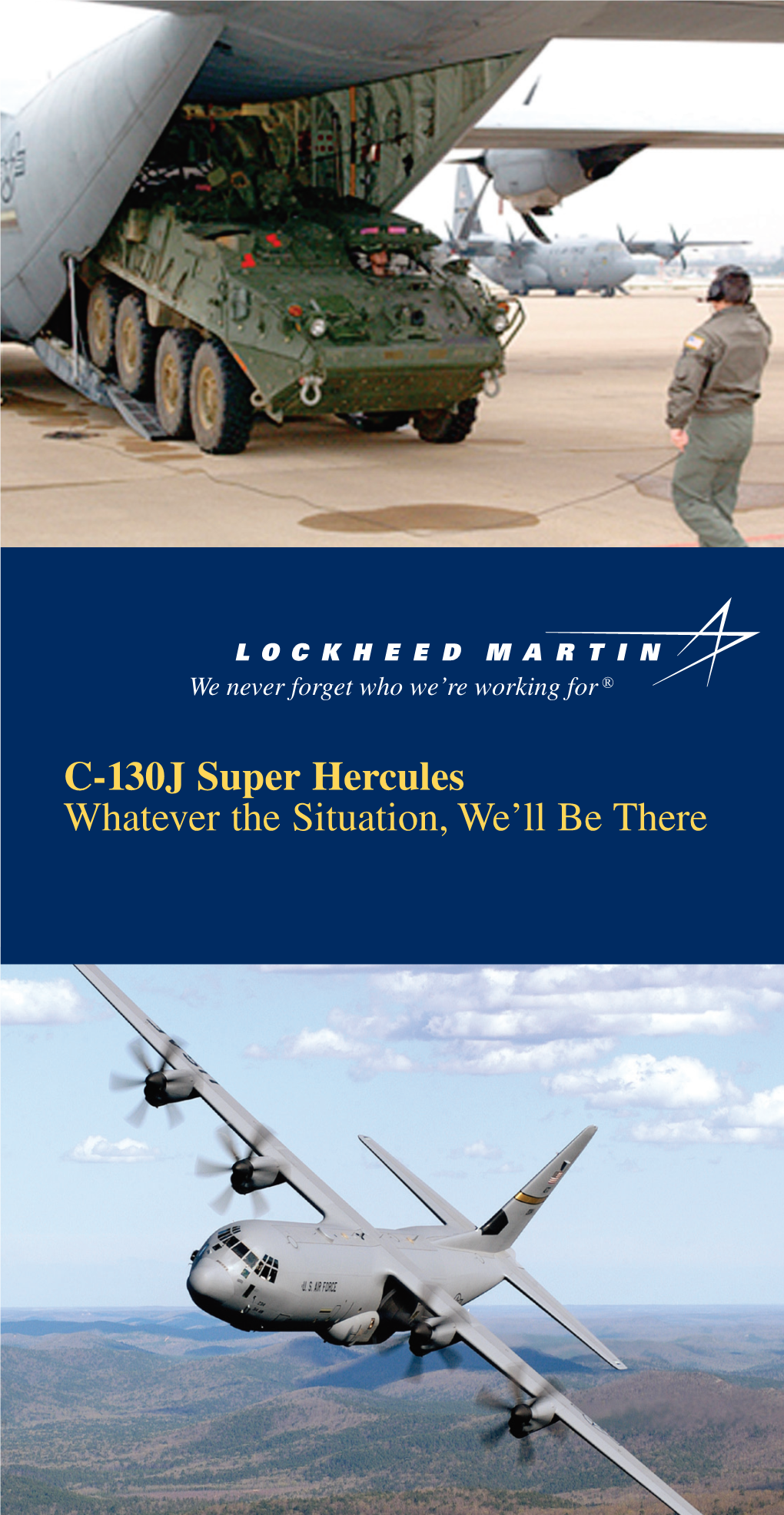

C-130J Super Hercules Whatever the Situation, We'll Be There

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Distribution: Electronically Initiated By: ANM-300 CHANGE U.S

