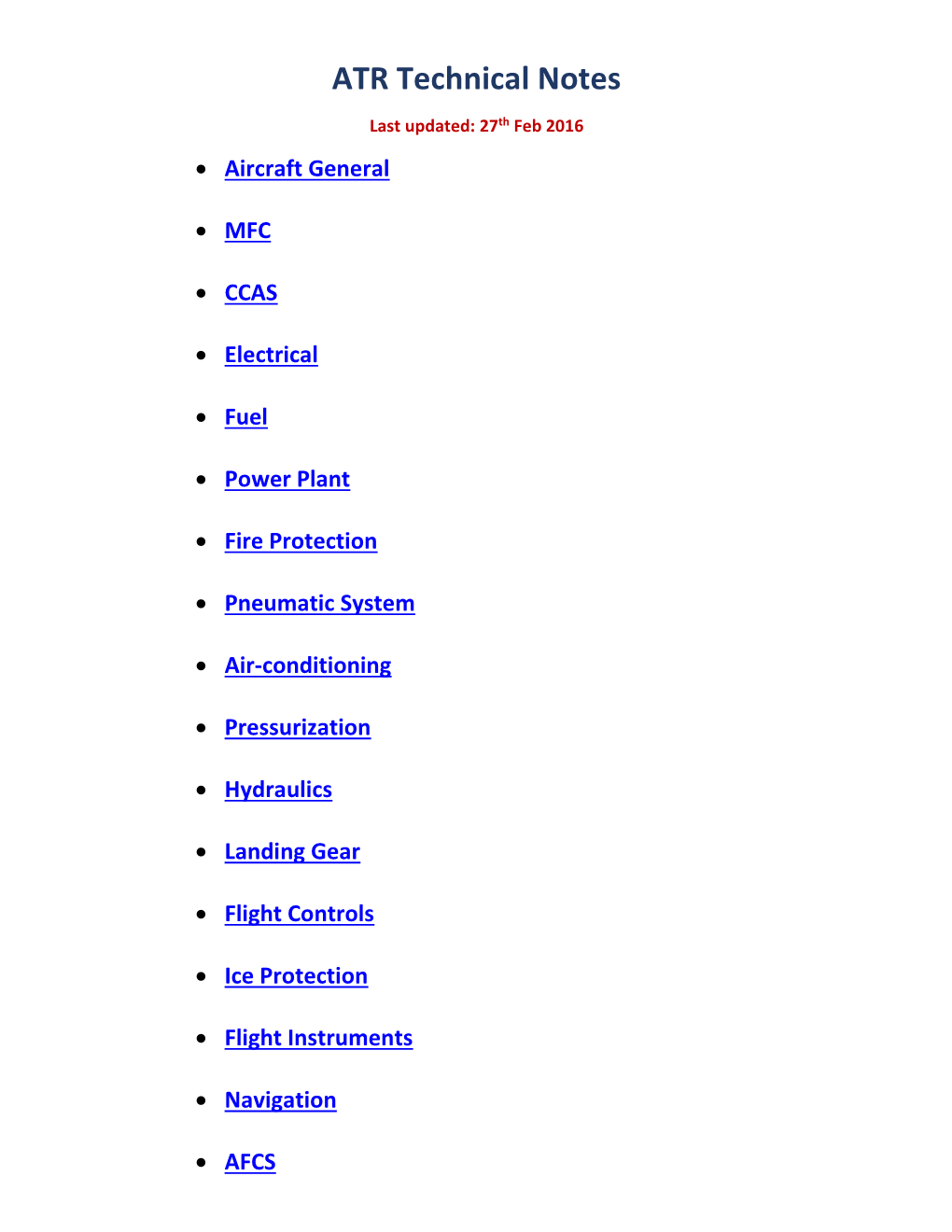

ATR Technical Notes

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Aero Twin, Inc. STC for Rudder Gust Lock

