Circular Sawing Technology + Tradition and Experience Since 1925

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Reporting ISIS

Shorenstein Center on Media, Politics and Public Policy Discussion Paper Series #D-101, July 2016 The Pen and the Sword: Reporting ISIS By Paul Wood Joan Shorenstein Fellow, Fall 2015 BBC Middle East Correspondent Licensed under a Creative Commons Attribution-NoDerivs 3.0 Unported License. May 2013: The kidnapping started slowly. 1 At first, it did not feel like a kidnapping at all. Daniel Rye delivered himself to the hostage-takers quite willingly. He was 24 years old, a freelance photographer from Denmark, and he had gone to the small town of Azaz in northern Syria. His translator, a local woman, said they should get permission to work. So on the morning of his second day in Azaz, only his second ever in Syria, they went to see one of the town’s rebel groups. He knocked at the metal gate to a compound. It was opened by a boy of 11 or 12 with a Kalashnikov slung over his shoulder. “We’ve come to see the emir,” said his translator, using the word – “prince” – that Islamist groups have for their commanders. The boy nodded at them to wait. Daniel was tall, with crew-cut blonde hair. His translator, a woman in her 20s with a hijab, looked small next to him. The emir came with some of his men. He spoke to Daniel and the translator, watched by the boy with the Kalashnikov. The emir looked through the pictures on Daniel’s camera, squinting. There were images of children playing on the burnt-out carcass of a tank. It was half buried under rubble from a collapsed mosque, huge square blocks of stone like a giant child’s toy. -

GI Special: [email protected] 11.12.04 Print It out (Color Best)

GI Special: [email protected] 11.12.04 Print it out (color best). Pass it on. GI SPECIAL 2#C20 Homeless military veteran in city park – because it’s a free country. Photo and caption from the I-R-A-Q ( I Remember Another Quagmire ) portfolio of Mike Hastie, U.S. Army Medic, Vietnam 1970-71. (Contact at: ([email protected]) for more examples of this outstanding work. T) IRAQ WAR REPORTS: Falluja: Resistance Counterattacks In Force Heavy Pressure On Perimeter Of Marine Hq, Air Strikes Called In; Attacks In Rear Of U.S. Forces Spreading 11 November 2004 BBC & Aljazeera & November 10, 2004, by Kim Sengupta, Independent Newspapers Ltd. US marines in Falluja have come under sustained attack from several different directions in the headquarters they have set up in the Iraqi city. The BBC's Paul Wood, who is at the scene, said there was sniper fire from four or five points on the horizon. The insurgents may have regrouped, he says, after US-led troops took over large parts of the city. Another BBC correspondent says troops have pulled back from the city hospital, captured on Sunday night. Our correspondent says the US marines have had to call in four air strikes as they came under heavy fire in central Falluja. Insurgents appear to have got to the perimeter of the headquarters, he says. At the same time, a rifle company of marines has been pushing out into the city, going literally house to house to try to clear out the insurgents. But the company came under continuous fire as soon as it left the base. -

Nato's Intervention in Kosovo: the Legal Case For

NATO’S INTERVENTION IN KOSOVO: THE LEGAL CASE FOR VIOLATING YUGOSLAVIA’S “NATIONAL SOVEREIGNTY” IN THE ABSENCE OF SECURITY COUNCIL APPROVAL Dr. Klinton W. Alexander∗ If a tyrant practices atrocities towards his subjects, which no just man can approve, the right of human social connection is not cut off in such a case . [I]t would follow that others may take up arms for them.1 Hugo Grotius I. INTRODUCTION Since the end of the Cold War, military intervention in the internal affairs of a sovereign state to protect civilians from wholesale slaughter by their own government has become the norm rather than the exception in international relations. The senseless murder of civilians in Iraq, Somalia, Haiti, Yugoslavia and East Timor has prompted the United Nations to assume a more active role in preventing human rights abuses and preserving order around the globe. The effect of this trend in favor of humanitarian intervention has been to undermine one of the basic tenets upon which the post-First World War international order has been built: the principle of national sovereignty. Countries that have resisted international intervention, according to United Nations Secretary-General Kofi Annan, will no longer be able to hide behind protestations of national sovereignty when they flagrantly violate the rights of citizens.2 “Nothing in the ∗ Dr. Alexander is an international law specialist who works on public and private international law matters. From 1993 to 1994, he was a Visiting Fellow for the Office of GATT/WTO Affairs at the Office of the United States Trade Representative under USTR Mickey Kantor. -

