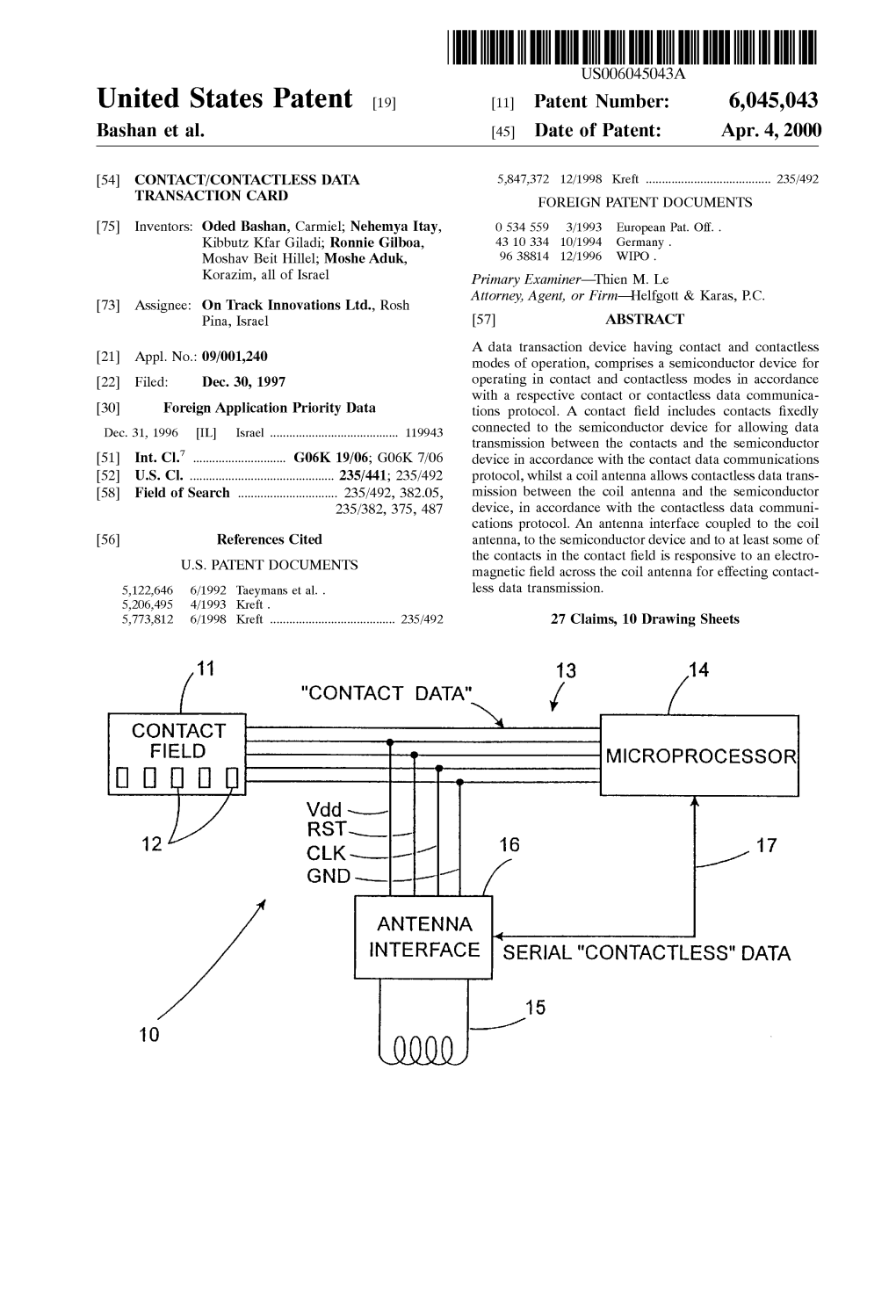

United States Patent (19) 11 Patent Number: 6,045,043 Bashan Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Israel-Hizbullah Conflict: Victims of Rocket Attacks and IDF Casualties July-Aug 2006

