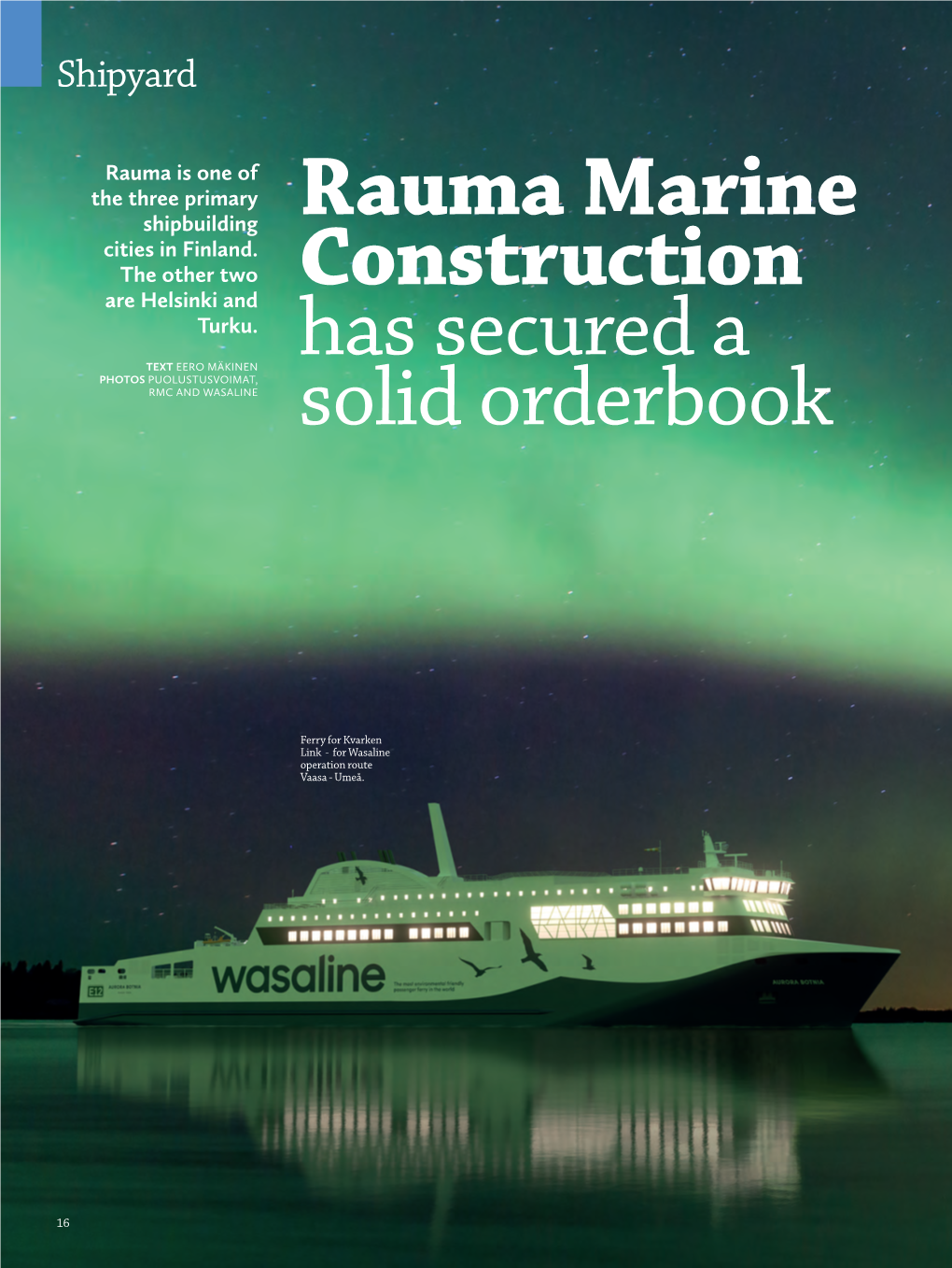

Rauma Marine Construction Has Secured a Solid Orderbook

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

M/S Viking Grace

M/S VIKING GRACE AMONG THE LARGE PASSENGER Wärtsilä delivers propulsion machinery for VESSELS BUILT TO DATE, the new M/S Viking Grace passenger ferry to M/S VIKING GRACE WILL BE THE be built for Viking Line by STX Finland at the MOST ENVIRONMENTALLY SOUND shipyard in Turku. The vessel is scheduled to AND MOST ENERGY EFFICIENT. enter service in 2013. VIKING GRACE STANDS FOR STYLE, Viking Grace will operate between DESIGN AND ATMOSPHERE AND WILL Turku and Stockholm in the Baltic Sea. The TAKE 2800 PASSENGERS. agreement includes an option for the supply of equipment for a similar sister ship. INCREASED PASSENGER COMFORT GROWING TOGETHER WÄRTSILÄ’S ENVIRONMENTALLY SOUND Due to the lowest possible pressure impulses Viking Line and Wärtsilä have for a long SOLUTIONS FOR VIKING GRACE: generated by the propellers, the vibration time successfully co-operated on ship • Four Wärtsilä 8L50DF dual-fuel level in the stern hull is very low. Wärtsilä will propulsion systems. Over the years Wärtsilä main engines supply a sound-absorbing system to minimise has been the main supplier of diesel engines • Transverse bow and noise generated by the engine, thus increasing for Viking Line’s new vessels. stern tunnel thrusters passenger comfort. A low noise level is also – It is in our best interests to co-operate • Two fixed pitch propellers important as the vessel’s route passes through with Wärtsilä, the experts in the development • Propeller shaft lines including the Turku and Stockholm archipelagos. of new types of engines, use of alternative environmentally sound, non-polluting fuels, low specific fuel consumption and shaft line seal systems CLEAN AND STRONG environmentally safe operation. -

Kojalainen 1/2015 MARINE AIR CONDITIONING PROJECTS

Wonder of the Seas, Chantiers de l`Atlantique MARINE AIR CONDITIONING PROJECTS Project Client Year Spirit of Tasmania NB 6009 & 6010, HVAC turnkey delivery Rauma Marine Construction 2023 - 2024 TT-Lines Hull no A35, Oasis -Class no 6, HVAC systems Chantiers de l`Atlantique 2024 RCI TUI Mein Schiff 7; HVAC system delivery Meyer Turku Shipyard 2024 TUI Cruises Project Vega, NB 516/517/518 Expedition Cruise Vessels; Helsinki Shipyard 2021 - 2022 HVAC turnkey delivery Swan Hellenic Cruises Silversea, S.719/720; Passenger and Crew Cabin Fancoils Meyer Werft GmbH Papenburg 2022 - 2023 RCI/Silversea Project Icon, S.1400/1401; AHUs, FP/FM fancoils, Pax cabin fancoils Meyer Turku Shipyard 2022 - 2024 