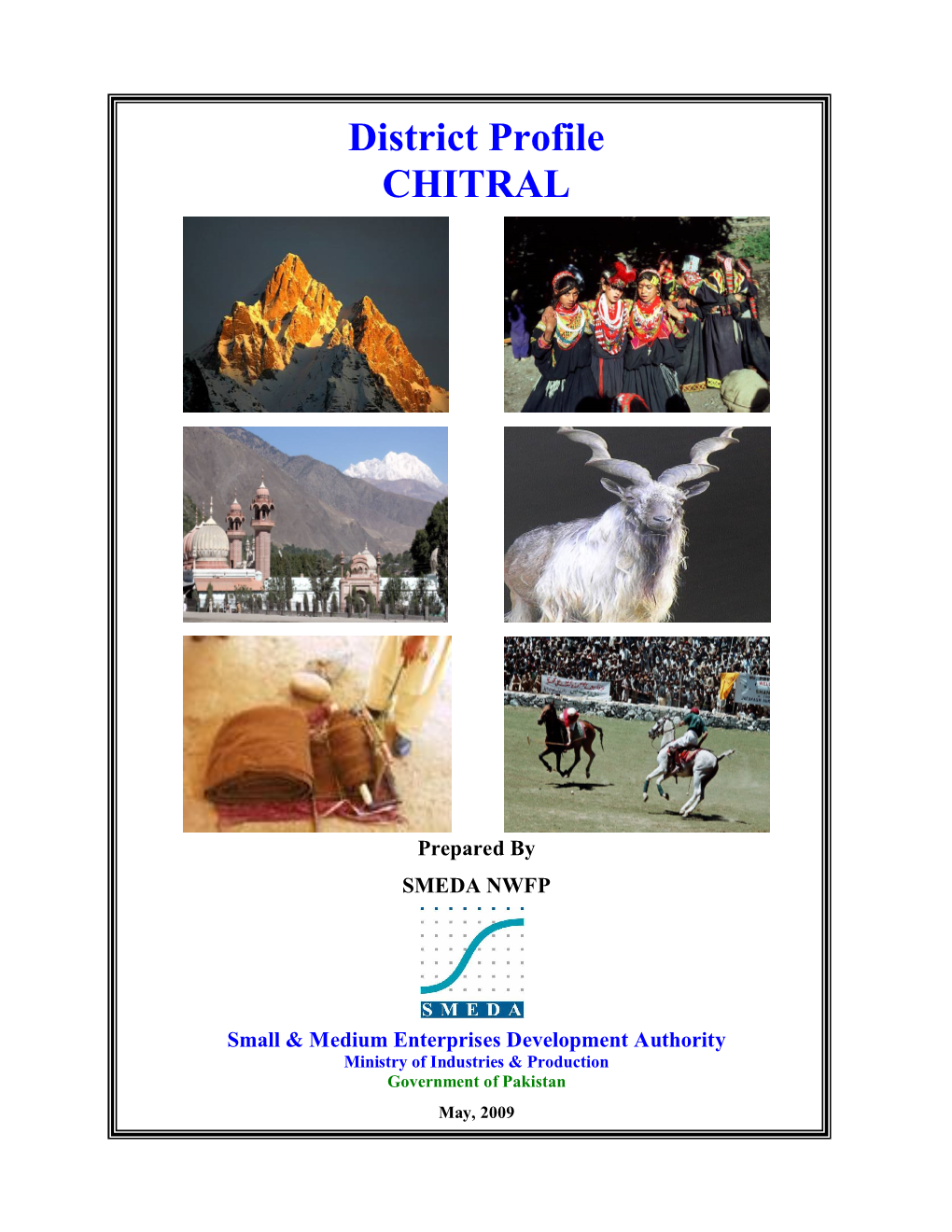

District Profile CHITRAL

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Copyright by Aarti Bhalodia-Dhanani 2012

Copyright by Aarti Bhalodia-Dhanani 2012 The Dissertation Committee for Aarti Bhalodia-Dhanani certifies that this is the approved version of the following dissertation: Princes, Diwans and Merchants: Education and Reform in Colonial India Committee: _____________________ Gail Minault, Supervisor _____________________ Cynthia Talbot _____________________ William Roger Louis _____________________ Janet Davis _____________________ Douglas Haynes Princes, Diwans and Merchants: Education and Reform in Colonial India by Aarti Bhalodia-Dhanani, B.A.; M.A. Dissertation Presented to the Faculty of the Graduate School of The University of Texas at Austin in Partial Fulfillment of the Requirements for the Degree of Doctor of Philosophy The University of Texas at Austin May 2012 For my parents Acknowledgements This project would not have been possible without help from mentors, friends and family. I want to start by thanking my advisor Gail Minault for providing feedback and encouragement through the research and writing process. Cynthia Talbot’s comments have helped me in presenting my research to a wider audience and polishing my work. Gail Minault, Cynthia Talbot and William Roger Louis have been instrumental in my development as a historian since the earliest days of graduate school. I want to thank Janet Davis and Douglas Haynes for agreeing to serve on my committee. I am especially grateful to Doug Haynes as he has provided valuable feedback and guided my project despite having no affiliation with the University of Texas. I want to thank the History Department at UT-Austin for a graduate fellowship that facilitated by research trips to the United Kingdom and India. The Dora Bonham research and travel grant helped me carry out my pre-dissertation research. -

