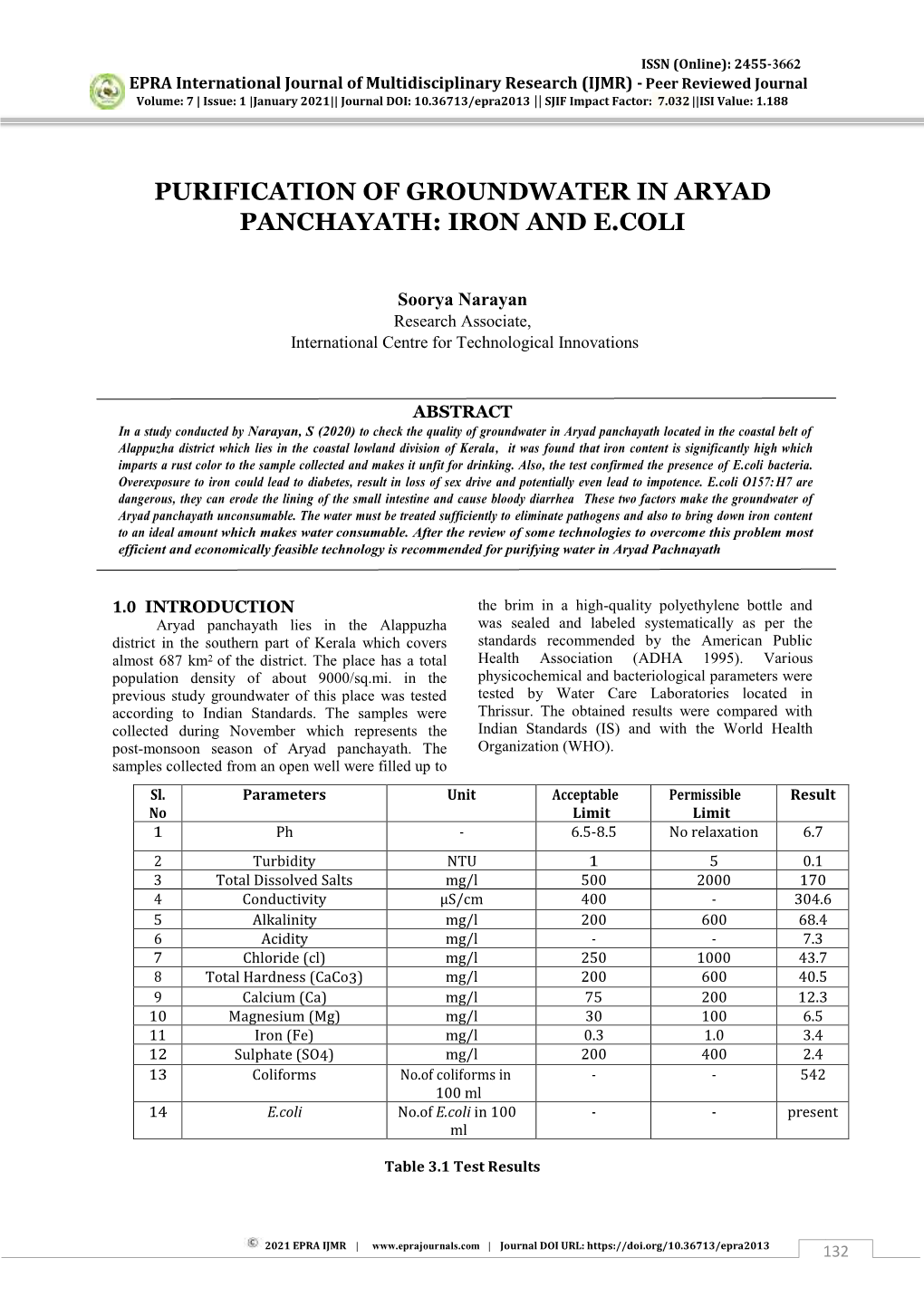

Purification of Groundwater in Aryad Panchayath: Iron and E.Coli

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Accused Persons Arrested in Alappuzha District from 19.04.2015 to 25.04.2015

