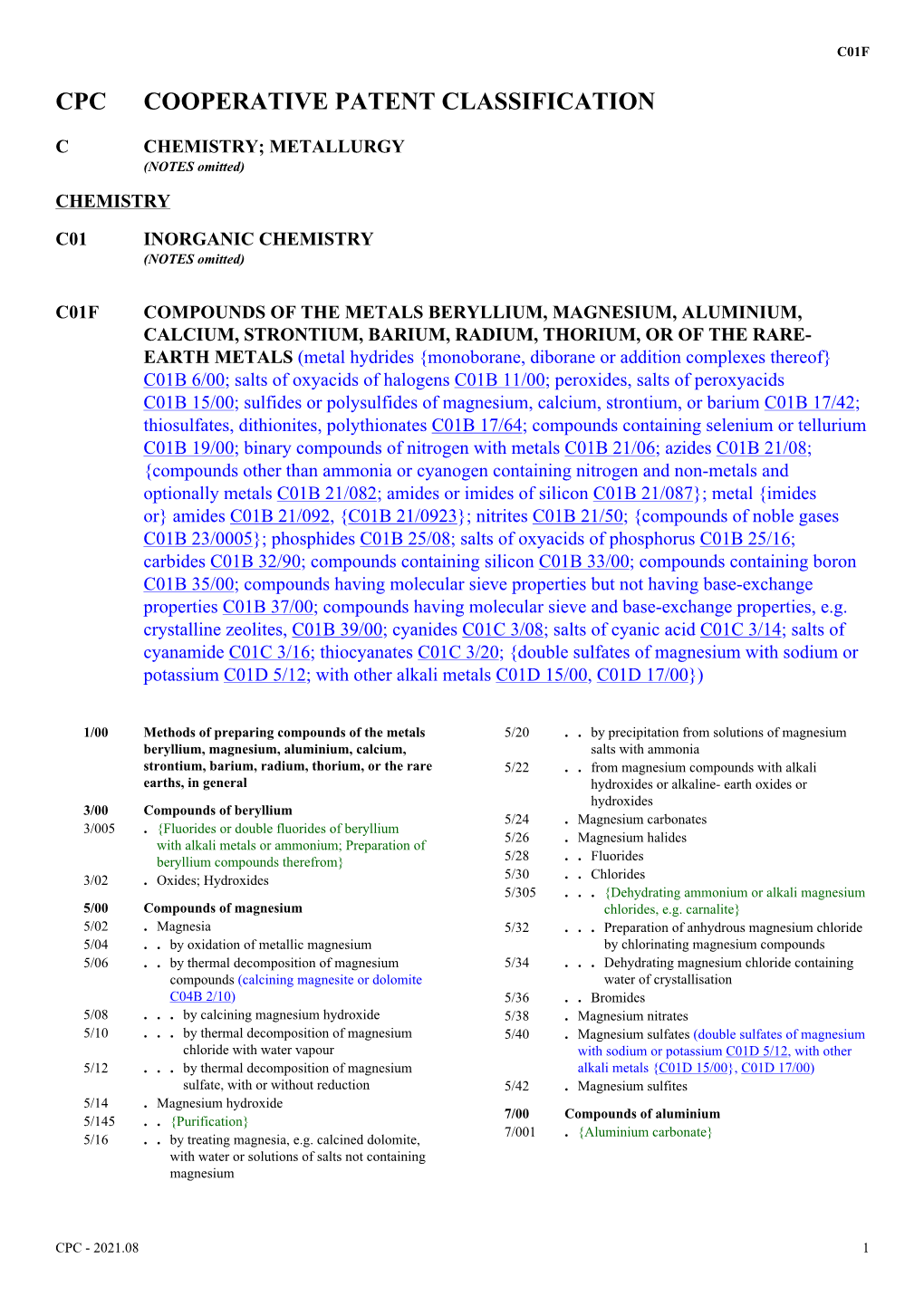

Compounds of the Metals Beryllium, Magnesium

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

SAFETY DATA SHEET Quicklime

Quicklime Conforms to HazCom 2012/United States SAFETY DATA SHEET Quicklime Section 1. Identification GHS product identifier : Quicklime Other means of identification : Snowbright Quicklime, Quicklime, High calcium quicklime, Pebble lime, Hi Cal, Unslaked lime, Calcium Oxide, CaO, Type S, Type N, Calcined limestone, Burnt lime, Chemical lime Identified uses : Water treatment, Caustic agent, pH adjustment, Neutralization, Acid gas absorption, Construction Supplier's details : Pete Lien & Sons, Inc. PO Box 440 Rapid City, SD 57702 Emergency telephone : (605) 342-7224 (Monday-Friday 8am-5pm) number (hours of operation) Section 2. Hazards identification Classification of the : SKIN IRRITATION - Category 2 substance or mixture EYE DAMAGE - Category 1 SPECIFIC TARGET ORGAN TOXICITY SINGLE EXPOSURE [Respiratory System] - Category 3 SPECIFIC TARGET ORGAN TOXICITY REPEAT EXPOSURE [Respiratory System] - Category 1 CARCINOGEN - Category 1A GHS label elements Hazard pictograms : Signal word : Danger Hazard statements : Causes skin irritation. Causes serious eye damage. May cause cancer through inhalation. May cause respiratory irritation. Reacts violently with water, releasing heat, which can ignite combustible material. Causes damage to lungs through prolonged and repeated exposure. Precautionary statements Prevention : Wear protective gloves/protective clothing/face protection /eye protection. Wash exposed skin thoroughly after handling. Use only outdoors or in a well-ventilated area. Obtain special instructions before use. Do not handle until all safety precautions have been read and understood. Do not breathe dust. Do not eat, drink or smoke when using this product. 1/7 Quicklime Response : IF ON SKIN: Wash exposed skin with plenty of water. If skin irritation occurs: Get medical attention. Take off contaminated clothing and wash it before reuse. -

Specialists Q & a on the Use of Lime Plastering

posed to much less water making it less reactive but retaining its dry nature as a powdered product so it Q To avoid shrinkage, should hair be added to never matures to become a good binder in its own the lime mix? form. Hydrate is used as a plasticiser for cement Hair is added to help lime mortars bind or hold mixes. Hydraulic lime is a powder and also burnt A but the limestone is not pure calcium carbonate onto laths but can still shrink and crack if cured too Specialists Q & A on the and contains impurities such as clays and silicates quickly. Hair is always used on lath and