U.S. DEPARTMENT OF TRANSPORTATION ORDER CHANGE NM 3930.11 FEDERAL AVIATION ADMINISTRATION CHG 6 Effective Date: National Policy 09/12/17 SUBJ: Aviation Medical Examiner for FAA Employees and Applicants Requiring Medical Certification. 1. Purpose. This order transmits Aviation Medical Examiner – Employee Examiner (AME- EE) information to the following: Transport Airplane Directorate (ANM-120s, ANM-130s, ANM-140s, ANM-150s), Flight Standards (FSDOs, Alaska CMO, SWA-CMO, Seattle AEG) and the ATO Western Service Area with Enroute and Terminal employees assigned to facilities located in Colorado, Idaho, Montana, Oregon, Utah, Washington and Wyoming requiring Federal Aviation Administration Aerospace Medical Certification. 2. Who this change affects. Branch level and above in the following divisions in the Northwest Mountain Region: Aerospace Medicine, Flight Standards, Transport Airplane Directorate and the ATO Western Service Area (CO, ID, MT, OR, UT, WA and WY) - Enroute and Terminal. 3. Disposition of Transmittal Paragraph. Retain this transmittal sheet until the directive is cancelled by a new directive. PAGE CHANGE CONTROL CHART Remove Pages Dated Insert Pages Dated Appendix A 9/1/17 Appendix A 9/12/17 4. 5. Administrative Information. This order change is distributed to Branch level and above in the following divisions in the Northwest Mountain Region: Aerospace Medicine, Flight Standards, Transport Airplane Directorate and the ATO Western Service Area (CO, ID, MT, OR, UT, WA and WY) - Enroute and Terminal. Responsibility for Distribution: The above divisions are responsible for verifying that there have been no updates to this order prior to scheduling an employee exam. Brett A. Wyrick, D.O. Regional Flight Surgeon Northwest Mountain Region Distribution: Electronically Initiated By: ANM-300 U.S. -

DAO Level 4 Certificate in Applied Aviation Studies (Fixed Wing Aircraft Loadmaster)

Qualification Handbook DAO Level 4 Certificate in Applied Aviation Studies (Fixed Wing Aircraft Loadmaster) QN: 603/0925/8 The Qualification Overall Objective for the Qualifications This handbook relates to the following qualification: DAO Level 4 Certificate Applied Aviation Studies (Fixed Wing Aircraft Loadmaster) This Level 4 Certificate provides the standards that must be achieved by individuals that are working within the Armed Forces. Pre-entry Requirements Entry requirements are detailed in the Course prospectus. Learners who are taking this qualification should be employed in the WSOp trade Unit Content and Rules of Combination This qualification is made up of a total of 16 mandatory units and no Optional units. To be awarded this qualification the candidate must achieve a total of 35 credits as shown in the table below. URN Unit of assessment Level TQT GLH Credit Value D/615/4342 Duties of the WSOp CMN Fixed Wing and associated aircraft 3 7 7 1 K/615/4344 WSOp Regulations 3 16 10 2 T/615/4346 Weight and balance in fixed wing aircraft 4 46 40 5 A/615/4347 Loading and Restraint of Aircraft Cargo 4 42 42 5 F/615/4348 Cargo and Mail in Fixed Wing Operations 4 38 36 4 J/615/4349 Dangerous Goods (DG) on AT & ARR aircraft 4 45 45 5 A/615/4350 Passengers in the AT & ARR aircraft 3 6 6 1 J/615/4352 In–flight catering for WSOp 2 9 9 1 K/615/4361 Regulations of AT & ARR operations 3 25 25 3 M/615/4362 Pre Flying Exercise checks 4 14 14 2 T/615/4363 Radio operation (Crewman) 4 6 6 1 A/615/4364 WSOp (CMN) during aircraft operations (Simulator) 4 6 6 1 F/615/4365 WSOp Crewman procedures 4 9 9 1 J/615/4366 Duties of the WSOp CMN Fixed Wing when away from home base 4 5 5 1 L/615/4367 Principles of aircraft servicing (WSOp) 4 8 8 1 R/615/4368 Agencies associated with WSOP (CMN) operations 3 7 7 1 Age Restriction This qualification is available to learners aged 18+. -

