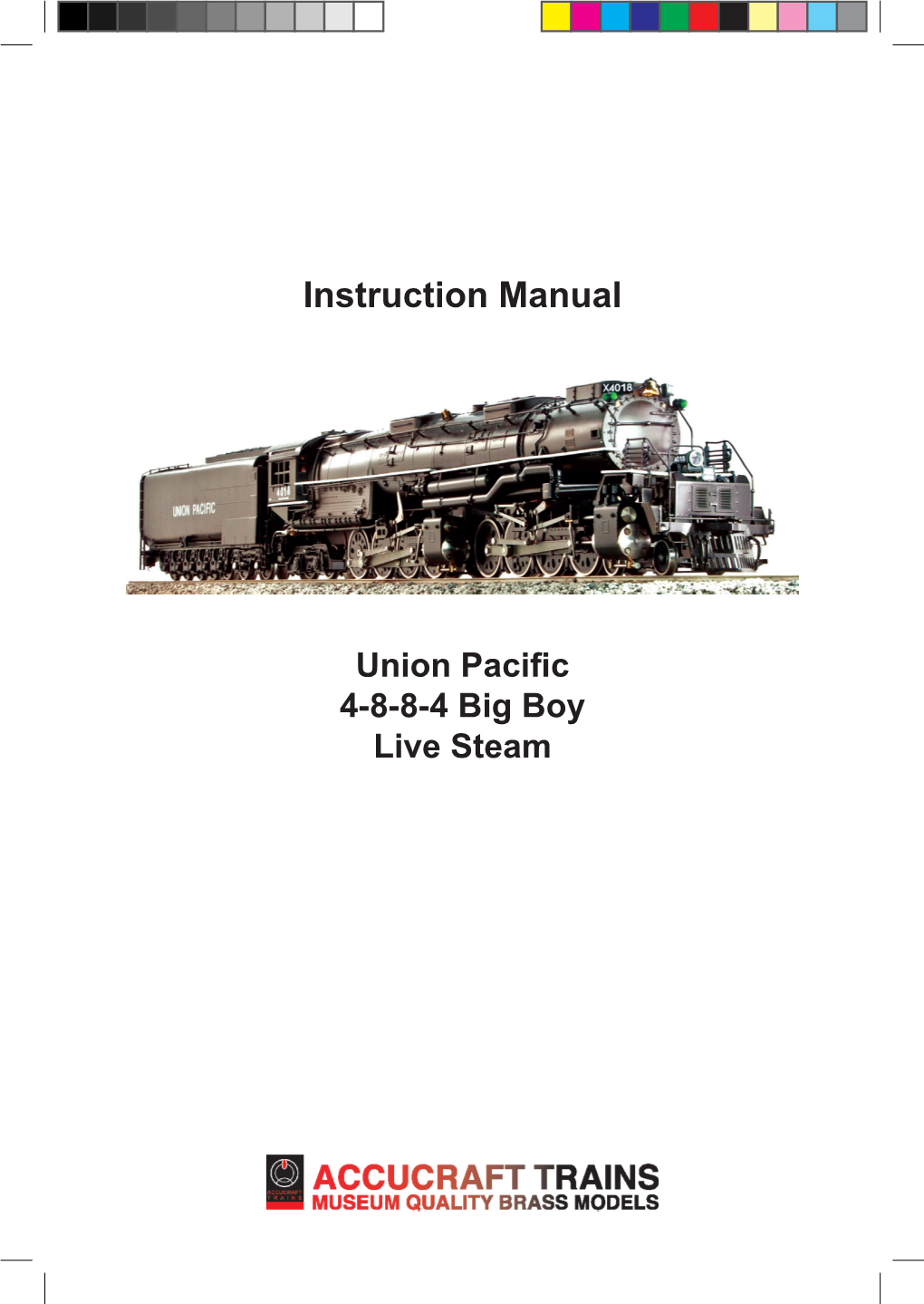

Big Boy UP, Live Steam

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Locomotive Dedication Ceremony

