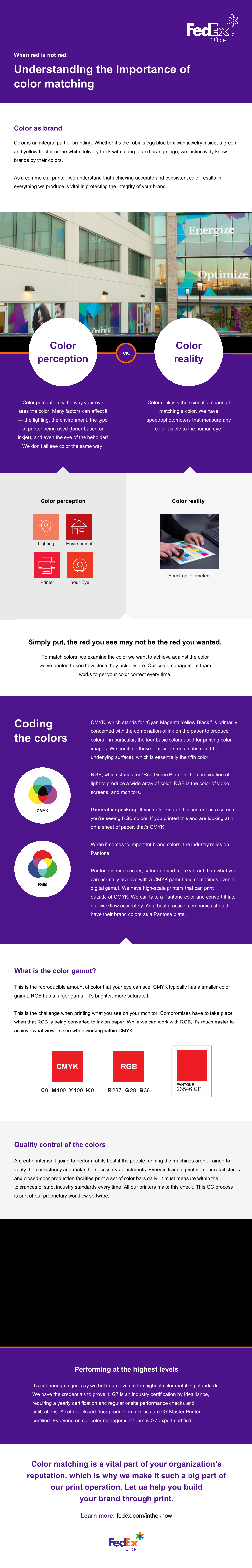

Understanding the Importance of Color Matching Coding the Colors

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Color Conversion Chart

Color Conversion Chart CMYK & RGB COLOR VALUES Opalescent C-M-Y-K R-G-B Opalescent C-M-Y-K R-G-B 000009 Reactive Cloud 4-2-1-0 241-243-247 000164 Egyptian Blue 81-48-0-0 49-116-184 000013 Opaque White 4-2-2-1 246-247-249 000203 Woodland Brown 22-63-87-49 120-70-29 000016 Turquoise Opaque Rod 65-4-27-6 75-174-179 000206 Elephant Gray 35-30-32-18 150-145-142 000024 Tomato Red 1-99-81-16 198-15-36 000207 Celadon Green 43-14-46-13 141-167-137 000025 Tangerine Orange 1-63-100-0 240-119-2 000208 Dusty Blue 60-25-9-28 83-123-154 000034 Light Peach Cream 5-12-15-0 243-226-213 000212 Olive Green 44-4-91-40 104-133-42 000100 Black 75-66-60-91 10-9-10 000216 Light Cyan 62-4-9-0 88-190-221 000101 Stiff Black 75-66-60-91 10-9-10 000217 Green Gold Stringer 11-6-83-13 206-194-55 000102 Blue Black 76-69-64-85 6-7-13 000220 Sunflower Yellow 5-33-99-1 240-174-0 000104 Glacier Blue 38-3-5-0 162-211-235 000221 Citronelle 35-15-95-1 179-184-43 000108 Powder Blue 41-15-11-3 153-186-207 000222 Avocado Green 57-24-100-2 125-155-48 000112 Mint Green 43-2-49-2 155-201-152 000224 Deep Red 16-99-73-38 140-24-38 000113 White 5-2-5-0 244-245-241 000225 Pimento Red 1-100-99-11 208-10-13 000114 Cobalt Blue 86-61-0-0 43-96-170 000227 Golden Green 2-24-97-34 177-141-0 000116 Turquoise Blue 56-0-21-1 109-197-203 000236 Slate Gray 57-47-38-40 86-88-97 000117 Mineral Green 62-9-64-27 80-139-96 000241 Moss Green 66-45-98-40 73-84-36 000118 Periwinkle 66-46-1-0 102-127-188 000243 Translucent White 5-4-4-1 241-240-240 000119 Mink 37-44-37-28 132-113-113 000301 Pink 13-75-22-10 -