My MFA MFA Terrorism Terror from Lebanon Israel-Hizbullah conflict: Victims of rocket attacks and IDF casualties July-Aug 2006 Search Israel-Hizbullah conflict: Victims of rocket E-mail to a friend attacks and IDF casualties Print the article 12 Jul 2006 Add to my bookmarks July-August 2006 Since July 12, 43 Israeli civilians and 118 IDF soldiers have See also MFA newsletter been killed. Hizbullah attacks northern Israel and Israel's response About the Ministry (Note: The figure for civilians includes four who died of heart attacks during rocket attacks.) MFA events Foreign Relations Facts About Israel July 12, 2006 Government - Killed in IDF patrol jeeps: Jerusalem-Capital Sgt.-Maj.(res.) Eyal Benin, 22, of Beersheba Treaties Sgt.-Maj.(res.) Shani Turgeman, 24, of Beit Shean History of Israel Sgt.-Maj. Wassim Nazal, 26, of Yanuah Peace Process - Tank crew hit by mine in Lebanon: Terrorism St.-Sgt. Alexei Kushnirski, 21, of Nes Ziona Anti-Semitism/Holocaust St.-Sgt. Yaniv Bar-on, 20, of Maccabim Israel beyond politics Sgt. Gadi Mosayev, 20, of Akko Sgt. Shlomi Yirmiyahu, 20, of Rishon Lezion Int'l development MFA Publications - Killed trying to retrieve tank crew: Our Bookmarks Sgt. Nimrod Cohen, 19, of Mitzpe Shalem News Archive MFA Library Eyal Benin Shani Turgeman Wassim Nazal Nimrod Cohen Alexei Kushnirski Yaniv Bar-on Gadi Mosayev Shlomi Yirmiyahu July 13, 2006 Two Israelis were killed by Katyusha rockets fired by Hizbullah: Monica Seidman (Lehrer), 40, of Nahariya was killed in her home; Nitzo Rubin, 33, of Safed, was killed while on his way to visit his children. -

The Israel Trip

THE EXPERIENCE OF A LIFETIME: JOIN RABBIS YOSHI ZWEIBACK & RON STERN ON THE ADULT MARCH OF THE LIVING IN POLAND AND ISRAEL FOR A CULTURAL AND CULINARY TOUR LIKE NO OTHER INAR UL Y C 7–MAY 4, 20 TO D IL 2 20 U N PR R A A L A R U T L U THE C ISRAEL TRIP 888.811.2812 New York: 500 7th Ave | 8th Floor | New York, NY 10018 Prague: Soukenicka 1194/13 | 110 00 Prague 1 | Czech Republic Jerusalem: 19 Washington Street | P.O. Box 71047 | Jerusalem, Israel 9171000 Tel Aviv: 6 Beit Hillel Street | Tel Aviv, Israel 6701709 Your Tour Educator Every journey we offer is accompanied by a Tour Educator (TE) who brings your itinerary to life. Some of our TE’s have decades of firsthand experience leading people to particular places. Your TE will provide you with an authentic understanding of the locations you will visit, will introduce you to the locals, and will share his/her enthusiasm and passion for the local culture. The result is a journey that transforms your understanding of a place, connecting you to the people and places you encounter in a way that is palpable and unforgettable. Our TE's are like no other: intelligent, knowledgeable, engaging and fun. They will become an indispensable part of your experience and some might just become lifetime friends. OUR TRIP APRIL 2 7– MAY 4, 2020 FROM $3,965 LAND & AIR FROM WARSAW TO TEL AVIV HIGHLIGHTS A journey of connection and exploration Experience the sights, sounds, and tastes of "the city that never sleeps” Access to top thinkers, writers, comedians, and journalists Party with the locals on Israel’s Independence Day From Israel’s early artists to contemporary street art and graffiti Explore Jewish-Arab efforts to create integrated communities Whiskey distillery, winery, and private dinner with a chef: a culinary adventure Musical Shabbat in Tel Aviv Exceptional service with top-notch tour educators and speakers DAY ONE MONDAY, APRIL 27, 2020 Lunch (not included in package), en route. -

