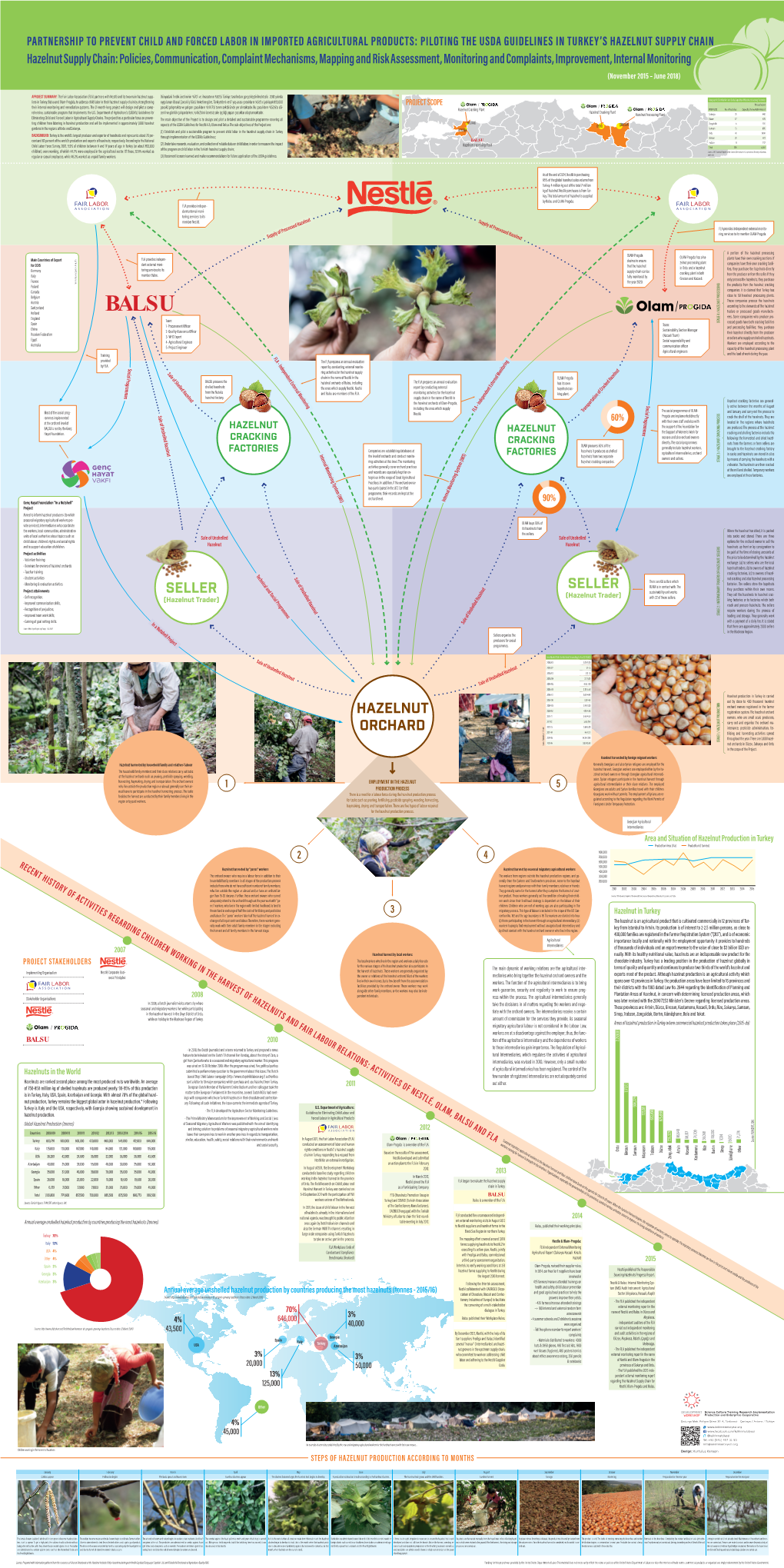

Piloting the Usda Guidelines in Turkey's Hazelnut Supply Chain

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

2018 YILI FAALİYET RAPORU.Pdf

SAKARYA İL TARIM ve ORMAN MÜDÜRLÜĞÜ 2018 YILI FAALİYET ÖZETİ SAKARYA ARALIK-2018 1 SAKARYA İL TARIM VE ORMAN MÜDÜRLÜĞÜ İl ve İlçe Müdürlükleri Personel Durumu Sakarya İl Tarım ve Orman Müdürlüğü 1 İl Müdürü, 3 İl Müdür Yardımcısı, 8 Şube Müdürü, 16 İlçe Müdürü yönetiminde toplam 516 personelle hizmetlerini yürütmektedir. Su Ürünleri SAKARYA İL TARIM VE ORMAN Ziraat Vet.Sağ. Ziraat Mühendisi Gıda Mühendisi Müh.- Balıkçılık Veteriner Hekim Teknis/Tekn. Tekns/Tekn. MÜDÜRLÜĞÜ Tek.Müh. Norm 4/A 4/B Norm 4/A 4/B Norm 4/A Norm 4/A 4/B Norm 4/A Norm 4/A ARAZİ TOP. VE TARIM.ALT YAPI ŞB.MD. 14 9 1 - 0 0 - 0 - 0 0 3 2 - 0 ÇAYIR, MERA VE YEM BİT.ŞB. 3 0 - 0 0 - 0 - 0 0 0 - 0 BİTKİSEL ÜRETİM VE SAĞ.