Accused Persons arrested in Alappuzha district from 19.04.2015 to 25.04.2015 Name of Name of the Name of the Place at Date & Arresting Court at Sl. Name of the Age & Cr. No & Sec Police father of Address of Accused which Time of Officer, Rank which No. Accused Sex of Law Station Accused Arrested Arrest & accused Designation produced 1 2 3 4 5 6 7 8 9 10 11 Kuttichirayil, Aryad P w- 20.04.15 480/15U/s 279, Alappuzha 1 Najeeb Jamal 49 Male poomkavu Jn SI Radhakrishnan JFMC I Alpy 9 01.30 Hrs 185 of M V act North Harijan colony, 20.04.15 481/15U/s 118(a) Alappuzha 2 Santhosh Vijayan 39 male Kaichoondi SI Sasikumar JFMC I Alpy amblppuzha North P w-1 12.10 Hrs of KP Act North Pazhampasseril, 20.04.15 482/15U/s 118(a) Alappuzha 3 Sarafil Francis 50 Male Malikamukku SI Sasikumar JFMC I Alpy Kanjiramchira ward 14.05 Hrs of KP Act North Kochuveli veedu, aryad P 20.04.15 484/15U/s 279, Alappuzha 4 Aju Paolose, Paulose 52 Male P H brdige SI Sasikumar JFMC I Alpy w-17 18.38 Hrs 185 of M V act North Karukaparambil, 20.04.15 483/15U/s 118(a) Alappuzha 5 Justin James 33 Male P H brdige SI Sasikumar JFMC I Alpy Punnapra south -2 18.05 Hrs of KP Act North Palchira veedu, 20.04.15 485/15U/s 279, Alappuzha 6 Kunujumon Chacko 47 Male Arattuvazhi Jn SI Sasikumar JFMC I Alpy Kanjiramchira ward 19.25 Hrs 185 of M V act North Kandasseri veedu, Aryad 20.04.15 486/15U/s 279, Alappuzha 7 Asokan Falgunan 45 Male arattuvazhi Jn SI Sasikumar JFMC I Alpy P w-17 19.50` Hrs 185 of M V act North Arackal veedu, Aryad P 20.04.15 487/15U/s 118(a) Alappuzha 8 Justin Sebastain -

Scheduled Caste Sub Plan (Scsp) 2014-15

Government of Kerala SCHEDULED CASTE SUB PLAN (SCSP) 2014-15 M iiF P A DC D14980 Directorate of Scheduled Caste Development Department Thiruvananthapuram April 2014 Planng^ , noD- documentation CONTENTS Page No; 1 Preface 3 2 Introduction 4 3 Budget Estimates 2014-15 5 4 Schemes of Scheduled Caste Development Department 10 5 Schemes implementing through Public Works Department 17 6 Schemes implementing through Local Bodies 18 . 7 Schemes implementing through Rural Development 19 Department 8 Special Central Assistance to Scheduled C ^te Sub Plan 20 9 100% Centrally Sponsored Schemes 21 10 50% Centrally Sponsored Schemes 24 11 Budget Speech 2014-15 26 12 Governor’s Address 2014-15 27 13 SCP Allocation to Local Bodies - District-wise 28 14 Thiruvananthapuram 29 15 Kollam 31 16 Pathanamthitta 33 17 Alappuzha 35 18 Kottayam 37 19 Idukki 39 20 Emakulam 41 21 Thrissur 44 22 Palakkad 47 23 Malappuram 50 24 Kozhikode 53 25 Wayanad 55 24 Kaimur 56 25 Kasaragod 58 26 Scheduled Caste Development Directorate 60 27 District SC development Offices 61 PREFACE The Planning Commission had approved the State Plan of Kerala for an outlay of Rs. 20,000.00 Crore for the year 2014-15. From the total State Plan, an outlay of Rs 1962.00 Crore has been earmarked for Scheduled Caste Sub Plan (SCSP), which is in proportion to the percentage of Scheduled Castes to the total population of the State. As we all know, the Scheduled Caste Sub Plan (SCSP) is aimed at (a) Economic development through beneficiary oriented programs for raising their income and creating assets; (b) Schemes for infrastructure development through provision of drinking water supply, link roads, house-sites, housing etc. -