plaster work which change the reactive nature of the lime and but is not necessary on brickwork. use of lime plastering allow it to set chemically when exposed to water. Q How do l make a lime wash? Q What type of lime should be used for lime A Lime wash is simply lime putty, water and a mineral pig- plastering? Q What are the advantages of using lime plas- ment, and for external use a water repellent such as linseed or tallow is added. ter? A Lime plaster can be made with lime putty or hydraulic lime but hydrate is too weak. Putty is best Q Can lime plaster be applied to plasterboard? A They allow buildings to breathe which is essential for ceilings and lath work as it has better flexural for older buildings that have been constructed with strength and sticks well to laths. Hydraulic lime is A The only benefit to applying a lime plaster to lime fine as a hard wall plaster where there is no move- plasterboard is the aesthetic look, however this mortars and soft bricks or stone. -

Recycling of Hazardous Waste from Tertiary Aluminium Industry in A

CORE Metadata, citation and similar papers at core.ac.uk Provided by Digital.CSIC 1 Recycling of hazardous waste from tertiary aluminium 2 industry in a value-added material 3 4 Laura Gonzalo-Delgado1, Aurora López-Delgado1*, Félix Antonio López1, Francisco 5 José Alguacil1 and Sol López-Andrés2 6 7 1Nacional Centre for Metallurgical Research, CSIC. Avda. Gregorio del Amo, 8. 28040. 8 Madrid. Spain. 9 2Dpt. Crystallography and Mineralogy. Fac. of Geology. University Complutense of 10 Madrid. Spain. 11 *Corresponding author e-mail: [email protected] 12 13 Abstract 14 15 The recent European Directive on waste, 2008/98/EC seeks to reduce the 16 exploitation of natural resources through the use of secondary resource management. 17 Thus the main objective of this paper is to explore how a waste could cease to be 18 considered as waste and could be utilized for a specific purpose. In this way, a 19 hazardous waste from the tertiary aluminium industry was studied for its use as a raw 20 material in the synthesis of an added value product, boehmite. This waste is classified as 21 a hazardous residue, principally because in the presence of water or humidity, it releases 22 toxic gases such as hydrogen, ammonia, methane and hydrogen sulphide. The low 23 temperature hydrothermal method developed permits the recovery of 90% of the 24 aluminium content in the residue in the form of a high purity (96%) AlOOH (boehmite). 25 The method of synthesis consists of an initial HCl digestion followed by a gel 26 precipitation. In the first stage a 10% HCl solution is used to yield a 12.63 g.l-1 Al3+ 27 solution. -

