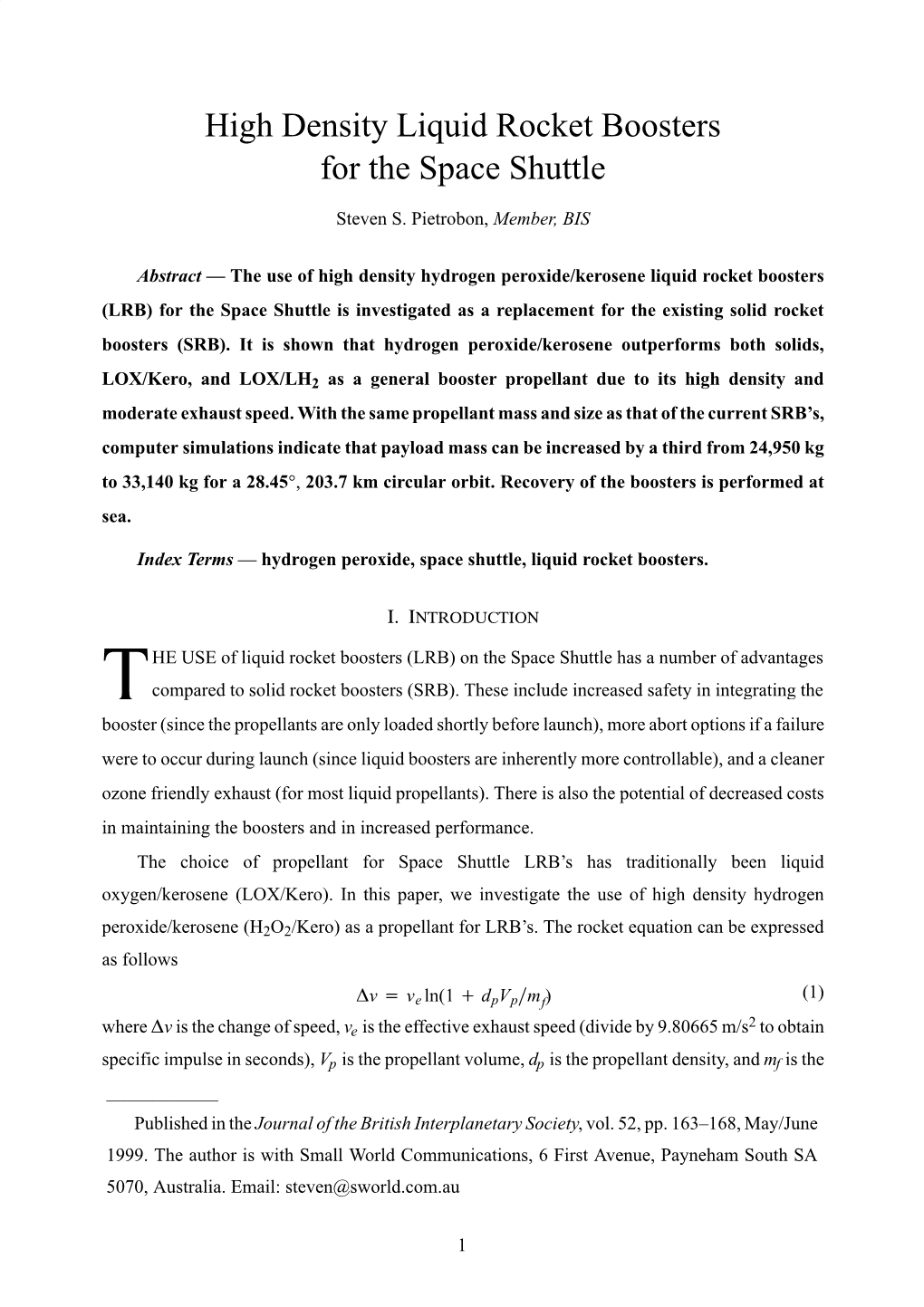

High Density Liquid Rocket Boosters for the Space Shuttle

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Launch Options for the Future: a Buyer's Guide (Part 7 Of

