publication Date 2 July 2009 (02.07.2009) WO 2009/082437 A9 (51) International Patent Classification: KZ, LA, LC, LK, LR, LS, LT, LU, LY, MA, MD, ME, C07D 207/08 (2006.01) A61K 31/402 (2006.01) MG, MK, MN, MW, MX, MY, MZ, NA, NG, NI, NO, C07D 207/09 (2006.01) A61P 5/26 (2006.01) NZ, OM, PG, PH, PL, PT, RO, RS, RU, SC, SD, SE, SG, C07D 498/04 (2006.01) SK, SL, SM, ST, SV, SY, TJ, TM, TN, TR, TT, TZ, UA, UG, US, UZ, VC, VN, ZA, ZM, ZW. (21) International Application Number: PCT/US2008/013657 (84) Designated States (unless otherwise indicated, for every kind of regional protection available): ARIPO (BW, GH, (22) International Filing Date: G M M N S D S L s z τ z U G Z M 12 December 2008 (12.12.2008) z w Eurasian (A M B γ KG> M D RU> τ (25) Filing Language: English TM), European (AT, BE, BG, CH, CY, CZ, DE, DK, EE, ES, FI, FR, GB, GR, HR, HU, IE, IS, IT, LT, LU, LV, (26) Publication Language: English M C M T N L N O P L P T R O S E S I s T R OAPI (30) Priority Data: B F ' B J ' C F ' C G ' C I' C M ' G A ' G N ' 0 G W ' M L ' M R ' 61/008,731 2 1 December 2007 (21 .12.2007) US N E ' S N ' T D ' T G ) - (71) Applicant (for all designated States except US): LIG- Declarations under Rule 4.17: AND PHARMACEUTICALS INCORPORATED [US/ — as to applicant's entitlement to apply for and be granted US]; 11085 N. -

United States Patent (19) 11) Patent Number: 5,072,065 Sun Et Al

United States Patent (19) 11) Patent Number: 5,072,065 Sun et al. 45 Date of Patent: Dec. 10, 1991 54 NHIBITING POPCORN POLYMER FORMATION WITH ALKYL HALDES FOREIGN PATENT DOCUMENTS 63-223003 9/1988 Japan. (75) inventors: Hsiang-ning Sun, Houston, Tex.; Steven J. Potlock, Baton Rouge, La. OTHER PUBLICATIONS Liu, Plugging-Up of Equipment by Self-Polymeriza (73) Assignee: Exxon Chemical Patents Inc., tion Butadiene Production and its Prevention, China Linden, N.J. Synthetic Rubber Industry, 11(5) 356-360 (1988) & English abstract. 21 Appl. No.: 647,358 Liu et al., Determination of Traces of Diethylhydrox ylamine Inhibitor in c5 Fraction by Gas Chromatogra 22 Fied: Jan. 29, 1991 phy, China Synthetic Rubber Industry, 12(6), 408-410 (1989) & English abstract. (51 Int, C. ........................... C07C 7/20; B08B 9/00 (52) U.S. C. ..................................... 585/2; 134/22.19; Primary Examiner-Curtis R. Davis 585/3,585/950 Attorney, Agent, or Firm-Linda K. Russell (58 Field of Search ............................... 585/3, 2,950; 57 ABSTRACT 34/22.19 Inhibition of popcorn polymer growth by treatment with an alkyl halide. This compound can be admixed (56) References Cited with organic material from which popcorn polymer is U.S. PATENT DOCUMENTS formed, or added to a system for the recovery, use or 4,404,413 9/1983 Heskell ................................ 585/950 storage of such organic material. 4,941,926 7/1990 Nakajima ................................ 585/5 4,956,020 9/1990 Nakajima ................................ 585/5 16 Claims, No Drawings 5,072,065 1. 2 once present in a system. Some of the seeds become NHIBITING POPCORN POLYMER FORMATION attached to the processing and handling equipment, and WITH ALKYL HALDES cannot be readily removed by mechanical means; more over, being insoluble in most common solvents, they are CONCURRENTLY FILED APPLICATIONS virtually impossible to wash out by use of such solvents. -