1 Impact of Aga Khan Rural Support Program's Gender Strategy On

Impact of Aga Khan Rural Support Program’s Gender Strategy on Rural Women in District Chitral Rabia Gul Allama Iqbal Open University Islamabad Email: [email protected] Abstract The study was conducted in Chitral Valley in the North of Pakistan to explore the gender related activities introduced by the Aga Khan Rural Support Program (AKRSP).The findings show that the AKRSP has been playing a key role in the development of women in the area and initiated development programs in water supply, health and credit facilities. It imparted trainings for the local women in different disciplines through the Women Organizations (WO’s) established in the area. These trainings were recorded and mostly repeated via video cassettes in different villages. Posters and charts were also used to make the trainings easier for the local women to understand. The AKRSP has also been successful to take few hours daily from the Local Government Radio in the area and communicate to the women in their local language about certain issues such as personal hygiene, procedure to get and pay back loans from the micro finance bank of AKRSP, about agricultural practices etc. Practical adoption of these trainings has made positive effect in the lives of the local women in terms of improved agricultural products and increase in income of the respondents. Further, the AKRSP is looking into the possibility of establishing a Community Radio which if established will play a major role for the development of the area. Thus, it is concluded that the AKRSP has made invaluable contributions in improving the access of women to education, health resources and economic empowerment opportunities. -

Migration and Small Towns in Pakistan

Working Paper Series on Rural-Urban Interactions and Livelihood Strategies WORKING PAPER 15 Migration and small towns in Pakistan Arif Hasan with Mansoor Raza June 2009 ABOUT THE AUTHORS Arif Hasan is an architect/planner in private practice in Karachi, dealing with urban planning and development issues in general, and in Asia and Pakistan in particular. He has been involved with the Orangi Pilot Project (OPP) since 1982 and is a founding member of the Urban Resource Centre (URC) in Karachi, whose chairman he has been since its inception in 1989. He is currently on the board of several international journals and research organizations, including the Bangkok-based Asian Coalition for Housing Rights, and is a visiting fellow at the International Institute for Environment and Development (IIED), UK. He is also a member of the India Committee of Honour for the International Network for Traditional Building, Architecture and Urbanism. He has been a consultant and advisor to many local and foreign CBOs, national and international NGOs, and bilateral and multilateral donor agencies. He has taught at Pakistani and European universities, served on juries of international architectural and development competitions, and is the author of a number of books on development and planning in Asian cities in general and Karachi in particular. He has also received a number of awards for his work, which spans many countries. Address: Hasan & Associates, Architects and Planning Consultants, 37-D, Mohammad Ali Society, Karachi – 75350, Pakistan; e-mail: [email protected]; [email protected]. Mansoor Raza is Deputy Director Disaster Management for the Church World Service – Pakistan/Afghanistan. -

Politics of Nawwab Gurmani

Politics of Accession in the Undivided India: A Case Study of Nawwab Mushtaq Gurmani’s Role in the Accession of the Bahawalpur State to Pakistan Pir Bukhsh Soomro ∗ Before analyzing the role of Mushtaq Ahmad Gurmani in the affairs of Bahawalpur, it will be appropriate to briefly outline the origins of the state, one of the oldest in the region. After the death of Al-Mustansar Bi’llah, the caliph of Egypt, his descendants for four generations from Sultan Yasin to Shah Muzammil remained in Egypt. But Shah Muzammil’s son Sultan Ahmad II left the country between l366-70 in the reign of Abu al- Fath Mumtadid Bi’llah Abu Bakr, the sixth ‘Abbasid caliph of Egypt, 1 and came to Sind. 2 He was succeeded by his son, Abu Nasir, followed by Abu Qahir 3 and Amir Muhammad Channi. Channi was a very competent person. When Prince Murad Bakhsh, son of the Mughal emperor Akbar, came to Multan, 4 he appreciated his services, and awarded him the mansab of “Panj Hazari”5 and bestowed on him a large jagir . Channi was survived by his two sons, Muhammad Mahdi and Da’ud Khan. Mahdi died ∗ Lecturer in History, Government Post-Graduate College for Boys, Dera Ghazi Khan. 1 Punjab States Gazetteers , Vol. XXXVI, A. Bahawalpur State 1904 (Lahore: Civil Military Gazette, 1908), p.48. 2 Ibid . 3 Ibid . 4 Ibid ., p.49. 5 Ibid . 102 Pakistan Journal of History & Culture, Vol.XXV/2 (2004) after a short reign, and confusion and conflict followed. The two claimants to the jagir were Kalhora, son of Muhammad Mahdi Khan and Amir Da’ud Khan I. -