1201: Introduction to Aluminium As an Engineering Material

TALAT Lecture 1201 Introduction to Aluminium as an Engineering Material 23 pages, 26 figures (also available as overheads) Basic Level prepared by M H Jacobs * Interdisciplinary Research Centre in Materials The University of Birmingham, UK Objectives To provide an introduction to metallurgical concepts necessary to understand how structural features of aluminium alloys are influenced by alloy composition, processing and heat treatment, and the basic affects of these parameters on the mechanical properties, and hence engineering applications, of the alloys. It is assumed that the reader has some elementary knowledge of physics, chemistry and mathematics. Date of Issue: 1999 EAA - European Aluminium Association 1201 Introduction to Aluminium as an Engineering Material Contents (26 figures) 1201 Introduction to Aluminium as an Engineering Material _____________________ 2 1201.01. Basic mechanical and physical properties__________________________________ 3 1201.01.01 Background _______________________________________________________________ 3 1201.01.02 Commercially pure aluminium ______________________________________________ 4 1201.02 Crystal structure and defects _____________________________________________ 6 1201.02.01 Crystals and atomic bonding __________________________________________________ 6 1201.02.02 Atomic structure of aluminium ______________________________________________ 8 1201.02.03 Crystal structures _________________________________________________________ 8 1201.02.04 Some comments on crystal structures of materials -

Standard X-Ray Diffraction Powder Patterns

NBS MONOGRAPH 25 — SECTION 1 Standard X-ray Diffraction U.S. DEPARTMENT OF COMMERCE NATIONAL BUREAU OF STANDARDS THE NATIONAL BUREAU OF STANDARDS Functions and Activities The functions of the National Bureau of Standards are set forth in the Act of Congress, March 3, 1901, as amended by Congress in Public Law 619, 1950. These include the development and maintenance of the national standards of measurement and the provision of means and methods for making measurements consistent with these standards; the determination of physical constants and properties of materials; the development of methods and instruments for testing materials, devices, and structures; advisory services to government agencies on scien- tific and technical problems; invention and development of devices to serve special needs of the Government; and the development of standard practices, codes, and specifications. The work includes basic and applied research, development, engineering, instrumentation, testing, evaluation, calibration services, and various consultation and information services. Research projects are also performed for other government agencies when the work relates to and supplements the basic program of the Bureau or when the Bureau's unique competence is required. The scope of activities is suggested by the listing of divisions and sections on the inside of the back cover. Publications The results of the Bureau's research are published either in the Bureau's own series of publications or in the journals of professional and scientific societies. The Bureau itself publishes three periodicals available from the Government Printing Office: The Journal of Research, published in four separate sections, presents complete scientific and technical papers; the Technical News Bulletin presents summary and preliminary reports on work in progress; and Basic Radio Propagation Predictions provides data for determining the best frequencies to use for radio communications throughout the world. -