Aldrich Vapor

Aldrich Vapor Library Listing – 6,611 spectra This library is an ideal tool for investigator using FT-IR to analyze gas phase materials. It contains gas phase spectra collected by Aldrich using a GC-IR interface to ensure chromatographically pure samples. The Aldrich FT-IR Vapor Phase Library contains 6,611 gas phase FT-IR spectra collected by Aldrich Chemical Company using a GC interface. The library includes compound name, molecular formula, CAS (Chemical Abstract Service) registry number, Aldrich catalog number, and page number in the Aldrich Library of FT-IR Spectra, Edition 1, Volume 3, Vapor-Phase. Aldrich Vapor Index Compound Name Index Compound Name 6417 ((1- 3495 (1,2-Dibromoethyl)benzene; Styrene Ethoxycyclopropyl)oxy)trimethylsilane dibromide 2081 (+)-3-(Heptafluorobutyryl)camphor 3494 (1-Bromoethyl)benzene; 1-Phenylethyl 2080 (+)-3-(Trifluoroacetyl)camphor bromide 262 (+)-Camphene; 2,2-Dimethyl-3- 6410 (1-Hydroxyallyl)trimethylsilane methylenebicyclo[2.2.1]heptane 6605 (1-Methyl-2,4-cyclopentadien-1- 2828 (+)-Diisopropyl L-tartrate yl)manganese tricarbonyl 947 (+)-Isomenthol; [1S-(1a,2b,5b)]-2- 6250 (1-Propynyl)benzene; 1-Phenylpropyne Isopropyl-5-methylcyclohexano 2079 (1R)-(+)-3-Bromocamphor, endo- 1230 (+)-Limonene oxide, cis + trans; (+)-1,2- 2077 (1R)-(+)-Camphor; (1R)-(+)-1,7,7- Epoxy-4-isopropenyl-1- Trimethylbicyclo[2.2.1]heptan- 317 (+)-Longifolene; (1S)-8-Methylene- 976 (1R)-(+)-Fenchyl alcohol, endo- 3,3,7-trimethyltricyclo[5.4.0 2074 (1R)-(+)-Nopinone; (1R)-(+)-6,6- 949 (+)-Menthol; [1S-(1a,2b,5a)]-(+)-2- Dimethylbicyclo[3.1.1]heptan-2- -

Chapter 2: Alkanes Alkanes from Carbon and Hydrogen

Chapter 2: Alkanes Alkanes from Carbon and Hydrogen •Alkanes are carbon compounds that contain only single bonds. •The simplest alkanes are hydrocarbons – compounds that contain only carbon and hydrogen. •Hydrocarbons are used mainly as fuels, solvents and lubricants: H H H H H H H H H H H H C H C C H C C C C H H C C C C C H H H C C H H H H H H CH2 H CH3 H H H H CH3 # of carbons boiling point range Use 1-4 <20 °C fuel (gasses such as methane, propane, butane) 5-6 30-60 solvents (petroleum ether) 6-7 60-90 solvents (ligroin) 6-12 85-200 fuel (gasoline) 12-15 200-300 fuel (kerosene) 15-18 300-400 fuel (heating oil) 16-24 >400 lubricating oil, asphalt Hydrocarbons Formula Prefix Suffix Name Structure H CH4 meth- -ane methane H C H H C H eth- -ane ethane 2 6 H3C CH3 C3H8 prop- -ane propane C4H10 but- -ane butane C5H12 pent- -ane pentane C6H14 hex- -ane hexane C7H16 hept- -ane heptane C8H18 oct- -ane octane C9H20 non- -ane nonane C10H22 dec- -ane decane Hydrocarbons Formula Prefix Suffix Name Structure H CH4 meth- -ane methane H C H H H H C2H6 eth- -ane ethane H C C H H H H C H prop- -ane propane 3 8 H3C C CH3 or H H H C H 4 10 but- -ane butane H3C C C CH3 or H H H C H 4 10 but- -ane butane? H3C C CH3 or CH3 HydHrydorcocaarrbobnos ns Formula Prefix Suffix Name Structure H CH4 meth- -ane methane H C H H H H C2H6 eth- -ane ethane H C C H H H H C3H8 prop- -ane propane H3C C CH3 or H H H C H 4 10 but- -ane butane H3C C C CH3 or H H H C H 4 10 but- -ane iso-butane H3C C CH3 or CH3 HydHrydoroccarbrobnsons Formula Prefix Suffix Name Structure H H -