ŞB.MD. 26 13 2 - 0 0 - 0 - 0 0 5 3 - 0 HAYVAN SAĞLIĞI YETİŞ.ŞB.MD. 4 0 0 - 0 0 - 0 19 8 6 - 0 5 3 BALIKÇILIK VE SU ÜRÜNLERİ ŞB.MD. - 0 0 - 0 0 8 7 1 0 0 - 0 - 0 KOORDİNASYON VE TAR.VER.ŞB.MD. 5 6 0 - 0 0 - 0 - 0 0 5 2 - 0 KIRSAL KALKINMA VE ÖRGÜT.ŞB.MD. 16 6 0 - 0 0 - 0 2 1 0 4 2 - 0 GIDA VE YEM ŞB.MD. 13 1 1 31 5 5 - 0 19 7 2 - 0 - 0 İL MÜDÜRLÜĞÜ TOPLAMI 78 38 4 31 5 5 8 7 41 16 8 17 9 5 3 ADAPAZARI 16 8 3 6 5 1 1 0 19 11 1 6 2 4 2 AKYAZI 12 4 4 2 0 1 2 0 12 6 0 5 1 3 2 ARİFİYE 4 4 1 1 1 0 - 1 2 2 0 2 2 2 1 ERENLER 9 7 1 2 4 0 - 0 9 6 1 6 2 2 0 FERİZLİ 9 1 3 1 0 1 - 0 5 1 0 6 1 3 0 GEYVE 15 2 5 1 0 1 - 0 8 3 3 9 1 3 2 HENDEK 15 8 3 2 0 1 2 0 13 8 1 5 2 3 1 KARAPÜRÇEK 4 3 0 - 0 0 - 0 2 2 1 2 0 2 0 KARASU 19 4 3 2 1 1 3 2 9 5 2 7 1 3 2 KAYNARCA 12 6 3 - 0 0 1 1 11 5 2 7 0 3 2 KOCAALİ 18 3 4 1 0 0 1 0 4 2 1 5 1 2 2 PAMUKOVA 9 3 4 1 0 1 1 0 5 4 1 5 2 3 1 SAPANCA -