The American Society of Mechanical Engineers REGIONAL MECHANICAL ENGINEERING HERITAGE COLLECTION LOCOMOTIVE DEDICATION CEREMONY Kenefick Park • Omaha, Nebraska June 7, 1994 Locomotives 4023 and 6900 are examples of the world’s largest motive power in the steam and diesel eras. These locomotives are on permanent display at Kenefick Park, which was established in 1989 in honor of noted former Union Pacific chairman, John C. Kenefick. The 4023 was one of twenty-five famous “Big Boy” type simple articulated locomotives Locomotive 4023 was a feature display lauded in the industry and press as the highest horsepower, heaviest and longest steam at the Omaha Shops locomotives ever built, developing seven thousand horsepower at their seventy miles until being moved to per hour design speed. Kenefick Park. 2 World’s largest The Big Boy type was designed at the Omaha headquarters of Union Pacific under the single unit diesel personal direction of the road’s noted mechanical head, Otto Jabelmann. The original locomotives required four axle trucks to distribute twenty locomotives of this type were built by American Locomotive Company in their heavy weight and Schenectady, New York, in the fall of 1941. They were built in preparation for the nation’s keep within track probable entry into World War II because no proven diesel freight locomotive was yet loading limits. in production. These 4-8-8-4 type locomotives were specifically designed to haul fast, heavy eastbound freight trains between Ogden, Utah, and Green River, Wyoming, over the 1.14 percent eastbound grade. The 4023 was one of five additional units built in 1944 under govern- ment authority in preparation for a twenty-five percent increase in traffic due to the shift from European to Pacific war operations. -

Baldwin Locomotive Works Location: Philadelphia (Eddystone, PA, in 1912) Operating Dates: 1831-1956 Principals: Matthias W

BUILDERS OF COLORADO OFFICE OF ARCHEOLOGY AND HISTORIC PRESERVATION BIOGRAPHICAL SKETCH COLORADO HISTORICAL SOCIETY Firm: Baldwin Locomotive Works Location: Philadelphia (Eddystone, PA, in 1912) Operating Dates: 1831-1956 Principals: Matthias W. Baldwin Information Jeweler and silversmith Matthias Baldwin founded the Baldwin Locomotive Works in 1831. The original manufacturing plant was on Broad Street in Philadelphia where the company did business for 71 years until moving in 1912 to Eddystone, PA. Baldwin made its reputation building steam locomotives for the Pennsylvania Railroad, the Baltimore & Ohio Railroad, the Atchison, Topeka & Santa Fe, and many of the other North American railroads, as well as for overseas railroads in England, France, India, Haiti and Egypt. Baldwin locomotives found their way onto the tracks of most Colorado railroads, both standard and narrow gauge. Baldwin built a huge number of 4-4-0 American type locomotives, but was perhaps best known for the 2-8-2 Mikado (D&RGW No. 491) and 2-8-0 Consolidation types (D&RGW No. 346 and DSP&P No. 191).1 It was also well known for the unique cab-forward 4-8-8-2 articulated locomotives built for the Southern Pacific Railroad and the massive 2-10-2 engines for the Santa Fe Railroad. One of Baldwin's last new and improved locomotive designs was the 4-8-4 (Northern) locomotive (Santa Fe No. 2911). In 1939, Baldwin offered its first standard line of diesel locomotives, all designed for rail yard service. Two years later, America's entry into World War II destroyed Baldwin's diesel development program when the War Production Board dictated that ALCO (American Locomotive Company) and Baldwin produce only diesel-electric yard switching engines. -

Lima 2-8-0 “Consolidation”, Developed for TS2013, by Smokebox

Union Pacific 4000 Class 4884-1 "Big Boy" circa 1948-49 Developed by Smokebox TM for Dovetail Games' Train Simulator © Smokebox 2021, all rights reserved Issue 1 Union Pacific 4000 Class 4884-1 "Big Boy" Steam Locomotive Page 2 Contents Introduction ....................................................................................................................................................... 7 32- and 64-bit TS ................................................................................................................................................ 7 Expert or Simple Controls mode, HUD and Automatic Fireman ....................................................................... 7 "All-in-one" .................................................................................................................................................... 7 Standard TS Automatic Fireman .................................................................................................................... 8 F4 HUD ........................................................................................................................................................... 8 High Detail (HD) and Standard Detail (SD) ........................................................................................................ 8 Recommended Settings ..................................................................................................................................... 9 Cab Layout ...................................................................................................................................................... -