By ZELDA KAIIAN, B.Sc. SOME Years Ago, Ur. Travers, Wishing to Prepare Butane, Employed for This Purpose the Well Known Method O

View Article Online / Journal Homepage / Table of Contents for this issue 132 KAHAN: THE EFFECT OF HEAT ON THE ALKYL IODIDES. By ZELDAKAIIAN, B.Sc. SOMEyears ago, Ur. Travers, wishing to prepare butane, employed for this purpose the well known method of heating together ethyl iodide and zinc. He found, however, that, instead of obtaining pure butane, a mixture of gases was formed, the chief constituent of which was ethane, To investigate the cause of this, a few preliminary experi- Published on 01 January 1908. Downloaded by State University of New York at Stony Brook 26/10/2014 03:29:37. ments were performed, but the work was abandoned owing to lack of time. The investigation of the influence of heat on the alkyl iodides is so much the more important in view of the interesting experiments performed by Nef, and the theory of the bivalent carbon atom based upon them. If it could be proved that in the state of vapour the alkyl iodides are dissociated, it would at least be strong evidence of their being in a similar state in solution. As a result of a large number of experiments (ilnnalen, 1892, 270, 267 ; 1897, 297, 202 ; 1899, 309, 126; 1901, 318, I), Nef has arrived at the conclusion that all chemical actions, whether of addition or substitution, are to be explained by an application, in each case, of the principle of dis- sociation. As regards the alkyl halides, Nef assumes that the first stage in their reaction in solution, whatever the other reacting sub- stance may be, is a dissociation into an alkylidene or methylene deriv- View Article Online KAIIAN: THE EFFECT OF HEAT ON THE ALKYI, IODIDES. -

SAFETY DATA SHEET Revision Date 07/28/2021 Print Date 09/18/2021

Version 6.4 SAFETY DATA SHEET Revision Date 07/28/2021 Print Date 09/18/2021 SECTION 1: Identification of the substance/mixture and of the company/undertaking 1.1 Product identifiers Product name : 2-Iodopropane Product Number : 148938 Brand : Aldrich CAS-No. : 75-30-9 1.2 Relevant identified uses of the substance or mixture and uses advised against Identified uses : Laboratory chemicals, Synthesis of substances 1.3 Details of the supplier of the safety data sheet Company : Sigma-Aldrich Inc. 3050 SPRUCE ST ST. LOUIS MO 63103 UNITED STATES Telephone : +1 314 771-5765 Fax : +1 800 325-5052 1.4 Emergency telephone Emergency Phone # : 800-424-9300 CHEMTREC (USA) +1-703- 527-3887 CHEMTREC (International) 24 Hours/day; 7 Days/week SECTION 2: Hazards identification 2.1 Classification of the substance or mixture GHS Classification in accordance with 29 CFR 1910 (OSHA HCS) Flammable liquids (Category 3), H226 Skin irritation (Category 2), H315 Eye irritation (Category 2A), H319 Specific target organ toxicity - single exposure (Category 3), Respiratory system, H335 For the full text of the H-Statements mentioned in this Section, see Section 16. 2.2 GHS Label elements, including precautionary statements Pictogram Signal word Warning Aldrich - 148938 Page 1 of 9 The life science business of Merck KGaA, Darmstadt, Germany operates as MilliporeSigma in the US and Canada Hazard statement(s) H226 Flammable liquid and vapor. H315 Causes skin irritation. H319 Causes serious eye irritation. H335 May cause respiratory irritation. Precautionary statement(s) P210 Keep away from heat/ sparks/ open flames/ hot surfaces. No smoking. P233 Keep container tightly closed. -