Plastic Smart Aryad

Plastic Smart Aryad Aryad Grama Panchayat has found smart Aryad Grama Panchayat, ways to use its plastic wastes (below 50 Alappuzha microns) that were being littered and Total area: 6.87 sq. km incinerated. The Panchayath is all set to Population- 30983 introduce recycled value-added products into Male – 15326 the market and use shredded plastics for Female – 15657 laying of roads. Households -9537 No. of divisions- 18 Operational area 18 wards in Aryad Panchayath, Alappuzha District Kerala • Plastic from about 7000 homes and 500 mercantile institutions are collected by Green Force Volunteers (GFVs) and transported to plastic shredding unit near plasukulam in 6th ward where it is being shredded are being sold to clean Kerala company and other private agencies. • Monitoring based on QR code is done where carry bags are kept in each household to store plastic waste. • A total of 36 Green Force Volunteers, are working in the Panchayat where they visit the houses twice in a month and Inauguration of plastic shredding unit by Hon Finance collect the waste. Minister Dr. T.M Isaac • The quantity of waste material collected by GFV is recorded in the computer, through which the source of highest quantity of waste is monitored so that further steps can be taken. Monitoring system • Centralized mobile-web monitoring system is used. • One room attached with the shredding is equipped with Wi-Fi. • Each GFV is given an android smart phone. • Collection bin materials with QR code are given to each house and GFV while making home visit scans the collection bin using android phone, which will enable the shredding unit to record the same. -

1 Alappuzha Ala JANATHA Near CSI Church, Kodukulanji Rural 5

No. LUNCH Home Sl. No Of LUNCH Parcel By Unit LUNCH Sponsored by of District Name of the LSGD (CDS) Kitchen Name Kitchen Place Rural / Urban Initiative Delivery No. Members (November 16 th) LSGI's (November 16 th) units (November 16 th) Near CSI church, 1 Alappuzha Ala JANATHA Rural 5 Janakeeya Hotel 30 0 0 Kodukulanji Ruchikoottu Janakiya Coir Machine Manufacturing 2 Alappuzha Alappuzha North Urban 4 Janakeeya Hotel 194 0 20 Bhakshanasala Company Samrudhi janakeeya 3 Alappuzha Alappuzha South Pazhaveedu Urban 5 Janakeeya Hotel 70 0 0 bhakshanashala Community kitchen 4 Alappuzha Alappuzha South MCH junction Urban 5 Janakeeya Hotel 0 155 197 thavakkal group 5 Alappuzha Ambalppuzha North Swaruma Neerkkunnam Rural 10 Janakeeya Hotel 0 0 0 6 Alappuzha Ambalappuzha South Patheyam Amayida Rural 5 Janakeeya Hotel 0 100 10 7 Alappuzha Arattupuzha Hanna catering unit JMS hall,arattupuzha Rural 6 Janakeeya Hotel 202 0 0 8 Alappuzha Arookutty Ruchi Kombanamuri Rural 5 Janakeeya Hotel 55 27 0 9 Alappuzha Aroor Navaruchi Vyasa charitable trust Rural 5 Janakeeya Hotel 20 0 0 10 Alappuzha Aryad Anagha Catering Near Aryad Panchayat Rural 5 Janakeeya Hotel 7 45 0 Sasneham Janakeeya 11 Alappuzha Bharanikavu Koyickal chantha Rural 5 Janakeeya Hotel 172 0 0 Hotel 12 Alappuzha Budhanoor sampoorna mooshari parampil building Rural 5 Janakeeya Hotel 55 0 0 13 Alappuzha Chambakulam Jyothis Near party office Rural 4 Janakeeya Hotel 81 0 0 chengannur market building 14 Alappuzha Chenganoor SRAMADANAM Urban 5 Janakeeya Hotel 95 0 0 complex Chennam pallipuram 15 -