İBRAHİM TELLİOĞLU, Trabzon Rum Devleti, Serander, Trabzon 2009

İBRAHİM TELLİOĞLU, Trabzon Rum Devleti, Serander, Trabzon 2009. 183 pages. ISBN 978-9944-374-23-1 Introduction İbrahim Tellioğlu, who is a professor at Ondokuz Mayıs University, Faculty of Letters, History Department, displays his knowledge and talent to address a highly debated issue: Trebizond Greek State11 from a perspective unlike the common Western historiography in that he discusses it introducing several sources such as the Chronicle of Michael Paneretos the major source of the period of III. Aleksios (1349-1390), the most important source, regarding the relations of the Comnenos dynasty with the Turks and Venetians and Geneose in the neighbourhood, the Byzantine sources such as the the Chronicle of Georgios Acropolites, which enlightens the struggle of David Comneos with Theodore Laskaris, the Chronicle of Nikephoras Gregoras, Ioannes Kantakouzenus, and Laonikas Chalkokondyles and the Chronicles of Papadopoulos regarding Trebizond included at the end of the works ofJ. P. Falmerayer, G. Finlay, W. Miller, S. I. Karpov and F. I. Uspenski. Besides, he introduces the Venetian and Geneose sources related to the political situation of the Black Sea region and the Comnenos, especially from the last quarter of the 13th century onwards (p.xııı-xvı). In addition, he uses the tavelogues of Clavijo, sent as a Spanish envoy to Tamerlane. He asserts that the travelogues of Clavijo are highly important in that they give detailed information about the period of Manuel related the sovereignity of the Comnenos in the Black Sea region. The other source he uses is the “Anonymous Georgian Chronicle” published by Brosset titled as “Historie de la Georgia” in 1849 and the Chronicle of Cardinal Bessarion. -

Hendek Ilçesi'nin Coğrafi Etüdü

ATATÜRK ÜNİVERSİTESİ SOSYAL BİLİMLER ENSTİTÜSÜ COĞRAFYA ANA BİLİM DALI Eşref ÇOLFAOĞLU HENDEK İLÇESİ’NİN COĞRAFİ ETÜDÜ YÜKSEK LİSANS TEZ YÖNETİCİSİ Yrd. Doç. Dr. Cemal SEVİNDİ ERZURUM – 2006 1 ÖZET YÜKSEK LİSANS TEZİ HENDEK İLÇESİNİN COĞRAFİ ETÜDÜ Eşref ÇOLFAOĞLU Danışman : Yrd. Doç. Dr. Cemal SEVİNDİ 2006 – SAYFA : 184 Jüri : Yrd. Doç. Dr. Cemal SEVİNDİ Yrd. Doç. Dr. Mehmet ZAMAN Doç. Dr. Ramazan SEVER Araştırma sahasını oluşturan Hendek İlçesi, Marmara Bölgesi’nin Çatalca-Kocaeli Bölümü sınırları içerisinde yer alır. Yönetim bakımından Sakarya iline bağlı olan Hendek bu merkeze yaklaşık 32 km uzaklıktadır. Aynı adı taşıyan ovanın kuzeyinde kurulan Hendek şehri 175 m yükseklikte bulunmaktadır. Hendek ilçesi yönetim bölgesi alanı, yaklaşık 581 km² kadardır. Bu arazi; batıdan Adapazarı ve Söğütlü, kuzeyden Karasu, doğudan Düzce ve güneyden Akyazı ilçesi yönetim bölgeleri ile çevrilidir. Saha coğrafi konumu nedeni ile Karasal Akdeniz iklim bölgesi ile Batı Karadeniz Bölgesi iklimi etkisi altında olup bir geçiş alanında bulunmaktadır. Hendek’te yıllık ortalama yağış miktarı 800 mm, ortalama sıcaklık ise 14,5 ºC kadardır. Hendek ilçesinin 2000 yılı Genel Nüfus Sayımı sonuçlarına göre toplam nüfusu, 64538 kadardır. Bu nüfusun yaklaşık %44 (28610)’ü Hendek Belediyesi sınırları içerisinde, geriye kalan %56 (35938) kadarı ise kırsal yerleşmelerde yaşamaktadır. Aynı yıl itibariyle aritmetik (matematiksel) nüfus yoğunluğu ise, 112 kişi/km2 kadardır. Araştırma sahasında, topoğrafik yapının uygunluğu ve iklim özelliklerinin elverişli olması tarımsal faaliyetleri olumlu yönde etkilemiş, bunun sonucunda ekonomik faaliyetlerin %60’ı tarıma dayanmaktadır. Çayır ve mera alanlarının çok az yer kaplaması, hayvancılık faaliyetlerini olumsuz yönde etkilemiştir. Hayvancılık daha çok ailelerin kendi ihtiyaçlarını karşılamaya yönelik yapılmaktadır. Hendek ilçesi sahip olduğu sosyo-ekonomik avantajlarını bulunduğu konumundan dolayı kullanamamıştır. -