Petroleum No

"2732 Petroleum No. 468 1973. No. 468 {NC] PETROLEUM Inflammable Liquids ORDER, DATED THE 19TH DAY OF NOVEMBER 1973, MADE BY THE SECRETA,RY OF STATE UNDER SECTION 19 OF THE PETROLEUM (CONSOLiDATION) ACT (NORTHERN 1;RELAND) 1929. " In exercise of the powers conferred on me by section 19 of the Petwleum (Consolidation) Act (Nor.thern Ireland) 1929(a) and sectien 1(1) of the Northern Ireland (Temporary Provisions) Act 1972(b) and of all other powers ena:bling me in ;that behalf I hereby make the follewing Order:- Application of the Act of 1929 to certain substances 1.-(1) Sections 6, 13(2) and (3), 14, 15, 16 and 18 of the Petroleum (Conselidation) Act (Northern Ireland) 1929 shall apply to s:uch of the fellowing substances, solutiens and mixtures as give eff an inflammable vapour at a ;temperature below 23 degrees Centigrade (73 degrees Fahrenheit), that is to say:- (a) the substances specified in the first column in Part I of the Schedule tOl this Order, being substances which are known also by the name or names (if any) mentioned in the second column; (b) any solutien or mixture (not being a mixture of petroleum as defined in the Schedule to. the Petroleum (Mixtures) Order (Northern Ireland) 1930(c) which contains any. of the said substances; and (c) any solutien specified in Part II ef the Schedule to this Order. (2) Fer the purposes ef this Ar.ticle a substance, solution or mixture shall be regarded as giving off an inflammable vapour at a temperature belew 23 degrees Centigrade (73' degrees Fahrenheit) if it does se when tested as if it were petroleum spirit in the manner set forth in Part II of the Secend Schedule ;to the Petroleum (Consolidation) Act (Northern Ireland) 1929. -

Process for the Production of Pentaerythritol

Europäisches Patentamt *EP001399456B1* (19) European Patent Office Office européen des brevets (11) EP 1 399 456 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention (51) Int Cl.7: C07F 9/6574 of the grant of the patent: 07.12.2005 Bulletin 2005/49 (86) International application number: PCT/US2002/019159 (21) Application number: 02744389.4 (87) International publication number: (22) Date of filing: 17.06.2002 WO 2003/002581 (09.01.2003 Gazette 2003/02) (54) PROCESS FOR THE PRODUCTION OF PENTAERYTHRITOL PHOSPHATE ALCOHOL VERFAHREN ZUR HERSTELLUNG VON PENTAERYTHRITOLPHOSOHATALKOHOL PROCEDE DE PRODUCTION D’ALCOOL DE PHOSPHATE DE PENTAERYTHRITOL (84) Designated Contracting States: (56) References cited: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU EP-A- 0 578 318 US-A- 4 454 064 MC NL PT SE TR • CHEMICAL ABSTRACTS, vol. 135, Columbus, (30) Priority: 29.06.2001 US 896710 Ohio, US; abstract no. 211146, PENG, XIAOPING ET AL: "Preparation method of pentaerythritol (43) Date of publication of application: phosphate" XP002214946 & CN 1 281 861 A 24.03.2004 Bulletin 2004/13 (RESEARCH INST., YUEYANG PETRO-CHEMICAL GENERAL PLANT, PEOP. (73) Proprietor: PABU Services, Inc. REP. CHINA) 31 January 2001 (2001-01-31) Wilmington, Delaware 19801 (US) • TSE H L A ET AL: "Constrained analogues of 2’-nor cyclic nucleoside monophosphates" (72) Inventors: BIOORGANIC & MEDICINAL CHEMISTRY • VYVERBERG, Frederick LETTERS, OXFORD, GB, vol. 7, no. 11, 3 June Chester, NY 10918 (US) 1997 (1997-06-03), pages 1387-1392, • CHAPMAN, Robert, W. XP004136222 ISSN: 0960-894X Mt. Vernon, IN 47620-9657 (US) (74) Representative: von Kreisler, Alek et al Deichmannhaus am Dom, Postfach 10 22 41 50462 Köln (DE) Note: Within nine months from the publication of the mention of the grant of the European patent, any person may give notice to the European Patent Office of opposition to the European patent granted. -