Syria's Military Opposition

Jeffrey White Andrew J. Tabler Aaron Y. Zelin SYRIA’S MILITARY HOW EFFECTIVE, OPPOSITION UNITED, OR EXTREMIST? SYRIA’S MILITARY HOW EFFECTIVE, OPPOSITION UNITED, OR EXTREMIST? Jeffrey White Andrew J. Tabler Aaron Y. Zelin POLICY FOCUS 128 | SEPTEMBER 2013 THE WASHINGTON INSTITUTE FOR NEAR EAST POLICY All rights reserved. Printed in the United States of America. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publisher. © 2013 by The Washington Institute for Near East Policy Published in 2013 in the United States of America by The Washington Institute for Near East Policy, 1828 L Street NW, Suite 1050, Washington, DC 20036. Cover photo: A member of the Free Syrian Army stands guard at a checkpoint after clashes with pro-government forces in Salqin city in Idlib, October 2012. REUTERS/Asmaa Waguih Contents Update U.S. Military Action in Response to the August 21 Chemical Weapons Attack ■ v Introduction Posing the Question, Patrick Clawson ■ 1 1. The Military Opposition on the Ground, Jeffrey White ■ 3 2. Opposition Unity and Western Supply, Andrew J. Tabler ■ 20 3. Causes for Pause: Spoilers and Risk, Aaron Y. Zelin ■ 25 Conclusion Implications: Realistic Appraisal, Targeted Assistance, Patrick Clawson ■ 35 The Authors ■ 37 ■ Map 1. Areas of Control ■ 2 Tables 1. Areas of Control and in Dispute, July 2013 ■ 4 2. Rebel Combat Effectiveness in Syria ■ 11 3. Examples of Rebel “Operations” ■ 11 4. Claimed Regime Armor Losses, March—May 2013 ■ 14 Figures 1. -

The Recognition of States: Case of Kosovo

THE RECOGNITION OF STATES: CASE OF KOSOVO A DISSERTATION SUBMITTED IN PARTIAL FULFILMENT OF THE DEGREE MASTER OF ARTS IN INTERNATIONAL RELATIONS AND EUROPEAN STUDIES CENTRAL EUROPEAN UNIVERSITY INTERNATIONAL RELATIONS AND EUROPEAN STUDIES DEPARTMENT BY ARMEND BEHLULI SUPERVISOR: DR. PAUL ROE BUDAPEST, HUNGARY 4 JUNE 2009 CEU eTD Collection (15.629 WORDS) ABSTRACT The concept of the recognition of states is considered as a difficult and complex concept among the international law literature because of the political and legal elements. This thesis explains the recognition of the former Yugoslav republics, particularly the recognition of Kosovo. It provides the reason why the international community did not recognize Kosovo in 1991 but it recognized in 2008. The argument of this thesis is that the reason why the international community decided to recognize Kosovo in 2008 is because the break up of Yugoslavia was not a closed issue; secession of Kosovo would close the last unresolved status issue as Ahtissari plan. Moreover, considering that Kosovo Albanians suffered under the Milosevic regime which carried out massive exclusion, repression, discrimination, violence, and genocide which made it impossible for Kosovo Albanians to return back under Serbia’s authority, and therefore made the international community change its position and recognize Kosovo as a sovereign and independent state. CEU eTD Collection i …… To my parents And ….To my sister Alisa CEU eTD Collection ii Table of content INTRODUCTION............................................................................................................................1 -