Qualatex Rainbow and Custom Colors

Rainbow of Colors Diamond White Pearl Gray Silver Pearl Ivory Pearl Yellow Citrine Pearl Clear White Ivory Silk Lemon Chion Yellow Citrine Yellow Goldenrod Gold Blush Neon Mocha Chocolate Pearl Rose Coral Orange Mandarin Orange Brown Brown Peach Gold Orange Pearl Mandarin Pearl Pink Neon Neon Rose Wild Pearl Jewel Red Ruby Red Orange Pink Pink Magenta Berry Magenta Magenta Pearl Maroon Sparkling Pearl Pearl Neon Spring Purple Quartz Pearl Pearl Ruby Red Burgundy Burgundy Lavender Violet Lilac Violet Purple Quartz Purple Light Blue Pearl Pale Neon Robin’s Periwinkle Dark Sapphire Pearl Pearl Navy Caribbean Azure Blue Blue Egg Blue Blue Blue Sapphire Blue Midnight Blue Blue Tropical Jewel Pearl Pearl Neon Wintergreen Lime Jewel Pearl Lime Spring Green Teal Teal Teal Mint Green Green Green Lime Green Green C h r o m e B all o on s Emerald Pearl Pearl Pearl Onyx Black Chrome Chrome Chrome Chrome Chrome Chrome Green Emerald Green Forest Green Onyx Black Silver Gold Mauve Purple Blue Green S u p e r A g a t e Traditional Fashion Red & Black & Yellow Orange Pink Violet Red Orange Blue Green White White Rainbow Rainbow Rainbow Rainbow Rainbow LEGEND Custom Colors Outside Balloon ® Inside Balloon Use the extensive Qualatex Rainbow of Colors as a palette from which to create custom colors by “layering” p two different balloons. This “double-stuffing” technique yields an unlimited number of unique colors and finishes. Custom Balloon Pearl White White Pearl Citrine Yellow Pearl White Gold Pearl Ivory Pearl Peach Ivory Silk Pearl Peach Mandarin Orange -

Color Select Color Select

control COLOR SELECT RGB In Line Controller LCS SPECIFICATIONS Voltage 5~24VDC Peak Output Power 144W@12V | 288W@24V COLOR SELECT Peak Output Current 3x4 Amps IlluminFx’s LCS Color Select controller is a simple and PWM Control 256 levels compact RGB color changing solution for almost any LED Working Temp -30°C~70°C system. Both the wireless and wired versions come with Components SMD parts | Gold plated double sided presets including 19 dynamic modes and 20 static colors. You FR-4 PCB can easily change the mode, speed, color and brightness. Certifications RoHS Both include an auto memorize function that will hold your last Power Connector Red/Black cable setting in memory for when you re-activate the system. LED Connector 4-Color Flat Cable LCS–1 : In Line LCS–1RF : Wireless Body Size 1.3” x 0.5” x 0.2” Body Size 1.3” x 0.5” x 0.2” Cable Length 4.33” Cable Length 4.33” Weight .233 ounces Weight .233 ounces Dynamic Modes 19 Dynamic Modes 19 Dynamic Speed 10 levels Dynamic Speeds 10 levels Static Color 20 Static Color 20 Color Brightness 5 levels Color Brightness 10 levels Remote Weight .7 ounces Remote Frequency 433.92 MHz Remote Battery CR2025 3V Remote Distance > 15 metes color select LCS 2013 | 2013 illuminFx illuminFx reserves the right to make changes illuminfx to specifications at any time with or without notice www.illuminfx.com | 585 - 254 - 8010 DYNAMIC MODES — LCS–1 DYNAMIC MODES — LCS–1RF Name Description Name Description Slow fade between cyan, white, blue, magenta, red, Slow fade between cyan, white, blue, magenta, red, 7 -

PROCION MX Technical Info. Chart PROCION MX COLOR INFO a Cold Water Fiber Reactive Dye

PROCION MX Technical Info. Chart PROCION MX COLOR INFO A cold water fiber reactive dye. Use it for immersion dyeing, tie dye, batik, airbrush, garment dyeing, screen printing, spatter painting, gradation dyeing and more. Procion MX fiber reactive dye will dye all cellulose (plant) fibers and some protein (animal) fibers. Common cellulose fibers are cotton, linen, jute, ramie, sisal, and rayon. There are 12 standardized colors (in bold below) in the Procion MX line. All other colors, no matter the manufacturer, are mixed formulas of two or more of these standardized colors. We offer these colors for your convenience, but the ultimate dyer needs only to stock the standardized colors. Item # Color Name Trade C.I. # Solubility Wash Light Dis- Name gm/l @ Fastness Fastness charg- ability 120F/50C 1-5 1-7 PMX 004 Lemon Yellow MX-8G Yellow 86 120 g/l 5 5 to 7 Good PMX 010 Bright Golden MX-3RA -- Yellow PMX 011 Antique Gold -- PMX 016 Rust Orange MX-GRN -- PMX 020 Brilliant Or- MX-2R -- ange PMX 028 Bright Scarlet MX-BA -- 130 g/l 5 3 to 5 Minor PMX 030 Fire Engine Red MX-BRA -- PMX 032 Carmine Red MX-BA -- PMX 034 Magenta MX-5B Red 5 40 g/l 5 3 to 5 Moder- ate PMX 035 Hot Pink Red 5 40 g/l 5 3 to 5 Moderate PMX 040 Fuchsia MX-8B Red 11 70 g/l 5 3 to 6 Minor PMX 042 Raspberry -- PMX 050 Deep Purple -- PMX 058 Marine Violet -- PMX 068 Turquoise MX-G Turquoise 115 g/l 4 to 5 4 to 6 Minor 140 PMX 069 Aquamarine -- PMX 070 Cerulean MX-G Blue 163 120 g/l 5 5 to 7 Moder- ate PMX 071 Teal -- PMX 072 Medium Blue MX-R Blue 4 55 g/l 5 6 to 7 Minor PMX 076 Cobalt Blue MX2G-150 -- PMX 078 Navy MX-4RD -- PMX 079 Midnight Blue -- Jacquard Products | Rupert, Gibbon & Spider, Inc. -

