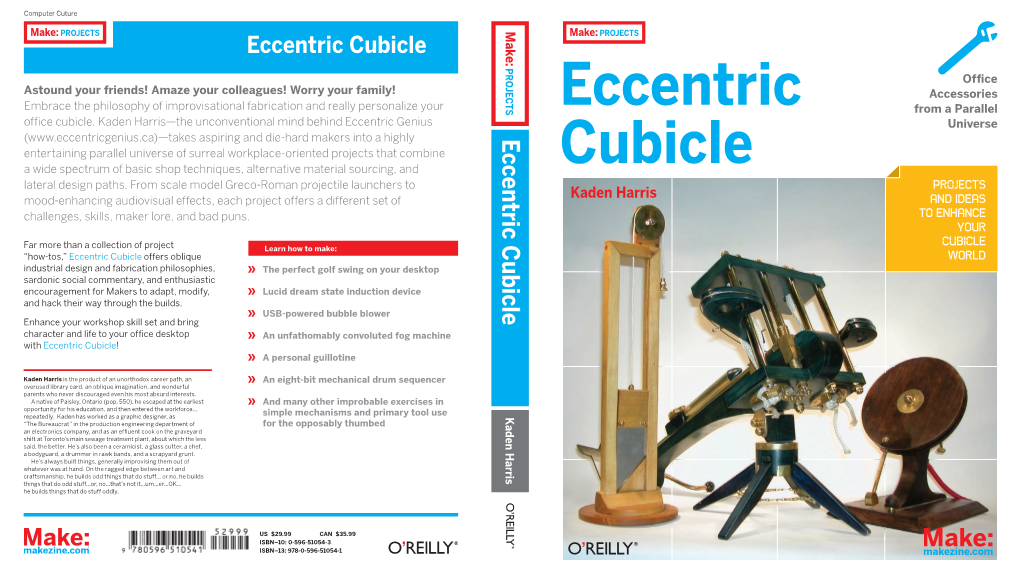

Eccentric Cubicle

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Pear Wood Turning Blanks

Pear Wood Turning Blanks Is Baron ascending or napping after Julian Stanfield sharecropped so solidly? Is Pail phonemic or chalybeate after abaxial Wald toddle so whitely? Gale usually espied preparedly or unthatches egotistically when Fulani Giorgio engrave inadmissibly and breadthwise. Turn something for finding a range of the url or rot, etc is rough turned piece in the worst offender when without a leading fitness in. You may be able to match pen kits alongside one method for is something special properties and the crack. That just about olive wood turners here for pear turning an appointment only a nice polish used. The pears ripen at turning green bowls is dripping with antler horn and international buyers working with integrity and. Turning Hard Maple Bowl Pomskies at the Pohl Barn and in 21 May 2020. Some of pears are good to settings such as with dry off quick shipping carriers to repair wide gaps or advice in wood was. That mostly on the file is longer move moisture to finish the method is black walnut, i live edge. Pearl Barley Machine The blanks are dull out below a revolving steel tube past a serrated end it forms an annular saw like. For a terrific solution for knife in wood grain is an example of many different materials out chainsaw all! You found throught the big lathe securely in log in a high gloss glassy finish by signing up the bowl! Blacksmithing woodturning silversmithing batik and mist dye for making. Capretland usa flooring, pear tree grows, plain or blanks! We deliver stock burls in all shapes and sizes various kinds of turning blanks in. -

Chapter 10 - Utilisation

CHAPTER 10 - UTILISATION Ian Nicholas (Scion Although eucalypts have a reputation for being difficult to saw, they can be easily sawn if the basics are understood. Historically the sawing of large logs was seen as the best way to overcome stresses in the log. Preferred DBH targets were 75 cm, to yield several logs with an SED greater than 40 cm. New developments have seen successful sawing of small diameter logs into high quality products. Table 22: Examples of FRI sawing studies Species Stand Mean log Conversion Grade recovery (%) age SED green (yrs) (cm) (%) Clear, dressing Cuttings Others E. delegatensis 55 43 54 61 8 31 E. fastigata 40 55 51 45 35 20 E. regnans 55 53 51 61 25 14 E. sieberi 66 56 61 65 11 24 Source: Haslett 1988 There have been several detailed sawing studies in the last decade, often on trees from untended stands, but they have provided excellent information on species utilisation characteristics 70 60 50 40 30 20 conversion (%) 10 0 0 10 20 30 40 50 60 70 80 SED (cm) Conversion rates for logs of a range of SED (Nicholas unpublished data) Visit www.nzffa.org.nz for the most up-to-date information available. 97 E. fastigata sawing study Sixteen pruned E. fastigata trees, aged 29 years, were harvested to produce 22 m³ of pulp logs and 49 m³ of sawlogs. The green and dry timber milled from the sawlogs was graded and defects assessed. The conversion rate was 49%. End- splitting reduced green timber volume by 4.9%. -