Reactions of Tertiary Phosphites with Alkyl Iodides in Acetonitrile

AN ABSTRACT OF THE THESIS OF LANE JOSEPH GOODELL for the MASTER OF SCIENCE (Name) (Degree) in CHEMISTRY presented on Mcy Q\-\ `j CIL4 (Major) (Dates Title: REACTIONS OF TERTIARY PHOSPHITES WITH ALKYL IODIDES IN ACETONITRILE Abstract approved: Redacted for Privacy Dr. John Thdma Yoke III The Arbuzov reaction is an important method of synthesis of compounds containing a carbon -phosphorus bond. (RO)3P + R'X 1 [(RO)3PR')X],-- (RO)2P(0)R' + RX The intermediate might have a salt -like or a penta- coordinate type of structure, or both in equilibrium. In many systems, the rate determining step of the reaction is not known. A polar solvent might have a significant influence on these points. Although the reaction is normally carried out without a solvent, two groups of workers have studied the kinetics of the reaction in acetonitrile. These two groups published conflicting reports, speci- fically related to the system of tri -n -butyl phosphite with ethyl iodide in acetonitrile at 310 . The possibilities for the reaction to be considered in the present work were (1) olefin elimination from the tertiary phosphite to give a dialkyl hydrogen phosphonate, (2) inadvertent hydrolysis to give a dialkyl hydrogen phosphonate and an alcohol, (3) the Arbuzov reaction to give a dialkyl alkylphosphonate, and (4) no reaction. Assuming that it is the Arbuzov reaction which actually occurs for such reactants in acetonitrile, the previous reports were also in conflict as to the rate determining step. In the present work, it was found by qualitative and quantitative analysis of this system that the Arbuzov reaction occurs, but very slowly, contrary to one of the previous reports. -

Flammability Limits, Flash Points, and Their Consanguinity: Critical Analysis, Experimental Exploration, and Prediction

Brigham Young University BYU ScholarsArchive Theses and Dissertations 2010-06-25 Flammability Limits, Flash Points, and Their Consanguinity: Critical Analysis, Experimental Exploration, and Prediction Jeffrey R. Rowley Brigham Young University - Provo Follow this and additional works at: https://scholarsarchive.byu.edu/etd Part of the Chemical Engineering Commons BYU ScholarsArchive Citation Rowley, Jeffrey R., "Flammability Limits, Flash Points, and Their Consanguinity: Critical Analysis, Experimental Exploration, and Prediction" (2010). Theses and Dissertations. 2233. https://scholarsarchive.byu.edu/etd/2233 This Dissertation is brought to you for free and open access by BYU ScholarsArchive. It has been accepted for inclusion in Theses and Dissertations by an authorized administrator of BYU ScholarsArchive. For more information, please contact [email protected], [email protected]. Flammability Limits, Flash Points, and their Consanguinity: Critical Analysis, Experimental Exploration, and Prediction Jef Rowley A dissertation submitted to the faculty of Brigham Young University in partial fulfillment of the requirements for the degree of Doctor of Philosophy W. Vincent Wilding, Chair Richard L. Rowley Larry L. Baxter Thomas A. Knotts David O. Lignell Department of Chemical Engineering Brigham Young University August 2010 Copyright © 2010 Jef Rowley All Rights Reserved ABSTRACT Flammability Limits, Flash Points, and their Consanguinity: Critical Analysis, Experimental Exploration, and Prediction Jef Rowley Department of Chemical Engineering Doctor of Philosophy Accurate flash point and flammability limit data are needed to design safe chemical processes. Unfortunately, improper data storage and reporting policies that disregard the temperature dependence of the flammability limit and the fundamental relationship between the flash point and the lower flammability limit have resulted in compilations filled with erroneous values. -