-- ST02540AK Aero Twin, Inc. 2403 Merrill Field Drive Anchorage, AK 99501 A43EU Airbus Defense and Space S. A. C-212-CB, CC, CD, CE, CF, DF, DE Fabrication and installation of Aero Twin, Inc., Rudder Gust Lock Kit No. 4111-212 on Airbus Defense and Space S. A. C-212 aircraft in accordance with Aero Twin, Inc., Master Data List No. 4111-212-MDL, Original Issue, dated May 8, 2020, or later FAA approved revision. : 1. The compatibility of this design change with previously approved modifications must be determined by the installer. 2. If the holder agrees to permit another person to use this Certificate to alter the product, the holder shall give the other person written evidence of that permission. 3. Instructions for Continued Airworthiness, Aero Twin, Inc. document number 4111-212-ICA, Original Issue, dated May 8, 2020, or later FAA accepted revision is a required part of this modification. 4. Airplane Flight Manual Supplement (AFMS), Aero Twin Doc. No. 4111-212-AFMS, Original Issue, dated August 27, 2020, or later FAA approved revision is a required part of this modification. November 20, 2017 September 8, 2020 _______________________________________________________ (Signature) August A. Asay Manager, Anchorage Aircraft Certification Office _______________________________________________________ (Title) _____________________________________________________________________________________________________________________________________ Any alteration of this certificate is punishable by a fine of not exceeding $1,000, or imprisonment not exceeding 3 years, or both. _____________________________________________________________________________________________________________________________________ FAA FORM 8110-2(10-68) PAGE 1 of 2 PAGES This certificate may be transferred in accordance with FAR 21.47. INSTRUCTIONS: The transfer endorsement below may be used to notify the appropriate FAA Regional Office of the transfer of this Supplemental Type Certificate. -

FAA Advisory Circular AC 91-74B

U.S. Department Advisory of Transportation Federal Aviation Administration Circular Subject: Pilot Guide: Flight in Icing Conditions Date:10/8/15 AC No: 91-74B Initiated by: AFS-800 Change: This advisory circular (AC) contains updated and additional information for the pilots of airplanes under Title 14 of the Code of Federal Regulations (14 CFR) parts 91, 121, 125, and 135. The purpose of this AC is to provide pilots with a convenient reference guide on the principal factors related to flight in icing conditions and the location of additional information in related publications. As a result of these updates and consolidating of information, AC 91-74A, Pilot Guide: Flight in Icing Conditions, dated December 31, 2007, and AC 91-51A, Effect of Icing on Aircraft Control and Airplane Deice and Anti-Ice Systems, dated July 19, 1996, are cancelled. This AC does not authorize deviations from established company procedures or regulatory requirements. John Barbagallo Deputy Director, Flight Standards Service 10/8/15 AC 91-74B CONTENTS Paragraph Page CHAPTER 1. INTRODUCTION 1-1. Purpose ..............................................................................................................................1 1-2. Cancellation ......................................................................................................................1 1-3. Definitions.........................................................................................................................1 1-4. Discussion .........................................................................................................................6 -

Electrically Heated Composite Leading Edges for Aircraft Anti-Icing Applications”