ZİRAİ İLAÇ BAYİLERİ 1 ADAPAZARI ÖZCAN TARIM 2 ADAPAZARI HUN TİCARET 3 ADAPAZARI Köseoğlu Süper Biofer 4 ADAPAZARI MOLÇOK TARIM 5 ADAPAZARI PANCAR EKİCİLERİ KOOP

ZİRAİ İLAÇ BAYİLERİ 1 ADAPAZARI ÖZCAN TARIM 2 ADAPAZARI HUN TİCARET 3 ADAPAZARI Köseoğlu Süper Biofer 4 ADAPAZARI MOLÇOK TARIM 5 ADAPAZARI PANCAR EKİCİLERİ KOOP. 6 ADAPAZARI ÖZ BAHAR TARIM 7 ADAPAZARI 708 S. YAĞLI TOHUMLAR 8 ADAPAZARI SAKARYA TARIM MARKET 9 ADAPAZARI ZİRAAT ODASI-1 10 ADAPAZARI EYLÜL TARIM 11 ADAPAZARI ARYA Tarım 12 ADAPAZARI YALÇIN PAZARLAMA 13 ADAPAZARI PANCAR EKİCİLERİ KOOP. 14 ADAPAZARI SAKARYA TOHUM TAR.SAN. 15 ADAPAZARI May Ada Tarım(TOPTANCI) 16 ADAPAZARI Özcan Tarım 17 ADAPAZARI PANCAR EKİCİLERİ KOOP. 18 ADAPAZARI ÖNCÜ TOHUM 19 ADAPAZARI PİRİMOĞLU TARIM 20 ADAPAZARI BUDAKLAR T.K.K. 21 ADAPAZARI ADA TARIM 22 ADAPAZARI ÖZMEN TARIM 23 ADAPAZARI SALMANLI T.K.K. 24 ADAPAZARI KOÇ TARIM 25 ADAPAZARI ERN Tarım Ürünleri 26 ADAPAZARI Sakarya Rekor Tarım 27 AKYAZI S.S. APEK AKYAZI SATIŞ MAĞAZASI 28 AKYAZI SEÇKİN TARIM 29 AKYAZI S.S. APEK ÇATALKÖPRÜ SATIŞ MAĞAZASI 30 AKYAZI ARSLAN TARIM 31 AKYAZI SERA TARIM 32 AKYAZI 275 SAYILI AKYAZI TKK. 33 AKYAZI 2868 SAYILI OSMANBEY TKK. 34 AKYAZI 1680 SAYILI YENİORMANKÖY T.K.K 35 AKYAZI ENKA TARIM 36 ARİFİYE ÇETİN ELEKTRO PLASTİK A.Ş. 37 ARİFİYE 490 SAYILI ARİFİYE TKK. 38 ERENLER TEKNİK TARIM 39 ERENLER MODEL GÜBRE İLAÇ (TOPTANCI) 40 ERENLER S.S. APEK ERENLER SATIŞ MAĞAZASI 41 FERİZLİ ONUR TARIM 42 FERİZLİ 2720 SAYILI FERİZLİ TKK. 43 FERİZLİ 2842 SAYILI GÖLKENT TKK 44 FERİZLİ FERİZLİ ZİRAAT ODASI 45 FERİZLİ FERİZLİ TARIM OFİSİ 46 GEYVE YAVUZ TARIM 47 GEYVE 1097 SAYILI AKDOĞAN T.K.K. 48 GEYVE ÇİNİ TARIM 49 GEYVE GENÇLER TARIM 50 GEYVE S.S. APEK GEYVE SATIŞ MAĞAZASI 51 GEYVE 1090 SAYILI GEYVE T.K.K. -

