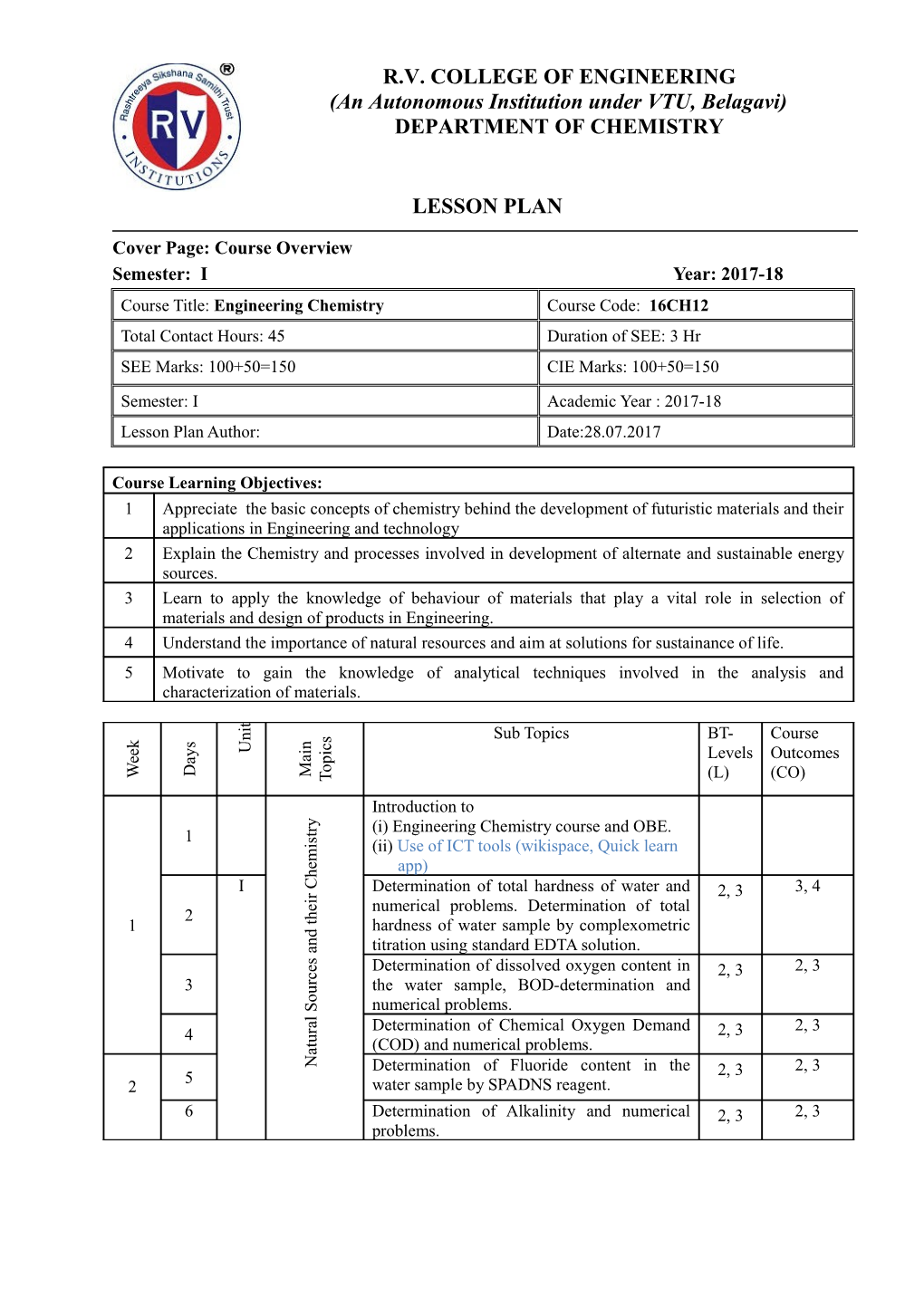

R.V. COLLEGE OF ENGINEERING (An Autonomous Institution under VTU, Belagavi) DEPARTMENT OF CHEMISTRY