The Development of the Periodic Table and Its Consequences Citation: J

Firenze University Press www.fupress.com/substantia The Development of the Periodic Table and its Consequences Citation: J. Emsley (2019) The Devel- opment of the Periodic Table and its Consequences. Substantia 3(2) Suppl. 5: 15-27. doi: 10.13128/Substantia-297 John Emsley Copyright: © 2019 J. Emsley. This is Alameda Lodge, 23a Alameda Road, Ampthill, MK45 2LA, UK an open access, peer-reviewed article E-mail: [email protected] published by Firenze University Press (http://www.fupress.com/substantia) and distributed under the terms of the Abstract. Chemistry is fortunate among the sciences in having an icon that is instant- Creative Commons Attribution License, ly recognisable around the world: the periodic table. The United Nations has deemed which permits unrestricted use, distri- 2019 to be the International Year of the Periodic Table, in commemoration of the 150th bution, and reproduction in any medi- anniversary of the first paper in which it appeared. That had been written by a Russian um, provided the original author and chemist, Dmitri Mendeleev, and was published in May 1869. Since then, there have source are credited. been many versions of the table, but one format has come to be the most widely used Data Availability Statement: All rel- and is to be seen everywhere. The route to this preferred form of the table makes an evant data are within the paper and its interesting story. Supporting Information files. Keywords. Periodic table, Mendeleev, Newlands, Deming, Seaborg. Competing Interests: The Author(s) declare(s) no conflict of interest. INTRODUCTION There are hundreds of periodic tables but the one that is widely repro- duced has the approval of the International Union of Pure and Applied Chemistry (IUPAC) and is shown in Fig.1. -

Alkali-Silica Reactivity: an Overview of Research

SHRP-C-342 Alkali-Silica Reactivity: An Overview of Research Richard Helmuth Construction Technology Laboratories, Inc. With contributions by: David Stark Construction Technology Laboratories, Inc. Sidney Diamond Purdue University Micheline Moranville-Regourd Ecole Normale Superieure de Cachan Strategic Highway Research Program National Research Council Washington, DC 1993 Publication No. SHRP-C-342 ISBN 0-30cL05602-0 Contract C-202 Product No. 2010 Program Manager: Don M. Harriott Project Maxtager: Inam Jawed Program AIea Secretary: Carina Hreib Copyeditor: Katharyn L. Bine Brosseau May 1993 key words: additives aggregate alkali-silica reaction cracking expansion portland cement concrete standards Strategic Highway Research Program 2101 Consti!ution Avenue N.W. Washington, DC 20418 (202) 334-3774 The publicat:Lon of this report does not necessarily indicate approval or endorsement by the National Academy of Sciences, the United States Government, or the American Association of State Highway and Transportation Officials or its member states of the findings, opinions, conclusions, or recommendations either inferred or specifically expressed herein. ©1993 National Academy of Sciences 1.5M/NAP/593 Acknowledgments The research described herein was supported by the Strategic Highway Research Program (SHRP). SHRP is a unit of the National Research Council that was authorized by section 128 of the Surface Transportation and Uniform Relocation Assistance Act of 1987. This document has been written as a product of Strategic Highway Research Program (SHRP) Contract SHRP-87-C-202, "Eliminating or Minimizing Alkali-Silica Reactivity." The prime contractor for this project is Construction Technology Laboratories, with Purdue University, and Ecole Normale Superieure de Cachan, as subcontractors. Fundamental studies were initiated in Task A. -

Determination of Aluminium As Oxide

DETERMINATION OF ALUMINIUM AS OXIDE By William Blum CONTENTS Page I. Introduction 515 II. General principles 516 III. Historical 516 IV. Precipitation of aluminium hydroxide. 518 1. Hydrogen electrode studies 518 (a) The method 518 (b) Apparatus and solutions employed 518 (c) Results of hydrogen electrode experiments 519 (d) Conclusions from hydrogen electrode experiments 520 2. Selection of an indicator for denning the conditions of precipita- '. tion . 522 3. Factors affecting the form of the precipitate 524 4. Precipitation in the presence of iron 525 V. Washing the precipitate . 525 VI. Separation from other elements 526 VII. Ignition and weighing of the precipitate 528 1. Hygroscopicity of aluminium oxide 529 2. Temperature and time of ignition 529 3. Effect of ammonium chloride upon the ignition 531 VIII. Procedure recommended 532 IX. Confirmatory experiments 532 X. Conclusions '534 I. INTRODUCTION Although a considerable number of precipitants have been pro- posed for the determination of aluminium, direct precipitation of aluminium hydroxide by means of ammonium hydroxide, fol- lowed by ignition to oxide, is most commonly used, especially if no separation from iron is desired, in which latter case special methods must be employed. While the general principles involved in this determination are extremely simple, it has long been recog- nized that certain precautions in the precipitation, washing, and ignition are necessary if accurate results are to be obtained. While, however, most of these details have been studied and dis- cussed by numerous authors, it is noteworthy that few publica- tions or textbooks have taken account of all the factors. In the 515 ; 516 Bulletin of the Bureau of Standards [Voi.i3 present paper it seems desirable, therefore, to assemble the various recommendations and to consider their basis and their accuracy. -