Alappuzha District 2013-14

LIST OF N.G.C SCHOOLS, ALAPPUZHA (2013-14) Sl. Head of Name of the School No: Institution 1 Headmaster ABVHSS, Aryakkara 2 Headmaster A.J.John Memorial High School, Kainady 3 Head master Govt. A.T Vocational Higher Secondary School, Mancompu 4 Principal Amrtha Vidyalayam, Thrippakkudom, Haripad 5 Headmaster B.B.M.H.S, Vaisyambhagam. 6 Headmaster Bethany Balikamadom H.S for Girls, Nangiarkulangara 7 Headmaster C.B.M High School, Nooranad 8 Headmaster C.M.H.S, Kunthrichal, Thalavady 9 Headmaster D.V.H.S ,Kandankary. 10 Headmaster Devamatha H.S, Chennamkary 11 Headmaster D.B Higher Secondary School, Thakazhy 12 Headmaster Govt. H.S , Kuppappuram. 13 Headmaster Govt. D.V.H.S , Charamangalam . 14 Principal Govt. H.S.S for Girls, Alappuzha 15 Headmaster Govt. Girls HSS , Cherthala 16 Headmaster Govt. H.S , Karumady. 17 Headmaster Govt. H.S, Kodupunna 18 Headmaster Govt. H.S.S , Mangalam , Arattupuzha 19 Headmaster Govt. H.S , Mannanchery. 20 Headmaster Govt. H.S , Paravoor . 21 Headmaster Govt. H.S, Thanneermukkom. 22 Headmaster Govt. H.S, Thekkekara, 23 Headmaster Govt. H.SS, Perumpalam, Cherthala 24 Headmaster Govt. H.SS , Kidangara, 25 Headmaster Govt. H.SS, Ramapuram, 26 Headmaster G.S.M.M. Govt. H.SS , S.L.Puram, 27 Headmaster Govt. Muhamadans HSS for Boys, Alappuzha 28 Headmaster Govt. Muhamadans HS for Girls, Alappuzha 29 Headmaster Govt. Sanskrit H.SS, Charamangalam, 30 Principal Govt. V.H.S , Thalavady 31 Headmaster Govt. UPS , Poomthoppil Bhagam, 32 Headmaster Govt. UPGS, Kannamangalam, 33 Headmaster Govt. UPS, Thiruvampady, 34 Headmaster Holy Family GHS, Kainakary, 35 Headmaster Holy Family HSS , Kattoor 36 Principal Holy Trinity Vidya Bhavan, Karthikappally, 37 Headmaster H.SS, Kandamangalam , Kadakkarappally 38 Principal Jawahar Navodaya Vidyalaya , Chennithala 39 Headmaster John Memorial HS , Kodukulanji 40 Headmaster KKKPM Govt. -

Members of Local Authority

1 Price. Rs. 150/- per copy UNIVESITY OF KERALA Election to the Senate by the member of the Local Authorities- 2017-18 (Under Section 17-Elected Members (7) of the Kerala University Act 1974) Electoral Roll of the Members of the Local Authorities- Alappuzha District Roll No. Name and Address of Local Authority Members 1 ward member, Alappuzha Municipality 2 ward member, Alappuzha Municipality 3 ward member, Alappuzha Municipality 4 ward member, Alappuzha Municipality 5 ! " # ward member, Alappuzha Municipality 6 $ %& ward member, Alappuzha Municipality 7 ' ( & )* + ward member, Alappuzha Municipality 8 &( ward member, Alappuzha Municipality 9 ' (, & ward member, Alappuzha Municipality 10 (( & $( ward member, Alappuzha Municipality 11 % - & . ward member, Alappuzha Municipality 12 ( &/ 0 ward member, Alappuzha Municipality 13 $ ( ward member, Alappuzha Municipality 14 * &12 & (345( ward member, Alappuzha Municipality 15 &/ (3 5 ward member, Alappuzha Municipality 16 & + ward member, Alappuzha Municipality 17 ward member, Alappuzha Municipality 18 6'7 . & & 6(5 % ward member, Alappuzha Municipality 19 $ 8( * ( ward member, Alappuzha Municipality 20 ? # ward member, Alappuzha Municipality 21 $ 8& ward member, Alappuzha Municipality 22 6'7 . $ $ *: &% ward member, Alappuzha Municipality 23 ; ( # * ward member, Alappuzha Municipality 2 24 < & 45( 0 = ward member, Alappuzha Municipality 25 $ $ & ( >+ ward member, Alappuzha Municipality 26 / $.$ . ward member, Alappuzha Municipality 27 -