Galilee Sea Of

UN Demilitarised Zone 0 10 km Mt Hermon 0 5 miles Mt Hermon Hatzbani Ski Station River Dan Nahal 98 Neve Ativ Tel Dan Banias (Israeli Metula Nature Nature Nimrod settlement) L E B A N O N Ghajar Reserve ReserveFortress Majdal Nahal Iyyun Shams Kibbutz 989 Kibbutz Kfar Nature Reserve Nimrod (Israeli Kibbutz Dan 99 Gil’adi settlement) Tel Hai Ma’ayan Ein Kinya ine Kibbutz Banias 4 99 Birket UN Demilitarised Zone 9977 Baruch Snir Waterfall Mas'ada Ram 7 HaGoshrim 9 1 Kiryat Beit Hillel raeli L Shmona Border of 1923 Is Buq'ata Manara 9888 British Mandate 918 of Palestine 978 98 90 Sde Nehemia Odem Kibbutz (Israeli Quneitra Kibbutz Neot Kfar Blum settlement) Viewpoint Mordechai 977 Mt Bental 959 (1165m) 886 Wasset Jct Hula 9881 Merom Golan Quneitra Valley (Israeli settlement) Ramot Agamon HaHula Mt Avital Naftali Ein Zivan 899 (Israeli Zivan Jct 886 978 settlement) Kerem Beit 90 Hula Bar'am Nature 918 Zimra Reserve Gilabon 98 Yesud Nature Ramat Dalton Nafah Jct HaMa'ala Yesud Reserve Jct HaMa'ala 91 Ramat Dalton Jordan River Rafting Jish Industrial Park Zavitan UPPER GALILEE Ayalet Mt Meron Summit (13km); Gadot GOLAN HaShahar Jct Nahariya (40km) Tel Hatzor Nahal HEIGHTS Kadita Hatzor B'not Ya'akov Katzrin Tomb of iver Bat Ya'ar HaGlilit 91 Bridge (Israeli Katzrin Industrial Zone the Rashbi Mahanayim R settlement) Rosh n 9088 87 Pina Yehudiya Nature Reserve – 866 Meron Mahanayim Kfar Ani'am Artists' Village Jct Jct HaNasi Jorda Mesushim Entrance (Israeli settlement) 888 Mt Meron Tsfat Yehudiya Nature Reserve Nature Reserve 89 90 Yehudiya Nature -

Nära 200 Reseguider Att Ladda Ner!

5 x telefonnummer Publicerad november 20172014 Mobil ringer till Israel och ta bort engelska talas. De kontaktas på Om du slår 112 från din mobil nollan i riktnumret. 0159952 05 20 dygnet runt. kommer du automatiskt till w Ze´ev Jabotinsky Road, 160 larmcentralen som kan dirigera Ringa till Sverige ditt samtal vidare. Vill du till Slå 0046 eller +46 och ta bort Ambassad polis slår du 100, ambulans 100 nollan i riktnumret. Sveriges ambassad i Tel Aviv har och brandkår 102. öppet måndag–fredag, 10–12. Terem w Adgar 360, 24 tr, 2, Hashlosha Ringa till Israel Om du blir sjuk är Terem akut Street, Tel Aviv Slå 00972 eller +972 när du kliniker ett bra alternativ där Tel. +972 3 718 00 00 5 x bra sajter Turistministeriets sajt TEL AVIV Officiell engelskspråkig sajt från turistministeriet i ✔ ✔ ✔ Israel. Kortfattad info om det mesta. Stränder Nöjeslivet Gratisnöjen S newgoisrael.com ✔ Kultur ✔ Mat & dryck ✔ Delta i sabbat Info om nöjen och kultur ✔ Shopping ✔ Marknader ✔ Bindefelds bästa Sajt om nattliv. Kalender med olika evenemang som konserter och utställningar. Info om restauranger och barer. Ett plus för användbar information om allt från att ta med sig husdjuret till att hyra bostad. S www.secrettelaviv.com Hitta bästa stranden. din resa. Bra och lättfattlig information och tips Bra tips till staden om vad du kan läsa mer om nyheter ibland annat Engelskspråkig. Många intressanta och roliga engelskspråkig media. uppslag om vad du kan hitta på i Tel Aviv. S www.swedenabroad.com S www.timeout.co/israel Pride på engelska Håll koll med UD Info på engelska om Pridefestivalen som går av UD:s hemsida är bra att läsa inför resan men också stapeln i juni varje år. -