— Chapter 3 Enhanced Baseline CONTENTS , Page Improving the Shuttle . 27 Advanced Solid Rocket Motors (ASRMs) . 27 Liquid Rocket Boosters (LRBs) . 28 Lighter Tanks . 29 Improving Shuttle Ground Operations . 29 Improving Existing ELVs . 29 Delta . 30 Atlas-Centaur . ● ● . .* . 30 Titan . ● . ✎ ✎ . 30 Capability . ✎ . ✎ ✎ . ● ✎ ✎ . 30 Table 3-1. Theoretical Lift Capability of Enhanced U.S. Launch Systems. 31 Chapter 3 Enhanced Baseline The ENHANCED BASELINE option is the U.S. Government’s “Best Buy” if . it desires a space program with current or slightly greater levels of activity. By making in- cremental improvements to existing launch vehicles, production and launch facilities, the U.S. could increase its launch capacity to about 1.4 million pounds per year to LEO. The investment required would be low compared to building new vehicles; however, the ade- quacy of the resulting fleet resiliency and dependability is uncertain. This option would not provide the low launch costs (e.g. 10 percent of current costs) sought for SDI deploy- ment or an aggressive civilian space initiative, like a piloted mission to Mars, IMPROVING THE SHUTTLE The Shuttle, though a remarkable tech- . reducing the number of factory joints and nological achievement, never achieved its in- the number of parts, tended payload capacity and recent safety . designing the ASRMs so that the Space modifications have further degraded its per- Shuttle Main Engines no longer need to formance by approximately 4,800 pounds. be throttled during the region of maxi- Advanced Solid Rocket Motors (ASRMs) or mum dynamic pressure, Liquid Rocket Boosters (LRBs) have the potential to restore some of this perfor- ● replacing asbestos-bearing materials, mance; studies on both are underway. -

![ミルスペース 140710------[What’S New in Virtual Library?]](https://docslib.b-cdn.net/cover/2515/140710-what-s-new-in-virtual-library-862515.webp)

ミルスペース 140710------[What’S New in Virtual Library?]

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -ミルスペース 140710- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - [What’s New in Virtual Library?] AW&ST Aviation Week & Space Technology 1406F_Contents.pdf, Cover.jpg 140630AWST_Contents.pdf, Cover.jpg 1405F_Contents.pdf, Cover.jpg NASA Spaceport Magazine 1404F_Contents.pdf, Cover.jpg 1407ksc_Spaceport_Mag_27pages.pdf 1403F_Contents.pdf, Cover.jpg 1407ksc_Spaceport_Mag_Contents.pdf, Cover.jpg Military Technology BIS Space Flight 1406MT_Contents.pdf, Cover.jpg 1407SF_Contents.pdf, Cover.jpg [What’s New in Real Library?] [謝辞] - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2014.7.10 12:30 http://sankei.jp.msn.com/wired/ スマートフォンが国際宇宙ステーション・ロボットの頭脳に 7 月 11 日に ISS に向け打上げる宇宙船には、グーグル 3D ヴィジョン Satellites」(姿勢保持、連動、方向修正同期型実験衛星)の略で、 搭載スマホ「Tango」が積込まれる。ISS 船内で浮遊しながら飛行士た 将来的には、ISS 船外での危険作業を含め、宇宙飛行士の代わりに ちを支援するロボットに利用される。 日常雑務をこなせるようになることが期待されていた。ただし、2006 年に 初めて ISS に送込まれたときには、正確な浮遊動作をする以外に大し たことはできなかった。カリフォルニア州マウンテンヴューにある NASA のエ イムズ研究センタの研究者たちは、2010 年から、SPHERES を改良す る最も優れた方法を探すべく取組んできた。 悩んだ結果、スマホにた どり着いた。 「SPHERES 高度化プロジェクト・マネージャー」のクリス・プ ロヴェンチャーは、Reuters に次のように話している。「われわれは、通信 やカメラ、処理能力の向上、加速度計をはじめとする各種センサなどを NASA は 7 月 11 日(米時間)、ISS に向けて、グーグル新型スマートフ 追加したかった。どうすればよいか頭を悩ませていたときに、その答えは ォンを乗せた宇宙船を打上げ予定。3D ヴィジョン技術「Tango」(日本 自分たちの手の中にあったことに気づいた。つまり、スマートフォンを使お 語版記事) うということになったのだ」 グーグルの「Tango」技術を搭載したスマートフ http://wired.jp/2014/05/26/google-creating-project-tango-tablets-with ォンには、SPHERES が利用するための 3D マップの作成に使用できる -3d-computer-vision/ 赤外線深度センサなど、魅力的な多数の技術が搭載されている。もち -