Series C14 II

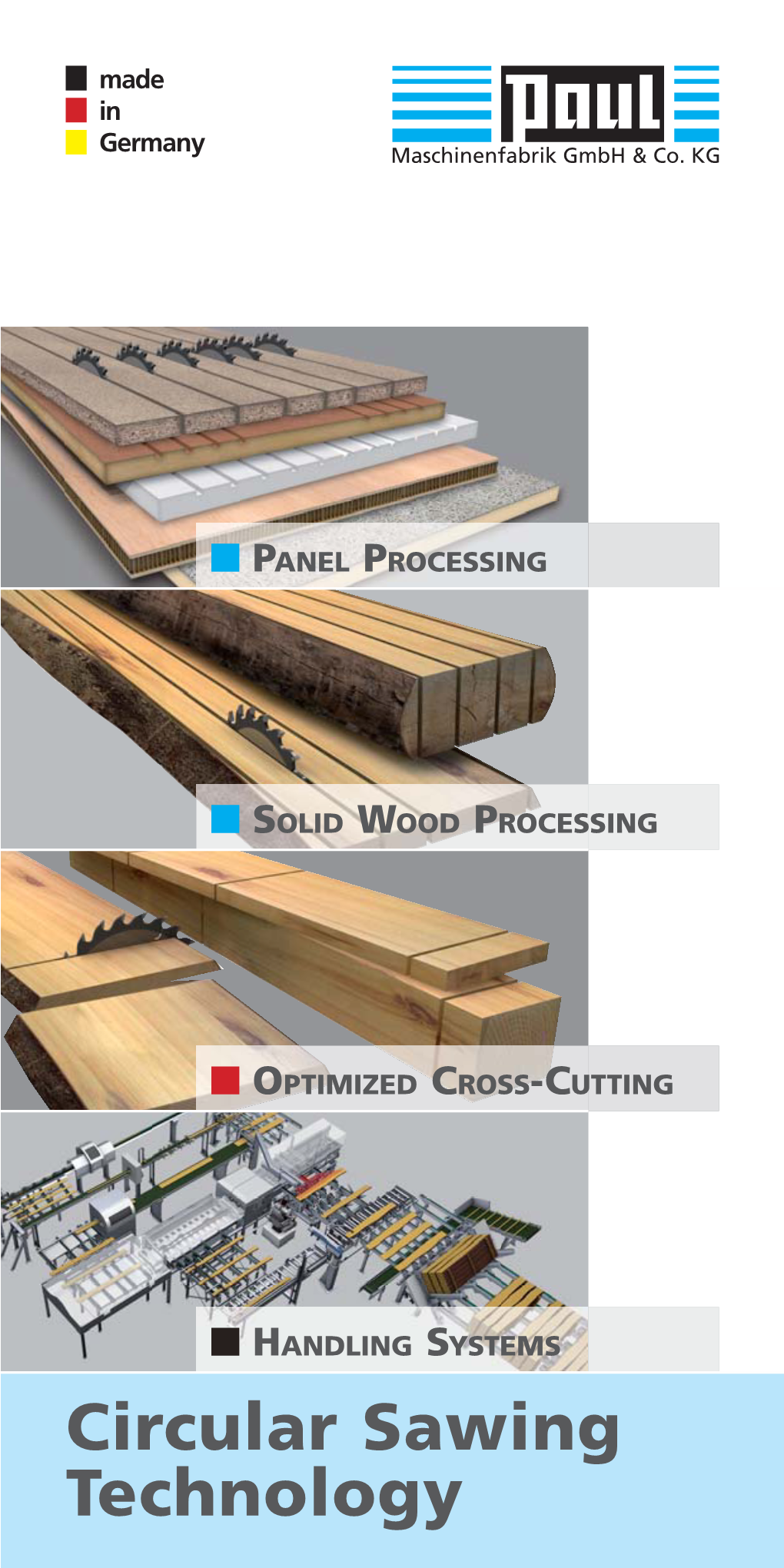

made in Germany Maschinenfabrik GmbH & Co. KG CNC Cross-Cut Systems Series C14 II PANEL PROCESSING SOLID WOOD PROCESSING OPTIMIZED CROSS-CUTTING HANDLING SYSTEMS PAUL Series C14 II CNC Cross-Cut Systems C14 II – ROBUST AND POWERFUL The C14 II is designed for cutting The heavy-duty design with a dis- high-efficiency cross-cut system for medium-sized to large cross sections tortion-free machine frame made of use in the modern timber industry. for use in the industrial timber pro- 30 mm thick steel plates, the over- cessing sector. It is suitable for heavy dimensioned bearings and guide ele- Optimally coordinated handling and difficult workpieces where high ments, a heavy-duty saw rocker with components along with intelligent demands are placed on production widely spaced bearings, etc. guaran- control technology result in a pro- speed and accuracy. Outstanding tee reliable continuous operation, cessing system that meets the high- productivity is achieved by the high maximum uptime and a long life for est demands. Customers benefit feed speed, the rapid sawing action the system. from PAUL’s long years of extensive and the quick acceleration character- system expertise. istic of the C14 II series. Combined Automatic defect identification sys- with state-of-the-art control tech- tems, such as the PAUL wood scan- nology, the reliable cross-cut systems ning system turn the C14 into a ensure profitable operation. Fig. 1: C14_MKL II with manual marking sta- tion and MAXI 6 PREMIUM control 2 Fig. 2: C14 II in operation C14_E II C14_KE II C14_MKL II Partial optimization • • • Defect cutting with luminescent scanner • • Full optimization •1) • Separate measuring station for quality and value optimization • 1) With auto infeed length identification (option) 3 PAUL Series C14 II CNC Cross-Cut Systems MODEL C14_MKL II Maximum increase in value, optimum length and crayon mark locations Combined with an automatic feed- length combinations and minimum (optionally also workpiece width and ing system, the C14_MKL II achieves waste is achieved on the top-of-the- thickness). -