ALT / VS Selector/Alerter

ALT / VS Selector / Alerter PN 01279-( ) Pilot’s Operating Handbook ENT ALT SEL ALR DH VS BARO S–TEC * Asterisk indicates pages changed, added, or deleted by List of Effective Pages current revision. Retain this record in front of handbook. Upon receipt of a Record of Revisions revision, insert changes and complete table below. Revision Number Revision Date Insertion Date/Initials 1st Ed. Oct 26, 00 2nd Ed. Jan 15, 08 3rd Ed. Jun 24, 16 3rd Ed. Jun 24, 16 i S–TEC Page Intentionally Blank ii 3rd Ed. Jun 24, 16 S–TEC Table of Contents Sec. Pg. 1 Overview...........................................................................................................1–1 1.1 Document Organization....................................................................1–3 1.2 Purpose..............................................................................................1–3 1.3 General Control Theory....................................................................1–3 1.4 Block Diagram....................................................................................1–4 2 Pre-Flight Procedures...................................................................................2–1 2.1 Pre-Flight Test....................................................................................2–3 3 In-Flight Procedures......................................................................................3–1 3.1 Selector / Alerter Operation..............................................................3–3 3.1.1 Data Entry.............................................................................3–3 -

Theater Airlift Modernization Options for Closing the Gap

Halvorsen loader pulls away from C-130J Super Hercules at Bagram Air Field, Afghanistan, where Airmen from aerial port and airlift squadrons support operations 24/7 at DOD’s busiest single runway airfield (U.S. Air Force/Brian Wagner) Theater Airlift Modernization Options for Closing the Gap By Robert C. Owen merica’s renewed strategic the Nation has and what it expects to whether the POR airlift fleet will be ade- emphasis on state-on-state con- acquire) presents serious shortfalls in quate to the demands likely to be placed A flict highlights significant gaps the ability to maneuver land forces on on it. The discussion then turns to the in the country’s theater airlift capa- the scale, to the destinations, or in the question of whether affordable opportu- bilities, particularly in the Asia-Pacific timeframes desired by Army planners. nities exist to mitigate the gaps identified. region. Quantitatively, there likely will Air commanders also have reason for not be enough airlift capacity available concern since the core aircraft of the Requirements to cover major conflict requirements. theater fleet, the C-17 and C-130, pose Many organizations articulate versions Qualitatively, the current program- capacity and operational risks in their of airlift requirements based on sub- of-record (POR) airlift fleet (what abilities to support high-volume combat jective guesses about future scenarios. operations at forward bases when Moreover, the details of the more threatened or damaged by attack. authoritative Department of Defense Given these gaps between capabilities (DOD) studies are classified. Therefore, Dr. Robert C. Owen is a Professor in the Department of Aeronautical Science at Embry- and requirements, this article considers this article asserts only that the steady Riddle Aeronautical University. -

How Doc Draper Became the Father of Inertial Guidance

(Preprint) AAS 18-121 HOW DOC DRAPER BECAME THE FATHER OF INERTIAL GUIDANCE Philip D. Hattis* With Missouri roots, a Stanford Psychology degree, and a variety of MIT de- grees, Charles Stark “Doc” Draper formulated the basis for reliable and accurate gyro-based sensing technology that enabled the first and many subsequent iner- tial navigation systems. Working with colleagues and students, he created an Instrumentation Laboratory that developed bombsights that changed the balance of World War II in the Pacific. His engineering teams then went on to develop ever smaller and more accurate inertial navigation for aircraft, submarines, stra- tegic missiles, and spaceflight. The resulting inertial navigation systems enable national security, took humans to the Moon, and continue to find new applica- tions. This paper discusses the history of Draper’s path to becoming known as the “Father of Inertial Guidance.” FROM DRAPER’S MISSOURI ROOTS TO MIT ENGINEERING Charles Stark Draper was born in 1901 in Windsor Missouri. His father was a dentist and his mother (nee Stark) was a school teacher. The Stark family developed the Stark apple that was popular in the Midwest and raised the family to prominence1 including a cousin, Lloyd Stark, who became governor of Missouri in 1937. Draper was known to his family and friends as Stark (Figure 1), and later in life was known by colleagues as Doc. During his teenage years, Draper enjoyed tinkering with automobiles. He also worked as an electric linesman (Figure 2), and at age 15 began a liberal arts education at the University of Mis- souri in Rolla. -