UNIVERSITY OF NAPLES “FEDERICO II” PhD course in Aerospace, Naval and Quality Engineering PhD Thesis in Aerospace Engineering “ELECTRICALLY HEATED COMPOSITE LEADING EDGES FOR AIRCRAFT ANTI-ICING APPLICATIONS” by Francesco De Rosa 2010 To my girlfriend Tiziana for her patience and understanding precious and rare human virtues University of Naples Federico II Department of Aerospace Engineering DIAS PhD Thesis in Aerospace Engineering Author: F. De Rosa Tutor: Prof. G.P. Russo PhD course in Aerospace, Naval and Quality Engineering XXIII PhD course in Aerospace Engineering, 2008-2010 PhD course coordinator: Prof. A. Moccia ___________________________________________________________________________ Francesco De Rosa - Electrically Heated Composite Leading Edges for Aircraft Anti-Icing Applications 2 Abstract An investigation was conducted in the Aerospace Engineering Department (DIAS) at Federico II University of Naples aiming to evaluate the feasibility and the performance of an electrically heated composite leading edge for anti-icing and de-icing applications. A 283 [mm] chord NACA0012 airfoil prototype was designed, manufactured and equipped with an High Temperature composite leading edge with embedded Ni-Cr heating element. The heating element was fed by a DC power supply unit and the average power densities supplied to the leading edge were ranging 1.0 to 30.0 [kW m-2]. The present investigation focused on thermal tests experimentally performed under fixed icing conditions with zero AOA, Mach=0.2, total temperature of -20 [°C], liquid water content LWC=0.6 [g m-3] and average mean volume droplet diameter MVD=35 [µm]. These fixed conditions represented the top icing performance of the Icing Flow Facility (IFF) available at DIAS and therefore it has represented the “sizing design case” for the tested prototype. -

Pilots Can Minimize the Likelihood of Aircraft Roll Upset in Severe Icing

FLIGHT SAFETY FOUNDATION JANUARY 1996 FLIGHT SAFETY DIGEST Pilots Can Minimize the Likelihood of Roll Upset in Severe Icing FLIGHT SAFETY FOUNDATION For Everyone Concerned Flight Safety Digest With the Safety of Flight Vol. 15 No. 1 January 1996 Officers/Staff In This Issue Stuart Matthews Chairman, President and CEO Pilots Can Minimize the Likelihood of Board of Governors Roll Upset in Severe Icing 1 Robert Reed Gray, Esq. Under unusual conditions associated with General Counsel and Secretary Board of Governors supercooled large droplets, roll upset can result from ice accretion on a sensitive area of the wing, ADMINISTRATIVE aft of the deicing boots. Pilots must be sensitive Nancy Richards to cues — visual, audible and tactile — that Executive Secretary identify severe icing conditions, and then promptly exit the icing conditions before control FINANCIAL of the airplane is degraded to a hazardous level. Brigette Adkins Accountant Approach-and-landing Accidents TECHNICAL Accounted for Majority of Commercial 10 Robert H. Vandel Director of Technical Projects Jet Hull Losses, 1959–1994 MEMBERSHIP The flight crew was the primary causal factor in the largest number of commercial jet hull-loss J. Edward Peery Director of Membership and Development accidents, according to Boeing statistics. Ahlam Wahdan Assistant to the Director of Membership and Development Report Disputes Commission’s Findings on Mt. Erebus Accident 14 PUBLICATIONS Book offers guidance on successful corporate Roger Rozelle aviation management. Director of Publications Girard Steichen Assistant Director of Publications Airbus A300 Crew Anticipates Clearance, Rick Darby Makes Unauthorized Takeoff 18 Senior Editor Helicopter strikes electrical wires, with two Karen K. -

Aviation Maintenance Alerts

ADVISORY CIRCULAR 43-16A AVIATION MAINTENANCE ALERTS ALERT FEBRUARY NUMBER 2006 331 CONTENTS AIRPLANES AVIAT .........................................................................................................................................1 BEECH ........................................................................................................................................2 CESSNA ......................................................................................................................................4 DASSAULT.................................................................................................................................6 GULFSTREAM...........................................................................................................................8 ISRAEL AIRCRAFT.................................................................................................................11 PIPER.........................................................................................................................................13 RAYTHEON..............................................................................................................................15 HELICOPTERS AGUSTA ...................................................................................................................................16 POWERPLANTS PRATT & WHITNEY ...............................................................................................................16 ACCESSORIES AERO-TRIM .............................................................................................................................18 -