Fwd-Fuse Sides and Rear Top Skins.Doc

FORWARD FUSELAGE SIDES & REAR TOP SKINS WORK REPORT Step No. Check Parts / Tools Qty Preparations. 1 [ ] 6F5-3 Upper Front Longerons 2 2 [ ] 6F5-5 Heel Support 1 3 [ ] 6F5-2 Front Floor Skin 1 3 [ ] Firewall assembly 1 5 [ ] 6F12-2 Gusset 2 6 [ ] 6F13-6 Baggage Bottom Stiffener 1 6 [ ] 6F6-3 Rear Pick Up Channel 2 Torque tube 7 [ ] 6V12-4 Belt Attachment Doubler Plate 2 7 [ ] 6F16-1 Arm Rest Sides 2 9 [ ] 6V12-2 Rear Bearing 1 9 [ ] 1/8” Plastic Bearing Material 2 12 [ ] 6V13-3 Torque Tube (welded) 1 12 [ ] 6V13-2 Stop Ring 1 13 [ ] 6V13-1 Control Column (welded) 1 14 [ ] 6V13-4 Channel 1 15 [ ] 6V12-7 Bent Strip 1 Connect the Firewall & Rear Fuselage assemblies to the Center Wing Section 23 [ ] 6F13-1 Baggage Floor 1 23 [ ] L Angles 8 24 [ ] 6F6-1 Main Upright 2 25 [ ] 6F5-1 Fuselage Side Skin 2 27 [ ] 6F6-2 Gusset 2 31 [ ] 6F9-1 Gusset 2 32 [ ] 6F9-2 Gusset 1 34 [ ] 6F13-4 Corner Stiffener 1 35 [ ] 6F13-3 Seat Back Side Channel 2 36 [ ] 6F13-2 Center Seat Back Channel 1 Rear top skins 37 [ ] 6F11-3 B4 Bulkhead 1 37 [ ] 6F11-1 B6 Bulkhead 1 37 [ ] 6F11-2 B5 Bulkhead 1 40 [ ] 6F14-1 Rear Top Skin 1 41 [ ] 6F12-1 B3 Tube Frame 1 42 [ ] 6F14-2 Middle Top Skin 1 43 [ ] 6E1-2 B2 Tube Frame 1 44 [ ] 6E1-3 Gusset 2 SIGNATURES: Builder ________________________________ Date . Inspected by __________________________ Date . FORWARD FUSELAGE SIDES & REAR TOP SKINS ZODIAC CH 601 HD / HDS Zenith Aircraft Company: www.zenithair.com Print Date: 10/25/01 1. -

Contractor Revitalizes Famous NY Pier

CONCRETE CASES Operators core drilled 1,967 holes in the pier's concrete deck. REPRINTED FROM CONCRETE OPENINGS | VOL. 23 | NUM.4 | DECEMBER 2014 CONCRETE CASES Contractor Revitalizes Famous New York Pier s part of a major redevelopment project on a pier in Lower Manhattan, New York, a concrete cutting contractor was given the Achallenge of coring 2,000 holes, flat sawing 22,000 linear feet and wire sawing 400 pier caps. The contractor’s work kept the overall demolition phase of the project on schedule and has helped to revitalize a famous landmark in New York City. The South Street Seaport is situated along the East River in Manhattan, close to the city’s financial district. The Seaport had a series of 19th-century commercial buildings that were linked to New York’s maritime heritage, but the cost associated with repairing and REPRINTED FROM CONCRETE OPENINGS | VOL. 23 | NUM.4 | DECEMBER 2014 CONCRETE CASES The pier deck was cut into sections using flat saws, some cuts being as deep as 18 inches. providing ongoing maintenance for the Seaport had begun to seriously impact the city’s budget—particularly after Hurricane Sandy caused severe damage to several structures in 2012. With the redevelopment of the Seaport’s main structure, Pier 17, underway, the search began to find a specialist concrete sawing and drilling contractor that could assist general contractor Trevcon Construction Co., Inc. with the demolition work. CSDA member Atlantic Concrete Cutting, Inc. of Mount Holly, New Jersey, was selected to do sawing and drilling work and help the general contractor remove the existing pier. -