RCI Tallink MyStar NB 6003; HVAC turnkey delivery Rauma Marine Construction 2021 Tallink Group Wasa Ferry NB 6002; HVAC turnkey delivery Rauma Marine Construction 2021 Kvarken Link Wonder of the Seas; HVAC systems Chantiers de l`Atlantique 2021 RCI Global Dream and Hull No. BN 126; HVAC systems, Cabin automation MV Werften Wismar 2021 - 2023 Dream Cruises Spectrum of the Seas and Odyssey of the Seas; AHUs and fancoils Meyer Werft GmbH Papenburg 2019, 2020 RCI Excellence -class Cruise Ships; Cabin control system delivery Meyer Werft GmgH Papenburg, 2018 - 2023 Carnival Corporation Meyer Turku Shipyard M/S Hammershus; HVAC system delivery, Automation Rauma Marine Constructions 2018 Mols- Linien TUI Mein Schiff 1 and 2; HVAC system delivery Meyer Turku Shipyard 2018 - 2019 TUI Cruises www.koja.com 1 KOJAlainen 1/2015 Quantum of the Seas, Ovation of the -

Marine Galley & Laundry Equipment for Cruise Ships

MARINE GALLEY & LAUNDRY EQUIPMENT FOR CRUISE SHIPS LOIPART IN A SEASHELL • 110 employees. • More than 800 customers in 62 countries. • A track record of deliveries on more than 12,000 ships. • 40 years of experience. • Privately owned. • The highest AAA credit rating. • Offices in Sweden, USA, Singapore, Finland and Korea • Agents and representatives all over the world. • Nearly 2,000 products for galleys and laundries. LAUNDRY & GALLEY EQUIPMENT FOR CRUISE SHIPS Loipart has installed catering systems on MORE THEN 40 YEARS board Cruise Ships for decades. Not only do OF EXPERIENCE we provide Galley equipment, Laundry equip- ment and furniture following USPH rules and Few companies have been in the business as regulations, but our vast range of products long as we have. Our history goes back to the late 1970s. With more than 40 years in the business, we and global services makes it possible for us have delivered marine catering systems for Cruise to outfit any vessel or marine installation no Ships, Yachts, Cruise Ferries, RoPax & Offshore matter of size or type. To make your product installations all over the world. That’s why you search easier, we have labelled all our prod- always can rely on our in-depth knowledge to meet ucts for your specific area of interest such your demands. as Cruise Ships. After all, features for galley But being experienced is only worth something if it equipment on board Cruise Ships are not the goes hand in hand with curiosity for new solutions same as for other kind of vessels. and technology. This makes it an exciting business, offering smarter handling, green energy solutions A broad program enables you to choose just and improved performance. -