Selling the Richness of Turkey by RONEN PALDI This Year ASTA Is

Selling The Richness Of Turkey BY RONEN PALDI This year ASTA is holding its International Destination Expo, April 19-22, in Istanbul, exposing travel agents to the richness of travel in a country that is nearly as varied as its landscape. I’ll be there to help educate agents on how to better sell travel to Turkey and its many regions. But here’s a quick summary of what you should know about this beautiful and fascinating country. Turkey’s legacy of the Roman and Ottoman empires includes exquisite palaces, churches and mosques. Its cities brim with personality, exotic cuisine and ancient treasure. Istanbul alone is worth the trip, but there is so much more to see as well as something for everyone. Building trips around client interests can introduce new travelers to Turkey – and those trips can be easily built around four areas: architecture tours, faith or pilgrimage tours, culinary programs, shopping tours, agricultural tourism and soft adventure. Architecture: Istanbul has the famed Blue Mosque, so named for its interior walls with 20,000 blue tiles. There is also the lesser known but equally impressive Topkapi Palace, home to the Ottoman sultans for 400 years. Also in Istanbul is Hagia Sophia, a former church and mosque that is now a museum. The building was built in a short five years, from 532 to 537 A.D., and is on par with the grandeur of St. Paul’s in London, but built 1,000 years earlier. Dedicated architecture buffs also will want to get to Gaziantep to see the recently rediscovered mosaics on display there and visit Trabzon in the north along the Black Sea. -

Three Trabzon Tales by ADAM SMITH ALBION

Three Trabzon Tales BY ADAM SMITH ALBION TRABZON, Turkey 17 October 1995 ALI, THE DRONE It all began one summer evening. Trabzon was shutting up shop for the day. From my balcony I could see the shutters being drawn down, crates of oranges stacked, fish-carts trundled away, and the whole class of esnaf Turkey's industrious, busy-bee middle stra- tum packing up to pray at mosque and go home. The evening call to prayer had already echoed around the city. The muezzins' voices are artificially pumped up though loudspeakers and ring at ear- splitting volume through this conservative, religious, moral town. As everyone knows, decibels are the proper measure of faith, and the amplifiers attached to the minarets have been turned up since the Is- lamist Welfare Party took control of Trabzon's town hall. Soaring above the din are the Pontic Mountains, emerald-green and lush. They looked grand with the sun, aloft but losing altitude fast, crash- ing down on them. Glinting at their feet, the Black Sea was changing in the light into a somber, impossibly vast zinc disk when the tele- phone rang. wished it would stop but it didn't so dragged myself indoors off the balcony and answered it. It was Mustafa. He was a neighborhood estate agent, always eager to show off his knowledge of American sports over tea in his office. liked him well enough although we had no interests in common, and certainly not American sports. noted at once the apologetic tone to his voice. "My wife's nephew Temel was driving the car. -

