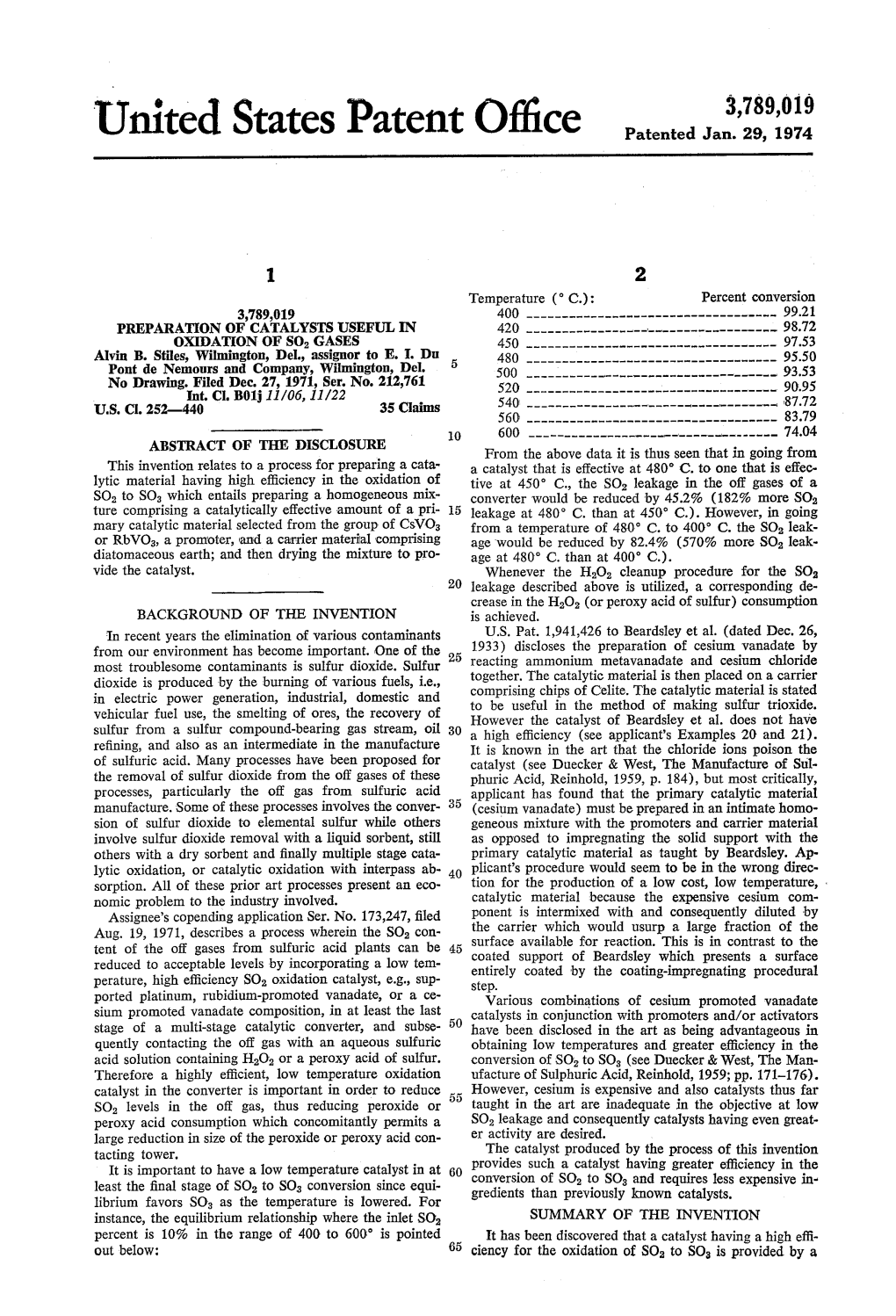

United States Patent Office Patented Jan

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Sd0000029 Evaluation of Chromfte Ore and The

SD0000029 EVALUATION OF CHROMFTE ORE AND THE OPTIMUM METHODS FOR INDUSTRIAL EXTRACTION OF CHROMIUM A TI1HSIS SUBMITTED BY Bakheit Mustafa Mohamed Salih IN CANDIDATURE FOR TIU:DI:GRFJ:OI MASTER OF SC1HNCT DEPARTMENT OF CHEMISTRY FACULTY OF SCIENCE (P.O.BOX 321) OCTOBER 1999 UNIVERSITY OF KHARTOUM 31/ 28 ABSTRACT Samples of chromite ore, collected from Gam and Cheikay mining area (Ingessana Hills) in east Sudan, were analysed to assess the chromium content. Methods for extraction and analysis of chromium metal were developed and established. Analysis were carried out using atomic absorption spectroscopy (AAS) to estimate the contents of chromium, iron, calcium, and magnesium. X-ray fluorescence (XRF) was used to evaluate the levels of chromium, iron, and calcium in the ore. Volumetric analysis was performed to assess chromium and iron, whilst gravimetric analysis was employed to measure the amounts of calcium, magnesium, aluminum and silicon present in the ore. The data was chemically and statistically analyzed to compare the results obtained by the given analytical methods. The results are in good agreement except iron oxide, which displayed a significantly different value when measured by x-ray fluorescence. The data obtained exhibited similarity in almost all cases, when compared with local and global researches, reports, and literature. The study has revealed the average contents of Cr2O3, FeO, CaO, MgO, A12O3, and SiO2 as 40.66. 11.96, 11.94. 0.36. 16.94, 11.45% respectively. MnO and NiO were detected in trace amounts, the corresponding levels in the ore being 72 and 27 ppm. The average chromium content in extracted potassium dichromate measured by using AAS, XRF, and volumetric methods was found to be 31.7%. -