C:\Users\CGO\Desktop\Final Part

Census of India 2011 KERALA PART XII-A SERIES-33 DISTRICT CENSUS HANDBOOK ALAPPUZHA VILLAGE AND TOWN DIRECTORY DIRECTORATE OF CENSUS OPERATIONS KERALA 2 CENSUS OF INDIA 2011 KERALA SERIES-33 PART XII-A DISTRICT CENSUS HANDBOOK Village and Town Directory ALAPPUZHA Directorate of Census Operations, Kerala 3 MOTIF Nehru Trophy Boat Race Subroided with a labyrinth of backwaters, Alappuzha District is the cradle of important boat races like the Nehru Trophy Boat Race at Punnamada, Pulinkunnu Rajiv Gandhi Boat Race, and the Payippad Jalotsavam at Payippad, Thiruvanvandoor, Neerettupuram Boat Race, Champakulam Boat Race, Karuvatta and Thaikottan races. The boat races are mainly conducted at the time of ‘Onam’ festival. The Nehru Trophy Boat Race was instituted by the then Prime Minister Jawaharlal Nehru in the year 1952, on being thrilled by the enchanting beauty of the racing snake shaped boats. Ever since, the race is being conducted at the time of Onam festival on second Saturday of August every year. Various cultural programmes are also conducted along with the race, creating a festive mood in the town. Thousands of tourists from all over the world flock in, to have a glimpse at this spectacular occasion. 4 CONTENTS Pages 1. Foreword 7 2. Preface 9 3. Acknowledgements 11 4. History and scope of the District Census Handbook 13 5. Brief history of the district 15 6. Analytical Note 17 Village and Town Directory 141 Brief Note on Village and Town Directory 7. Section I - Village Directory (a) List of Villages merged in towns and outgrowths -

Alappuzha District from 18.04.2021To24.04.2021

Accused Persons arrested in Alappuzha district from 18.04.2021to24.04.2021 Name of Name of Name of the Place at Date & Arresting the Court Sl. Name of the Age & Cr. No & Police father of Address of Accused which Time of Officer, at which No. Accused Sex Sec of Law Station Accused Arrested Arrest Rank & accused Designation produced 1 2 3 4 5 6 7 8 9 10 11 Mappom thara Vijayakaumar. house, Neelamperoor 19 18-04-2021 119/2021 U/s K.K, Si of JFMC 1 Bennet Benny village, Eara KAINADI Male 14:40 279 IPC Police, Kainady RAMANKARY Neelamperoor P.S panchayath ward 5 120/2021 U/s Puthuparambil 188, 269 IPC& House, Thottakkadu Sec. 4(2)(e) (j) Vijayakaumar. Pradeep 23 Village, Vakathanam 18-04-2021 of Kerala K.K, Si of JFMC 2 Abhijith Cherukara KAINADI Kumar Male panchayath w-5, 15:25 Epidemic Police, Kainady RAMANKARY pariyaram Diseases P.S chakamchira Ordinance 2020 121/2021 U/s Kanakalil House, 188, 269 IPC Neelamperoor P.O, & Sec. 4(2)(e) Vijayakaumar. 60 Neelamperoor 18-04-2021 (j) of Kerala K.K, Si of JFMC 3 Mohan Kumar Sukumaran Neelamperoor KAINADI Male Village, 16:10 Epidemic Police, Kainady RAMANKARY Neelamperoor Diseases P.S Panchayath Ward 3 Ordinance 2020 122/2021 U/s 188, 269 IPC Idampadi Chira & Sec. Vijayakaumar. House, Neelamperoor 4(2)(e)(j) of 26 18-04-2021 K.K, Si of JFMC 4 ARUN Sivaprasad village, Valady Kerala KAINADI Male 18:10 Police, Kainady RAMANKARY Neelamperoor Epidemic P.S panchayath ward 8 Diseases Ordinance 2020 143/2021 U/s puthen 23 PULLUKULANG 18-04-2021 279 KANAKAKUN JFMC I 5 Vipin viswan parambil,nallanikkal,A santhoshkumar Male ARA 12:05 IPC,4(2)(a) & 5 NU HARIPAD rattupuzha OF KEDO 177/2021 U/s Panachikkal, 31 20-04-2021 269 IPC JFMC 6 Xavier Joy Kuthirapanthy, Poopally NEDUMUDI kurian T V SI Male 18:30 ,4(2)(f) r/w 5 RAMANKARY Alappuzha of KEDO 2020 227/2021 U/s 40 ATTUCHIRA HOUSE, 18-04-2021 JFMC 7 JOSEMON THOMAS Veliyanadu 4(2)(j) r/w. -