Federal Aviation Administration Administration

Federal Aviation Federal Aviation Administration Administration Cargo Focus Team And Air Cargo Operations Presented to: EMI FSDO Operators By: AFS-330 Date: February 2016 Overview Background Cargo Focus Team . NTSB . Working with Stakeholders . Short and Long Term Goals . Accomplishments . AC 120-85A Highlights Cargo Operations Changes to the AFM/WBM Current Issues and Initiatives February 2016 Cargo Focus Team Federal Aviation 2 Administration Background Cargo Aircraft Accident likelihood 20 times more likely than a passenger aircraft (according to IATA data) FAA CAST team is currently showing 30 to 50 February 2016 Cargo Focus Team Federal Aviation 3 Administration Background Following the Air Cargo accident in Afghanistan, a team was assembled to determine whether or not systemic problems exist regarding special cargo loads Aircraft Certification (AIR) and Flight Standards (AFS) are working jointly to address Cargo Operation with a focus on “Special Cargo” February 2016 Cargo Focus Team Federal Aviation 4 Administration Cargo Focus Team The FAA, Cargo Focus Team (CFT) exists as a permanent technical resource for cargo operations For cargo operations questions or suggestions contact CFT @ [email protected] February 2016 Cargo Focus Team Federal Aviation 5 Administration Cargo Focus Team Team Structure Interdependency Multi Discipline . Transport Airplane Directorate (ANM-100) . Air Transport Operations (AFS-200) . Aircraft Maintenance Division (AFS-300) . National Field Office (AFS-900) . Field Inspector (CMO- Detailees) February 2016 Cargo Focus Team Federal Aviation 6 Administration Cargo Focus Team The CFT Vision is to enhance the safety of air cargo operations. The CFT Mission is to directly support FAA field personnel, act as a focal point for the integrity of air cargo operations while serving as the FAA’s technical matter expert in air cargo operations February 2016 Cargo Focus Team Federal Aviation 7 Administration NTSB NTSB final report on from B-747 accident published July 29, 2015. -

AIRLIFT RODEO a Brief History of Airlift Competitions, 1961-1989

"- - ·· - - ( AIRLIFT RODEO A Brief History of Airlift Competitions, 1961-1989 Office of MAC History Monograph by JefferyS. Underwood Military Airlift Command United States Air Force Scott Air Force Base, Illinois March 1990 TABLE OF CONTENTS Foreword . iii Introduction . 1 CARP Rodeo: First Airdrop Competitions .............. 1 New Airplanes, New Competitions ....... .. .. ... ... 10 Return of the Rodeo . 16 A New Name and a New Orientation ..... ........... 24 The Future of AIRLIFT RODEO . ... .. .. ..... .. .... 25 Appendix I .. .... ................. .. .. .. ... ... 27 Appendix II ... ...... ........... .. ..... ..... .. 28 Appendix III .. .. ................... ... .. 29 ii FOREWORD Not long after the Military Air Transport Service received its air drop mission in the mid-1950s, MATS senior commanders speculated that the importance of the new airdrop mission might be enhanced through a tactical training competition conducted on a recurring basis. Their idea came to fruition in 1962 when MATS held its first airdrop training competition. For the next several years the competition remained an annual event, but it fell by the wayside during the years of the United States' most intense participation in the Southeast Asia conflict. The airdrop competitions were reinstated in 1969 but were halted again in 1973, because of budget cuts and the reduced emphasis being given to airdrop operations. However, the esprit de corps engendered among the troops and the training benefits derived from the earlier events were not forgotten and prompted the competition's renewal in 1979 in its present form. Since 1979 the Rodeos have remained an important training event and tactical evaluation exercise for the Military Airlift Command. The following historical study deals with the origins, evolution, and results of the tactical airlift competitions in MATS and MAC. -