A Study on Avifauna Present in Different Zones of Chitral Districts

Journal of Bioresource Management Volume 4 Issue 1 Article 4 A Study on Avifauna Present in Different Zones of Chitral Districts Madeeha Manzoor Center for Bioresource Research Adila Nazli Center for Bioresource Research, [email protected] Sabiha Shamim Center for Bioresource Research Fida Muhammad Khan Center for Bioresource Research Follow this and additional works at: https://corescholar.libraries.wright.edu/jbm Part of the Environmental Sciences Commons Recommended Citation Manzoor, M., Nazli, A., Shamim, S., & Khan, F. M. (2017). A Study on Avifauna Present in Different Zones of Chitral Districts, Journal of Bioresource Management, 4 (1). DOI: 10.35691/JBM.7102.0067 ISSN: 2309-3854 online (Received: May 29, 2019; Accepted: May 29, 2019; Published: Jan 1, 2017) This Article is brought to you for free and open access by CORE Scholar. It has been accepted for inclusion in Journal of Bioresource Management by an authorized editor of CORE Scholar. For more information, please contact [email protected]. A Study on Avifauna Present in Different Zones of Chitral Districts Erratum Added the complete list of author names © Copyrights of all the papers published in Journal of Bioresource Management are with its publisher, Center for Bioresource Research (CBR) Islamabad, Pakistan. This permits anyone to copy, redistribute, remix, transmit and adapt the work for non-commercial purposes provided the original work and source is appropriately cited. Journal of Bioresource Management does not grant you any other rights in relation to this website or the material on this website. In other words, all other rights are reserved. For the avoidance of doubt, you must not adapt, edit, change, transform, publish, republish, distribute, redistribute, broadcast, rebroadcast or show or play in public this website or the material on this website (in any form or media) without appropriately and conspicuously citing the original work and source or Journal of Bioresource Management’s prior written permission. -

Deforestation in the Princely State of Dir on the North-West Frontier and the Imperial Strategy of British India

Central Asia Journal No. 86, Summer 2020 CONSERVATION OR IMPLICIT DESTRUCTION: DEFORESTATION IN THE PRINCELY STATE OF DIR ON THE NORTH-WEST FRONTIER AND THE IMPERIAL STRATEGY OF BRITISH INDIA Saeeda & Khalil ur Rehman Abstract The Czarist Empire during the nineteenth century emerged on the scene as a Eurasian colonial power challenging British supremacy, especially in Central Asia. The trans-continental Russian expansion and the ensuing influence were on the march as a result of the increase in the territory controlled by Imperial Russia. Inevitably, the Russian advances in the Caucasus and Central Asia were increasingly perceived by the British as a strategic threat to the interests of the British Indian Empire. These geo- political and geo-strategic developments enhanced the importance of Afghanistan in the British perception as a first line of defense against the advancing Russians and the threat of presumed invasion of British India. Moreover, a mix of these developments also had an impact on the British strategic perception that now viewed the defense of the North-West Frontier as a vital interest for the security of British India. The strategic imperative was to deter the Czarist Empire from having any direct contact with the conquered subjects, especially the North Indian Muslims. An operational expression of this policy gradually unfolded when the Princely State of Dir was loosely incorporated, but quite not settled, into the formal framework of the imperial structure of British India. The elements of this bilateral arrangement included the supply of arms and ammunition, subsidies and formal agreements regarding governance of the state. These agreements created enough time and space for the British to pursue colonial interests in Ph.D. -

