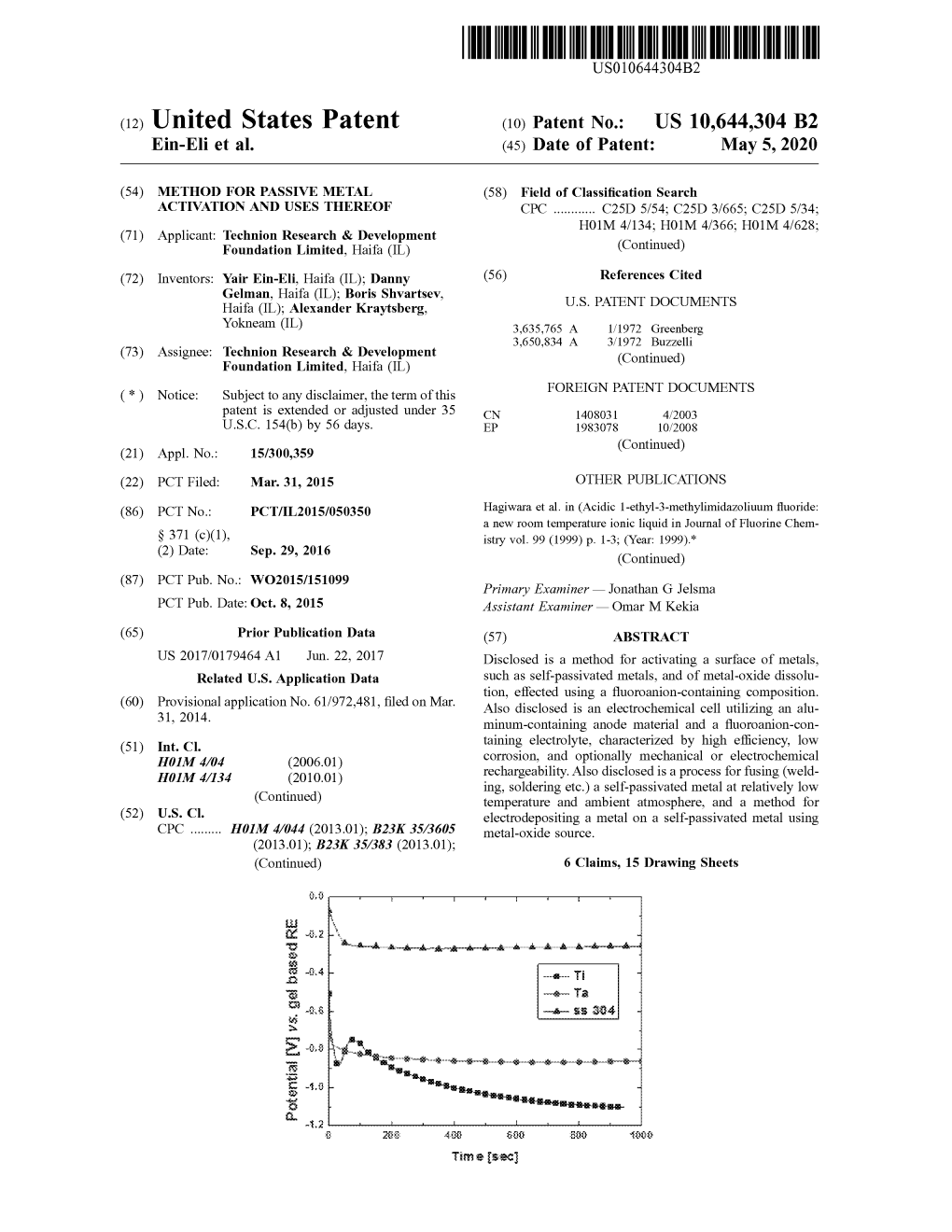

Potential Ivvs.Gelbasedre

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

On the Formation of Higher Carbon Oxides in Extreme Environments

Chemical Physics Letters 465 (2008) 1–9 Contents lists available at ScienceDirect Chemical Physics Letters journal homepage: www.elsevier.com/locate/cplett FRONTIERS ARTICLE On the formation of higher carbon oxides in extreme environments Ralf I. Kaiser a,*, Alexander M. Mebel b a Department of Chemistry, University of Hawaii at Manoa, 2545 The Mall (Bil 301A), Honolulu, HI 96822, USA b Department of Chemistry and Biochemistry, Florida International University, Miami, FL 33199, USA article info abstract Article history: Due to the importance of higher carbon oxides of the general formula COx (x > 2) in atmospheric chem- Received 15 May 2008 istry, isotopic enrichment processes, low-temperature ices in the interstellar medium and in the outer In final form 22 July 2008 solar system, as well as potential implications to high-energy materials, an overview on higher carbon Available online 29 July 2008 oxides COx (x = 3–6) is presented. This article reviews recent developments on these transient species. Future challenges and directions of this research field are highlighted. Ó 2008 Elsevier B.V. All rights reserved. 1. Introduction tion has no activation energy, proceeds with almost unit efficiency, and most likely involves a reaction intermediate. However, neither In recent years, the interest in carbon oxides of higher complex- reaction products (kinetics studies) nor the nature of the interme- 1 + ityP than carbon monoxide (CO; X R ) and carbon dioxide (CO2; diate (kinetics and dynamicsP studies) were determined. On the 1 þ 1 + 3 À X g ) of the generic formula COx (x > 2) has been fueled by com- other hand, a CO(X R )+O2(X g ) exit channel was found to have plex reaction mechanisms of carbon oxides with atomic oxygen in an activation energy between 15 and 28 kJ molÀ1 in the range of the atmospheres of Mars [1–4] and Venus [5]. -

Study of the Modifications of Manganese Dioxide

U. S. Department of Commerce Research Paper RP1941 National Bureau of Standards Volume 41, December 1948 Part of the Journal of Research of the National Bureau of Standards Study of the Modifications of Mangan,ese Dioxide By Howard F. McMurdie and Esther Golovato P ast work on the modificat ions of manganese dioxide of in terest in dry-cell manufacture is revie wed. New X -ray data, at both room and elevaLcd temperatures, combined 'with differen tial hea ting curves lead to the concl usion that five type of manga nese dioxide exi t : (1) well-crystallized p yrolusite ; (2) gamma m a nganese diox ide, a