Black Sea Coast--Trabzon

NOT FOR PUBLICATION ASA-3 WITHOUT WRITER'S CONSENT INSTITUTE OF CURRENT WORLD AFFAIRS Trabzon, 7 December 1994 Mr Peter Bird Martin, Executive Director Institute of Current World Affairs 4 West Wheelock Street Hanover, NH 03755 USA Black Sea Coast-, Trabzon: football, hamsi I set up shop last month in Trabzon, a port on Turkey's far north-eastern coast, to get a first- hand look at how Soviet disintegration has affected a Turkish town. Trabzon (population about 250,000) is a 90-minute flight from Istanbul and a 3-hour drive (198 km) from the Georgian border. It is a long, skinny town squeezed along the coast by mountains which are strikingly green and usually covered in mist. It rains very often. Because of these conditions and the dramatic green I have heard this part of the coastline referred to as Turkey's Shangri-La and I like to repeat it. Tea and hazelnuts are grown on the slopes since the climate is more humid as a rule than one might expect. A few of the peaks are snow- capped now because 18 inches of snow fell last week, a freak fall such as has not happened in a decade. The sea is fiat and grey as gun-metal with a sharp wind coming off it. As a result I am always cold but the truth is that after the hot summer in Istanbul I rather like it. I remember the end of Brave New World when the Controller gives the rebel Helmholtz a choice of exile in the Falklands or Samoa, and he chooses the Falklands because he thought the cooler weather would focus his mind. -

591-4447 Fax (650)

900 Alameda Belmont, CA 94002-1604 (650) 591-4447 fax (650) 508-9846 e-mail [email protected] website www.goholycross.org Dearly Beloved in the Lord, Did you ever stop and wonder what makes one a saint? I am not referring to the ecclesiastical procedures, but the personal, the individual attributes that qualify one as a saint. On the Sunday after Pentecost, we are called to give our attention to building up the Body of Christ – The Church by becoming “saints”! Responding to the interests of many people, the Rev. Fr. Jon Magoulias and I are blessed to announce that we are planning a pilgrimage from October 12 – 26, 2015 entitled: “Saints Alive”! This experience will take us to some of the most famous and revered sites of our Christian Orthodox Faith. It will enable us to learn the lives of saints who were people just like us and journeyed through life to give glory to God. We will visit Constantinople and the Ecumenical Patriarchate where the relics of many saints are venerated; we will travel to Trabzon (Trebizon) on the Black Sea (known as Pontus) to visit sites that have been only been opened to us in recent years. At Trabzon we will visit the famous monastery of Panaghia Soumela, along with other churches and museums. Today the monastery's primary function is as a tourist attraction. It overlooks forests and streams, making it extremely popular for its aesthetic attraction as well as for its cultural and religious significance. As of 2012, the Turkish government has been funding restoration work, and the monastery is enjoying a revival in pilgrimage from Greece, the USA and Russia. -

0015?3-0 Evaluation of Steel Furnace Slags As Cement

Cement and Concrete Research, Vol. 27, No. I I, pp. 1713-1717, 1997 Copyright 0 1997 Elsewer Science Ltd Pergamon Printed in the USA. All rights reserved 0008~8846/97 $17.00 + .OO PI1 SOOOS-8S46(97)0015?3-0 EVALUATION OF STEEL FURNACE SLAGS AS CEMENT ADDITIVES M. Tiifekqi,* A. Demirba$,“f and H. Genqt *Technical University of the Black Sea, Department of Chemistry, Trabzon, Turkiye tTechnica1 University of the Black Sea, Department of Science Education, 61335 Akcaabat, Trabzon, Tiirkiye (Refereed) (Received September 16, 1996; in final form August 25, 1997) ABSTRACT Chemical and physical properties and strength development have been studied for six granulated steel furnace slags from the normal steelmaking process. This paper reports results of research performed to develop cement mixture proportions using these slags. The influence of slag proportions, specific surface, and water demand on compressive strength and bulk density of cement blends are presented in this paper. The different test results, which were compared with the Turkish Standards, in general, were found to be within the limits. 0 1997 Elsevier Science Ltd Introduction Reutilization of industrial by-products has been a thrust area of research, both ecologially and economically, in recent decades. The cementitious materials presently used for that purpose are silica fume, fly ash, and blast furnace slag (1). The use of iron blast furnace slag as a cementitious material has been practised in Europe since the late 1800s. It was not until World War II, when slag cement was used extensively as an energy saving measure, that its excellent performance and durability properties were fully appreciated. -