ACS Style Guide

➤ ➤ ➤ ➤ ➤ The ACS Style Guide ➤ ➤ ➤ ➤ ➤ THIRD EDITION The ACS Style Guide Effective Communication of Scientific Information Anne M. Coghill Lorrin R. Garson Editors AMERICAN CHEMICAL SOCIETY Washington, DC OXFORD UNIVERSITY PRESS New York Oxford 2006 Oxford University Press Oxford New York Athens Auckland Bangkok Bogotá Buenos Aires Calcutta Cape Town Chennai Dar es Salaam Delhi Florence Hong Kong Istanbul Karachi Kuala Lumpur Madrid Melbourne Mexico City Mumbai Nairobi Paris São Paulo Singapore Taipei Tokyo Toronto Warsaw and associated companies in Berlin Idaban Copyright © 2006 by the American Chemical Society, Washington, DC Developed and distributed in partnership by the American Chemical Society and Oxford University Press Published by Oxford University Press, Inc. 198 Madison Avenue, New York, NY 10016 Oxford is a registered trademark of Oxford University Press All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior permission of the American Chemical Society. Library of Congress Cataloging-in-Publication Data The ACS style guide : effective communication of scientific information.—3rd ed. / Anne M. Coghill [and] Lorrin R. Garson, editors. p. cm. Includes bibliographical references and index. ISBN-13: 978-0-8412-3999-9 (cloth : alk. paper) 1. Chemical literature—Authorship—Handbooks, manuals, etc. 2. Scientific literature— Authorship—Handbooks, manuals, etc. 3. English language—Style—Handbooks, manuals, etc. 4. Authorship—Style manuals. I. Coghill, Anne M. II. Garson, Lorrin R. III. American Chemical Society QD8.5.A25 2006 808'.06654—dc22 2006040668 1 3 5 7 9 8 6 4 2 Printed in the United States of America on acid-free paper ➤ ➤ ➤ ➤ ➤ Contents Foreword. -

The Preparation of Alkyl Iodides Ernest Milford Parrott University of Massachusetts Amherst

University of Massachusetts Amherst ScholarWorks@UMass Amherst Masters Theses 1911 - February 2014 1932 The preparation of alkyl iodides Ernest Milford Parrott University of Massachusetts Amherst Follow this and additional works at: https://scholarworks.umass.edu/theses Parrott, Ernest Milford, "The preparation of alkyl iodides" (1932). Masters Theses 1911 - February 2014. 1861. Retrieved from https://scholarworks.umass.edu/theses/1861 This thesis is brought to you for free and open access by ScholarWorks@UMass Amherst. It has been accepted for inclusion in Masters Theses 1911 - February 2014 by an authorized administrator of ScholarWorks@UMass Amherst. For more information, please contact [email protected]. MASSACHUSETTS STATE COLLEGE DATE DUE UNIVERSITY OF MASSACHUSETTS LIBRARY PHYS sell LD ' M268 1932 P26$ PhYS IL?.?'^«2 . ,CE Thes IS TIE PREPARATION OF AUCYL IODIDES Emset Uilford r^rrott Thasis Submitted for The Degree of Master of SeleiK* MASSACHUSSTTS STATE COLLm mj 1932 TABLE OF CONTENTS Page ^ Introduction • Methods of Preparation 10 Experimental Part *3 (1) Preparation of Ethyl Iodide 23 24 (2) Preparation of Methyl Iodide 25 (3) Preparation of Propyl Iodides (a) Using Is ©propyl Alcohol 25 (b) Using Normal Propyl Alcohol 26 27 (4) Preparation of Butyl Iodides (a) Using Normal Butyl Alcohol 27 (b) Using Isobutyl Alcohol 28 28 (e) Using Tertiary Butyl Alcohol 33 Conclusions ..... 34 Bibliography • 36 Acknowledgments . » DfTRODUCTIQH Alkyl faalldttB may be r«gard*d aither as hydrocarbons im which hydrogSB atom ar« rsplaead by halogni at on or as esters of halogen hydraeids and alkyl radicals. By alatalning those two points of view the aode of foraation and the reactions of this class of bodies should be folleved with no difficulty.