How Middle East Reporters Deal with Challenging Situations

MWC0010.1177/1750635216648051Media, War & ConflictVandevoordt 648051research-article2016 View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by Ghent University Academic Bibliography MWC Article Media, War & Conflict 2016, Vol. 9(3) 306 –324 Covering the Syrian conf lict: © The Author(s) 2016 Reprints and permissions: How Middle East reporters sagepub.co.uk/journalsPermissions.nav DOI: 10.1177/1750635216648051 deal with challenging mwc.sagepub.com situations Robin Vandevoordt Research Centre on Poverty, Inequality, Social Exclusion and the City, Department of Sociology, University of Antwerp, Belgium Abstract Reporters covering the Middle East are often confronted with situations where information is notoriously hard to verify and where confrontations with witnesses’ harsh realities can be extraordinarily intense. How does one deal with claims that there are no chemical weapons in Syria, for instance, if no foreign visitors are allowed to enter the neighbourhoods where the attacks allegedly took place? And how far does one go in adopting or contextualizing the story of a crying little girl blaming ‘terrorists’ for destroying her life if you are taken to her by a regime official, who considers every form of opposition an act of terror? Under such conditions, reporters can hardly rely upon seemingly self-evident routines, nor can they simply revert to general values such as impartiality or bearing witness without much further ado. Instead, they find themselves forced to make judgements on particular situations time and time again. Based on 14 in-depth interviews with Dutch and Flemish reporters covering Syria, this article sets out to identify, first, the challenging situations with which these journalists have been confronted, and second, how they have responded to these challenges through the use of particular professional strategies. -