Return of Organization Exempt from Income

Return of Organization Exempt From Income Tax Form 990 Under section 501 (c), 527, or 4947( a)(1) of the Internal Revenue Code (except black lung benefit trust or private foundation) 2005 Department of the Treasury Internal Revenue Service ► The o rganization may have to use a copy of this return to satisfy state re porting requirements. A For the 2005 calendar year , or tax year be and B Check If C Name of organization D Employer Identification number applicable Please use IRS change ta Qachange RICA IS RAEL CULTURAL FOUNDATION 13-1664048 E; a11gne ^ci See Number and street (or P 0. box if mail is not delivered to street address) Room/suite E Telephone number 0jretum specific 1 EAST 42ND STREET 1400 212-557-1600 Instruo retum uons City or town , state or country, and ZIP + 4 F nocounwro memos 0 Cash [X ,camel ded On° EW YORK , NY 10017 (sped ► [l^PP°ca"on pending • Section 501 (Il)c 3 organizations and 4947(a)(1) nonexempt charitable trusts H and I are not applicable to section 527 organizations. must attach a completed Schedule A ( Form 990 or 990-EZ). H(a) Is this a group return for affiliates ? Yes OX No G Website : : / /AICF . WEBNET . ORG/ H(b) If 'Yes ,* enter number of affiliates' N/A J Organization type (deckonIyone) ► [ 501(c) ( 3 ) I (insert no ) ] 4947(a)(1) or L] 527 H(c) Are all affiliates included ? N/A Yes E__1 No Is(ITthis , attach a list) K Check here Q the organization' s gross receipts are normally not The 110- if more than $25 ,000 . -

Israeli Settler-Colonialism and Apartheid Over Palestine

Metula Majdal Shams Abil al-Qamh ! Neve Ativ Misgav Am Yuval Nimrod ! Al-Sanbariyya Kfar Gil'adi ZZ Ma'ayan Baruch ! MM Ein Qiniyye ! Dan Sanir Israeli Settler-Colonialism and Apartheid over Palestine Al-Sanbariyya DD Al-Manshiyya ! Dafna ! Mas'ada ! Al-Khisas Khan Al-Duwayr ¥ Huneen Al-Zuq Al-tahtani ! ! ! HaGoshrim Al Mansoura Margaliot Kiryat !Shmona al-Madahel G GLazGzaGza!G G G ! Al Khalsa Buq'ata Ethnic Cleansing and Population Transfer (1948 – present) G GBeGit GHil!GlelG Gal-'A!bisiyya Menara G G G G G G G Odem Qaytiyya Kfar Szold In order to establish exclusive Jewish-Israeli control, Israel has carried out a policy of population transfer. By fostering Jewish G G G!G SG dGe NG ehemia G AGl-NGa'iGmaG G G immigration and settlements, and forcibly displacing indigenous Palestinians, Israel has changed the demographic composition of the ¥ G G G G G G G !Al-Dawwara El-Rom G G G G G GAmG ir country. Today, 70% of Palestinians are refugees and internally displaced persons and approximately one half of the people are in exile G G GKfGar GB!lGumG G G G G G G SGalihiya abroad. None of them are allowed to return. L e b a n o n Shamir U N D ii s e n g a g e m e n tt O b s e rr v a tt ii o n F o rr c e s Al Buwayziyya! NeoG t MG oGrdGecGhaGi G ! G G G!G G G G Al-Hamra G GAl-GZawG iyGa G G ! Khiyam Al Walid Forcible transfer of Palestinians continues until today, mainly in the Southern District (Beersheba Region), the historical, coastal G G G G GAl-GMuGftskhara ! G G G G G G G Lehavot HaBashan Palestinian towns ("mixed towns") and in the occupied West Bank, in particular in the Israeli-prolaimed “greater Jerusalem”, the Jordan G G G G G G G Merom Golan Yiftah G G G G G G G Valley and the southern Hebron District. -

Download File

Halevy, Halivni and The Oral Formation of the Babylonian Talmud Ari Bergmann Submitted in partial fulfillment of the requirements for the degree of Doctor of Philosophy in the Graduate School of Arts and Sciences COLUMBIA UNIVERSITY 2014 © 2014 Ari Bergmann All rights reserved ABSTRACT Halevy, Halivni and The Oral Formation of the Babylonian Talmud Ari Bergmann This dissertation is dedicated to a detailed analysis and comparison of the theories on the process of the formation of the Babylonian Talmud by Yitzhak Isaac Halevy and David Weiss Halivni. These two scholars exhibited a similar mastery of the talmudic corpus and were able to combine the roles of historian and literary critic to provide a full construct of the formation of the Bavli with supporting internal evidence to support their claims. However, their historical construct and findings are diametrically opposed. Yitzhak Isaac Halevy presented a comprehensive theory of the process of the formation of the Talmud in his magnum opus Dorot Harishonim. The scope of his work was unprecedented and his construct on the formation of the Talmud encompassed the entire process of the formation of the Bavli, from the Amoraim in the 4th century to the end of the saboraic era (which he argued closed in the end of the 6th century). Halevy was the ultimate guardian of tradition and argued that the process of the formation of the Bavli took place entirely within the amoraic academy by a highly structured and coordinated process and was sealed by an international rabbinical assembly. While Halevy was primarily a historian, David Weiss Halivni is primarily a talmudist and commentator on the Talmud itself. -