![Jacquard Procion Upcs [Pdf]](https://docslib.b-cdn.net/cover/1113/jacquard-procion-upcs-pdf-6261113.webp)

Jacquard Procion Upcs [Pdf]

Title Brand Color Part # UPC Procion 2/3oz #004 Lemon Yellow Jacquard Lemon Yellow PMX1004 743772100409 Procion 2/3oz #010 Golden Yellow Jacquard Golden Yellow PMX1010 743772101000 Procion 2/3oz #011 Antique Gold Jacquard Antique Gold PMX1011 743772101116 Procion 2/3oz #016 Rust Orange Jacquard Rust Orange PMX1016 743772101604 Procion 2/3oz #020 Brilliant Orange Jacquard Brilliant Orange PMX1020 743772102007 Procion 2/3oz #028 Bright Scarlet Jacquard Bright Scarlet PMX1028 743772102809 Procion 2/3oz #030 Fire Engine Red Jacquard Fire Engine Red PMX1030 743772103004 Procion 2/3oz #032 Carmine Red Jacquard Carmine Red PMX1032 743772103202 Procion 2/3oz #034 Magenta Jacquard Magenta PMX1034 743772103400 Procion 2/3oz #035 Hot Pink Jacquard Hot Pink PMX1035 743772103509 Procion 2/3oz #040 Fuchsia Jacquard Fuchsia PMX1040 743772104001 Procion 2/3oz #042 Raspberry Jacquard Raspberry PMX1042 743772104209 Procion 2/3oz #050 Deep Purple Jacquard Deep Purple PMX1050 743772105008 Procion 2/3oz #058 Marine Violet Jacquard Marine Violet PMX1058 743772105800 Procion 2/3oz #068 Turquoise Jacquard Turquoise PMX1068 743772106807 Procion 2/3oz #069 Aqua Marine Jacquard Aqua Marine PMX1069 743772106906 Procion 2/3oz #070 Cerulean Blue Jacquard Cerulean Blue PMX1070 743772107002 Procion 2/3oz #071 Teal Jacquard Teal PMX1071 743772107101 Procion 2/3oz #072 Med. Blue Jacquard Med. Blue PMX1072 743772107200 Procion 2/3oz #076 Cobalt Blue Jacquard Cobalt Blue PMX1076 743772107606 Procion 2/3oz #078 Navy Jacquard Navy PMX1078 743772107804 Procion 2/3oz #079 Midnight -