LESSON PLAN

Cover Page: Course Overview Semester: I Year: 2017-18 Course Title: Engineering Chemistry Course Code: 16CH12 Total Contact Hours: 45 Duration of SEE: 3 Hr SEE Marks: 100+50=150 CIE Marks: 100+50=150

Semester: I Academic Year : 2017-18 Lesson Plan Author: Date:28.07.2017

Course Learning Objectives: 1 Appreciate the basic concepts of chemistry behind the development of futuristic materials and their applications in Engineering and technology 2 Explain the Chemistry and processes involved in development of alternate and sustainable energy sources. 3 Learn to apply the knowledge of behaviour of materials that play a vital role in selection of materials and design of products in Engineering. 4 Understand the importance of natural resources and aim at solutions for sustainance of life. 5 Motivate to gain the knowledge of analytical techniques involved in the analysis and characterization of materials. t i

n Sub Topics BT- Course s s k n c U i i e y Levels Outcomes a e p a o D M W (L) (CO) T Introduction to y

r (i) Engineering Chemistry course and OBE. t

1 s i (ii) Use of ICT tools (wikispace, Quick learn m

e app) h C

I Determination of total hardness of water and 3, 4

r 2, 3 i

e numerical problems. Determination of total

2 h t 1 hardness of water sample by complexometric d n

a titration using standard EDTA solution.

s

e Determination of dissolved oxygen content in 2, 3 2, 3 c r

3 u the water sample, BOD-determination and o

S numerical problems.

l

a Determination of Chemical Oxygen Demand 2, 3 r 2, 3

4 u t (COD) and numerical problems. a

N Determination of Fluoride content in the 2, 3 5 2, 3 2 water sample by SPADNS reagent. 6 Determination of Alkalinity and numerical 2, 3 2, 3 problems. y r

t Purification of Water- Desalination of water 3, 4 s 3, 4 s e i

c by Reverse Osmosis. Membrane technology: r m u e

o Use of polysulfone and polyurethane h S C

7 l membranes for desalination process. r a i r e u h t t a

d N n a Introduction, Definition, classification and 1, 2 1, 2 importance of hydrocarbons as fuel, Calorific s

8 l Value - Gross calorific value (GCV) and Net e

u calorific value (NCV), Units. Numerical F

l problems. a c i Determination of calorific value of a 2, 3 2, 3 9 m e solid/liquid fuel using Bomb calorimeter h

C Bomb calorimeter numerical problems, 4 2, 3, 4 10 Alternate liquid Fuels - Biodiesel, Power Alcohol. s l

e Knocking - Meaning, reasons for Knocking 1, 2 1, 2 u

F and its prevention methods - Unleaded Petrol.

l

a Octane number, Cetane number. c i Revision of Unit-1 through wikispace and 3 m 11 e h videos (ICT Tools) C

Introduction, Electrode Potential – Origin of 1, 2 2, 3 12 II s Single Electrode Potential, Galvanic Cell - m e t Signs & Conventions. s y

13 s Nernst Equation and numerical problems. 3 3

y

g Nernst equation-Derivation, problems and 5 2, 3 r

e H

14 n applications in Potentiometric Titrations, P e

l determination. a c i

4 m Types of Electrodes - Metal-Metal-ion, Metal- 2, 3 1 e

15 h gas, metal insoluble salt, Redox electrode, Ion c o

r selective electrode t c

e Construction and Working of Calomel 3 2 l

16 E electrode and Glass electrode. Determination of pH using Glass electrode 3, 4 3 17 5 and numerical Problems. Nerve conduction - application of 4, 5 3 electrochemistry in biological systems. 18 Battery Technology – Characteristics and Classification – primary, secondary and Reserve batteries. 3 2, 3 Construction and Working of Lithium LiCoO2 19 batteries. Fuel cells– Classification based on electrolyte. 20 Construction and working of Methanol- 3 2, 3 Oxygen fuel cell. Revision of Unit-II. Revision of Unit-2 through wikispace and videos (ICT Tools) 7 6 8 30 29 28 27 26 25 24 23 22 21 III