Moving Forward

Moving Forward FY2012 ANNUAL REPORT The Trevor Project is the leading national organization providing crisis intervention and suicide prevention services to lesbian, gay, bisexual, transgender and questioning young people under 24. Every day, The Trevor Project saves young lives through its free and confidential lifeline and instant messaging services, in-school workshops, educational materials, online resources and advocacy. TABLE OF CONTENTS 3 Executive and Board Message 4 Trevor Timeline: Fiscal Year 2012 5 Spotlights 9 Program Introduction Message 10 Trevor’s Programs 14 Donor Report 18 Trevor Board of Directors and Staff 19 Financial Report EXECUTIVE AND 2/3 | Annual Report FY2012 | MOVING FORWARD BOARD MESSAGE Dea r Friends, Thanks to your unwavering support over this past year, The Trevor Project has moved forward and served more lesbian, gay, bisexual, transgender and questioning (LGBTQ) youth than ever before while adding valuable staff members, embracing new executive and Board leadership, and extending Trevor’s reach to new cities nationwide. This year has been full of change, growth, and progress. Our call reports, chat logs, and digital services make it very clear that The Trevor Project is still urgently needed. We saw one of the largest membership increases on TrevorSpace since the program’s inception in 2008 and we watched the number of calls to the Trevor Lifeline surpass 35,000 – nearly 4,000 more than last year. We also expanded the first nationally available chat service specifically for LGBTQ youth in need of support. While we sincerely wish that the need for Trevor’s services would diminish, we are truly grateful to be present to fulfill the needs of young LGBTQ people in crisis. -

Jabhat Al-Nusra in Syria

December 2014 Jennifer Cafarella MIDDLE EAST SECURITY REPORT 25 JABHAT AL-NUSRA IN SYRIA AN ISLAMIC EMIRATE FOR AL-QAEDA Cover: Members of al Qaeda’s Nusra Front drive in a convoy as they tour villages, which they said they have seized control of from Syrian rebel factions, in the southern countryside of Idlib, December 2, 2014. REUTERS/Khalil Ashawi. Reproduced with permission. All rights reserved. Printed in the United States of America. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without permission in writing from the publisher. ©2014 by the Institute for the Study of War. Published in 2014 in the United States of America by the Institute for the Study of War. 1400 16th Street NW, Suite 515 | Washington, DC 20036 www.understandingwar.org Jennifer Cafarella MIDDLE EAST SECURITY REPORT 25 JABHAT AL-NUSRA IN SYRIA AN ISLAMIC EMIRATE FOR AL-QAEDA ABOUT THE AUTHOR Jennifer Cafarella is a Syria Analyst and Evans Hanson Fellow at the Institute for the Study of War. In her research, she focuses on the Islamic State of Iraq and al-Sham (ISIS), the al-Qaeda affiliate Jabhat al-Nusra (JN), and Syrian rebel groups. She is the author of “ISIS Works to Merge its Northern Front across Iraq and Syria,” “Local Dynamics Shift in Response to U.S.-Led Airstrikes in Syria,” and “Peace-talks between the Islamic State and Jabhat al-Nusra in Syria.” In addition, she oversees the research for and production of weekly Syria Update maps and periodic Syria Control of Terrain maps. -

Additional Estimates 2011-2012

Senate Standing Committee on Foreign Affairs, Defence and Trade ADDITIONAL BUDGET ESTIMATES 2011-2012 – THURSDAY, 16 FEBRUARY 2012 FOREIGN AFFAIRS PORTFOLIO 9.00am – 5.30pm Department of Foreign Affairs and Trade Senator Conroy, Minister for Broadband, Communications and the Digital Economy, Deputy Leader of the Government in the Senate and Minister Assisting the Prime Minister on Digital Productivity Portfolio Overview Mr Dennis Richardson, Departmental Secretary Mr Bruce Gosper, Deputy Secretary (Trade) Mr Chris Moraitis, First Assistant Secretary, Corporate Management Division Ms Ann Thorpe, Chief Finance Officer Mr Bryce Hutchesson, Assistant Secretary, Executive Planning and Evaluation Branch Outcome 1— The advancement of Australia's international strategic, security and economic interests including through bilateral, regional and multilateral engagement on Australian Government foreign and trade policy priorities Program 1.1 Foreign Affairs and Trade Operations North Asia: [This includes Democratic People's Republic of Korea, Japan, Mongolia, People's Republic of China, Republic of Korea, Taiwan] Mr Peter Rowe, First Assistant Secretary, North Asia Division South-East Asia: [This includes ASEAN, Brunei, Burma, Cambodia, East Timor, Indonesia, Laos, Malaysia, Philippines, Singapore, Thailand, Vietnam] Mr Rod Smith, First Assistant Secretary, South-East Asia Division Americas: [This includes Canada, United States of America, South America, the Caribbean.] Mr Justin Brown, First Assistant Secretary, Americas and Africa Division Ms -