Accused Persons Arrested in Alappuzha District from 11.11.2018To17.11.2018

Accused Persons arrested in Alappuzha district from 11.11.2018to17.11.2018 Name of Name of the Name of the Place at Date & Arresting Court at Sl. Name of the Age & Cr. No & Sec Police father of Address of Accused which Time of Officer, which No. Accused Sex of Law Station Accused Arrested Arrest Rank & accused Designation produced 1 2 3 4 5 6 7 8 9 10 11 Renji nivas, SI, KC 1 Radhakrishnan Kidangamparambu 11.11.2018 2074/2018 U/s Alappuzha Bhuvanendra Renjith Kumar Nair 35 M Ward, Alappuzha District Court at 10.00 118(a) of KP Act North babu Bailed Valiuparambil, 2075/2018 U/s SI, KC 2 Ramankary P/w 4, 11.11.2018 279, 185 of MV Alappuzha Bhuvanendra Sijumon Paulose 36 M Ramankary PO District Court at 11.00 Act North babu Bailed 2076/2018 U/s SI, KC 3 Arya Bhavan, Aryad P/w 11.11.2018 279, 185 of MV Alappuzha Bhuvanendra Shibu Raveendran 47 M 3, Avalookunnu PO Poomkavu at 12.30 Act North babu Bailed SI, KC 4 Chakku Parambu, 11.11.2018 2077/2018 U/s Alappuzha Bhuvanendra Purushothaman Neelakandan 49 M Kalapura Ward Arattuvazhi at 13.30 279, 185 of MV North babu Bailed SI, KC 5 Kadavil, Karalakom 12.11.2018 2080/2018 U/s Alappuzha Bhuvanendra Bipin Babu 30 M Ward Punnamada at 06.30 279, 185 of MV North babu Bailed 6 Deepumon@Un Padinjare Veli, 12.11.2018 2081/2018 U/s Alappuzha ni Maniyappan 28 M Pathirapoalli PO PH Bridge at 10.30 118(a) of KP Act North SI, D. -

Accused Persons Arrested in Alappuzha District from 18.01.2015 to 24.01.2015

Accused Persons arrested in Alappuzha district from 18.01.2015 to 24.01.2015 Name of Name of the Name of the Place at Date & Arresting Court at Sl. Name of the Age & Cr. No & Sec Police father of Address of Accused which Time of Officer, Rank which No. Accused Sex of Law Station Accused Arrested Arrest & accused Designation produced 1 2 3 4 5 6 7 8 9 10 11 Oanam Parampil, Cr. 117/15 1 Ala Panchayath 18/1/2015 U/s 279 IPC & TC Mathari Sivan Pillai Krishna Pillai 62 ward-2, Ala Village ITI Jn. 12.25hrs 185 of MV Act Chengannur SI Traffic Unit Nil Kizhakkepainumoott il, Puthenkavu, Cr. 118/15 2 Mamman Angadicka 18/1/2015 U/s 279 IPC & D Varghese, Shibu Mon Thomas 41 Chengannur Puthen Kavu 18.50hrs 185 of MV Act Chengannur SI of Police, Nil Iakkaramala Modiyil veedu, Idasserimala Cr. 119/15 3 Narayannan muri, Aranmulla 18/1/2015 U/s 279 IPC & D Varghese, Ajith@Babu Nair 28 village Puthen Kavu 12.55hrs 185 of MV Act Chengannur SI of Police, Nil Pullithittaveedu, Chengannur 4 Muncipal Ward-XX, Cr. 120/15 Saiman Angadickal Muri, Moolappadav 18/1/2015 U/s 279 IPC & TC Mathari George George 28 Chengannur village u 16.18hrs 185 of MV Act Chengannur SI Traffic Unit Nil Thachilethu veedum <ulakuzha 5 Panchayath ward- Cr. 121/15 Varkey XVIII, Mulakuzha 18/1/2015 U/s 279 IPC & TC Mathari T S Samuel Samuel 53 muri Mulakuzha 16.38hrs 185 of MV Act Chengannur SI Traffic Unit Nil Kochukannankara veedu, Areekara Cr. -