2019 Chevrolet Low Cab Forward 3500/4500 Series Owners Manual

19_CHEV_Low_Cab_Forward_6.0L_Gasoline_Engine_3500_4500_Series_Medium_Duty_6.0L_GAS_Engine_COV_en_US_84445127A_2018NOV27.ai 1 11/27/2018 9:42:08 AM C M Y CM MY CY CMY K Chevrolet Low Cab Forward 6.0L Gasoline Engine 3500/4500 Series (GMNA- Localizing-U.S.-12533400) - 2019 - CRC - 11/19/18 Contents Introduction . 2 In Brief . 7 Keys, Doors, and Windows . 23 Seats and Restraints . 36 Storage . 52 Instruments and Controls . 62 Lighting . 80 Infotainment System . 85 Climate Controls . 121 Driving and Operating . 128 Vehicle Care . 186 Service and Maintenance . 269 Technical Data . 292 Customer Information . 304 Reporting Safety Defects . 311 Index . 313 Chevrolet Low Cab Forward 6.0L Gasoline Engine 3500/4500 Series (GMNA- Localizing-U.S.-12533400) - 2019 - CRC - 11/19/18 2 Introduction Introduction Information booklet. We urge you to Model Reference read these publications carefully. The models covered in this The following recommendations will manual are: help ensure the most enjoyable, safe, and trouble-free operation of Single Cab: your vehicle. When it comes to service, keep in mind that your commercial truck dealer knows your vehicle best and is interested in The names, logos, emblems, your complete satisfaction. Your slogans, vehicle model names, and dealer invites you to return for all of vehicle body designs appearing in your service needs both during and this manual including, but not limited after the warranty period. 3500 to, GM, the GM logo, CHEVROLET, Remember, if you have a concern . 4500 and the CHEVROLET Emblem are that has not been handled to your trademarks and/or service marks of satisfaction, follow the steps in the Crew Cab: General Motors LLC, its separate Warranty and Owner subsidiaries, affiliates, or licensors. -

ARKANSAS-BOSTON MOUNTAINS CHAPTER NATIONAL RAILWAY HISTORICAL SOCIETY Chapter No

ARKANSAS-BOSTON MOUNTAINS CHAPTER NATIONAL RAILWAY HISTORICAL SOCIETY Chapter No. 188 founded in 1987 2010 DIRECTORY OF OFFICERS President Bob Stark Vice President David McDonald Secretary Malcolm Cleaveland Treasurer Bill Longston Program Director David McDonald National Director Chuck Girard Board Director Larry Cain Editor Bill Merrifield Our website address is www.arkrailfan.com NRHS Chapter boards the A&M dinner train by reservation before 6:30 PM, December 20 The Scrambler Volume 26, No. 4 December, 2012 Monthly Newsletter of the Arkansas-Boston Mountains Chapter, National Railway Historical Society CHAPTER MINUTES Meeting of the Arkansas- Boston Mtns. Chapter of the National Railway Historical Society at the Shiloh Mu- seum, Springdale, AR. November 15, 2012. Meeting was called to order at 7:00PM by President, Bob Stark. 19 members were present . The minutes of the October meeting were approved. Chuck Girard, National Director, reported that we have 62 members, 44 primary, 18 family, 4 new, 31 have paid (Shiloh Museum and A&M RR memberships paid by the chapter). There was discussion of the way checks are held to sync with National's billing cycle. Scramblers have been mailed. Bill Longston, the Treasurer, reported that the money market account had $11,500.43. The checking account current balance is $1,555.47. Bill Merrifield, Scrambler editor, reported that the latest issue of the Scrambler was somewhat mail delayed be- cause the 11th was a federal holiday. The Archivist (also organizer of our anniversary gala and Xmas outing), All Kaeppel, said we got 62 name tags for $227, a really good price. -