Peer Review of the Finnish Shipbuilding Industry Peer Review of the Finnish Shipbuilding Industry

PEER REVIEW OF THE FINNISH SHIPBUILDING INDUSTRY PEER REVIEW OF THE FINNISH SHIPBUILDING INDUSTRY FOREWORD This report was prepared under the Council Working Party on Shipbuilding (WP6) peer review process. The opinions expressed and the arguments employed herein do not necessarily reflect the official views of OECD member countries. The report will be made available on the WP6 website: http://www.oecd.org/sti/shipbuilding. This document and any map included herein are without prejudice to the status of or sovereignty over any territory, to the delimitation of international frontiers and boundaries and to the name of any territory, city or area. © OECD 2018; Cover photo: © Meyer Turku. You can copy, download or print OECD content for your own use, and you can include excerpts from OECD publications, databases and multimedia products in your own documents, presentations, blogs, websites and teaching materials, provided that suitable acknowledgment of OECD as source and copyright owner is given. All requests for commercial use and translation rights should be submitted to [email protected]. 2 PEER REVIEW OF THE FINNISH SHIPBUILDING INDUSTRY TABLE OF CONTENTS FOREWORD ................................................................................................................................................... 2 EXECUTIVE SUMMARY ............................................................................................................................. 4 PEER REVIEW OF THE FINNISH MARITIME INDUSTRY .................................................................... -

Cruise & Ferry References

VIKING GRACE Environmentally compliant and efficient with LNG Owner: Viking Line, Finland Yard: STX, Finland Delivery: 2012 Scope of supply: • Dual-fuel machinery and propulsion system • LNG tanks and fuel supply and handling system • Safety and automation systems • Related system engineering and analysis • Integrated automation system Wärtsilä NACOS VALMATIC Platinum • CCTV System 1 © Wärtsilä 17.6.2016 Wärtsilä Marine References SUPERSPEED II Color Line selects Wärtsilä scrubber systems to operate in emission controlled areas Owner: Color Line Yard: Aker Yards, Rauma, Finland Delivery: 2014 Scope of supply: • 4 x inline open loop scrubber systems • 4 x Wärtsilä 9L46 engines • 4 x Wärtsilä 6L46 auxiliary engines • Integrated Automation System DAMATIC 2 © Wärtsilä 17.6.2016 Wärtsilä Marine References QUEEN MARY II Cruise ship to meet strict environmental regulations with Wärtsilä wastewater treatment systems Owner: MSC Cruises Yard: STX Europe, France Scope of supply: • 2 x membrane bioreactor (MBR) systems • 4 x Wärtsilä 46 engines 3 © Wärtsilä 17.6.2016 Wärtsilä Marine References OASIS OF THE SEAS Full focus on the core business Owner: Royal Caribbean International Yard: STX Europe, Finland Delivery: 2009 Scope of supply: • 6 x Wärtsilä 46 engines • 3 x 12-cylinder engines • 4 x 5.5 MW Wärtsilä bow thrusters • Wärtsilä Dynamic Positioning (DP) • Entertainment AV and lightning systems in all venues • Crew TV head-end • 4 x Wärtsilä Serck Como MSF evaporators • 5 year service agreement covering engines on 29 RCL cruise ships 4 © Wärtsilä 17.6.2016 Wärtsilä Marine References CROWN PRINCESS Wärtsilä MBR plant allows for the treatment of black and grey water to satisfy the most stringent standards Owner: Princess Cruise Line Yard: Fincantieri Scope of supply: • 3 x Wärtsilä Hamworthy MBR16 Membrane BioReactor plants capable of managing up to 947 m3/day of waste water. -