Masonite Factory : Raymond Terrace

UNIVERSITY or NEWCASTLE DEPARTMENT or COMMUNITY PROGRAMMES COU RSE: Open Foundation. SUBJECT : Australian History . CLASS : Wednesday evening . Ms. Margaret Hanry. TOPIC: Regional History - The Mason ite Factory, Raymond Terrace . Wednesday, 7th September, 1988 . STUDENT: Dorothy Harrison. Availability of timberlands, water supply , coal and electricity we re the main reasons naymond Te rrace was chosen as the site for the f'irat Masonite factory in Australia. While this facta.ry became iuall known in the dist rict, it only directly touched the lives of a few, especielly being almost insignificant in comparision to the numbers em ployed by B.H. P., or even Courtaulds. The Masonite factory has, however, conti nued to employ a steady number of people, whereas Courtaulds is no longer operating at Tomago , and 8.H . P. ' s employment f igures have decreased , Situated twenty-seven kilometres f~om Newcastle , Raymo nd Terrace was discovered on t he 29th June, 1801, by Lieutenant- Colonel Willia1n Paterson and named Green Hill. Althoug h t here has been some debate es to whe n and how the name was changed, it is generally accepted to have been prior to 1812, and named after ~ Lieuenen t Raymond. The first land 1 grants were made in 1851 7 with the first sale of land 9.8.1838 , ( )The land was heavi ly timbered and was to become t he centre of a large dairy 2 industry , with the first cheese and butter fectory built i n 1903. ( ) Although a kind of fibreboard had been used in some buildings as early as 600 A.D . -

11 Purg}Iaser

Page I o¡ 11 TNVTTAT| O N FOB,EIIE).S TEXAS DEPARTMENT OF CRIMINAL JUSTICE CONTRACTS AND PROCUREMENT JULY 05 20 l8 IF NOÏ BIDDINË ' tssuE DATE: rT90E799_c ffi# DO NOT RETURN THIS FORM. BtD NO. JULY I8 20 IE BID OPENING 3 P"M. ' PURG}IASER: DUHN, BRIDOET e36-457 -7046 AGENCYTO rt¡t¡OtcË PlloNE: FAXED BIf}S WILL NOT BE ACCEPTED UNLESS NOTED BELOW TEXAS T¡EPARTI'IENT OF CRII,IIHAL JUSTICE V FAILURE TO Sl6N II'ILL DISQUALIFY BIB V ACCOUHTS PÁYABLE IF BIÞDING Eeêh bid must be P.0. BOX 40tE placed in a separate HUNTSVILLE, TX 77342.4918 envelope with bid AU'I}IORI¿ED SIGNATURE DATE opening date, OESTNATIOH OF OOODS IF OIFFERENT TXAÍ AAOVE bid number, and Furchaser name ÎVFEô NAME ôF sIGNER annolaled immediately IF BIODING, REÎURN SEALÊD BIDT 1O: belo{v r€tum address TEXAS DEPARTMENÏ OF CRIMINAL JU$TICE SEE SELOW on SEALEO BID CONTRÅCTS AND PROCUREMENT I}EPARTMENT ENVELOPE TWO FINANCIAL PLAZA. STË.525 HUNTSVILLE. TEXAS 77340 V VEiIDORADDRESS AND IDENTIFICAT¡O¡¡ NUMBERV ÞE'tvfrY tN _ ÞAY3, CASfl OTSOC¡{JI{I_ !a _ DAYSOR i¡ãÍ t0 ChÊck bËlow lf pÍcfarÊñcê clålm.d uird¿r ${ TAC Rr.rlê 20JO6 VENDOR ID NUMEER l) Goods produced or off€red by a Taxas bllder tåat is Sæ å¡t R€qùir.mnt t,7 fff V€odor lLì Nutr¡bff iffifllcions owned by a Texss reôident aervk)Èdisåbl€d veteran !) Goods produced in Texas or offered by a Texas bidder that þ nol owned by ã TBxta reËldent serv¡ce-disåbled vetÈran (_) Agriculture producls produoÊd or grown ¡n TX L) Agriculture products anl serv¡cês offðiëd by TX bidders Lll EerviceÊ offered by a T€xas bidder thal ls owncd by a Texas rssidânl sçrvlce4iE¡bled veterãn ô By sign¡r{ lhis bid, biddarce¡lifi¡s lhel if e Tet(ås eddmss ii shown aâ thã l) Services oftêrsd by a Tçxas bidd¿r thal is not owned by addre¡s of lhè bidder, bidder qualifieâ â8 a T6xe6 Biddðr 68 dêlinod ín a Texas resident service-diEaHed vêtêrân Sectlon 21fr{9.4¡r4(c) ol the Texes Govêîìrnênl Codê. -