PC-6/B2-H4 Airplane Flight Manual Doc. No. 1820 at Revision 8

PILOT’S INFORMATION MANUAL PC-6/B2-H4 applicable from AC S/N 825 PILOT’S INFORMATION MANUAL PC-6/B2-H4 applicable from AC S/N 825 WARNING •This PC-6 Pilot’s Information Manual is published for general and familiarization purposes only. •This Pilot’s Information Manual does NOT meet FAA, FOCA or any other civil aviation authority regulations for operation of ANY Aircraft. •This Pilot’s Information Manual is a reproduction of a PC-6 Airplane Flight Manual, however, it is NOT revised or updated. •This Pilot’s Information Manual does NOT reflect the configuration or operating parameters of any actual aircraft. •Only the Approved Airplane Flight Manual issued for a specific serial number aircraft may be used for actual operation of that serial number aircraft. Pilatus Aircraft Ltd P.O. Box 992 6371 Stans, Switzerland Phone +41 41 619 67 00 Fax +41 41 619 92 00 [email protected] www.pilatus-aircraft.com AIRPLANE FLIGHT MANUAL PC-6/B2-H4 ONLY REPORT NO. 1820 PURPOSES REGISTRATION ._____ __. SERIAL NO . APPLICABLE FROM A/C SIN 825 FAMILIARIZATION THIS AIRPLANDANE IS TO BE OPERAT ED IN COMPLIANCE WITH INFORMATION AND LIMI TATIONS CONTAINED HEREIN THIS FLIGHT MANUAL IS TO BE KEPT GENERAL IN THE AIRCRAFT AT ALL TIMES FOR Approved by: SWISS FEDERAL OFF FOR CIVIL AVIATION · �L Nov 20, JS�S" Date of Approval : ____·- ______ PILATUS AIRCRAFT LTD STANS/SWITZERLAND ONLY PURPOSES FAMILIARIZATION AND GENERAL FOR © Pilatus Aircraft Ltd. This document contains proprietary information that is protected by copyright. All rights are reserved, No part of this document may be copied, reproduced or translated to other languages without the prior written consent of Pilatus Aircraft Ltd. -

AIR FORCE Magazine / April 1998 42

Data on these pages are drawn from several official and unofficial studies.The two principal sources are Gulf War Air Power Survey, Eliot A. Cohen, et al, USAF, Washington, 1993; and Airpower in the Gulf, James P. Coyne, the Aerospace Edu cation Foundation, Arlington, Va., 1992. Also consulted were studies from the US Air Force, Department of Defense, and Congress. 42 AIR FORCE Magazine / April 1998 USAF photo by Fernando Serna AIR FORCE Magazine / April 1998 43 Flight Operations Summary n USAF’s in-theater fighter, bomber, and attack aircraft numbered 693 at the height of the war, or 58 percent of US in-theater air assets. They flew 38,000 wartime sorties. n USAF aircraft dropped nearly 160,000 munitions on Iraqi targets, 72 percent of the US forces total. n Air Force aircraft dropped 91 percent of all precision bombs and 96 percent of precision missiles used in the war. n Air Force B-52 bombers flew 1,624 combat missions and dropped 72,000 bombs, or 26,000 tons of ordnance. This F-15D from the 1st Tactical Fighter Wing, Langley AFB, Va., was among the first US forces to arrive in the Persian Gulf after Iraq invaded Kuwait. n Before the ground battle began, the USAF–led air campaign against Iraqi ground forces destroyed 1,688 battle tanks (39 percent of total), 929 armored personnel carriers (32 percent), and 1,452 artillery tubes (47 percent). n USAF combat support aircraft Chronology numbered 487 at the height of the war, 54 percent of the US support 1990 assets in-theater. -

Fly-By-Wire - Wikipedia, the Free Encyclopedia 11-8-20 下午5:33 Fly-By-Wire from Wikipedia, the Free Encyclopedia