Language Documentation and Description

Language Documentation and Description ISSN 1740-6234 ___________________________________________ This article appears in: Language Documentation and Description, vol 17. Editor: Peter K. Austin Countering the challenges of globalization faced by endangered languages of North Pakistan ZUBAIR TORWALI Cite this article: Torwali, Zubair. 2020. Countering the challenges of globalization faced by endangered languages of North Pakistan. In Peter K. Austin (ed.) Language Documentation and Description 17, 44- 65. London: EL Publishing. Link to this article: http://www.elpublishing.org/PID/181 This electronic version first published: July 2020 __________________________________________________ This article is published under a Creative Commons License CC-BY-NC (Attribution-NonCommercial). The licence permits users to use, reproduce, disseminate or display the article provided that the author is attributed as the original creator and that the reuse is restricted to non-commercial purposes i.e. research or educational use. See http://creativecommons.org/licenses/by-nc/4.0/ ______________________________________________________ EL Publishing For more EL Publishing articles and services: Website: http://www.elpublishing.org Submissions: http://www.elpublishing.org/submissions Countering the challenges of globalization faced by endangered languages of North Pakistan Zubair Torwali Independent Researcher Summary Indigenous communities living in the mountainous terrain and valleys of the region of Gilgit-Baltistan and upper Khyber Pakhtunkhwa, northern -

Survey of Predatory Coccinellids (Coleoptera

Survey of Predatory Coccinellids (Coleoptera: Coccinellidae) in the Chitral District, Pakistan Author(s): Inamullah Khan, Sadrud Din, Said Khan Khalil and Muhammad Ather Rafi Source: Journal of Insect Science, 7(7):1-6. 2007. Published By: Entomological Society of America DOI: http://dx.doi.org/10.1673/031.007.0701 URL: http://www.bioone.org/doi/full/10.1673/031.007.0701 BioOne (www.bioone.org) is a nonprofit, online aggregation of core research in the biological, ecological, and environmental sciences. BioOne provides a sustainable online platform for over 170 journals and books published by nonprofit societies, associations, museums, institutions, and presses. Your use of this PDF, the BioOne Web site, and all posted and associated content indicates your acceptance of BioOne’s Terms of Use, available at www.bioone.org/page/terms_of_use. Usage of BioOne content is strictly limited to personal, educational, and non-commercial use. Commercial inquiries or rights and permissions requests should be directed to the individual publisher as copyright holder. BioOne sees sustainable scholarly publishing as an inherently collaborative enterprise connecting authors, nonprofit publishers, academic institutions, research libraries, and research funders in the common goal of maximizing access to critical research. Journal of Insect Science | www.insectscience.org ISSN: 1536-2442 Survey of predatory Coccinellids (Coleoptera: Coccinellidae) in the Chitral District, Pakistan Inamullah Khan, Sadrud Din, Said Khan Khalil and Muhammad Ather Rafi1 Department of Plant Protection, NWFP Agricultural University, Peshawar, Pakistan 1 National Agricultural Research Council, Islamabad, Pakistan Abstract An extensive survey of predatory Coccinellid beetles (Coleoptera: Coccinellidae) was conducted in the Chitral District, Pakistan, over a period of 7 months (April through October, 2001). -

Claiming Territory: Colonial State Space and the Making of British India’S North-West Frontier

CLAIMING TERRITORY: COLONIAL STATE SPACE AND THE MAKING OF BRITISH INDIA’S NORTH-WEST FRONTIER A Thesis Presented to the Faculty of the Graduate School of Cornell University In Partial Fulfillment of the Requirements for the Degree of Master of Science by Jason G. Cons January 2005 © 2005 Jason G. Cons ABSTRACT In this thesis, I examine the discursive construction of colonial state space in the context of British India’s turn of the century North-West Frontier. My central argument is that notions of a uniform state space posited in official theorizations of the frontier need to be reexamined not as evidence of a particular kind of rule, but rather as a claim to having accomplished it. Drawing on new colonial historiographies that suggest ways of reading archives and archival documents for their silences and on historical sociological understandings of state-formation, I offer close readings of three different kinds of documents: writing about the North-West Frontier by members of the colonial administration, annual general reports of the Survey of India, and narratives written by colonial frontier officers detailing their time and experience of “making” the frontier. I begin by looking at the writings of George Nathanial Curzon and others attempting to theorize the concept of frontiers in turn of the century political discourse. Framed against the backdrop of the “Great Game” for empire with Russia and the progressive territorial consolidation of colonial frontiers into borders in the late 19th century, these arguments constitute what I call a “colonial theory of frontiers.” This theory simultaneously naturalizes colonial space and presents borders as the inevitable result of colonial expansion. -