Paper Session I-A - Liquid Rocket Boosters for Shuttle

The Space Congress® Proceedings 1989 (26th) Space - The New Generation Apr 25th, 2:00 PM Paper Session I-A - Liquid Rocket Boosters for Shuttle James E. Hughes Manager, LRB Studies, Marshall Space Flight Center, NASA Follow this and additional works at: https://commons.erau.edu/space-congress-proceedings Scholarly Commons Citation Hughes, James E., "Paper Session I-A - Liquid Rocket Boosters for Shuttle" (1989). The Space Congress® Proceedings. 8. https://commons.erau.edu/space-congress-proceedings/proceedings-1989-26th/april-25-1989/8 This Event is brought to you for free and open access by the Conferences at Scholarly Commons. It has been accepted for inclusion in The Space Congress® Proceedings by an authorized administrator of Scholarly Commons. For more information, please contact [email protected]. LIQUID ROCKET BOOSTERS FOR SHUTTLE James E. Hughes, Manager LRB Studies Marshall Space Flight Center, NASA ABSTRACT The Liquid Rocket Booster study was initiated vehicles, and a pressure fed system, once by NASA to define an alternative to the Solid referred to as the "Big Dumb Booster". The Rocket Boosters used on the STS. These prime study contractors, Martin Marietta Cor studies have involved MSFC, JSC and KSC poration and General Dynamics Space Sys and their contractors. The prime study con tems, were assisted considerably by the ef tractors, Martin Marietta Corporation and forts of Lockheed Space Operations Co. General Dynamics Space Systems, have (LSOC) at the Kennedy Space Center and identified Liquid Booster configurations which Lockheed Engineering and Sciences Co. would replace the SRB's in the Shuttle stack. (LESC) at Johnson Space Center, as well as wind tunnel testing at MSFC, and other sup The Liquid Rocket Booster increases Shuttle port. -

+ Part 17: Acronyms and Abbreviations (265 Kb PDF)