The Foreign Service Journal, December 1989

An Interview A Profile by Jim Anderson Uncharted Waters: U.S. Foreign Policy in a Time of Transition by Laurence S. Eagleburger After FSX: A New Approach to U.S.-Japan Relations by Kevin L. Kearns "Insuring the "Storing the furnishings valuables you leave you move in Washington also overseas calls for Security.” Roland Showalter, Vice President Overseas Division, joined Paul Wood, Manager, Security in 1947. Insurance Division has worked with Security since 1956. When you’re posted abroad, you can insure You can store rugs, furs and clothing in household goods in-transit or at your overseas temperature-controlled Security-at government residence—at special low rates. expense. And, you can give your valuables and art the Security's Government Service Policy covers Security of a bank vault. Call Roland Showalter at furnishings and personal effects including automobiles 1202)797-5679. anywhere outside the U.S. Call Paul Wood at Your move overseas calls for the expertise of the (202)797-5625. world's most experienced moving and storage company. Since 1 890 «< MOVING & STORAGE 1701 Florida Avenue NW Washington DC 20009 Can your insurance company do all of this for you? Auto Provide an overseas package “Ship and Drive” auto policy which includes “All-Risks” protection plus transit coverage. Household Effects Provide a package policy combining transit “at post” and U.S. commercial storage. Full Replacement Cost Coverage is available. Scheduled Property Provide a separate “All-Risks” policy covering your high-valued items such as jewelry, fine arts, silver. Stateside Coverage Anticipate the domestic insurance needs of the American Foreign Service in the Metropolitan Washington Area. -

Palestinian and Iraqi Women Refugees: an Examination of the Past Sixty Years Kim Anthony Grand Valley State University

McNair Scholars Journal Volume 12 | Issue 1 Article 2 2008 Palestinian and Iraqi Women Refugees: An Examination of the Past Sixty Years Kim Anthony Grand Valley State University Follow this and additional works at: http://scholarworks.gvsu.edu/mcnair Recommended Citation Anthony, Kim (2008) "Palestinian and Iraqi Women Refugees: An Examination of the Past Sixty Years," McNair Scholars Journal: Vol. 12: Iss. 1, Article 2. Available at: http://scholarworks.gvsu.edu/mcnair/vol12/iss1/2 Copyright © 2008 by the authors. McNair Scholars Journal is reproduced electronically by ScholarWorks@GVSU. http://scholarworks.gvsu.edu/ mcnair?utm_source=scholarworks.gvsu.edu%2Fmcnair%2Fvol12%2Fiss1%2F2&utm_medium=PDF&utm_campaign=PDFCoverPages Palestinian and Iraqi Women Refugees: An Examination of the Past Sixty Years Introduction and the worldwide attention they have received due to their increasing plight. Palestinian and Iraqi women refugees By better understanding Palestinian face daily challenges that many women and Iraqi women’s roles in their societ- throughout the world do not. These ies and histories, researchers can reject refugees cope with issues like poverty, personal biases and make well-informed deprived living conditions, violence, and recommendations to help alleviate the sexual abuse, while access to medical collective concerns of these refugees. and educational facilities remains limit- This paper also aims to make educated ed. They depend on assistance provided recommendations to governmental and by the United Nations, the United States, humanitarian organizations thus adding and host nations. According to several to the dialogue on the social concerns of refugee commissions, the chronic under- these women. Further, it attempts to pre- Kim Anthony funding of the United Nations’ humani- dict and project future needs of Palestin- McNair Scholar tarian organizations threatens to force a ian and Iraqi women refugees.