THE FUTURE DIRECTIONS of TANNING* by ANTHONY D

7 QUO VADIT CHROMIUM? THE FUTURE DIRECTIONS OF TANNING* by ANTHONY D. COVINGTON* British School of Leather Technology The University of Northampton BOUGHTON GREEN ROAD, NORTHAMPTON NN2 7AL, UK ABSTRACT La pregunta expuesta es: donde nos llevará este nuevo concepto en términos del futuro de la curtición? From leather science, a deeper understanding of the La respuesta es: a un desplazamiento paradigmático. theoretical basis of the tanning mechanism has unified the inorganic and organic chemistries of Curtición al cromo permanecerá con nosotros, pero leather making processes. The 'link-lock' mechanism en un futuro se visualizará muy diferentemente provides an explanation of present reactions and a su tecnología por hoy percibida. Opciones para la tool for future developments. transformación del proceso ya sí se pueden proponer. Es importante en este ejercicio cuestionar detalladamente The question now posed is: where does this new los aspectos convencionalmente aceptados de thinking take us, in terms of the future of tanning? esta reacción. The answer is: into a paradigm shift. Tecnologías alternativas de curtición en la era Chrome tanning will remain with us, but in the moderna pueden ahora ser desarrolladas, para future it can be viewed very differently from its producir cueros altamente estables hidrotérmicamente. currently perceived technology. Options for Aquí la teoría eslabón-cerrojo ha demostrado que tales transforming the process may now be proposed. resultados no son obtenibles con un solo reactivo, por lo Important in this exercise is to question closely the menos dos componentes de curtido son requeridos. conventionally accepted features of the reaction. Más aun, la curtición podrá ser más acertadamente formulada para que encaje con la química (o bioquímica) Alternative technologies for tanning in the modern de la reacción según su rendimiento y los requerimientos era can now be developed, to make high hydrothermal del impacto ambiental del cuero. -

Food and Drug Administration, HHS § 178.3130

Food and Drug Administration, HHS § 178.3130 List of substances Limitations Alum (double sulfate of aluminum and ammonium, potassium, or sodium). 4-Chloro-3-methylphenol(p-chlorome-tacresol) ............................................ For use as preservative only. Chromium potassium sulfate (chrome alum) ............................................... For use only in glue used as a colloidal flocculant added to the pulp suspension prior to the sheet- forming operation in the manufacture of paper and paper board. 3,5-Dimethyl-1,3,5,H-tetrahydrothiadia-zine-2-thione .................................. For use as preservative only. Disodium cyanodithioimidocarbonate .......................................................... Do. Defoaming agents ........................................................................................ As provided in § 176.210 of this chapter. Ethanolamine. Ethylenediamine. Formaldehyde .............................................................................................. For use as a preservative only. Potassium N-methyldithiocarbamate ........................................................... Do. Potassium pentachlorophenate .................................................................... Do. Rosins and rosin derivatives ........................................................................ As provided in § 178.3870. Sodium chlorate. Sodium dodecylbenzenesulfonate. Sodium 2-mercaptobenzothiazole ................................................................ For use as preservative only. Sodium -

The Structure and Color of Alums Student Version.Pdf

Created by Erica Gunn, Simmons College ([email protected]) and posted on VIPEr (www.ionicviper.org ) on 7/21/2014. Copyright Erica Gunn 2014. This work is licensed under the Creative Commons Attribution-NonCommerical-ShareAlike 3.0 Unported License. To view a copy of this license visit http://creativecommons.org/about/license/ . The Structure and Color of Alums Alum is the common name for the hydrated salt of potassium aluminum sulfate. This is called a “double salt” because it contains two different cations - in this case, potassium and aluminum - that crystallize together in a single solid. The alum crystal structure shown below contains aluminum (gray) and 2- i potassium (purple) ions, as well as tetrahedral sulfate (SO 4 ) counterions. The crystal is a hydrate, and the red atoms shown attached to the metals indicate oxygens from the water molecules. (Hydrogens are not shown, for simplicity.) As indicated in the figure, the metal atoms have an octahedral coordination sphere, with a single metal ion surrounded by 6 water molecules. (The site symmetry of the potassium atoms is somewhat distorted from a true octahedron.) The formula for this compound is KAl[SO 4]2*12H2O. It is important to note that this compound is a salt, and so it fully dissolves into individual ions in solution. Here, the octahedral coordination of the metal ions depends on the crystal structure, unlike coordination compounds that maintain the same coordination geometry in the solid and solution states. a b c d Figure 1. a) Crystal structure of KAl[SO ] *12H O. (K = purple, Al = gray, S = yellow, O = red). -