17. Acronyms and Abbreviations °C . Degrees.Celsius °F. Degrees.Fahrenheit °R . Degrees.Rankine 24/7. 24.Hours/day,.7.days/week 2–D. Two-Dimensional 3C. Command,.Control,.and.Checkout 3–D. Three-Dimensional 3–DOF . Three-Degrees.of.Freedom 6-DOF. Six-Degrees.of.Freedom A&E. Architectural.and.Engineering ACEIT. Automated.Cost-Estimating.Integrated.Tools ACES . Acceptance.and.Checkout.Evaluation.System ACP. Analytical.Consistency.Plan ACRN. Assured.Crew.Return.Vehicle ACRV. Assured.Crew.Return.Vehicle AD. Analog.to.Digital ADBS. Advanced.Docking.Berthing.System ADRA. Atlantic.Downrange.Recovery.Area AEDC. Arnold.Engineering.Development.Center AEG . Apollo.Entry.Guidance AETB. Alumina.Enhanced.Thermal.Barrier AFB .. .. .. .. .. .. .. Air.Force.Base AFE. Aero-assist.Flight.Experiment AFPG. Apollo.Final.Phase.Guidance AFRSI. Advanced.Flexible.Reusable.Surface.Insulation AFV . Anti-Flood.Valve AIAA . American.Institute.of.Aeronautics.and.Astronautics AL. Aluminum ALARA . As.Low.As.Reasonably.Achievable 17. Acronyms and Abbreviations 731 AL-Li . Aluminum-Lithium ALS. Advanced.Launch.System ALTV. Approach.and.Landing.Test.Vehicle AMS. Alpha.Magnetic.Spectrometer AMSAA. Army.Material.System.Analysis.Activity AOA . Analysis.of.Alternatives AOD. Aircraft.Operations.Division APAS . Androgynous.Peripheral.Attachment.System APS. Auxiliary.Propulsion.System APU . Auxiliary.Power.Unit APU . Auxiliary.Propulsion.Unit AR&D. Automated.Rendezvous.and.Docking. ARC . Ames.Research.Center ARF . Assembly/Remanufacturing.Facility ASE. Airborne.Support.Equipment ASI . Augmented.Space.Igniter ASTWG . Advanced.Spaceport.Technology.Working.Group ASTP. Advanced.Space.Transportation.Program AT. Alternate.Turbopump ATCO. Ambient.Temperature.Catalytic.Oxidation ATCS . Active.Thermal.Control.System ATO . Abort-To-Orbit ATP. Authority.to.Proceed ATS. Access.to.Space ATV . Automated.Transfer.Vehicles ATV . -

Round Trip to Orbit: Human Spaceflight Alternatives

Round Trip to Orbit: Human Spaceflight Alternatives August 1989 NTIS order #PB89-224661 Recommended Citation: U.S. Congress, Office of Technology Assessment, Round Trip to Orbit: Human Spaceflight Alternatives Special Report, OTA-ISC-419 (Washington, DC: U.S. Government Printing Office, August 1989). Library of Congress Catalog Card Number 89-600744 For sale by the Superintendent of Documents U.S. Government Printing Office, Washington, DC 20402-9325 (order form can be found in the back of this special report) Foreword In the 20 years since the first Apollo moon landing, the Nation has moved well beyond the Saturn 5 expendable launch vehicle that put men on the moon. First launched in 1981, the Space Shuttle, the world’s first partially reusable launch system, has made possible an array of space achievements, including the recovery and repair of ailing satellites, and shirtsleeve research in Spacelab. However, the tragic loss of the orbiter Challenger and its crew three and a half years ago reminded us that space travel also carries with it a high element of risk-both to spacecraft and to people. Continued human exploration and exploitation of space will depend on a fleet of versatile and reliable launch vehicles. As this special report points out, the United States can look forward to continued improvements in safety, reliability, and performance of the Shuttle system. Yet, early in the next century, the Nation will need a replacement for the Shuttle. To prepare for that eventuality, NASA and the Air Force have begun to explore the potential for advanced launch systems, such as the Advanced Manned Launch System and the National Aerospace Plane, which could revolutionize human access to space. -

Large Reusable Liquid Rocket Booster

Determination of the Nose Cone Shape for a Large Reusable Liquid Rocket Booster by ROBERT LAUREN ACKER B.S., Massachusetts Institute of Technology 1987 SUBMITTED IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF MASTER OF SCIENCE IN AERONAUTICS AND ASTRONAUTICS at the MASSACHUSETTS INSTITUTE OF TECHNOLOGY February 1988 ©Robert L. Acker 1988 The author hereby grants M.I.T. and Hughes Aircraft Company permission to reproduce and to distribute copies of this thesis document in whole or in part. Signature of Author Department of Aeronautics and Astronautics January 12, 1988 Reviewed by C. P. Rubin Hughes Aircraft Company Certified by - rv -- - Prof. Walter M. Hollister Thesis Supervisor, Deprtment of Aeronautics and Astronautics Accepted by , {"' Prof. Harold Y. Wachman Chairman, Department Graduate Committee Department of Aeronautics and Astronautics MASSACHUSETTSINST:7, a OF TECHNOLOGY WHDAWN I FEB 0 4198 M.LT.W LIB-RAiES , J Determination of the Nose Cone Shape for a Large Reusable Liquid Rocket Booster by Robert L. Acker Submitted to the Department of Aeronautics and Astronautics in partial fulfillment of the requirements for the degree of Master of Science in Aeronautics and Astronautics January 15, 1988 Abstract Recently there has been a lot of interest in making reusable space vehicles in an effort to lower launch costs. In addition, the use of liquid propellant in a multistage vehicle provides for the maximum performance. This study examines the forces on the nose cone of the first stage of such a rocket and uses them to determine the best shape for the nose cone. The specific stage looked at is a strap-on booster on a design proposed at Hughes Aircraft Company. -