SIRA ADI SOYADI BRANŞ Hizmet Puanı ATANDIĞI KURUM 1 ERSİN

Hizmet SIRA ADI SOYADI BRANŞ ATANDIĞI KURUM Puanı 1ERSİN TÜRKER Beden Eğitimi 36 KARASU / (732617) - Şehit İsmail Hakkı Yılmaz Ortaokulu 2FATİH BAYRAM Beden Eğitimi 287 KARASU / (732598) - Karasu Ortaokulu 3 HASAN DOĞAN Beden Eğitimi 131 ADAPAZARI / (733115) - Adapazarı İmam Hatip Ortaokulu 4HÜSEYİN KİREZ Beden Eğitimi 150 ADAPAZARI / (973797) - Yunus Emre Anadolu Lisesi 5MURAT YARDIM Beden Eğitimi 219 SERDİVAN / (748502) - Mehmet Demir İmam Hatip Ortaokulu 6MUSTAFA SABAN Beden Eğitimi 209 ERENLER / (732417) - Abdullah Esma Kocabıyık Ortaokulu 7NESLİHAN PAMUKLAR Beden Eğitimi 94 SERDİVAN / (747307) - Şehit Ali Borinli Özel Eğitim Ortaokulu 8ONUR CINGIR Beden Eğitimi 128 ADAPAZARI / (732131) - Arif Nihat Asya Ortaokulu 9 SERDAL AĞAÇ Beden Eğitimi 200 SERDİVAN / (747911) - Şehit Ali Borinli Özel Eğitim Mesleki Eğitim Merkezi (Okulu) 10 SEVGİ TAPŞIN Beden Eğitimi 127 SERDİVAN / (967720) - Serdivan Mesleki ve Teknik Anadolu Lisesi 11 SEYHAN SUKENARI Beden Eğitimi 77 AKYAZI / (732368) - Şehit Ahmet Çondul Ortaokulu 12 YAKUP KURT Beden Eğitimi 288 ERENLER / (967933) - Figen Sakallıoğlu Anadolu Lisesi 13 YAVUZ TÜRKKAN Beden Eğitimi 263 ARİFİYE / (732415) - Üzeyir Garih Ortaokulu 14 ZAFER BIÇAK Beden Eğitimi 50 HENDEK / (732530) - Fatih Ortaokulu 15 ASLI ŞAHİN Bilişim Teknolojileri 17 PAMUKOVA / (732726) - Şehit Peyami Ortaokulu 16 BELGİN KOCABIYIKOĞLU Bilişim Teknolojileri 120 ERENLER / (732449) - Yeşiltepe Ortaokulu 17 EDA ŞAN Bilişim Teknolojileri 105 ERENLER / (760275) - Şehit Hüseyin Avni Bey İmam Hatip Ortaokulu 18 LEVENT BİLDİRİCİ Bilişim Teknolojileri 97 ADAPAZARI / (760143) - Mustafa Kemalpaşa İmam Hatip Ortaokulu 19 SEDAT COŞAR Bilişim Teknolojileri 120 ERENLER / (967933) - Figen Sakallıoğlu Anadolu Lisesi 20 SERKAN KOCABIYIKOĞLU Bilişim Teknolojileri 122 ADAPAZARI / (732210) - Şirinevler Ortaokulu 21 TURGAY DUĞAN Bilişim Teknolojileri 150 SERDİVAN / (967695) - Serdivan Farabi Mesleki ve Teknik Anadolu Lisesi 22 ESİN DÖNER Biyoloji 93 KARASU / (757951) - Karasu Anadolu Lisesi 23 NAMIK GÖKDEMİR Biyoloji 217 ADAPAZARI / (194112) - Adapazarı Prof. -