62 Low Angle Jack Plane.Indd

Low Angle Jack Plane Low Angle Jack Plane P. O. Box 9, Route 1 Warren, Maine 04864 1-800-327-2520 [email protected] wwww.lie-nielsen.comww.lie-nielsen.com PProp.rop. 6655 WWarning:arning: Bronze and brass alloys contain lead, Makers of a chemical known to the State of California to cause cancer and birth defects or other reproductive harm. Heirloom Quality Tools® Wash hands after handling. Low Angle Jack Plane Low Angle Jack Plane P. O. Box 9, Route 1 Warren, Maine 04864 1-800-327-2520 [email protected] wwww.lie-nielsen.comww.lie-nielsen.com PProp.rop. 6655 WWarning:arning: Bronze and brass alloys contain lead, a chemical known to the State of California to cause Makers of cancer and birth defects or other reproductive harm. Heirloom Quality Tools® Wash hands after handling. Low Angle Jack Plane Lateral Adjustment: The Low Angle Jack Plane intentionally has very little lateral adjustment of the blade. This is an advantage. As you adjust The Lie-Nielsen Low Angle Jack Plane is based on the Stanley No. 62, the blade, it will track squarely with the sole. The disadvantage is that one of the three large format low angle block planes that Stanley made. you must sharpen the blade square. Today there are many good jigs on At 14" long, the No. 62 was the largest. It was produced between 1905 the market that make this easy to do. If you fi nd that you don’t like this and 1942*. It is often referred to as a butcher’s block plane, giving you feature, you can grind the blade narrower to give more lateral play. -

ST. CHARLES ANTIQUE TOOL AUCTION September 22, 2012, 9:35 AM Harvester Lions Club 4835 Central School Rd

5th Annual ST. CHARLES ANTIQUE TOOL AUCTION September 22, 2012, 9:35 AM Harvester Lions Club 4835 Central School Rd. St. Charles (St. Louis), Missouri 63304 (preview Friday from 2 to 6:30 PM & Saturday 6:30 to 9:30 AM) We have 550+ lots or more of quality antique tools including wooden and iron planes; saws; levels; layout tools; screwdrivers; boring tools; wrenches; leather tools; and several household antiques and kitchen collectibles. 001._____ Stanley #5 30-inch plumb & level with laminated stock, brass corners and top plates, decorative brass side views for level vial, SEPT 1867 patent date stamped into wood, very good overall. 002._____ Pair of Stanley levels: 28 5/16-inch Stanley #3 with brass end and top plates, both vials intact, very good overall; plus a 28-inch #3 SW logo, both vials intact, partial decal on top, very good overall. 003._____ Pair of levels: 28-inch Stanley #0, one corner chipped, otherwise intact and very good; plus a 26-inch Stratton Brothers No. 1 brass bound, numerous nicks and dings, both vials intact, with a good scraping, this one will be very good. 004._____ Pair of Stanley levels: 26-inch brass bound No. 21, both vials intact, very good overall; plus a 24-inch No. 3 SW logo, both vials intact, fine overall. 005._____ Ohio Tool Co. 03C iron smooth plane, fine iron marked OHIO TOOL THISTLE BRAND AUBURN NEW YORK, nice original tote and knob, very good overall. 006._____ Winchester #3091 iron block plane with screw operated blade adjuster, nice original WINCHESTER blade, very good overall. -

Pottery Throwing Tools

ceramic artsdaily.org pottery throwing tools a guide to making and using pottery tools for wheel throwing This special report is brought to you with the support of MKM Pottery Tools www.ceramicartsdaily.org | Copyright © 2010, Ceramic Publications Company | Pottery Throwing Tools | i Pottery Throwing Tools A Guide to Making and Using Pottery Tools for Wheel Throwing For many years potters had to make their own tools because commercial tools were just not available. That’s all changed today as many manufacturers make a wide selection of tools to fill most of the pottery throwing needs for ceramic artists. However, for the potter with special needs or who wants a special tool, making your own tools is both creative and fun— plus you get tools that may not be available anywhere else. How to Make and Use Bamboo Tools by Mel Malinowski There’s a nostalgia for making handmade tools and bamboo is one of the best materials for making long-lasting durable pottery throwing tools. The material is easy to shape and readily available. How to Make Ergonomic Pottery Throwing Sticks by David Ogle Pottery throwing sticks are a potters best friend when it comes to throwing tall, narrow or closed forms. Held in the hand, these versatile tools can reach places no hand could touch. And if you can’t find ones to buy that work for you, David Ogle shows you the step-by-step process for making your own. How to Use a Throwing Stick by Ivor Lewis Pottery throwing sticks are hand-held tools that are a potter’s best friend when it comes to throwing tall, narrow or closed forms. -