poorly crystalli zed pyrol u site; (3) ramsdellite ; (4) cryp tomelane, a form co ntaining esse ntial p otassium or sodiulll.; a nd (5) delta m anganese dioxide, belie ved to be a poorly crystallize d cryptomela ne. The high-temperature X-r ay diffraction data indicated the phase cha nges t hat cause the heating curve effects. A new crystal fo rm of manganosic oxide (Mn30 4), stable above 1,1700 C, w ~ s fo und t o be cubic of spinel structure. Fincness dcten n inaLion by both thc nitrogen a dsorp t ion and Lhe X-ray line broadening me thods were made on selected samples. I. Introduction this equipment a fla t specinlen is used, and no During the years 1940- 46 there wa increased special teclmiq Ll es were employed to prcven t pre researeh on dry cells. This was stimulated by fcn 'cd orientation. It is r ealized that in a few increased demand for the cell as well a new u es cascs this may have res ulted in r elative intcnsitics for them , combined with certain hor Lages of raw that differ from those in other r eporLs. -

Source Test Method ST-20 SULFUR DIOXIDE, SULFUR TRIOXIDE

Source Test Method ST-20 SULFUR DIOXIDE, SULFUR TRIOXIDE, SULFURIC ACID MIST (Adopted January 20, 1982) REF: Regulations 6-320, 6-330, 9-1-302, 9-1-304 thru 310, 10-1-301, 12-6-301 1. APPLICABILITY 1.1 This method is used to quantify emissions of s ulfur dioxide, sulfur trioxide and sulfuric acid mist. It determines compliance with Regulations 6-320 and 6-330 for SULFUR TRIOXIDE and SULFURIC ACID MIST, and 9-1-302, 9- 1-304 thru 310 and 10-1-301 and 12-6-301 for SULFUR DIOXIDE. 1.2 This method, modified with a glass fiber disc filter as the back-up SO 3 filter, has been given alternate status by the EPA to EPA Method 8. It may be used to determine compliance with oxides of sulfur regulations under Regulation 9. 2. PRINCIPLE 2.1 Sulfuric acid mist, sulfur trioxide and sulfur dioxide are collected in a single extractive sampling train. Acid mist is trapped in a quartz wool plug in the sample probe and is subsequently analyzed with an acid-base titration. Sulfur trioxide is absorbed in an 80% isopropyl alcohol (IPA)/water solution with a quartz wool back-up filter and is analyzed using analytical procedure Lab-12. Sulfur dioxide is absorbed in an aqueous hydrogen peroxide solution and is analyzed using analytical procedure Lab-12. 3. RANGE 3.1 The minimum measurable concentration using this method listed below are: 3 3.1.1 Acid mist - 0.0002 gr/ft as H2SO4 3.1.2 Sulfur trioxide - 7 ppm 3.1.3 Sulfur dioxide - 7 ppm 3.2 The maximum measurable concentrations using this method listed below are: 3.2.1 Acid mist - undetermined 3.2.2 Sulfur trioxide - 350 ppm 3.2.3 Sulfur dioxide - 2.5 % 4. -