T.C. Sakarya Valiliği

T.C. SAKARYA VALİLİĞİ MAYIS-2015 İÇİNDEKİLER GİRİŞ... ...................................................................................................................... …3 İL HAKKINDA SAYISAL BİLGİLER... ...................................................................... …5 SOSYAL DURUM... .................................................................................................. …9 1) NÜFUS ve YÖNETİM DURUMU ........................................................................... 9 2) EĞİTİM DURUMU. ....................................................................................... ……11 3) SAĞLIK ................................................................................................................ 18 4) KÜLTÜR ve TURİZM ........................................................................................... 22 5) GENÇLİK HİZMETLERİ ve SPOR ................................................................... … 29 6) MALİYE ............................................................................................................... 33 7) AİLE ve SOSYAL POLİTİKALAR ...................................................................... .. 35 8) SOSYAL YARDIMLAŞMA ve DAYANIŞMA VAKIFLARI ..................................... 38 9) SOSYAL GÜVENLİK ........................................................................................... 41 10) TAPU ve KADASTRO DURUMU ....................................................................... 42 EKONOMİ ................................................................................................................. -

NEW ITINERARIES 2022/2023 Now, More All-Inclusive Than Ever

NEW ITINERARIES 2022/2023 Now, more all-inclusive than ever. SILVER SPIRIT 608 GUESTS DATE DAYS PORTS MEDITERRANEAN 2022 31 Mar 7 LISBON > Cadiz > Malaga > Cartagena > Valencia > Palma de Mallorca > BARCELONA 07 Apr 7 BARCELONA > Palamos > Marseille (Provence) > Monte Carlo > Portofino > Livorno (Tuscany) > Ajaccio > ROME (CIVITAVECCHIA) 14 Apr 11 ROME (CIVITAVECCHIA) > Naples > Sorrento > Palermo > Taormina (Giardini Naxos) > Valletta > Day at Sea > Souda Bay > Santorini > Rhodes > Kusadasi > ATHENS (PIRAEUS) 25 Apr 7 ATHENS (PIRAEUS) > Nafplion > Souda Bay > Santorini > Mykonos > Rhodes > Kusadasi > ATHENS (PIRAEUS) 02 May 11 ATHENS (PIRAEUS) > Kusadasi > Patmos > Rhodes > Antalya > Day at Sea > Jerusalem (Ashdod) > Nazareth (Haifa) > Day at Sea > Souda Bay > ATHENS (PIRAEUS) 13 May 11 ATHENS (PIRAEUS) > Santorini > Kusadasi > Dikili > Istanbul > Cruising the Dardanelles > Thessaloniki > Mykonos > Rhodes > Paros > ATHENS (PIRAEUS) 24 May 15 ATHENS (PIRAEUS) > Day at Sea > Istanbul > Day at Sea > Trabzon > Batumi > Sochi > Day at Sea > Odessa > Constanta > Bourgas > Cruising the Bosphorus > Kusadasi > Santorini > ATHENS (PIRAEUS) 08 Jun 9 ATHENS (PIRAEUS) > Santorini > Souda Bay > Olympia (Katakolon) > Corfu > Kotor > Dubrovnik > Split > Rovinj > VENICE 17 Jun 7 VENICE > Opatija > Split > Hvar > Dubrovnik > Sibenik > Trieste> VENICE 24 Jun 7 VENICE > Opatija > Hvar > Split > Dubrovnik > Sibenik > Trieste> VENICE 01 Jul 9 VENICE > Hvar > Split > Dubrovnik > Kotor > Corfu > Argostoli > Souda Bay > Santorini > ATHENS (PIRAEUS) 10 Jul 15