October, 1974 National Aeronautics and Space Administration 0 Space Shuttle Fact Sheet

https://ntrs.nasa.gov/search.jsp?R=19740027171 2020-03-23T02:05:58+00:00Z l0 RELEASE NO: 74-267 NASA Headquarters Library 300 E St. SW Rm.1120 Washington, DC 20546 OCTOBER, 1974 NATIONAL AERONAUTICS AND SPACE ADMINISTRATION 0 SPACE SHUTTLE FACT SHEET Introduction The Space Shuttle will be a reusable space vehicle operated as a transportation system for a wide variety of space missions in low Earth orbit. The Shuttle will deploy scientific and applications satellites of all types. Since it can carry payloads weigh- ing up to 29,500 kilograms (65,000 pounds) it will replace most of the expendable launch vehicles currently used. The Shuttle will be able to retrieve satellites from Earth orbit; to repair and redeploy them; or bring them back to Earth for refurbishment and reuse. It can also be used to carry out missions in which scientists and technicians conduct experiments in Earth orbit or ser- vice automated satellites already orbiting. The National Aeronautics and Space Administration plans A to develop the Shuttle over the next six years. Horizontal test flights are to begin in 1977, orbital test flights in 1979, and the complete vehicle is to be operational in 1980. The Shuttle will provide an effective and economical means for the United States to utilize and advance its capa- 40 bilities in space. It will reduce substantially the cost of space operations for civilian and defense needs in the decade of the 1980's and beyond. The Shuttle will consist of a reusable orbiter, mounted piggy back at launch on a large expendable liquid propellant tank and two recoverable and reusable solid propellant rocket boosters. -

Big Dumb Boosters: a Low-Cost Space Transportation Option? Big Dumb Boosters

Big Dumb Boosters: A Low-Cost Space Transportation Option? Big Dumb Boosters February 1989 A Low·Cosl Space Transporlati on OpUon? An OTA 8 ackgroun d Paper NTIS order #PB89-155196 FEBRUARY 1989 Inte,n.lIonal Security &. Commerce P'OlI •• m OUice of T8¢hnology A Sa&:!.Sment Cone"'" or the United Stale. Washln,ton, DC 20510-8025 Advisory Panel on Advanced Space Transportation Technologies M. Granger Morgan, Chair Head, Department of Engineering and Public Policy Carnegie-Mellon University I. Melvin Bernstein Hugh F. Loweth Provost and Consultant Academic Vice President Illinois Institute of Technology Anthony J. Macina Program Manager Michael A. Berta Onboard Software Systems Assistant Division Manager IBM Federal Systems Division Government Electronics Systems Space&Communications Group George B. Merrick Hughes Aircraft Company Vice President Aerospace Technologies Richard E. Brackeen Rockwell International Corporation President Martin Marietta Commercial Titan, Inc. Alan Parker Consultant Preston S. Craig Chief Scientist Gerard Piel United Technologies Space Chairman emeritus Flight Systems Scientific American Edward T. Gerry Bryce Poe, II President General, USAF (retired) W. J. Schafer Associates, Inc. Ben R. Rich Jerry Grey Vice President and General Manager Director, Science Advanced Development Projects and Technology Policy Lockheed Corporation American Institute of Aeronautics and Astronautics Sally Ride Center for International Security William H. Heiser and Arms Control Consultant Stanford University Otto W. Hoernig, Jr. Tom Rogers Vice President President Contel/American Satellite Corp. The Sophron Foundation Donald B. Jacobs Richard Smith Vice President Consultant Space Systems Division Boeing Aerospace Co. William F. H. Zersen Consultant John Logsdon Director, Space Policy Institute George Washington University NOTE: OTA appreciates the valuable assistance and thoughtful critiques provided by the advisory panel members. -