STX Finlandille Sen Pyytämää 3 300 Telakoilla 50 Miljoonan Euron Pääomalainaa

ahjo.fi METALLILIITTOLAISEN LEHTI 20.02.2014 NRO 3 PIISKALLA EI TUOTTAVUUS PARANE KYLMÄT TERÄSFAKTAT LIITON LOMALLE! MOTIVERADE STUDERANDE I VASA MITÄ NYT? Ahjo 2014_3_ALKU.indd 1 11.2.2014 10:43:41 2 3 20.02.2014 Kilpailu korventaa Laivanrakennustelakoita on maailmalla liikaa. Kilpailu on teräksenkovaa. Tehdäänkö Suomessa laivoja tulevaisuudessa? Metalliliiton vastaava tutkija Timo Eklund sanoo, ettei ole enää varma. Helsingin-telakan toiminta on ollut monesti katkolla. Myös Turun-telakan tulevaisuus olisi ollut vaakalaudalla, jollei TUI-ristei- lijöiden rahoitusta olisi saatu kuntoon. – Suomalaisilla telakoilla on ollut huonot omistajat. Samaan aikaan on ollut huono markkinatilanne. Telakoiden ja valtiovallan yhteispe- li ei ole toiminut kuten aikaisemmin. Näiden asioiden summana voi laivojen rakentaminen loppua Suomesta jossain vaiheessa, Eklund sanoo. Yhteispelin puutteista voi esimerkki- nä pitää Oasis-risteilyalustilauksen me- 450 yritystä* nettämistä vuoden 2012 lopulla. Valtio ei 17 850 työntekijää, joista myöntänyt STX Finlandille sen pyytämää 3 300 telakoilla 50 miljoonan euron pääomalainaa. Mil- 8 600 järjestelmä- ja laite- jardin euron arvoinen tilaus meni STX:n toimittajayrityksissä Ranskan-telakalle. 1 100 kokonaistoimittaja - – Suomen teollisuuspolitiikan suurin yrityksissä yksittäinen munaus oli antaa Oasis 3 -ris- yli 80 % muualla kuin teilyalustilaus Ranskaan, STX Finlandin telakoilla pääluottamusmies Jari Aalto manaa. Suomi on laivanrakennuksen kärki- maita. Täällä on rakennettu maailman suurimmat loistoristeilijät ja 60 prosenttia maailmalla toiminnassa olevista jäänmurtajista. Halutaanko tästä osaamisesta luopua? Jos telakkateollisuus halutaan pitää Suomessa hengissä, valtiota tarvitaan talkoisiin. Työ- ja elinkeinoministeriön ylitarkastaja Janne Peltola muis- tuttaa valtion viimeaikaisesta avusta telakoille. Joulukuussa valtion pääomasijoitusyhtiö Teollisuussijoitus hankki STX:ltä enemmistön jäänmurtajia suunnittelevan yhtiön Aker Arcticin osakkeista. Kaup- pasumma oli 9,3 miljoonaa euroa. – Valtion tukisummat ovat olleet melko merkittäviä. -

STX Shipyard in Rauma (Finland)

STX Shipyard in Rauma (Finland) Reference EGF/2014/008 FI/STX Rauma BACKGROUND • The global maritime industry changed dramatically in Member State Finland recent years. Resulting from the explosive growth of the order book in the period 2002 to 2008, new Sector Shipbuilding shipyards were built, most of them in Asia. However, the global economic and financial crisis meant that the Submitted to European 27 May 2014 order book was halved between 2007 and 2013. As a Commission result of the reduced orders and the significant Total budget planned 2 378 000 expansion by Asia in the shipbuilding market, the sector is currently suffering from global overcapacity EGF contribution 1 426 800 leading to tough competition. Intervention criterion Trade related globalisation • As part of this trend, the EU market share has plummeted. Measured by production volume, the EU Period of reference 7.11.2013 - 7.3.2014 market share in shipbuilding was 5 % in the first three quarters of 2013, down from 13 % in 2007. The Redundancies during period 577 equivalent share of China, South Korea and Japan of reference combined was 86 % in the first three quarters of 2013, Active employment measures while in 2007 this same share had been 77 %. • The Korean STX Group, which owned the shipyard, To be provided to 565 workers got into difficulties in early 2013. In September 2013, and will include : STX Finland unexpectedly announced that the operations of the Rauma shipyard would be Coaching and preparatory discontinued and that the company would concentrate measures its operations in Turku. Services at a service point Training and retraining • More than 40 % of the dismissed workers are over 55 Entrepreneurship promotion and years of age, an age group which in the region is expert services particularly threatened with long-term unemployment. -

ROYAL CARIBBEAN INTERNATIONAL “FLOATS OUT” OASIS of the SEAS the World’S Most Revolutionary Cruise Ship Is One Step Closer to Redefining the Cruise Vacation