Electrochemical Electroless plating Electroplating Corrosion Control Corrosion Science energy systems eiin o nt3 truh wksae and wikispace (ICTvideos Tools). through Unit-3 of Cu- Revision of plating. plating electroless Electroless FabricationPCB of and Application: plating electro between Distinction Principle, Introduction, influencing nature Plating. Chromeof deposition, Factors Principle, Introduction, and cathodiccoating, Technological coating-Introduction-anodic importance. Metallic and Enamels, Paints, Lacquers. coating- Organic coating-Phosphating, Anodising conversion Chemical conversion coating. Metallic and Chemical coating organic coating, techniques: Coating corrosion: of cathodicareas. rate & anodic Relative the Polarization, Temperature, affecting the Factors of pH product, medium, corrosion metals, embrittlement. of Caustic nature - corrosion of rate the affecting Factors corrosion- and Stress corrosion corrosion- Pitting Water corrosion. line Differential of corrosion, Corrosion, aeration Types Metal Differential Series, Galvanic with corrosion respecttoFe. of theory Electrochemical Wet & Corrosion. of Effect corrosion examples, with corrosion Dry types, Introduction, nano materials,nano and materials, micro bulk. nano cluster,dimensional –Atom, materials Nanomaterials/Science/Technology, Defining Introduction to 1,2,3 2,3 2,3 2,3 1,2 1,2 2,3 1,2 4 4 1, 1, 2, 4 2, 3, 4 1, 1, 3 1, 2 1, 2 1, 1, 2 1, 2 2 2 3 10 11 9 43 42 41 40 39 38 37 36 35 34 33 32 31 IV V

Polymeric materials Nanomaterials Chemistry Nanomaterials Chemistry ls rniin temperature-meaning, transition significance and factors affectingit. of Glass Methods Emulsion. polymer, and suspension bulk, Polymerisation-solution, to Introduction materialsPolymeric of working and wikispace (ICTvideos Tools) through Unit-4 of and Introduction, Revision LED: inorganic/organicwithnanomaterials. LED for Construction Nanomaterials Optical cells, nano size examples. with above with Modulation gap electrochemical Band properties, Photo conversion like Energy TiO nanostructure for Semiconductor devices: Preparation, materials Nano Introduction, properties applications. and Graphene: properties applications. and different functionalization, preparation, Introduction, doping, forms, nanotubes: Carbon nanoparticles, Nano Carbon materials. TiO for Sol-Gel- Nanomaterials: of Synthesis metal oxide. for SCS Magnetic, Nanomaterials: of Synthesis Optical, area, Electrical. etcMechanical Surface bulk: to comparison in Nanomaterials of Properties plctos o idgaal oyes in industry.medical polymers biodegradable of Applications andacidPoly poly caprolactum.lactic and of synthesis and Properties requirements. their Introduction polymers: Biodegradable and properties applications. preparation, formaldehyde phenol resin, Epoxy polymers: Thermosetting of Synthesis inindustries. polymers: Polycarbonate plastic Thermo 2 , CdSe for , CdSe photovoltaics. , ABS and specific applications specific and ABS ,

2 2,3,4 4,5 2,3 2,3 1,2 2,3 3,4 2,3 1,2 4 4 4 4 4 2, 2, 3, 4 2, 3, 4 2, 2, 3 3, 4 3, 4 2, 4 2, 2, 3 2, 3 1, 2 1, 2 1, 2 3 3 3 Smart Polymeric materials 3,4 1, 2 Conducting polymers: Introduction, 44 requirements for conducting polymers, mechanism of conduction, synthesis of poly aniline and Polypyrrole. 3 2, 3 45 Use of conducting polymers in energy harvesting, sensing and defence applications. Photo conducting polymers: Synthesis of poly 3,4 3 12 46 vinyl carbazole applications of photo- conducting polymers in printing. Synthetic Fibres: Synthesis of carbon fibre 2,3,4 2, 3 from PAN, applications of carbon fibre in 47 polymer composites. Revision of Unit-5 through wikispace and videos (ICT Tools) PRACTICALS Volumetric Analysis and Preparations 1. Determination of hardness of water sample. 2. Determination of calcium oxide in the given sample of cement solution (Rapid EDTA method) 3. Estimation of percentage of copper in brass. 4. Estimation of iron in the given sample of haematite ore. 5. Determination of Chemical Oxygen Demand (COD) of the given industrial waste water sample. 6. Determination of Dissolved Oxygen in the given water sample by Winkler’s method. 7. Preparation of polystyrene by bulk polymerization method. 8. Preparation of MgO by solution combustion method. Instrumental methods of Analysis 1. Determination of pKa of a weak acid using pH meter.