The Kibbutz and the Ma'abara (Transit Camp): the Case of the Upper

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/297686928 The kibbutz and the ma’abara (transit camp): The case of the Upper Galilee kibbutzim and Kiryat Shmona, 1949–1953 Article in Journal of Israeli History · March 2016 DOI: 10.1080/13531042.2016.1140878 CITATIONS READS 2 394 1 author: Amir Goldstein Tel-Hai Academic College 63 PUBLICATIONS 24 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: Microhistory of Kiryat shmona and Hula Valley View project Zionist right - the road to power View project All content following this page was uploaded by Amir Goldstein on 15 October 2017. The user has requested enhancement of the downloaded file. Journal of Israeli History Politics, Society, Culture ISSN: 1353-1042 (Print) 1744-0548 (Online) Journal homepage: http://www.tandfonline.com/loi/fjih20 The kibbutz and the ma’abara (transit camp): The case of the Upper Galilee kibbutzim and Kiryat Shmona, 1949–1953 Amir Goldstein To cite this article: Amir Goldstein (2016) The kibbutz and the ma’abara (transit camp): The case of the Upper Galilee kibbutzim and Kiryat Shmona, 1949–1953, Journal of Israeli History, 35:1, 17-37, DOI: 10.1080/13531042.2016.1140878 To link to this article: http://dx.doi.org/10.1080/13531042.2016.1140878 Published online: 09 Mar 2016. Submit your article to this journal Article views: 94 View related articles View Crossmark data Full Terms & Conditions of access and use can be found at http://www.tandfonline.com/action/journalInformation?journalCode=fjih20 Download by: [77.138.104.170] Date: 12 September 2016, At: 12:40 JOURNAL OF ISRAELI HISTORY, 2016 VOL. -

Zion of Their Own Hebrew Women's Nationalist Writing

Zion of Their Own Hebrew Women’s Nationalist Writing By Orian Zakai A dissertation submitted in partial fulfillment of the requirements for the degree of Doctor of Philosophy (Comparative Literature) in The University of Michigan 2012 Doctoral Committee: Associate Professor Carol B. Bardenstein, Chair Associate Professor Shahar M. Pinsker Professor Anton Shammas Associate Professor Ruth Tsoffar © Orian Zakai 2012 Acknowledgements Many people have kindly offered me their invaluable support and guidance throughout the writing of this dissertation. I am particularly grateful to my advisor Carol Bardenstein for her patient and warm mentorship and her unwavering faith in my project. Carol’s uncompromising critical insights have driven me to expand my analytical horizons, and to constantly strive for more rigorous, original and precise thinking. I thank Ruth Tsoffar for inspiring conversations, for her attentive reading and perceptive commentary on my work, and, in particular, for being a guide and a model in the process of opening up texts and investigating the possibilities that every text holds. Shachar Pinsker’s scholarship and teaching have been a source of inspiration throughout the years. Shachar’s advice and support were invaluable in initiating me as a scholar of Hebrew literature. I feel fortunate for having worked with such a kind and generous mentor. I would like to extend my deep gratitude to Anton Shammas, whose wise remarks, as of the early stages of writing, have shaped my overall approach to the politics and poetics of texts. I hope I have managed to follow Anton’s advice and read the texts of the past with acute awareness of the present. -