Proto-Sound 3.0

2014 HO MODEL TRAINS Proto-Sound® 3.0... THE RICHEST SET OF FEATURES IN MODEL RAILROADING! Whether you operate with a conventional transformer or in com- GREAT SMOKE They’ll run in perfect synchronization with each other at any mand mode with DCC or DCS™ (M.T.H.’s Digital Command Sys- Proto-Sound engines feature fan-driven ProtoSmoke™, the most speed. You can even set your lashup so only the lead engine’s tem), the Proto-Sound 3.0 system available in every locomotive in powerful smoke system in the hobby. You can vary the intensity bell and whistle will sound, as in real life multiple-unit operation. this catalog offers more realism, more fun, and more variety than with the smoke “volume” control on the locomotive or remotely any other locomotive control system in any scale. with any DCC or DCS controller. DCC Features VIVID ENGINE SOUNDS SYNCHRONIZED CHUFF AND PUFF Proto-Sound 3.0-equipped locomotives can be controlled in com- Proto-Sound features crystal-clear digital sounds. We strive to mand mode with any DCC-compliant command control system. Like a real steam engine, M.T.H. steamers feature puffs of smoke While you won’t have access to all of the incredible features of make our sounds as authentic as possible, using the charac- and steam chuff sounds synchronized with the drive wheels. Bet- Proto-Sound 3.0, you will have full DCC command control. This teristic whistle for a particular steam engine, for example. With ter than any other model train, an M.T.H. -

The Steam Locomotive Table, V1

The Steam Locomotive Table, v1 If you’re reading this; you either like steam trains, or want to know more about them. Hopefully, either way, I can scratch your itch with this; a set of randomizer/dice-roll tables of my own making; as inspired by some similar tables for tanks and aircrafts. Bear with me, I know not everyone knows the things I do, and I sure know I don’t know a lot of things other train enthusiasts do; but hopefully the descriptions and examples will be enough to get anyone through this smoothly. To begin, you’ll either want a bunch of dice or any online dice-rolling/number generating site (or just pick at your own whim); and somewhere or something to keep track of the details. These tables will give details of a presumed (roughly) standard steam locomotive. No sentinels or other engines with vertical boilers; no climax, shay, etc specially driven locomotives; are considered for this listing as they can change many of the fundamental details of an engine. Go in expecting to make the likes of mainline, branchline, dockyard, etc engines; not the likes of experiments like Bulleid’s Leader or specific industry engines like the aforementioned logging shays. Some dice rolls will have uneven distribution, such as “1-4, and 5-6”. Typically this means that the less likely detail is also one that is/was significantly less common in real life, or significantly more complex to depict. For clarity sake examples will be linked, but you’re always encouraged to look up more as you would like or feel necessary. -

O-Steam-Price-List-Mar2017.Pdf

Part # Description Package Price ======== ================================================== ========= ========== O SCALE STEAM CATALOG PARTS LIST 2 Springs, driver leaf........................ Pkg. 2 $6.25 3 Floor, cab and wood grained deck............. Ea. $14.50 4 Beam, end, front pilot w/coupler pocket...... Ea. $8.00 5 Beam, end, rear pilot w/carry iron.......... Ea. $8.00 6 Bearings, valve rocker....................... Pkg.2 $6.50 8 Coupler pockets, 3-level, for link & pin..... Pkg. 2 $5.75 9 Backhead w/fire door base.................... Ea. $9.00 10 Fire door, working........................... Ea. $7.75 11 Journal, 3/32" bore.......................... Pkg. 4. $5.75 12 Coupler pockets, small, S.F. Street Railway.. Pkg.2 $5.25 13 Brakes, engine............................... Pkg.2 $7.00 14 Smokebox, 22"OD, w/working door.............. Ea. $13.00 15 Drawbar, rear link & pin..................... Ea. $5.00 16 Handles, firedoor............................ Pkg.2. $5.00 17 Shelf, oil can, backhead..................... Ea. $5.75 18 Gauge, backhead, steam pressure.............. Ea. $5.50 19 Lubricator, triple-feed, w/bracket, Seibert.. Ea. $7.50 20 Tri-cock drain w/3 valves, backhead.......... Ea. $5.75 21 Tri-cock valves, backhead, (pl. 48461)....... Pkg. 3 $5.50 23 Throttle, nonworking......................... Ea. $6.75 23.1 Throttle, non working, plastic............... Ea. $5.50 24 Pop-off, pressure, spring & arm.............. Ea. $6.00 25 Levers, reverse/brake, working............... Kit. $7.50 26 Tri-cock drain, less valves.................. Ea. $5.75 27 Seat boxes w/backs........................... Pkg.2 $7.50 28 Injector w/piping, Penberthy,................ Pkg.2 $6.75 29 Oiler, small hand, N/S....................... Pkg.2 $6.00 32 Retainers, journal........................... Pkg. -