Alappuzha Municipality Textiles Managing Director Foam Mattings (India) Ltd

Industrial Potential Survey Report 2017 DIC Alappuzha Industrial Potential Survey Report 2017 INDUSTRIAL POTENTIAL SURVEY 2017 ALAPPUZHA DISTRICT DISTRICT INDUSTRIES CENTRE ALAPPUZHA DIC Alappuzha CONTENTS 1. Introduction 1 2. Resource Analysis 2.1. Agriculture 5 2.1.1 Land use pattern in hectares (2015-16) 2.1.2 Area production and productivity of Agriculture crops (2015-16) 6 2.1.2.3 Area and production of plantation crop 6 2.2. Water 8 2.2.1 Surface water resources 10 2.2.2 Surface water natural resources 10 2.3 Animal Husbandry 11 2.3.1 Live Stock population 11 2.3.2 Milk Production in the district 12 2.3.3 Society Milk Procurement (Metric ton) 12 2.3.4 Meet production (metric ton) 13 2.4 Fisheries 13 2.4.1 Fish Production (metric ton) 14 2.5 Major mineral resources 14 2.6 Forest resources 16 2.6.1 Forest plantation with Division 17 2.6.2 Distribution/species wise distribution of plantation area 17 2.7 Human resources-2011-census 17 2.8 Education 20 2.8.1 Educational Institutions 22 2.9 Health 23 2.9.1 Medical Facilities 24 2.10 Employment 25 2.10.1 Registration Details of Unemployed persons as on March 2017 25 2.10.2 Details of Apprenticeship through related instruction centre 2016-17 26 2.11 Tourism 27 2.11.1 Tourist Centers 28 3. Infrastructure facilities 31 3.1 Transportation 31 3.1.1 Roads 31 3.1.2 Registration details of Motor Vehicles as on 31.3.2017 31 3.1.3 Details of Road facility 32 3.2 Railways 32 3.3 Airports 33 3.4 Waterways 33 3.5 Communications 34 3.5.1 Post Offices 34 3.5.2 Telecommunications 34 3.6 Electric power -

Manappuram Finance Ltd IV/470A(Old) W638A(New) Manappuram House Valapad Post, Thrissur-680567 Ph: 0487- 3050417/415/3104500 List

Manappuram Finance Ltd IV/470A(Old) W638A(New) Manappuram House Valapad Post, Thrissur-680567 Ph: 0487- 3050417/415/3104500 FOLIO / DEMAT ID NAME ADDRESS LINE 1 ADDRESS LINE 2 List of Unpaid Dividend as on ADDRESS09.08.2016 LINE (Dividend 3 for the periods 2008-09 toADDRESS 2015-16) LINE 4 PINCOD DIV.AMOUNT DWNO MICR PERIOD IEPF. TR. DATE 000642 JNANAPRAKASH P.S. POZHEKKADAVIL HOUSE P.O.KARAYAVATTAM TRICHUR DIST. KERALA STATE 1800.00 16400038 54773 2015-16 4TH INTERIM DIVIDEND 26-APR-23 000671 SHEFABI K M C/O.SEENATH HUSSAIN CHINNAKKAL HOME PO. VALAPAD PAINOOR 1800.00 16400039 54774 2015-16 4TH INTERIM DIVIDEND 26-APR-23 000691 BHARGAVI V.R. C/O K.C.VISHWAMBARAN,P.B.NO.63 ADV.KAYCEE & KAYCEE AYYANTHOLE TRICHUR DISTRICT KERALA STATE 1800.00 16400040 54775 2015-16 4TH INTERIM DIVIDEND 26-APR-23 000902 SREENIVAS M.V. SAI SREE, KOORKKENCHERY TRICHUR - 7 KERALA STATE 1800.00 16400046 54781 2015-16 4TH INTERIM DIVIDEND 26-APR-23 001036 SANKAR T.C. DAYA MANDIRAM TRICHUR - 4. KERALA 9000.00 16400052 54787 2015-16 4TH INTERIM DIVIDEND 26-APR-23 002626 DAMODARAN NAMBOODIRI K T KANJIYIL THAMARAPPILLY MANA P O MANALOOR THRISSUR KERALA 3600.00 16400071 54806 2015-16 4TH INTERIM DIVIDEND 26-APR-23 002679 NARAYANAN P S PANAT HOUSE P O KARAYAVATTOM, VALAPAD THRISSUR KERALA 3600.00 16400074 54809 2015-16 4TH INTERIM DIVIDEND 26-APR-23 002769 RAMLATH V E ELLATHPARAMBIL HOUSE NATTIKA BEACH P O THRISSUR KERALA 1800.00 16400079 54814 2015-16 4TH INTERIM DIVIDEND 26-APR-23 002966 KUNHIRAMAN K KADAVATH HOUSE OZHINHA VALAPPU (PO) (DIST) KARASAGOD 000000 1800.00