Aryans, Harvesters and Nomads (Thursday July 6 2.00 – 5.00) Convenor: Prof

PANEL: Aryans, Harvesters and Nomads (Thursday July 6 2.00 – 5.00) Convenor: Prof. Asko Parpola: Department of Asian & African Studies University of Helsinki Excavations at Parwak, Chitral • Pakistan. Ihsan Ali: Directorate of Archaeology & Museums, Government of NWFP & Muhammad Zahir: Lecturer, Government College, Peshawar The Directorate of Archaeology & Museums, Government of NWFP, under the supervision of Prof. (Dr.) Ihsan Ali, Director, Directorate of Archaeology & Museums, Government of NWFP, Peshawar has completed the first ever excavations in Chitral at the site of Parwak. The team included Muhammad Zahir, Lecturer, Government College, Peshawar and graduates of the Department of Archaeology, University of Peshawar. Chitral, known throughout the world for its culture, traditions and scenic beauty, has many archaeological sites. The sites mostly ranging from 1800 B.C. to the early 600 B.C, are popularly known as Gandhara Grave Culture. Though brief surveys and explorations were conducted in the area earlier, but no excavations were conducted. The site of Parwak was discovered by a team of Archaeologists from Directorate of Archaeology and Museums, Government of NWFP and Boston University, USA in a survey conducted in June 2003 under the direction of Prof. (Dr.) Ihsan Ali and Dr. Rafique Mughal. The site is at about 110 km north east of Chitral, near the town of Buni, on the right bank of river Chitral and set in a beautiful environment. The site measures 121 x 84 meter, divided in to three mounds. On comparative basis, the site is datable to the beginning of 2nd millennium BC and represents a culture, commonly known as Gandhara Grave Culture of the Aryans, known through graves and grave goods. -

Water Conflict Management and Cooperation Between Afghanistan and Pakistan

Journal of Hydrology 570 (2019) 875–892 Contents lists available at ScienceDirect Journal of Hydrology journal homepage: www.elsevier.com/locate/jhydrol Research papers Water conflict management and cooperation between Afghanistan and T Pakistan ⁎ Said Shakib Atefa, , Fahima Sadeqinazhadb, Faisal Farjaadc, Devendra M. Amatyad a Founder and Transboundary Water Expert in Green Social Research Organization (GSRO), Kabul, Afghanistan b AZMA the Vocational Institute, Afghanistan c GSRO, Afghanistan d USDA Forest Service, United States ARTICLE INFO ABSTRACT This manuscript was handled by G. Syme, Managing water resource systems usually involves conflicts. Water recognizes no borders, defining the global Editor-in-Chief, with the assistance of Martina geopolitics of water conflicts, cooperation, negotiations, management, and resource development. Negotiations Aloisie Klimes, Associate Editor to develop mechanisms for two or more states to share an international watercourse involve complex networks of Keywords: natural, social and political system (Islam and Susskind, 2013). The Kabul River Basin presents unique cir- Water resources management cumstances for developing joint agreements for its utilization, rendering moot unproductive discussions of the Transboundary water management rights of upstream and downstream states based on principles of absolute territorial sovereignty or absolute Conflict resolution mechanism territorial integrity (McCaffrey, 2007). This paper analyses the different stages of water conflict transformation Afghanistan -

Analysis of Y-Chromosome Polymorphisms in Pakistani

ANALYSIS OF Y-CHROMOSOME POLYMORPHISMS IN PAKISTANI POPULATIONS Thesis submitted to the Sindh Institute of Medical Sciences for the degree of Doctor of Philosophy. BY Sadaf Firasat Centre of Human Genetics and Molecular Medicine Sindh Institute of Medical Sciences Sindh Institute of Urology and Transplantation (SIUT) Karachi, Pakistan 2010 TABLE OF CONTENTS Title page Acknowledgements ii List of Tables iii List of Figures iv Summary vi Introduction 1 Literature Review 19 Materials and Methods 34 Results Phylogeography of Pakistani ethnic groups. 51 Comparison between the Pakistani and Greek populations 73 Discussion 86 Comparison within Pakistan 88 Comparison between the Pakistani and Greek population 94 Comparison with world populations 98 Insight in to populations origins 111 Conclusions 121 References 122 Appendix a i ACKNOWLEDGEMENT I thank Prof. Dr. Syed Qasim Mehdi H.I. S.I., for his support, encouragement and for providing all the facilities for doing scientific work in his laboratory. The work presented in this thesis was done under the supervision of Dr. Qasim Ayub T.I. It is great pleasure for me to acknowledge the keen interest, advice, patient guidance and kindness that I have received from him during the course of this work. I would like to thank Dr. Shagufta Khaliq, (PoP), for teaching all the molecular genetics lab techniques and also to Dr Aiysha Abid for comments on this manuscript and suggestion for its improvement. I am also grateful to Mrs. Ambreen Ayub for her help in making the contour map. I thank my colleague Ms. Sadia Ajaz for her help and cooperation in proof reading the thesis.