2019 Building America Report

UNION PACIFIC 2019 Building America Report A report to communities on our social, environmental and economic sustainability progress. Our Company Economic Impact Delivering an Excellent Customer Experience Operating Safely Strengthening Our Communities Engaging Employees Protecting the Environment Appendix About the Report Union Pacific’s vision of Building America means we connect the nation’s businesses We used the Global Reporting Initiative’s global sustainability reporting standards as and communities to each other and the world by providing safe, reliable and efficient a framework to report our most material social responsibility issues. This publication supply chain solutions that support sustainable economic growth. In doing so, we strive focuses on initiatives and accomplishments from the 2019 calendar year and includes to serve our customers, enhance shareholder value, invest in our communities and 2019 data, unless otherwise noted. The impact of COVID-19 and our response provide promising careers, while operating in an ethical manner. occurred in 2020 and will be thoroughly detailed in the 2020 Building America Report. Information also is available at up.com. This report details progress in key areas supporting our environmental, social, and governance pillars: delivering an excellent customer experience, operating safely, strengthening communities, engaging employees and protecting the environment. We also summarize our 2019 financial performance. Table of Contents LETTER TO STAKEHOLDERS 3 DELIVERING AN EXCELLENT CUSTOMER EXPERIENCE -

Baldwin Locomotive Works SOUTHERN PACIFIC AC-8/10/11/12 4-8-8-2 Cab Forward Articulated Steam Locomotive

Baldwin Locomotive Works SOUTHERN PACIFIC AC-8/10/11/12 4-8-8-2 Cab Forward Articulated Steam Locomotive Operators Manual AC-12 LokSound Documentation Insert - V2.2.odt 1 Operators Manual Your Presentation Quality Collectors Box Includes: •N Scale Baldwin Locomotive Works Model •Operators Manual AC-8/10/11/12 4-8-8-2 Articulated Locomotive •Warranty Information •Oil Tender with Electronics •Traction Tire & Coupler Pack Table of Contents: •N Scale AC-8/10/11/12 4-8-8-2 Articulated Steam Locomotive Features •Oil Tender Features •Preparing The InterMountain AC-8/10/11/12 Steam Locomotive For Operation •DC (Basic Analog Mode) Operation •Digital Command Control (DCC) Operation •Ongoing Maintenance Activities •Pilot Coupler Conversion N Scale AC-8/10/11/12 4-8-8-2 Articulated Steam Locomotive Features: •Detailed cab interior •Formed wire railings and grab irons •Painted gauge faces •Diamond Plate patterned walkways and deck plate •Detailed boiler back-head •Prototypically correct articulation of the trailing •Directional lighting and lighted number boards engine •Highly detailed piping including flexible high •Recommend operation on 15” Radius minimum pressure piping curve •Operating side rods, eccentric cranks and valve •10 Pin NMRA Standard Plug for quick & easy gear DCC Installation •Detailed feed-water system, air pumps, generator •Micro-Trains® Pilot Coupler and brake gear Oil Tender Features: •Formed wire railings and grab irons •Operating directional back-up light •Detailed trucks and brake piping •Micro-Trains® Coupler •Diamond Plate patterned deck plate AC-12 LokSound Documentation Insert - V2.2.odt 2 Preparing the InterMountain AC-8/10/11/12 Steam Locomotive for Operation: Every InterMountain AC-8/10/11/12 Steam Locomotive is factory tested prior to release. -