Reactive Potential of Bullseye Glass

Reactive Potential of Bullseye Glass Combinations with Reactive Potential COPPER COPPER LEAD REACTIVE SULFUR/SELENIUM SULFUR/SELENIUM Glasses in the top row may react with glasses + + + + + + in the bottom row. Note: Many glasses can be SULFUR/SELENIUM REACTIVE SULFUR/SELENIUM COPPER COPPER LEAD stained or even react when fired with silver. LEAD-BEARING COPPER-BEARING SULFUR/SELENIUM-BEARING This category of glasses will also react with silver. 000243 Translucent White Opal 000104 GlACIER BLUE OPAL 000024 Tomato Red Opal 001137 Medium Amber 000301 Pink Opal 000116 Turquoise Blue Opal 000025 Tangerine Orange Opal 001138 DARK AMBER 000303 Dusty Lilac Opal 000144 Teal Green Opal 000120 Canary Yellow Opal 001207 Fern Green 000305 Salmon Pink Opal 000145 Jade Green Opal 000124 Red Opal 001241 Pine Green 000313 Dense White Opal 000146 Steel Blue Opal 000125 Orange Opal 001320 Marigold Yellow 000334 Gold Purple Opal 000161 ROBIN'S EGG BLUE OPAL 000126 Spring Green Opal 001321 Carnelian 001205 Light Coral 000164 Egyptian Blue Opal 000137 French Vanilla Opal 001322 Garnet Red 001215 Light Pink 000216 Light Cyan Opal 000203 Woodland Brown Opal 001422 LEMON LIME GREEN 001234 Violet 000345 STEEL JADE OPAL 000220 Sunflower Yellow Opal 001437 Light Amber 001305 Sunset Coral 001116 Turquoise Blue 000221 CITRONELLE OPAL 001838 Dark Amber Tint 001311 Cranberry Pink 001145 Kelly Green 000222 AVOCADO GREEN OPAL 001857 red amber tint 001332 FuCHSia 001164 caribbean blue 000224 Deep Red Opal 001334 Gold Purple 001217 LEAF GREEN 000225 Pimento Red Opal 001823 Burnt Scarlet Tint 001226 LILY PAD GREEN 000227 Golden Green Opal ALCHEMY SERIES 001824 Ruby Red Tint 001408 Light Aquamarine 000309 Cinnabar Opal Reacts with silver (foil, wire). -

Color Select Color Select Cs

control COLOR SELECT RGB Controller CS SPECIFICATIONS Voltage 5~24VDC Peak Output Power 144W@12V | 288W@24V COLOR SELECT Peak Output Current 3x4 Amps IlluminFx’s CS Color Select controller is a simple and compact PWM Control 256 levels RGB color changing solution for almost any LED system. Working Temp -22°~176°F Both the wireless and wired versions come with presets Components SMD parts | Gold plated double sided FR-4 including dynamic modes and static colors. You can easily PCB change the mode, speed, color and brightness. Both include Certifications RoHS an auto memorize function that will hold your last setting in Power Connector Red/Black cable memory for when you re-activate the system. The CS200 inline LED Connector 4-Color Flat Cable controller component is also IP67 rated for easier installation. CS–1 : In Line CS200 : Wireless Body Size 1.3” x 0.5” x 0.2” Body Size 3.5” x 1” x 0.375” Cable Length 4.33” Cable Length 4.33” Weight .233 ounces Weight .233 ounces Dynamic Modes 19 Dynamic Modes 42 Dynamic Speed 10 levels Dynamic Speeds 10 levels Static Color 20 Static Color 30 Color Brightness 5 levels Color Brightness 10 levels Remote Weight .7 ounces Remote Frequency 433.92 MHz Remote Battery CR2025 3V Remote Distance > 15 metes illuminFx reserves the right to make changes 8 illuminfx to specifications at any time with or without notice DYNAMIC MODES — CS–1 Name Description 1 7 Color Slow Fade Slow fade between cyan, white, blue, magenta, red, yellow, and green 2 Blue Fade Slow blue brightness fade 3 Cyan Fade Slow cyan brightness -

Egg-Celent Activity Book

Egg-celent Activity Book #bringingthezootoyou fresnochaffeezoo.org Bunny Craft Supplies • Toilet paper roll • Glue • Scissors • Black marker • Pink, white, and orange paper Steps 1. Gather your supplies 6. Add eyes and a triangular nose 2. Cut pink paper and glue it to the toilet paper roll 7. Draw a mouth and whiskers 3. Cut out the ears 8. Cut out the feet 4. Glue the ears together 9. Glue the feet together 5. Glue the ears onto the bunny 10. Glue feet to the bottom of your bunny 1 4 7 10 2 5 8 3 6 9 Dino Coloring Page Dinosaurs may be egg-stinct but there is still a lot to learn about them! Paleontologists have learned the size and shape of dinosaur eggs by studying fossils, but just like the dinosaurs themselves, we do not know what colors or patterns their eggs may have been. Decorate your dinosaur egg. Fun Fact: Fossils show us that dinosaurs laid between 3 and 20 eggs at a time. Decorate more eggs to create a whole dino nest! Bunny Mask Supplies • Paper plate • Craft stick • Glue • Scissors • Pink, white, and orange paper Steps 1. Gather your supplies 6. Glue the white heart to your paper plate and glue the pink heart 2. Cut paper plate in half and cut out the eyes on top of the white heart 3. Cut out the ears 7. Cut out six whiskers 4. Glue the ears onto the paper plate 8. Glue two sets of three together 5. Cut out hearts 1 4 7 2 5 8 3 6 Egg-celent Animal Facts Did you know that not all egg-producing animals actually lay their eggs? There are two dierent types of ‘egg-laying’. -