A “Short Course” on Ice and the TBM

A “Short Course” on Ice and the TBM. Icing is topical at the present time as a result of a recent accident in a TBM. I have had a number of conversations with pilots who I would consider knowledgeable and it is apparent that there is a lot of confusion surrounding this subject. Also noting on line posts this confusion is not limited to owner pilots. I have had occasion to be a victim of my own stupidity in a serious icing condition years ago and I can vouch that icing is a deadly serious situation in more ways than one. Before going on with the subject we want to stipulate that the data we are about to provide is a summary of information that is to be found on line, along with narrative and data provided from knowledgeable instructors, if any of the data provided conflicts with anything you have been taught we urge you to satisfy yourself as to which data is correct. TBM operators fly in the same airspace where we find Part 25 aircraft (Commercial Category) aircraft. There is a big difference in how these two categories of aircraft are affected by icing conditions. A 767 will often be climbing at over 300 kts and 4000+ ft/min at typical icing altitudes. This creates two very distinct advantages for the 767: first, their icing exposure time may be less than 1/3 of ours. Second, icing conditions are a function of TAT (Total Air Temperature), not SAT (static air temp). TAT is warmer than SAT because of the effects of compressibility as the airplane operates at faster and faster speeds. -

2018 KODIAK 100, Series II Serial Number: 100-253 Registration: N352CL

2018 KODIAK 100, Series II Serial Number: 100-253 Registration: N352CL www.modern-aviation.com | [email protected]| 1.206.762.6000 2018 KODIAK 100, Series II Serial Number: 100-253 Registration: N352CL AIRCRAFT HIGHLIGHTS • Upgraded Timberline Interior Seating • TKS Ice Protection • 10-Place Oxygen Upgrade • Air Conditioning • Garmin G1000 Nxi Avionics Suite Airframe Total Time Since New Airframe 60 Hrs Engine 1 60 Hrs Modern Aviation Aircraft Sales *All Specifications subject to independent verification Options Options Installed on Kodiak S/N 253 Kodiak Series II Standard Equipped Aircraft $2,150,000 Series II Paint Scheme allover white with black and silver stripes External baggage compartment $94,500 TKS Ice Protection System (Tank in Cargo Pod) $124,500 29” Tire Combo $1,750 GTS 800 TAS/WX-500 Stormscope Package $28,700 GDL 69A-XM Data Link with Audio Infotainment $6,950 ChartView Enable Card $5,000 Timberline Interior (Warm Brown) 4 seats $20,000 2 additional seats $17,700 10-place oxygen system $10,000 Bose A20 Headset (Passenger) (x2) $ 2,190 Air Conditioning $42,500 Total Retail Price as Optioned $2,503,790 Modern Aviation Aircraft Sales *All Specifications subject to independent verification Avionics and Equipment AVIONICS ENGINE INSTRUMENTS (Fully integrated in the G1000NXI) •Garmin G1000NXi Integrated Avionics Suite: • Torque (ft-lb) • RPM Prop •(2) Primary Flight Displays – PFD • ITT •Multifunction Display – MFD • RPM NG (%) •All three are next gen, high resolution 10. inch displays • Oil Temp/Pressure •Enhanced -

The Gulfstream IV Operator Had All the Appearance of a Good Operation But

SAFETY REPORT The Gulfstream IV operator had all the appearance of a good operation but the flightcrew lacked cockpit discipline NTSB finds widespread non-compliance with checklist use and control checks, leading to this tragic BED runway overrun crash. Paved overrun Source: Massachusetts State Police Main wreckage Flightcrew failure to review the checklist and release the gust lock prior to the takeoff run of Gulfstream IV N121JM on BED’s 7000-ft Rwy 11 as well as failure to be time-sensitive and abort the takeoff before running out of runway length led to destruction of the aircraft and the deaths of all occupants aboard. By Robert Sumwalt Gulfstream IV N121JM was frequently used for air transportation both NTSB Board Member domestically and overseas by Lewis Katz, the well-known and highly ATP/CFII/FE. Airbus A320, King Air 350, Boeing respected publisher of The Philadelphia Inquirer newspaper. 737, Fokker F28, Fokker 100 s often is the case in corporate aviation, the pas- at 1325 edt for the short hop to ACY, where they picked up sengers were running a few hours late. The 2 pi- the 4 passengers and flew them to BED (Hanscom Field, Alots and flight attendant decided to pass the time Bedford MA). After the passengers attended a charity event, by ordering a pizza and eating in the comfort of the cabin the plan was to return them to ACY and then reposition the of N121JM, the Gulfstream IV they had operated for 7 Gulfstream back to its home base at ILG. years. When the billionaire principal showed up with 3 Tragically, the evening didn’t end that way. -