The Trainmaster

The Trainmaster The Official Publication of the July Pacific Northwest Chapter, National Railway Historical Society 2001 Portland, Oregon Board of Directors Meetings: July 12, Aug. 9, Room 208, Portland Union Station, 7:30 PM Membership Meetings: June 15, July 20,St. Mark's Lutheran Church,5415 S.E. Powell Blvd.7:30 PM PLEASE ARRIVE AT OR BEFORE 7:30 AT OUR MEETINGS for security. If you arrive after 7:30 the parking lot door will be locked. You will need use the basement door on the West side of the building. ZOOMSILoco This is a photograph of Georgia Pacific #10 on display in Cottage Grove in 1963. One can only speculate that, due to the blind nature of the "forward" view, that the locomotive must have been much easier to operate while operating as a "cab-forward" steam locomotive. The locomotive also has the "ZOOMSI" logo on the side of it, identifying it as the locomotive that Georgia Pacific donated to the "ZOOMS!" auction that helped raise money for the Oregon Museum of Science and Industry and the Washington Park Zoo. The locomotive was- apparently sold at the auction as scrap metal, but was purchased for display in Cottage Grove. A collection of steam locomotives remained there until "The Goose" steam tourist operation ceased. Salem Public Library, Ben Maxwell Collection. Salem Public Library Photos on the World Wide Web: h :// hotos.salemhistor .or / I am working on plans for activities and members are invited to suggest ideas to the both the activities and excursions chairs. I would also like to ask members to contact me if they would like to go to Chehallis & Centrallia later this year. -

Glorious Trains Tuesday 17Th April 2018 at 10:00 Viewing: Monday 16Th April 1018 10:00-16:00 Morning of Auction from 9:00 Otherwise by Appointment

Hugo Marsh Neil Thomas Plant (Director) Shuttleworth (Director) (Director) Glorious Trains Tuesday 17th April 2018 at 10:00 Viewing: Monday 16th April 1018 10:00-16:00 Morning of auction from 9:00 Otherwise by appointment Saleroom One 81 Greenham Business Park NEWBURY RG19 6HW Telephone: 01635 580595 Fax: 0871 714 6905 Bob Leggett Graham Bilbe Email: [email protected] Toys, Trains & Trains Figures www.specialauctionservices.com Bid Here Without Being Here All you need is your computer and an internet connection and you can make real-time bids in real-world auctions at the-saleroom.com. You don’t have to be a computer whizz. All you have to do is visit www.the-saleroom.com and register to bid - its just like being in the auction room. A live audio feed means you hear the auctioneer the auctioneer at exactly the same time as other bidder. You see the lots on your computer screen as they appear in the auction room, and the auctioneer is aware of your bids the moment you make them. Just register and click to bid! Order of Auction Tri-ang TT Gauge 1-13 Tri-ang Hornby OO Gauge 14-21 Hornby OO Gauge 22-63 Lima OO Gauge 64-66 Bachmann 67-79 Hornby-Dublo 80-127 Wrenn OO Gauge 128-151 Trix OO/ HO Gauge 152-158 Other OO Gauge 159-172 Kitbuilt OO Gauge 173-202 HO Gauge 203-311 Railway Collectables 312-324 Railway Pictures 325-336 Toy & Floor Trains 337-360 Hornby O Gauge 361-427 Bassett Lowke O Gauge 428-440 Finescale O Gauge 441-562 Other O Gauge 563-656 Gauge I 657-692 LGB 693-738 Wide Gauges & Live Steam 739-766 Swiss Collection 767-776 Lot 1 Lot 42 Buyers Premium: 15% plus Value Added Tax making a total of 18% of the Hammer Price Internet Buyers Premium: 18% plus Value Added Tax making a total of 21.6% of the Hammer Price 2 www.specialauctionservices.com TRI-ANG TT GAUGE 9.