Isotopic Exchange Between Carbon Dioxide and Ozone Via O1D in The

GEOPHYSICAL RESEARCH LETTERS, VOL. 18, NO. 1, PAGES 13-16, JANUARY 1991 ISOTOPICEXCHANGE BETWEEN CARBONDIOXIDE AND OZONEVIA O(!D) IN THE STRATOSPHERE Yuk L. Yung, W.B. DoMore,and Joseph P. Pinto Abstract. We proposea novelmechanism for isotopic Table 1 exchangebetween CO 2 and0 3 vi•aO(ID) + CO2 -->CO_•* followedby CO3' --> CO2 + O(aP). A one-•ensior•al List of essentialreactions used in the photochemicalmodel. model calculation shows that this mechanism can account for The units for photodissociationcoefficients and two-body theenrichment in 180 in thestratospheric CO2 observed by rateconstants are s -1 andcm 3 s-l, respectively.The coeffi- Gatnoeta!. [1989],using the heavy 0 3 profile-observed by cientsfor photolysisrefer to nfid-latitudedimally averaged Mauersberger[1981]. The implicationsof this mechanism values at 30 kan. All molecular kinetic data are taken frmn for otherstratospheric species and as a sourceof isotopically DoMore etal. [1990], except otherwise stated. Rate heavyCO 2 in thetroposphere are briefly discussed. constantsforisotopic species are estimated byus. Q = 180. h•troduction Rla O3+ bY-->O2 + O(1D) Jla=7.4x10 -5 RecentlyGamo et at. [1989] reportedmeasurements of Rib O2Q+ hv-->O2 + Q(!D) Jlb=1/2 J la heavyisotopes of CO2 in the stratosphereover Japan. Let O R2a O(ID)+ M--->O+ M k2a= 2.0x 10-11 e ll0/T = 160 andQ = 180.The fiQ of stratosphericCO2, as defined R2b Q(1D) + M --->Q + M k2b= k2a in Gatno et at., was found to be 2O/oo(two parts in a R3 O(ID)+ CO2---->CO2 + O k3 = 7.4x 10-11 e 120/T thousand)greater than that of troposphericCO 2 at 19 km, R4a Q(1D)+ CO2-->CO Q + O k4a= 2/3k 3 and appearsto continueto increasewith altitudeup to the R4b O(ID)+ COQ-->CO2 + Q k4b= 1/3k 3 highestaltitude (25 km) where sampleswere taken. -

A Two-Step Graph Convolutional Decoder for Molecule Generation

A Two-Step Graph Convolutional Decoder for Molecule Generation Xavier Bresson Thomas Laurent School of Computer Science and Engineering Department of Mathematics NTU, Singapore Loyola Marymount University [email protected] [email protected] Abstract We propose a simple auto-encoder framework for molecule generation. The molec- ular graph is first encoded into a continuous latent representation z, which is then decoded back to a molecule. The encoding process is easy, but the decoding pro- cess remains challenging. In this work, we introduce a simple two-step decoding process. In a first step, a fully connected neural network uses the latent vector z to produce a molecular formula, for example CO2 (one carbon and two oxygen atoms). In a second step, a graph convolutional neural network uses the same latent vector z to place bonds between the atoms that were produced in the first step (for example a double bond will be placed between the carbon and each of the oxygens). This two-step process, in which a bag of atoms is first generated, and then assembled, provides a simple framework that allows us to develop an efficient molecule auto-encoder. Numerical experiments on basic tasks such as novelty, uniqueness, validity and optimized chemical property for the 250k ZINC molecules demonstrate the performances of the proposed system. Particularly, we achieve the highest reconstruction rate of 90.5%, improving the previous rate of 76.7%. We also report the best property improvement results when optimization is constrained by the molecular distance between the original and generated molecules. 1 Introduction A fundamental problem in drug discovery and material science is to design molecules with arbitrary optimized chemical properties. -