Crayola Crayon Color History

CRAYOLA CRAYON COLOR HISTORY Colors Available Beginning 1903 Number of colors: 8 Black Brown Orange Violet Blue Green Red Yellow Colors Available 1949 - 1957 Number of Colors: 48 Apricot Gold Orange Silver Bittersweet Gray Orange Red Spring Green Black Green Orange Yellow Tan Blue Green Blue Orchid Thistle Blue Green Green Yellow Periwinkle Turquoise Blue Blue Violet Lemon Yellow Pine Green Violet (Purple) Brick Red Magenta Prussian Blue* Violet Blue Brown Mahogany Red Violet Red Burnt Sienna Maize Red Orange White Carnation Pink Maroon Red Violet Yellow Cornflower Melon Salmon Yellow Green Flesh** Olive Green Sea Green Yellow Orange Colors Available 1958-1971 Number of Colors: 64 All colors previously listed plus the following colors added in 1958. Aquamarine Copper Lavender Raw Sienna Blue Gray Forest Green Mulberry Raw Umber Burnt Orange Goldenrod Navy blue Sepia Cadet Blue Indian Red*** Plum Sky Blue Colors Available 1972-1989 Number of Colors: 72 All colors previously listed plus the following fluorescent colors added in 1972. Atomic Tangerine Hot Magenta Outrageous Orange Shocking Pink Blizzard Blue Laser Lemon Screamin’ Green Wild Watermelon *Name changed to “midnight blue” in 1958 in response to teachers’ requests. **Name voluntarily changed to “peach” in 1962, partially as a result of the U. S. Civil Rights Movement. Colors Available 1990-1992 All Colors previously listed plus the following fluorescent colors added in 1990. Electric Lime Purple Pizzazz Razzle Dazzle Rose Unmellow Yellow Magic Mint Radical Red Sunglow Neon Carrot In 1990, eight colors were retired and replaced by eight new shades. Retired Colors Replacement Colors Green Blue Cerulean Orange Red Vivid Tangerine Orange Yellow Jungle Green Violet Blue Fuchsia Maize Dandelion Lemon Yellow Teal Blue Blue Gray Royal Purple Raw Umber Wild Strawberry Retired colors were enshrined in the Crayola Hall of Fame on August 7, 1990. -

KOHLER Blueberry New Orleans Blue Cerulean Blue Navy Heron Blue

Remee Expresso Fawn Beige Moka Peach Blow American Brown Antique Bone Industry colors Suez Tan Bali Jasmin Yellow available in solid, Taupe Maple Cream Twilight Blue marble, and onyx Terra Nueva Candle Light Platinum Grey products. Tiger Lilly Manchu Yellow Sea Spray Green Harvest Gold Harvest Gold BRIGGS KOHLER Sunflower Saffron Yellow Venetian Pink Blueberry French Vanilla Regency Blue Suez Tan New Orleans Blue Lemon Yellow Dresden Blue Sky Blue Cerulean Blue Lemon Twist Colonial Blue FERRO Navy ELJER Sorrento Blue Carnation Red Heron Blue Natural Dark Turquoise Rose Pink Teal Island Sea Aquamarine Chestnut Brown Vermont Blue Almond Sterling Silver Hucon Cobalt Blue Misty Rose Bayberry Avacado Country Grey Blossom Pink Aegean Mist Thunder Grey Peach Bisque Willow Mist Tender Grey Dusty Rose Tahiti Sand Ice Grey Ruby Honeydew Dry pigments Fresh Green Beige Ming Green available in marble and Avocado Tuscan Tan Rainforest onyx products. Evergreen Cocoa Light Turquoise Aspen Green Sandlewood Light Mink Dark Almond Seafoam Green Desert Gold Dark Mink Slate Grey Chamois Daffodil Loganberry Peach Timberline Creamy Yellow Rhapsody Blue Eggshell Almond Beige Twilight Blue Warm White Antique White Platinum Denim Blue Skylight Warm White Black Black Glacier Blue UNIVERSAL Bone Parchment Dark Raspberry Royal Blue RUNDLE Cream Parchment Platinum Creme Adobe Almond Classic Grey Doeskin Tuscan Tan Innocent Blush Frost Green Mushroom Ferro Bone Jersey Cream Sea Mist Green Eggshell Custom Bone Zinfandel Verde Black Verde Rose dawn Peach Bisquit Zinfandel -