Liquid Rocket Booster Summary (LRB) for the Space Transportation System (STS) Svstems Study

NAS8-37136 DR-4 Volume I March 1989 Executive Liquid Rocket Booster Summary (LRB) for the Space Transportation System (STS) Svstems Study / X / \ / k p k / s \ ! I I ^ i l ^ "-' i : :sf _ ..... ._1,_.: , ' _ ,,,a "c L.-: k--- : :: ,t / l o / i ......!.......!! -! .... ..,O.o,o i,.,... ,. .o "" ..........' :g -i o°,.. ..... m VV VV MANNED SPACE SYSTEMS (NASA-CR-183822) LIQUID ROCKET BOOSTER (LR_) F_)R THE SPACE TRANSPORTATION SYSTEM L-OO4_er (STS) SYSTEMS STUOY. VOLUME i: EXFCUTIVE SUMMARY (_rtin Marietta Corp.) 55 p Unc] _S CSCL 2!H G3/20 0251_90 FOREWORD This document provides the Executive Summary, Volume I, for the Liquid Rocket Booster (LRB) for the Space Transportation Systems (STS) Study performed under NASA Contract NAS8-37136. The report was prepared by Manned Space Systems, Martin Marietta Corporation, New Orleans, Louisiana, for NASA/Marshall Space Flight Center (MSFC). The MSFC Contracting Representative is Larry Ware. The Martin Marietta Study Manager is Thomas Mobley. ACRONYMS AND ABBREVIATIONS ALS Advanced Launch System ALMMH Aluminized Mono Methyl Hydmzine CH4 Methane CSTI Civil Space Technology Initiative • DDT&.E Design, Development, Test, and Evaluation ET External Tank FSS Fixed Service Structure GHe Gaseous Helium GMA Gas Metal Arc GSE Ground Support Equipment GVTA Ground Vibration Test Article IR&D Independent Research and Development JSC Johnson Space Center KSC Kennedy Space Center LCC Life Cycle Cost LEO Low Earth Orbit LH2 Liquid Hydrogen LO2 Liquid Oxygen LRB Liquid Rocket Booster MAF Michoud Assembly Facility MFG Manufacturing MLP Mobile Launch Platform MMH Mono Methyl Hydrazine MPS Main Propulsion System MPTA Main Propulsion Test Article MSFC Marshall Space Fright Center NASA National Aeronautics and Space AdminisWation N204 Nitrogen Tetroxide NSTS National Space Transportation System P/A Propulsion and Avionics P/A & S Propulsion and Avionics and Structure R&T Research and Technology RP-1 Rocket Propellant SETA . -

Incorporation of RD-180 Failure Response 2011

Incorporation of RD-180 Failure Response Features in the Atlas V Booster Emergency Detection System Felix Y. Chelkis NPO Energomash Khimki, Moscow Region, Russia Thaddeus D. Chwiedor United Launch Alliance, Denver, Colorado, USA Paul T. Connolly and John P. Hansen Pratt & Whitney Rocketdyne, Jupiter, Florida, USA Abstract Approximately 70% of the parts on the RD-180 engine as used on Atlas V launch vehicles are common with the RD-170 engine. The RD-170 engine was developed by NPO Energomash and certified in 1985 to power the Energia Buran rocket launch system, which was rated for human spaceflight as defined by the Russian standards. With over 45,000 seconds of operational time, the RD-180 has an extensive history of demonstrated performance, robustness, and reliability as does the Atlas vehicle that it powers. This paper describes why the RD-180/Atlas combination provides an optimal solution for human space flight directly applicable to the near-term commercial crew transportation program. The paper will examine how the RD-180/Atlas booster combination could meet Commercial Crew space flight requirements. An overview of the past NASA human space flight requirements to the Russian approach for manned flight will also be made. The paper will discuss the work that has been done to understand not only the potential failure modes to which the RD-180 propulsion system could be subjected to but also how these failure modes could be quickly identified, mitigated or managed such that a safe crew abort sequence could be initiated. The RD-180/Atlas Emergency Detection System (EDS) will be described and shown to be a viable approach to meeting Commercial Crew space flight requirements. -