ROYAL CARIBBEAN INTERNATIONAL “FLOATS OUT” OASIS OF THE SEAS The World’s Most Revolutionary Cruise Ship Is One Step Closer to Redefining the Cruise Vacation MIAMI, November 21, 2008 – In just over one year, Royal Caribbean International’s Oasis of the Seas will make her long awaited debut. The ship, under construction at STX Europe in Turku, Finland, reached an important maritime milestone today when she was “floated out” – moved from dry dock to wet dock – to begin the final stages of interior work. At official ceremonies held at the shipyard, Royal Caribbean Cruises Ltd. executives, Richard Fain, chairman and CEO and Harri Kulovaara, executive vice president, Maritime were joined by Martin Landtman, president, STX Finland Cruise Oy, and Toivo Ilvonen, project director, Oasis-class, to turn the valve releasing 87 million gallons of water into the wet dock area. “This is a historic day for our company. After more than three years of intense planning and collaboration and with 65 percent of the ship already complete, it’s exciting to see Oasis entering its final stages,” said Richard D. Fain, chairman and CEO, Royal Caribbean Cruises Ltd. “Oasis of the Seas truly represents the innovative spirit that our company is known for and to see that come to fruition is wonderful.” The line chose this important milestone to announce that Oasis of the Seas will enter service under the command of Captain William S. Wright and Captain Tor Olsen. Wright, a 15-year veteran of Royal Caribbean International, was also the start up Captain for Freedom of the Seas, currently the largest ship in the world with sister-ships Liberty of the Seas and Independence of the Seas, and 40 percent smaller than Oasis of the Seas. -

6 from War Reparations to Luxury Cruise Liners

6 From war reparations to luxury cruise liners Production changes and labour relations at the Turku shipyard (Finland) between 1950 and 2010 Kari Teräs Introduction This chapter analyses how production reforms and labour relations of the shipbuilding industry in Turku were interrelated in the shipyard of Crichton-Vulcan in the post-1945 period. In addition, shipyard work and its wider local and national effects, as well as their connections to the global development of shipbuilding, are examined. One of the objectives of this chapter is to reflect on the factors that have affected the nature and speed of production reforms that have taken place in the shipbuilding industry in Turku. To accomplish this, it is necessary to consider the actions of company management, trade unions, and shipyard employees in a wider social context. The extended operational environment of the shipyard was affected by both domestic and international markets, as well as by national industrial relations. Strong traditions In order to understand the period after the Second World War, it is necessary to briefly consider the traditions of shipbuilding in Turku. Shipbuilding as a supply-side industry is particularly sensitive to economic fluctuation, and thus prone to slumps in demand; however, continuity of work has had a significant influence on the industry and employment in the field during the period under study. This is due in part to the conscious preservation of traditions, and in part to the phenomenon known as path dependence: shipbuilding is, in many ways, a sluggish field, and earlier technological decisions have influenced its development in numerous ways. -

The Russian Maritime Industry and Finland Hanna Mäkinen

Hanna Mäkinen The Russian maritime industry and Finland Electronic Publications of Pan-European Institute 2/2015 ISSN 1795 - 5076 The Russian maritime industry and Finland Hanna Mäkinen 2/2015 Electronic Publications of Pan-European Institute http://www.utu.fi/pei Hanna Mäkinen PEI Electronic Publications 2/2015 www.utu.fi/pei Executive summary 1) Due to historical reasons, the civil shipbuilding industry is weakly developed in Russia and is currently not competitive in commercial sense. The Russian shipyards are in a rapid need of modernisation and the shipbuilding industry suffers from low productivity and technological inferiority compared to other shipbuilding nations. In order to improve the industry’s competitiveness, international cooperation is needed. 2) The Russian maritime industry has recently received increased political attention and funding. Particularly the growing interest in the Arctic hydrocarbon fields and sea routes as well as the continuous importance of energy exports for the Russian economy have boosted the development of the shipbuilding sector. In addition, as Russia has engaged into rearmament, the demands of the Russian navy significantly direct the development of the Russian maritime industry. 3) The current unstable political and economic situation, particularly the ruble’s decline against the euro, the plunge in world oil prices and the economic sanctions imposed on Russia, have complicated the implementation of maritime and offshore industry projects in Russia. The sanctions have a negative impact on the Russian shipbuilding and offshore industries as they complicate companies’ possibilities to attract foreign financing and prohibit exports of products and services and technology transfer to Russia if they are related to defence and oil industries. -