Intervention Strategies for the Management of Human Error

NASA Contractor Report 4547 Intervention Strategies for the Management of Human Error Earl L. Wiener University of Miami at Coral Gables Department of Management Science P. O. Box 248237 Coral Gables, FL 33124 Prepared for Ames Research Center CONTRACT NCA2-441 August 1993 National Aeronautics and Space AdministTation Ames Research Center Moffett Field, California 94035-1000 CONTENTS I , THE MANAGEMENT OF HUMAN ERROR A. Introduction B. The advent of modern cockpit automation C. Purpose and limitations of this study II. HUMAN ERROR AND INTERVENTION i0 A. Lines of defense I0 B. Intervention strategies - examples 13 C. Is there an intervention strategy for every problem? 25 D. Two models of intervention 27 III. INTERVENTION STRATEGIES: TRADITIONAL TECHNOLOGIES 29 A. Hardware 29 B. Procedures and supporting documentation 40 C. Communication 50 D. Training 55 IV. INTERVENTION STRATEGIES: ADVANCED TECHNOLOGIES 58 A, Employment of advanced technologies 58 B. Error management 62 C. Summary of management techniques 75 V, CONCLUSIONS AND OVERVIEW 76 A. Human error can be managed 76 B. Management strategies 77 C. The role of government 86 D. Summary 88 VI. REFERENCES 90 VII. NOTES AND ACKNOWLEDGMENTS i01 VIII. APPENDICES 103 I. Guidelines for intervention strategies 104 2. Wiener-Curry automation guidelines (1980) 107 3. Degani-Wiener guidelines for checklists (1990) 109 4. Glossary of abbreviations iii iii PI_Ord_NG PAGE Bt.ANK NOT FILMED SUMMARY This report examines the manaqement of human error in the cockpit. The principles probably apply as well to other applications in the aviation realm (e.g. air traffic control, dispatch, weather, etc.) as well as other high-risk systems outside of aviation (e.g. -

Service Bulletin

MANDATORY SERVICE BULLETIN TITLE: FLIGHT CONTROLS - FLIGHT CONTROL (GUST) LOCK INSPECTION / REPLACEMENT SYNOPSIS OF CHANGE This Service Bulletin has been revised to add ending serial effectivity. The first paragraph of th e Description statement has been moved to the Reason statement. The Material Information table has been revised to reflect additional control lock part number information and ending serial effectivity. Although a company name change to Textron Aviation occurred, this service bulletin will revise only technical and contact information. Relevant technical changes are marked with change bars in the outside margins. 1. Planning Information A. Effectivity (1) Airplanes (a) Civil Beech Model 19 Series, Serials MB-1 through MB-722, and MB-724 through MB-905; Beech Model 23 Series, Serials M-3, and M-555 through M-2392; Beech Model 24 Series, Serials MA-1 through MA-368, MC-2 through MC-150, and MC-152 through MC-795; Beech Model 33 Series, Serials CD-1 through CD-981, CD-983 through CD-1304, CE-1 through CE-235, CE-249, CE-250, CE-256, CE-260, CE-264 through CE-268, CE-270 through CE-1791, and CJ-1 through CJ-179; Beech Model 35 Bonanza Series, Serials D-1 through D-10403; Beech Model 36 Bonanza, Serials E-1 through E-184; Beech Model A36 Bonanza, Serials E-185 through E-3629; E-3631 through E-3635; Beech Model G36 Bonanza, Serials E-3630, E-3636 and after; Beech Model A36TC Bonanza, Serials EA-1 through EA-241 and EA-243 through EA-272; Beech Model B36TC Bonanza, Serials EA-242 and EA-273 through EA-695; The export of t hese commodities, technology or software are subject to th e U.S. -