Reengineering Systems Engineering Joseph Kasser, National University of Singapore; Derek Hitchins, ASTEM, Consultant Systems Architect; Thomas V

rd 3 Asia-Pacific Conference on Welcome from the Systems Engineering General Chair APCOSE 2009 Singapore Welcome to the 19th Annual INCOSE International Symposium (INCOSE 2009), which will be held in conjunction with the 3rd July 20 - 23 Asia-Pacific Conference on Systems Engineering (APCOSE 2009) from 20-23 July 2009. As the General Chair, I have the pleasure to welcome you to the choice international forum of the systems engineering community. The theme of the symposium, East meets West: The Human Dimension to Systems Engineering, highlights the human cognitive dimension as an integral part of systems thinking and systems engineering processes across different cultures. Moreover, human capital and capability form the fundamental basis for large-scale systems engineering. This is the first time that the INCOSE Symposium is held in Singapore and in Asia. Jointly hosted by INCOSE Region VI Chapters of Australia, Beijing, Japan, Korea, Singapore and Taiwan, the symposium reflects the growth of systems engineering as an emerging discipline in the region. This premier event will present researchers, students, educators, academics, professionals, public and private organisations from the East and East Meets West the West the opportunity to share and deliberate on the latest The Human Dimension to Systems Engineering systems engineering developments in education, research and applications. I believe this mutual exchange of ideas across different cultures can only spur greater dynamism and thinking in stretching the existing boundaries of systems engineering. Hosted by the Region VI Chapters of Finally, Singapore with its strategic location and world-class Australia, Beijing, Japan, Korea, infrastructure, serves as the logical meeting place for industry, Singapore and Taiwan academia and government from East and West to network, develop and grow partnerships. -

Comparison of Return to Launch Site Options for a Reusable Booster Stage

RTLS Comparisons Comparison of Return to Launch Site Options for a Reusable Booster Stage Barry Mark Hellman Space Systems Design Lab School of Aerospace Engineering Georgia Institute of Technology ASC/XRE 1970 Monahan Way WPAFB, OH 45433 [email protected] ABSTRACT There is a major need in the U.S. Air Force to develop launch vehicles that can be used for Operational Responsive Spacelift and possibly be used for rapid global Strike. One strategy to achieve these mission goals is to develop a Reusable Mlitary Launch System (RMLS) or a hybrid system which uses a reusable booster with expendable upper stages. In support of the development work of the Aerospace Systems Design Branch (ASC/ENMD) of the USAF Aeronautical Systems Center at Wright-Patterson AFB, this study looked at comparing three basic methods for Return to Launch Site (RTLS) for a reusable booster. These methods are glideback to launch site, flyback using an airbreathing turbofan, and boostback using the booster's main or secondary rocket engines. The booster carries the upper stage(s)on its back to the staging point. Currently, most RTLS vehicle studies either assume a glideback or flyback booster. Very little work outside of the Kistler K-1 has been done to look at boostback methods. The vehicle modeling was integrated into ModelCenter using the MDO method of Optimizer Based Decomposition to handle the branching trajectory problem that arises from the booster performing a RTLS maneuver. Each of the three vehicles was optimized to minimize dry weight and gross weight separately in order to get a better understanding if boostback can provide any advantages over the two more traditional RTLS methods.