The Periodic Table of Elements

The Periodic Table of Elements 1 2 6 Atomic Number = Number of Protons = Number of Electrons HYDROGENH HELIUMHe 1 Chemical Symbol NON-METALS 4 3 4 C 5 6 7 8 9 10 Li Be CARBON Chemical Name B C N O F Ne LITHIUM BERYLLIUM = Number of Protons + Number of Neutrons* BORON CARBON NITROGEN OXYGEN FLUORINE NEON 7 9 12 Atomic Weight 11 12 14 16 19 20 11 12 13 14 15 16 17 18 SODIUMNa MAGNESIUMMg ALUMINUMAl SILICONSi PHOSPHORUSP SULFURS CHLORINECl ARGONAr 23 24 METALS 27 28 31 32 35 40 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 POTASSIUMK CALCIUMCa SCANDIUMSc TITANIUMTi VANADIUMV CHROMIUMCr MANGANESEMn FeIRON COBALTCo NICKELNi CuCOPPER ZnZINC GALLIUMGa GERMANIUMGe ARSENICAs SELENIUMSe BROMINEBr KRYPTONKr 39 40 45 48 51 52 55 56 59 59 64 65 70 73 75 79 80 84 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 RUBIDIUMRb STRONTIUMSr YTTRIUMY ZIRCONIUMZr NIOBIUMNb MOLYBDENUMMo TECHNETIUMTc RUTHENIUMRu RHODIUMRh PALLADIUMPd AgSILVER CADMIUMCd INDIUMIn SnTIN ANTIMONYSb TELLURIUMTe IODINEI XeXENON 85 88 89 91 93 96 98 101 103 106 108 112 115 119 122 128 127 131 55 56 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 CESIUMCs BARIUMBa HAFNIUMHf TANTALUMTa TUNGSTENW RHENIUMRe OSMIUMOs IRIDIUMIr PLATINUMPt AuGOLD MERCURYHg THALLIUMTl PbLEAD BISMUTHBi POLONIUMPo ASTATINEAt RnRADON 133 137 178 181 184 186 190 192 195 197 201 204 207 209 209 210 222 87 88 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 FRANCIUMFr RADIUMRa RUTHERFORDIUMRf DUBNIUMDb SEABORGIUMSg BOHRIUMBh HASSIUMHs MEITNERIUMMt DARMSTADTIUMDs ROENTGENIUMRg COPERNICIUMCn NIHONIUMNh -

Delayed Ettringite Formation

Ettringite Formation and the Performance of Concrete In the mid-1990’s, several cases of premature deterioration of concrete pavements and precast members gained notoriety because of uncertainty over the cause of their distress. Because of the unexplained and complex nature of several of these cases, considerable debate and controversy have arisen in the research and consulting community. To a great extent, this has led to a misperception that the problems are more prevalent than actual case studies would indicate. However, irrespective of the fact that cases of premature deterioration are limited, it is essential to address those that have occurred and provide practical, technically sound solutions so that users can confidently specify concrete in their structures. Central to the debate has been the effect of a compound known as ettringite. The objectives of this paper are: Fig. 1. Portland cements are manufactured by a process that combines sources of lime (such as limestone), silica and • to define ettringite and its form and presence in concrete, alumina (such as clay), and iron oxide (such as iron ore). Appropriately proportioned mixtures of these raw materials • to respond to questions about the observed problems and the are finely ground and then heated in a rotary kiln at high various deterioration mechanisms that have been proposed, and temperatures, about 1450 °C (2640 °F), to form cement compounds. The product of this process is called clinker • to provide some recommendations on designing for durable (nodules at right in above photo). After cooling, the clinker is concrete. interground with about 5% of one or more of the forms of Because many of the questions raised relate to cement character- calcium sulfate (gypsum shown at left in photo) to form portland cement. -