Flight Safety Digest June-September 1997

FLIGHT SAFETY FOUNDATION JUNE–SEPTEMBER 1997 FLIGHT SAFETY DIGEST SPECIAL ISSUE Protection Against Icing: A Comprehensive Overview Report An Urgent Safety FLIGHT SAFETY FOUNDATION For Everyone Concerned Flight Safety Digest With the Safety of Flight Vol. 16 No. 6/7/8/9 June–September 1997 Officers/Staff In This Issue Protection Against Icing: A Comprehensive Stuart Matthews Chairman, President and CEO Overview Board of Governors An Urgent Safety Report James S. Waugh Jr. The laws of aerodynamics, which make flight possible, can Treasurer be subverted in moments by a build-up of ice that in some Carl Vogt situations is barely visible. During icing conditions, ground General Counsel and Secretary deicing and anti-icing procedures become an essential Board of Governors element in safe operations. Moreover, in-flight icing issues continue to be made more complex by a growing body of ADMINISTRATIVE new knowledge, including refinements in our understanding Nancy Richards of aerodynamics and weather. Executive Secretary This unprecedented multi-issue Flight Safety Digest brings Ellen Plaugher together a variety of informational and regulatory documents Executive Support–Corporate Services from U.S. and European sources. Collectively, they offer an overview of the knowledge concerning icing-related accident FINANCIAL prevention. Brigette Adkins Documents included in this special report are from such Controller widely divergent sources as the International Civil Aviation Organization (ICAO), the Association of European Airlines TECHNICAL (AEA), the U.S. Federal Aviation Administration (FAA), the Robert H. Vandel European Joint Aviation Authorities (JAA) and the Air Line Director of Technical Projects Pilots Association, International (ALPA). In addition, pertinent articles from FSF publications have MEMBERSHIP been reprinted here. -

Airframe & Aircraft Components By

Airframe & Aircraft Components (According to the Syllabus Prescribed by Director General of Civil Aviation, Govt. of India) FIRST EDITION AIRFRAME & AIRCRAFT COMPONENTS Prepared by L.N.V.M. Society Group of Institutes * School of Aeronautics ( Approved by Director General of Civil Aviation, Govt. of India) * School of Engineering & Technology ( Approved by Director General of Civil Aviation, Govt. of India) Compiled by Sheo Singh Published By L.N.V.M. Society Group of Institutes H-974, Palam Extn., Part-1, Sec-7, Dwarka, New Delhi-77 Published By L.N.V.M. Society Group of Institutes, Palam Extn., Part-1, Sec.-7, Dwarka, New Delhi - 77 First Edition 2007 All rights reserved; no part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of the publishers. Type Setting Sushma Cover Designed by Abdul Aziz Printed at Graphic Syndicate, Naraina, New Delhi. Dedicated To Shri Laxmi Narain Verma [ Who Lived An Honest Life ] Preface This book is intended as an introductory text on “Airframe and Aircraft Components” which is an essential part of General Engineering and Maintenance Practices of DGCA license examination, BAMEL, Paper-II. It is intended that this book will provide basic information on principle, fundamentals and technical procedures in the subject matter areas relating to the “Airframe and Aircraft Components”. The written text is supplemented with large number of suitable diagrams for reinforcing the key aspects. I acknowledge with thanks the contribution of the faculty and staff of L.N.V.M.