The Chemical Behaviors of Nitrogen Dioxide Absorption in Sulfite Solution

Article The Chemical Behaviors of Nitrogen Dioxide Absorption in Sulfite Solution Ye Sun, Xiaowei Hong, Tianle Zhu *, Xiaoyan Guo and Deyuan Xie School of Space and Environment, Beihang University, Beijing 100191, China; [email protected] (Y.S.); [email protected] (X.H.); [email protected] (X.G.); [email protected] (D.X.) * Correspondence: [email protected]; Tel.: +86-10-8231-4215 Academic Editor: Agustín Bueno López Received: 14 March 2017; Accepted: 6 April 2017; Published: 12 April 2017 Abstract: The simultaneous removal of nitrogen oxides (NOx) and sulfur dioxide (SO2) by absorption is considered to be one of the most promising technologies for flue gas treatment, and sulfite is the main component of the absorption solution. To understand the chemical behaviors of the NO2 absorption in sulfite solution, the absorption time dependences of concentrations of nitrogen and sulfur compositions in both gas phase and liquid phases were investigated by flue gas analyzer, Ion chromatography (IC), Gas chromatography (GC), and Fourier transform infrared spectrometry (FTIR) methods using a bubbling reactor. The mass equilibrium of the N and S compositions were also studied. The results indicate that sulfite concentration plays a vital role in NO2 absorption. The main absorption products are NO3− and NO2−, and NO2− can be converted into NO3− in the presence of oxygen. Besides, about 4% to 9% by-products of S compositions are formed, and 4% to 11% by-products of N compositions such as NO, N2, N2O5, N2O, and HNO3 in the gas phase were detected in the emissions from the bubbling reactor. On the basis of N and S compositions, a possible pathway of NO2 absorption in sulfite solution was proposed. -

Assessing the Chemistry and Bioavailability of Dissolved Organic Matter from Glaciers and Rock Glaciers

RESEARCH ARTICLE Assessing the Chemistry and Bioavailability of Dissolved 10.1029/2018JG004874 Organic Matter From Glaciers and Rock Glaciers Special Section: Timothy Fegel1,2 , Claudia M. Boot1,3 , Corey D. Broeckling4, Jill S. Baron1,5 , Biogeochemistry of Natural 1,6 Organic Matter and Ed K. Hall 1Natural Resource Ecology Laboratory, Colorado State University, Fort Collins, CO, USA, 2Rocky Mountain Research 3 Key Points: Station, U.S. Forest Service, Fort Collins, CO, USA, Department of Chemistry, Colorado State University, Fort Collins, • Both glaciers and rock glaciers CO, USA, 4Proteomics and Metabolomics Facility, Colorado State University, Fort Collins, CO, USA, 5U.S. Geological supply highly bioavailable sources of Survey, Reston, VA, USA, 6Department of Ecosystem Science and Sustainability, Colorado State University, Fort Collins, organic matter to alpine headwaters CO, USA in Colorado • Bioavailability of organic matter released from glaciers is greater than that of rock glaciers in the Rocky Abstract As glaciers thaw in response to warming, they release dissolved organic matter (DOM) to Mountains alpine lakes and streams. The United States contains an abundance of both alpine glaciers and rock • ‐ The use of GC MS for ecosystem glaciers. Differences in DOM composition and bioavailability between glacier types, like rock and ice metabolomics represents a novel approach for examining complex glaciers, remain undefined. To assess differences in glacier and rock glacier DOM we evaluated organic matter pools bioavailability and molecular composition of DOM from four alpine catchments each with a glacier and a rock glacier at their headwaters. We assessed bioavailability of DOM by incubating each DOM source Supporting Information: with a common microbial community and evaluated chemical characteristics of DOM before and after • Supporting Information S1 • Data Set S1 incubation using untargeted gas chromatography–mass spectrometry‐based metabolomics. -

Modification of Manganese Dioxide Catalyst Owing to the Change in Gas Composition