Safety Data Sheet

SAFETY DATA SHEET Date of issue/Date of revision 22 September 2015 Version 6 Section 1. Identification Product name : ROBIN EGG BLUE Product code : 151L Other means of : Not available. identification Product type : Liquid. Relevant identified uses of the substance or mixture and uses advised against Product use : Industrial applications. Use of the substance/ : Coating. Paints. Painting-related materials. mixture Uses advised against : Not applicable. Supplier : PPG Industries, Inc. One PPG Place, Pittsburgh, PA 15272 Emergency telephone : (412) 434-4515 (U.S.) number (514) 645-1320 (Canada) 01-800-00-21-400 (Mexico) Technical Phone Number : 1-800-647-6050 Section 2. Hazards identification OSHA/HCS status : This material is considered hazardous by the OSHA Hazard Communication Standard (29 CFR 1910.1200). Classification of the : FLAMMABLE LIQUIDS - Category 3 substance or mixture SERIOUS EYE DAMAGE/ EYE IRRITATION - Category 2A CARCINOGENICITY - Category 2 TOXIC TO REPRODUCTION (Fertility) - Category 2 TOXIC TO REPRODUCTION (Unborn child) - Category 2 SPECIFIC TARGET ORGAN TOXICITY (REPEATED EXPOSURE) (central nervous system (CNS)) - Category 1 Percentage of the mixture consisting of ingredient(s) of unknown toxicity: 36.6% GHS label elements United States Page: 1/16 Product code 151L Date of issue 22 September 2015Version 6 Product name ROBIN EGG BLUE Section 2. Hazards identification Hazard pictograms : Signal word : Danger Hazard statements : Flammable liquid and vapor. Causes serious eye irritation. Suspected of damaging fertility or the unborn child. Suspected of causing cancer. Causes damage to organs through prolonged or repeated exposure. (central nervous system (CNS)) Precautionary statements Prevention : Obtain special instructions before use. Do not handle until all safety precautions have been read and understood. -

358 Color Chart

BV V RV R YR Y YG G BG B E C T N W F BV0000 V0000 RV0000 RV21 R0000 R27 YR0000 Y0000 YG0000 YG23 G0000 G19 BG0000 BG23 B0000 B32 E0000 E23 E49 C-00 W-00 FRV1 Pale Thistle Rose Quartz Evening Primrose Light Pink Pink Beryl Cadmium Red Pale Chiffon Yellow Fluorite Lily White New Leaf Crystal Opal Bright Parrot Green Snow Green Coral Sea Pale Celestine Pale Blue Floral White Hazelnut Dark Bark Cool Gray No.00 Warm Gray No.00 Fluorescent Pink BV000 V000 RV000 RV23 R000 R29 YR000 Y000 YG00 YG25 G000 G20 BG000 BG32 B000 B34 E000 E25 E50 C-0 T-0 N-0 W-0 FYR1 Iridescent Mauve Pale Heath Pale Purple Pure Pink Cherry White Lipstick Red Silk Pale Lemon Mimosa Yellow Celadon Green Pale Green Wax White Pale Aqua Aqua Mint Pale Porcelain Blue Manganese Blue Pale Fruit Pink Caribe Cocoa Egg Shell Cool Gray No.0 Toner Gray No.0 Neutral Gray No.0 Warm Gray No.0 Fluorescent Orange BV00 V01 RV00 RV25 R00 R30 YR00 Y00 YG01 YG41 G00 G21 BG01 BG34 B00 B37 E00 E27 E51 C-1 T-1 N-1 W-1 FY1 Fluorescent Mauve Shadow Heath Water Lily Dog Rose Flower Pinkish White Pale Yellowish Pink Powder Pink Barium Yellow Green Bice Pale Cobalt Green Jade Green Lime Green Aqua Blue Horizon Green Frost Blue Antwerp Blue Skin White Africano Milky White Cool Gray No.1 Toner Gray No.1 Neutral Gray No.1 Warm Gray No.1 Yellow Orange BV01 V04 RV02 RV29 R01 R32 YR01 Y02 YG03 YG45 G02 G24 BG02 BG45 B01 B39 E01 E29 E53 C-2 T-2 N-2 W-2 FYG1 Viola Lilac Sugared Almond Pink Crimson Pinkish Vanilla Peach Peach Puff Canary Yellow Yellow Green Cobalt Green Spectrum Green Willow New Blue Nile