Fly-by-wire - Wikipedia, the free encyclopedia 11-8-20 下午5:33 Fly-by-wire From Wikipedia, the free encyclopedia Fly-by-wire (FBW) is a system that replaces the Fly-by-wire conventional manual flight controls of an aircraft with an electronic interface. The movements of flight controls are converted to electronic signals transmitted by wires (hence the fly-by-wire term), and flight control computers determine how to move the actuators at each control surface to provide the ordered response. The fly-by-wire system also allows automatic signals sent by the aircraft's computers to perform functions without the pilot's input, as in systems that automatically help stabilize the aircraft.[1] Contents Green colored flight control wiring of a test aircraft 1 Development 1.1 Basic operation 1.1.1 Command 1.1.2 Automatic Stability Systems 1.2 Safety and redundancy 1.3 Weight saving 1.4 History 2 Analog systems 3 Digital systems 3.1 Applications 3.2 Legislation 3.3 Redundancy 3.4 Airbus/Boeing 4 Engine digital control 5 Further developments 5.1 Fly-by-optics 5.2 Power-by-wire 5.3 Fly-by-wireless 5.4 Intelligent Flight Control System 6 See also 7 References 8 External links Development http://en.wikipedia.org/wiki/Fly-by-wire Page 1 of 9 Fly-by-wire - Wikipedia, the free encyclopedia 11-8-20 下午5:33 Mechanical and hydro-mechanical flight control systems are relatively heavy and require careful routing of flight control cables through the aircraft by systems of pulleys, cranks, tension cables and hydraulic pipes. -

Glider Handbook, Chapter 2: Components and Systems

Chapter 2 Components and Systems Introduction Although gliders come in an array of shapes and sizes, the basic design features of most gliders are fundamentally the same. All gliders conform to the aerodynamic principles that make flight possible. When air flows over the wings of a glider, the wings produce a force called lift that allows the aircraft to stay aloft. Glider wings are designed to produce maximum lift with minimum drag. 2-1 Glider Design With each generation of new materials and development and improvements in aerodynamics, the performance of gliders The earlier gliders were made mainly of wood with metal has increased. One measure of performance is glide ratio. A fastenings, stays, and control cables. Subsequent designs glide ratio of 30:1 means that in smooth air a glider can travel led to a fuselage made of fabric-covered steel tubing forward 30 feet while only losing 1 foot of altitude. Glide glued to wood and fabric wings for lightness and strength. ratio is discussed further in Chapter 5, Glider Performance. New materials, such as carbon fiber, fiberglass, glass reinforced plastic (GRP), and Kevlar® are now being used Due to the critical role that aerodynamic efficiency plays in to developed stronger and lighter gliders. Modern gliders the performance of a glider, gliders often have aerodynamic are usually designed by computer-aided software to increase features seldom found in other aircraft. The wings of a modern performance. The first glider to use fiberglass extensively racing glider have a specially designed low-drag laminar flow was the Akaflieg Stuttgart FS-24 Phönix, which first flew airfoil. -

CRUISE FLIGHT OPTIMIZATION of a COMMERCIAL AIRCRAFT with WINDS a Thesis Presented To

CRUISE FLIGHT OPTIMIZATION OF A COMMERCIAL AIRCRAFT WITH WINDS _______________________________________ A Thesis presented to the Faculty of the Graduate School at the University of Missouri-Columbia _______________________________________________________ In Partial Fulfillment of the Requirements for the Degree Master of Science _____________________________________________________ by STEPHEN ANSBERRY Dr. Craig Kluever, Thesis Supervisor MAY 2015 The undersigned, appointed by the dean of the Graduate School, have examined the thesis entitled CRUISE FLIGHT OPTMIZATION OF A COMMERCIAL AIRCRAFT WITH WINDS presented by Stephen Ansberry, a candidate for the degree of Master of Science, and hereby certify that, in their opinion, it is worthy of acceptance. Professor Craig Kluever Professor Roger Fales Professor Carmen Chicone ACKNOWLEDGEMENTS I would like to thank Dr. Kluever for his help and guidance through this thesis. I would like to thank my other panel professors, Dr. Chicone and Dr. Fales for their support. I would also like to thank Steve Nagel for his assistance with the engine theory and Tyler Shinn for his assistance with the computer program. ii TABLE OF CONTENTS ACKNOWLEDGEMENTS………………………………...………………………………………………ii LIST OF FIGURES………………………………………………………………………………………..iv LIST OF TABLES…………………………………………………………………………………….……v SYMBOLS....................................................................................................................................................vi ABSTRACT……………………………………………………………………………………………...viii 1. INTRODUCTION.....................................................................................................................................1