Title Modification of Manganese Dioxide Catalyst Owing to the Change in Gas Composition Author(s) Kobayashi, Masayoshi; Kobayashi, Haruo Citation 北海道大學工學部研究報告, 69, 221-225 Issue Date 1973-11-15 Doc URL http://hdl.handle.net/2115/41166 Type bulletin (article) File Information 69_221-226.pdf Instructions for use Hokkaido University Collection of Scholarly and Academic Papers : HUSCAP Modification of Manganese Dioxide Catalyst Owing to the Change in Gas Composition Masayoshi KoBAyAsm and Haruo KoBAyAsm (Received April 28, 1973) Abstruct Modification of the electrolytic manganese dioxide surface during oxidation of carbon monoxide was studied experimentaly by purteybing the reaction steady state with a stepwise change in the concentration of carbon monoxide. The transient behavior of the oxidation activity corresponded exactly to that of the amount of surface oxygen species having a higher oxidation power, OgL*, and moreover t};1e apparent first order rate constant predicted by the steady state kinetics varied in proportion to the amount of Oge’. lt was shown that the modification of catalyst surface owing to he change in gas composition affected the oxidation activity through the change of the amount of 03t* which was catalytically active for oxidation of cabon monoxide. 1. lntroductioR It has been pointed out’un3) that the original composition of soiid catalysts is modified as a result of the equi正ibration processes of the solid-gas system and the catalytic activity of the surface is thereby changed correspondiRg to the composition of the -

Catalysis of the Oxygen Evolution Reaction by 4–10 Nm Cobalt Nanoparticles

Topics in Catalysis https://doi.org/10.1007/s11244-018-0923-4 ORIGINAL PAPER Catalysis of the Oxygen Evolution Reaction by 4–10 nm Cobalt Nanoparticles Edward Locke1 · Shan Jiang1 · Simon K. Beaumont1 © The Author(s) 2018 Abstract Electrolysis of water is key technology, not only for clean energy production, but to ensure a continued supply of hydrogen beyond fossil resources, essential to the manufacture of many chemical goods other than fuels. Cobalt nanomaterials have been widely identified as a promising candidate for the anode (oxygen evolution) reaction in this process, but much work has focused on applied materials or electrode design. Given the importance of oxidation state changes Co(III) → Co(IV) in the accepted reaction mechanism, in this work we look at size effects in small (4–10 nm) cobalt nanoparticles, where the ease of oxidation for lower cobalt oxidation states is known to change with particle size. To discriminate between geometric and chemical effects we have compared the catalysts in this study to others in the literature by turnover frequency (widely used in other areas of catalysis), in addition to the more commonly employed performance metric of the overpotential required to produce a current density of 10 mA cm−2. Comparisons are drawn to key examples of using well defined nanomaterials (where the surface are of cobalt sites can be estimated). This has enabled an estimated intrinsic turnover rate of ~ 1 O2 mol- ecule per surface Co atom per second at an overpotential of 500 mV in the oxygen evolution reaction under typical alkaline reaction conditions (pH 14.0) to be identified. -

Preparation of Magnetite and Manganese Oxide Ionic Polymer Nanocomposite for Adsorption of a Textile Dye in Aqueous Solutions

Digest Journal of Nanomaterials and Biostructures Vol. 11, No. 3, July - September 2016, p. 909 - 920 PREPARATION OF MAGNETITE AND MANGANESE OXIDE IONIC POLYMER NANOCOMPOSITE FOR ADSORPTION OF A TEXTILE DYE IN AQUEOUS SOLUTIONS A. M. ATTAa,b*, H. A. AL-HODANa, S. A. AL-HUSSAINc, A. O. EZZATa, A. M. TAWFIKd, Y. A. EL-DOSARYc aSurfactants research chair, Chemistry department, college of science, King Saud University, Riyadh 11451, Saudi Arabia bPetroleum Application Department, Egyptian Petroleum Research Institute, Nasr City 11727, Cairo, Egypt. Fax: 0020222747433; Tel: 0020222747917. c Department of Chemistry, Faculty of science, Al Imam Mohammad Ibn Saud Islamic University ( IMSIU), Riyadh 13318, Kingdom of Saudi Arabia. dCollege of Science, King Saud University, Riyadh, Saudi Arabia The present work aims to investigate new method to prepare manganese dioxide as well as magnetite nanocomposite based on in-situ technique. The crosslinked copolymeric hydrogel based on 2-acrylamido-2-methylpropane sulfonic acid-co-acrylic acid (AMPS/AA) was used as template to encapsulate the metal oxides by introducing the metal cations followed by redoxy reaction into the gel networks. The chemical, crystal structures, morphology and metal oxide contents were investigated using different spectroscopy and instrumental analyses. The ability of AMPS/AA metal oxide nanocomposites to remove different concentrations of textile cationic dye water pollutants such as crystal violet (CV) from aqueous environments was investigated using UV-visible measurements. The adsorption measurements confirmed the AMPS/AA metal oxide nanocomposites have high efficiency of to remove 1.5 g/L of CV during short time ranged between 20 and 60 minute. The kinetic study indicated that the adsorption process of CV adsorbate using AMPS/AA metal oxide nanocomposite adsorbents obey chemical adsorption mechanism. -