Cruise Ship Deliveries

Reference list 2020 CRUISE SHIP DELIVERIES Water treatment Owner Cruise ship name Shipyard equipment by Pointman ALOHA CRUISE S/S Monterey Wärtsilä Turku, Finland YES NYK M/S Crystal Harmony Mitsubishi, Nagasaki, Japan NO CCL Fantasy Wärtsilä Helsinki, Finland YES CCL Ecstasy Wärtsilä Helsinki, Finland YES CCL Sensation Wärtsilä Helsinki, Finland YES CCL Fasination Wärtsilä Helsinki, Finland YES CCL Imagination Wärtsilä Helsinki, Finland YES CCL Elation Wärtsilä Helsinki, Finland YES EFFJOHN INT. Silja Serenade Kvaerner Masa-Yards, Turku, Finland YES EFFJOHN INT. Silja Symphony Kvaerner Masa-Yards, Turku, Finland YES DIAMOND CRUISE Radisson Diamond Rauma Yards, Finland YES HURTIGRUTE Three ships Warnow-Werft, Germany NO SOUTH LAKE LTD. Star Pisces Finnyards, Rauma, Finland YES RCL Royal Odussey Perama, Greece YES SNCM Napoleon Bonaparte Chantiers de l’Atlanticue, France YES RCCL Legend of the Seas Chantiers de l’Atlanticue, France YES RCCL Splendour of the Seas Chantiers de l’Atlanticue, France YES 1 RCCL Rhapsody of the Seas Chantiers de l’Atlanticue, France YES RCCL Vision of the Seas Chantiers de l’Atlanticue, France YES RCCL Sovereign of the Seas Baltimore Iron Works, USA YES RCCL Voyager of the Seas Kvaerner Masa-Yards, Helsinki, Finland NO RCCL Explorer of the Seas Kvaerner Masa-Yards, Helsinki, Finland NO RCCL Adventurer of the Seas Kvaerner Masa-Yards, Helsinki, Finland NO RCCL Mariner of the Seas Kvaerner Masa-Yards, Helsinki, Finland NO COSTA CROSIERE Costa Atlantica Kvaerner Masa-Yards, Helsinki, Finland YES CCL Carnival Spirit -

Meritaito Oy:N Sopeuttamistoimissa on Liian Kova Vauhti

VSuomenoima & Käyttö Konepäällystö- liiton julkaisu 11-12 / 2012 Kraft& Drift Hyvää Joulua ja onnellista uutta vuotta God jul och gott nytt år Sisällys 11-12 / 2012 • Pääkirjoitus/chefredaktör 3 • Vähähiilinen Suomi on suuri haaste mutta saavutettavissa 11 • Työntekijät eivät sitoudu tuottavuuden ja kilpailukyvyn • Kuusakosken R&D-keskus rakenteilla Lahteen 12 parantamiseen ellei vastapainona ole sosiaalinen hyvinvointi 4 • AREVA vahvistaa yhteistyöverkostojaan Suomessa 12 • STTK on tyytyväinen • Merieläkeläinen / Sjöpensionär 13 työeläkemaksukiistan neuvotteluratkaisuun 4 • Meritaito Oy:n sopeuttamistoimissa on liian kova vauhti Sähkön käyttö nousi lokakuussa ja 14 • Wärtsilä’s success in Brazilian drill ship programme continues kulutus oli 5,4 prosenttia edellisvuotta suurempi • 5 with latest genset and propulsion order Fingrid, Statnett ja Svenska Kraftnät 14 • Arctia rakentaa kelluvan konttorin Katajanokalle kohti pohjoismaiden yhteistä sähkön taseselvitystä 6 • 15 Arctia myy jäänmurtaja Botnican Viroon • Lupaavat tulokset voivat jouduttaa • 15 ITER-reaktorin fuusiokokeita 6 • ”Viking 3” teki ensivisiitin ja Linnasatama syntyi 16 • Fortum VahvaVerkko -hanke edennyt • ”Valtio pysyköön irti telakoista” 17 maastosuunnitteluvaiheeseen 7 • “Viking 3” gjorde premiärvisit och Slottshamnen föddes 18 • Metso toimittaa biomassavoimalaitoksen Värnamo • “Staten skall hålla sig borta från varvsindustrin” 19 Energille vihreän sähkön tuotannon kaksinkertaistamiseksi 8 • Ammattihakemisto 20 Metso ska leverera ett nytt kraftvärmeverk till • Aloita