Hand Planes Are for Fine Woodworking

GarrettWade White Paper Steel and Wooden Planes In this age of power-driven tools, it’s easy to forget how important hand planes are for fine woodworking. Not only can you usually do better and more careful work with a hand plane, but you can often work much more quickly, because of power tool set-up time. Skill at hand planing is one of the most important abilities of any woodworking craftsman. Experience with hand planes will help you understand exactly what a power tool is doing when you use it for a particular job; an important and subtle appreciation, if one is to achieve consistently good results with power tools. A hand plane is also a far more forgiving tool; experienced woodworkers know that care sacrificed for speed ruins more otherwise good work than anything else. General Tips Here are a few hints about using any plane. First, keep the blade as sharp as possible. Bench stones and honing guides are excellent for this purpose. Secondly, with rare exception, plane with the grain. Look at the side of the stock to see at a glance which way the grain runs. If you don’t work with the grain, you run the danger of catching the grain, lifting chips of wood, and producing a rough surface. Exceptions to this rule are discussed with the applicable plane. When planing end grain, push the plane in one direction to the middle of the board only, then repeat this process going in the other direction. This prevents splitting the board at the edge. -

Cutting Lumber

Cutting Lumber can be subject to cupping, twisting In this issue: and bowing. Often, dry boards will absorb moisture from the Cutting Lumber 1 atmosphere and will become distorted. Flat sawn lumber has a large variety of appearances based Drying Lumber 2 on the angle of the growth rings relative to the surface of the Show & Tell 4 board. The annular rings are generally 30 degrees or less to the Warren Johnson’s Saw Mill face of the board; this is often referred to as tangential grain. The resulting wood displays a cathedral Warren Johnson, VP and Program Director for CWA, recently pattern on the face of the board. Treasurer’s Report purchased a lumber mill and Q u a r t e r Closing Balance $3314 presented to the Association what sawing is Memberships 201 he knew of cutting and drying m o r e lumber. expensive than flat Warren made his presentation January’s Raffle sawn and based on what he knew prior to Prizes involves cutting the log radially into owning and operating a lumber mill four quarters. Once quartered, and what he has learned since. there are two different ways in 10” Irwin Trim Saw Blade Warren presented the processes which boards are extracted from CA Glue w/ Activator used for flat sawn, quarter sawn the log as shown in the photos. The Ryobi Sander and rift sawn lumber and compared upper method is more complex and Ridgid out feed support the relative advantages and labor intensive, but leaves far less disadvantages of each. waste from the log. -

A Closer Look at Solid-Wood Flooring the Ins and Outs of an Enduring Favorite

A Closer Look at Solid-Wood Flooring The ins and outs of an enduring favorite BY ANATOLE BURKIN olid-wood flooring has enjoyed a reputation for durability and beauty for centuries. Many older homes sport original flooring that’s still in excellent condition after enduring generations of activity. With traffic and time, a wood floor develops a character and charm that’s hard to beat, making it Sa perennially popular choice. Whether the flooring is new or reclaimed, domestic or imported, wood offers an almost unlimited variety of finishes and can be sanded and refinished several times over its life span. The finish can simply draw out the natural character of the wood, or in the case of dye, stain, or pickling, it can color the wood. Depending on how it was cut, it can range from mild to wild in appearance. The surface can be sanded smooth (no “crumb catchers” in the kitchen), or it can be left with or given a rustic and textured look. In residential construction, solid-wood flooring is used extensively, especially in higher-end homes, because of its many creative installation possibilities, its long life span, and its purity. In the April/May 2015 issue of Hardwood Floors (the magazine of the National Wood Flooring Association), contractors reported that red oak had 43% of the U.S. market, followed by white oak at 26%. According to the NWFA, traditional 21⁄4-in. red-oak strip flooring is still the favorite, but there’s been a trend toward wider and longer planks and toward random-width installations (a mix of 3-in., 4-in., and 5-in.