2012 Summer Undergraduate Research Fund (SURF) Recipients

2012 Summer Undergraduate Research Fund (SURF) Recipients Project Title: Improving Efficiency of Narrative Discourse Analysis in Persons with Brain Injuries Alexandra Addabbo, Communications Disorders , YOG: 2013 Faculty Mentor: Dr. Carl Coelho, Department of Communications Disorders Project Title: The Role of BspA-like Protein in the Microbial Gut Community of Reticulartermes Flavipes and Identification of Species that are Involved in Lignocellulose Degredation Adam Bartholomeo, Molecular and Cell Biology, YOG: 2013 Faculty Mentor: Dr. Daniel Gage, Department of Molecular and Cell Biology Named Award: Ocean Rain Family Foundation Fund for Summer Undergraduate Research Award Project Title: Surveying the Self-Medication Practices of Adults with Sickle Cell Disease Courtney Beyers, Nursing, YOG: 2013 Faculty Mentor: Victoria Odesina, DNP, Department of Nursing Project Title: Investigating of an Efficient System to Harvest Clean Energy from Structural Vibrations Bryan Blanc, Civil Engineering, YOG: 2013 Faculty Mentor: Dr. Ramesh Malla, Department of Civil and Environmental Engineering Named Award: The DeMaio Family Summer Undergraduate Research Fund Project Title: Investigating of an Efficient System to Harvest Clean Energy from Structural Vibrations Kelsey Boch, Chemical Engineering, YOG: 2013 Faculty Mentor: Dr. Yong Wang, Department of Chemical, Materials, and Biomolecular Engineering Project Title: On the Semantic Organization of Concrete and Abstract Terms: a Follow-up to Dunabietia et al. 2009 Christopher Brozowski, Cognitive Science, YOG: 2013 Faculty Mentor: Dr. James Magnuson, Department of Psychology Project Title: Psychological and Emotional Factors to Development in Young Adults with HIV Jenna Burns, Nursing, YOG: 2013 Faculty Mentor: Dr. Elizabeth Anderson, Department of Nursing Project Title: An Investigation into the Synthesis and Reaction Properties of Sulfur Monoxide Casey Camire, Chemistry, YOG: 2014 Faculty Mentor: Dr. -

Empirical and Molecular Formulas INFORMATION (P

See book pages 343 – 351 Name: _____________________ Empirical and Molecular Formulas INFORMATION (p. 348 – 349): An empirical formula is a “lowest common denominator” molecular formula for covalent molecules. It represents the ratio in which atoms (or MOLES of atoms) combine to form compounds, but not the actual numbers of atoms in the compound. Multiple compounds can have the same empirical formula. Glucose, C6H12O6, contains carbon, hydrogen, and oxygen. The ratio of carbon to hydrogen to oxygen is 1:2:1. CH2O is the empirical formula for glucose. Since the percent composition of each element in an empirical formula represents the ratio in which they occur, the percent composition can be used, in conjunction with the molar masses of the elements, to determine the empirical formula of a compound. It is generally prudent to assume a 100.0 gram sample of the compound for the purpose of simplifying the calculations. Example 1: Caffeine has the following percent composition: carbon, 49.48%; hydrogen 5.19%; oxygen, 16.48%; and nitrogen, 28.85%. What is its empirical formula? (see page 349) INFORMATION (p. 350 – 351): A molecular formula is a formula that represents the actual number of each atom in a compound. Whereas CH2O is the empirical formula for glucose, C6H12O6 is the molecular formula. An actual molecule of glucose contains six carbon atoms, twelve hydrogen atoms, and six oxygen atoms. (Or six moles of carbon atoms, 12 moles of hydrogen atoms, and six moles of oxygen atoms). Since an empirical formula indicates the ratios of the elements in the compound, it can be used, along with the molar mass of the compound, to determine the molecular formula.