2. Potentiometric titration – Estimation of FAS using standard K2Cr2O7 solution. 3. Colorimetric estimation of copper. 4. Conductometric estimation of HCl using standard NaOH solution. 5. Determination of viscosity coefficient of a given liquid using Ostwald’s viscometer (density of the liquid to be given). 6. Flame photometric estimation of sodium in the given solution. 7. Determination of relative and kinematic viscosities of given lubricating oil at different temperatures using Redwood Viscometer.

8. Determination of Tg of polymer using DSC.

Expected Course Outcomes: After completing the course, the students will be able to 1 Explain the principles of chemistry in engineering. (L1)

2 Applying the knowledge of Chemistry in solving societal problems related to public health safety and environmental issues (L2, L3) 3 Identify, analyze and interpret Engineering problems associated with chemistry to achieve solutions. (L3,L4) 4 Develop solutions for problems associated with water, fuel, corrosion, battery, nano material and polymer technologies. (L4) Text Books 1 R V Gadag and A Nityananda Shetty, “Engineering Chemistry”, I K Internation publishing house, Second Edition. ISBN- 9380578598, 9789380578590 2 Jain & Jain, “Engineering Chemistry”, Dhanpat Rai Publishing Company, 15th Edition -2007. ISBN: 13:9788-19041-0861. 3. Satyanarayana S and H C Shashidhara, Engineering Chemistry” Himalaya Publishing house” Edition- 2011, ISBN-9789350514986. Reference Book 1 Shubha Ramesh et.al., “Engineering Chemistry”, Wiley India, 1st Edition, 2011, ISBN: 978-81-265- 1988-0. Wikispace link http://engineeringchemistryrvce.wikispaces.com Quiklrn-app (details will be given) CO-PO Mapping CO/PO PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 CO1 3 CO2 3 2 2 1 CO3 3 2 2 CO4 3 1 1 2 High-3: Medium-2: Low-1

Achievable Matrix (To set up question paper as per BT level and portion distribution)

Table 2 Portion CO1 % CO2 % CO3 % CO4 % Total CO1 CO2 CO3 CO4 Coverage Marks Marks Marks Marks Marks

Target 22.23 28.89 32.23 16.67 Actual Quiz 7.41 9.63 10.74 5.56 Test 14.82 19.26 21.49 11.11 Q1=Q2=Q3 2.47 3.21 3.58 1.85 T1=T2 7.41 9.63 10.74 5.56 Quiz1 unit 1 2.47 3.21 3.58 1.85 10 2.3 2.9 3.3 1.7 Quiz2 unit 2b + unit 3 2.47 3.21 3.58 1.85 10 2.3 2.9 3.3 1.7 Quiz3 unit 4 + unit 5 2.47 3.21 3.58 1.85 10 2.3 2.9 3.3 1.7 Test 1 unit 1 + unit 2a 7.41 9.63 10.74 5.56 50 11.2 14.5 16.2 8.4 Test 2 unit 2b + unit 3 7.41 9.63 10.74 5.56 50 11.2 14.5 16.2 8.4 Compensatory 100% 14.82 19.26 21.49 11.11 50 11.2 14.5 16.2 8.4

Test Probable date Remark Quiz-1 21-8-2017 to 26-8-2017 e

Test-1 4-9-2017 to 6-9-2017 g e l Quiz-2 3-10-2017 to 10-10-2017 l o c Test-2 23-10-2017 to 25-10-2017 y b

Quiz-3 30-10-2017 to 3-11-2017 n

Compensatory 7-11-2017 to 9-11-2017 e v i g

Course end Survey 13-11-2017 to 17-11-2017 e Finalization of CIE 17-11-2017 l b a t

Last working day 17-11-2017 e m i t

o t

g n i d r o c c A