Guide for the New and Visiting Faculty

GUIDE FOR THE NEW AND FOR VISITING FACULTY GUIDE FOR THE NEW AND VISITING FACULTY Twelfth Edition The Hebrew University of Jerusalem Guide For The New And Visiting Faculty CONTENTS | 2 CONTENTS FOREWORD 3 The Pscyho-Educational Service 65 Health Services in Schools 65 CHAPTER ONE English for English Speakers 65 THE HEBREW UNIVERSITY OF JERUSALEM 4 Extracurricular Activities 66 The Adviser’s Office 4 Sports 66 Introduction to the Hebrew University of Jerusalem 5 Music and Art 66 The Edmond J. Safra (Givat Ram) Campus 6 Other Activities 67 The Ein Kerem Campus 7 Community Centers 67 The Rehovot Campus 7 Youth Movements 67 Libraries 8 Field Schools 68 Other University Units 12 Summer, Hanukkah and Passover Camps 68 The Rothberg International School 15 CHAPTER SIX International Degree Programs 18 UNIVERSITY, ADULT, AND CONTINUING EDUCATION 70 Non-Degree Graduate Programs 19 Academic Year 21 The Hebrew University of Jerusalem 70 Adult Education 71 CHAPTER TWO Hebrew Language Studies 72 FACILITIES ON CAMPUS 22 CHAPTER SEVEN Getting There 22 GETTING TO KNOW JERUSALEM: LIFESTYLE AND CULTURE 73 Security: Entry to Campus 24 Administration 26 General Information 73 Traditional and Religious Activities 30 Leisure Time 74 Academon 32 Touring Jerusalem 74 Performing Arts 76 CHAPTER THREE Cafés, Bars and Discotheques 76 PLANNING TO COME 40 Cinema 76 Visa Information 40 Media 77 Salaries and Taxes 42 Museums 78 Income Tax 42 Libraries 81 Value Added Tax (VAT/“ma’am”) 43 CHAPTER EIGHT National Insurance (Bituah Leumi) 43 OUT AND ABOUT IN JERUSALEM 82 -

TISHA B'av 5779 at PARDES August 11, 2019 10:00-11

TISHA B’AV 5779 AT PARDES August 11, 2019 10:00-11:15 a.m. The Temple & Jerusalem: Destruction & Dreams of Rebuilding through Art Dr. Susan Nashman Fraiman 3rd floor-Beit Midrash The longing for Jerusalem and the Temple is expressed in both Jewish and Christian art. This class will take a look at this artistic expression through the lens of destruction and hope for a better future. Dr. Susan Nashman Fraiman is a lecturer and researcher in the field of Jewish and Israeli art at the Rothberg International School of Hebrew University and received her Ph.D. from Hebrew University in 2013. She has been living in Israel for over 40 years. She is a Pardes alumna and she and her husband met at Pardes! In Conversation: Spiritual Exile & Redemption-Within oneself & the World at Large Rabbanit Nechama Goldman Barash & Yiscah Smith 3rd floor-Dining Room An exploration and conversation on what many consider to be the most well-known one verse declaration of one's Jewish identity, belief and trust in the Almighty --- the Shema Yisrael. How does the Shema restore the Divine unity to a fragmented world, exile followed by redemption --- both to the outer world and to one's inner world? What is the power of the Shema that Jews throughout the past 3500 years continuously recite this verse: whenever and wherever they have lived, regardless of degree of commitment to traditional or non-traditional Jewish Law and tradition, regardless of one's environment both in Israel and in the Diaspora, during times of health and joy and during times of suffering and pain, regardless of just about any other aspect of a person's life that defines a person's identity? And why is the Shema always read from the Torah on the Shabbat following Tisha B'Av? Rabbanit Nechama Goldman Barash studied for three years in Matan’s Advanced Talmud Institute and finished a master’s degree in Talmud at Bar-Ilan University. -

General Assembly Security Council Sixtieth Session Sixty-First Year Agenda Item 14 the Situation in the Middle East

United Nations A/60/990–S/2006/692 General Assembly Distr.: General 28 August 2006 Security Council Original: English General Assembly Security Council Sixtieth session Sixty-first year Agenda item 14 The situation in the Middle East Identical letters dated 23 August 2006 from the Deputy Permanent Representative of Israel to the United Nations addressed to the Secretary-General and the President of the Security Council On behalf of my Government, I have the honour to share with you a consolidated list containing the names of Israelis killed from 12 July 2006 to 14 August 2006 in Hizbullah terrorist attacks (see annex). As you know, on 12 July 2006, Israel was attacked by Hizbullah terrorists on its northern border, when eight soldiers were killed and two more abducted. What followed was 34 days of continued rocket attacks on northern Israeli communities, launched by Hizbullah terrorists in southern Lebanon. The attacks killed 157 Israelis and injured thousands of others, caused considerable damage to civilian infrastructure, and inflicted psychological trauma on Israel’s civilian population. It should also be mentioned that the two abducted soldiers, Udi Goldwasser and Eldad Regev, have yet to be released by their terrorist captors. I should be grateful if you would have the present letter and its annex circulated as a document of the sixtieth session of the General Assembly, under agenda item 14, and of the Security Council. (Signed) Daniel Carmon Ambassador Deputy Permanent Representative 06-48187 (E) 010906 *0648187* A/60/990 S/2006/692