Preparation of Barium Strontium Titanate Powder from Citrate

APPLIED ORGANOMETALLIC CHEMISTRY Appl. Organometal. Chem. 13, 383–397 (1999) Preparation of Barium Strontium Titanate Powder from Citrate Precursor Chen-Feng Kao* and Wein-Duo Yang Department of Chemical Engineering, National Cheng Kung University, Tainan, 70101, Taiwan TiCl4 or titanium isopropoxide reacted with INTRODUCTION citric acid to form a titanyl citrate precipitate. Barium strontium citrate solutions were then BaTiO3 is ferroelectric and piezoelectric and has added to the titanyl citrate reaction to form gels. extensive applications as an electronic material. It These gels were dried and calcined to (Ba,Sr)- can be used as a capacitor, thermistor, transducer, TiO3 powders. The gels and powders were accelerometer or degausser of colour television. characterized by DSC/TGA, IR, SEM and BaTiO3 doped with strontium retains its original XRD analyses. These results showed that, at characteristics but has a lower Curie temperature 500 °C, the gels decomposed to Ba,Sr carbonate for positive temperature coefficient devices under and TiO2, followed by the formation of (Ba,Sr)- various conditions. TiO3. The onset of perovskite formation oc- Besides solid-state reactions, chemical reactions curred at 600 °C, and was nearly complete at have also been used to prepare BaTiO3 powder. 1 1000 °C. Traces of SrCO3 were still present. Among them the hydrolysis of metal alkoxide , The cation ratios of the titanate powder oxalate precipitation in ethanol2, and alcoholic prepared in the pH range 5–6 were closest to dehydration of citrate solution3 are among the more the original stoichiometry. Only 0.1 mol% of the attractive methods. In 1956 Clabaugh et al.4 free cations remained in solution. -

WO 2009/112156 Al

(12) INTERNATIONALAPPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT) (19) World Intellectual Property Organization International Bureau (10) International Publication Number (43) International Publication Date 17 September 2009 (17.09.2009) WO 2009/112156 Al (51) International Patent Classification: AO, AT, AU, AZ, BA, BB, BG, BH, BR, BW, BY, BZ, A61K 45/06 (2006.01) A61P 1/04 (2006.01) CA, CH, CN, CO, CR, CU, CZ, DE, DK, DM, DO, DZ, A61K 9/20 (2006.01) EC, EE, EG, ES, FI, GB, GD, GE, GH, GM, GT, HN, HR, HU, ID, IL, IN, IS, JP, KE, KG, KM, KN, KP, KR, (21) International Application Number: KZ, LA, LC, LK, LR, LS, LT, LU, LY, MA, MD, ME, PCT/EP2009/001353 MG, MK, MN, MW, MX, MY, MZ, NA, NG, NI, NO, (22) International Filing Date: NZ, OM, PG, PH, PL, PT, RO, RS, RU, SC, SD, SE, SG, 26 February 2009 (26.02.2009) SK, SL, SM, ST, SV, SY, TJ, TM, TN, TR, TT, TZ, UA, UG, US, UZ, VC, VN, ZA, ZM, ZW. (25) Filing Language: English (84) Designated States (unless otherwise indicated, for every (26) Publication Language: English kind of regional protection available): ARIPO (BW, GH, (30) Priority Data: GM, KE, LS, MW, MZ, NA, SD, SL, SZ, TZ, UG, ZM, 08290223.0 10 March 2008 (10.03.2008) EP ZW), Eurasian (AM, AZ, BY, KG, KZ, MD, RU, TJ, TM), European (AT, BE, BG, CH, CY, CZ, DE, DK, EE, (71) Applicant (for all designated States except US): BAYER ES, FI, FR, GB, GR, HR, HU, IE, IS, IT, LT, LU, LV, CONSUMER CARE AG [CWCH]; Peter-Merian-Str.