Questions TRANSITION METALS: CHROMIUM

Chemguide – questions TRANSITION METALS: CHROMIUM It is quite likely that you won't need to know all the chemistry below. Check your syllabus and past papers and concentrate on those questions that you need to be able to answer. 1. This question is mainly about the reactions of chromium(III) ions in solution. a) What sort of pH would you expect to find if you tested a solution containing chromium(III) sulphate? b) Write an equation to show the cause of that pH. c) A solution of chromium(III) sulphate is a violet-blue-grey colour, but on heating it turns green. Explain what is happening. d) The diagrams in this part of the question show the effect of adding various other solutions to a solution containing hexaaquachromium(III) ions. In each case, give the formula for the chromium- containing complex(es) in each tube. (i) addition of sodium hydroxide solution: (ii) addition of ammonia solution: (iii) addition of sodium carbonate solution: e) Describe briefly how you would produce a sample of sodium chromate(VI) solution starting from a solution containing hexaaquachromium(III) ions. www.chemguide.co.uk Chemguide – questions f) To convert the sodium chromate(VI) solution formed in part (e) into sodium dichromate(VI), you would first boil the solution, and then add an acid to it. (i) Why is it necessary to boil the solution before adding the acid? (ii) Adding the acid disturbs an equilibrium in the solution between chromate(VI) and dichromate(VI) ions. Write the equation showing that equilibrium. (iii) Explain why adding an acid converts chromate(VI) ions into dichromate(VI) ions. -

Chromate and the Environment: Removal and Utilization of Industrial Waste

J. Chem. Chem. Eng. 10 (2016) 147-152 doi: 10.17265/1934-7375/2016.03.006 D DAVID PUBLISHING Chromate and the Environment: Removal and Utilization of Industrial Waste Fernando B. Mainier, Pedro Paulo B. Leite, Marcone F. Reis and Thiago Teobaldo Silva Engineering School, Federal Fluminense University(UFF), Niterói, Rio de Janeiro 24220-261, Brazil Abstract: Chromate and dichromate sodium as a function of oxidizer characteristics are used in several industrial areas; for example, in surface protection of coated parts of cadmium, zinc and aluminum (chromate coated treated), corrosion inhibitors, the treatment of leather, the manufacture of pigments, etc. However, the use of such products has been questioned due to the problems of toxicity and pollution that can be caused in the environmental. The Brazilian environmental agency has established that the concentrations of 2- chromate in water courses are less than 0.5 ppm. In order to reuse chromate (CrO4 ) from industrial effluent, laboratory experiments have been proposed based on chemical reduction or electrolytic processes, in order to transform these chromate ions in a final mix of oxides (in solid form), which can then be packed and sent to the production process of sodium chromate. The results of these experiments have become useful industrially (without regard to costs) considering the environmental reuse and the life cycle of the chemical compound. Key words: Chromate, dichromate, contamination, chemical reduction, electrolytic process. 1. Introduction waste, among others [1, 2]. In -

MC251: Potassiumchromate-(III)-Sulphate CAS#: 10141-00-1

the art and science of smart patch testingTM MC251: Potassiumchromate-(III)-sulphate CAS#: 10141-00-1 Patient Information Your patch test results indicate that you have a contact allergy to potassiumchromate-(III)-sulphate. This contact allergy may cause your skin to react when it is exposed to this substance although it may take several days for the symptoms to appear. Typical symptoms include redness, swelling, itching, and fluid-filled blisters. Where is potassiumchromate-(III)-sulphate found? This substance is a violet-red crystalline compound used in tanning and in photography. How can you avoid contact with potassiumchromate-(III)- sulphate? Avoid products that list any of the following names in the ingredients: 0% Basicity chrome alum Crystal Chrome Alum CCRIS 7532 EINECS 233-401-6 Chrome alum Potassium chromic sulfate Chrome potash alum Potassium chromic sulphate Chromic potassium sulfate Potassium chromium alum Chromic potassium sulphate Potassium chromium disulfate Chromium potassium sulfate (KCr(SO4)2) (CrK(SO4)2) Potassium chromium(III) sulfate Chromium potassium sulphate Potassium disulphatochromate (III) What are some products that may contain potassiumchromate-III- sulphate? Photography Products Tanning Products *For additional information about products that might contain potassiumchromate-(III)-sulphate, go to the Household Product Database online (http:/householdproducts.nlm.nih.gov) at the United States National Library of Medicine. These lists are brief and provide just a few examples. They are not comprehensive. Product formulations also change frequently. Read product labels carefully and talk to your doctor if you have any questions. These are general guidelines. Talk to your doctor for more specific instructions. . -

Preparation of Alum 1

NTU - Experiment 7 Preparation of alum 1 Experiment 7 PREPARATION OF ALUM Objective The purpose of this experiment is using aluminum cans to synthesize alum (aluminum potassium sulfate dodecahydrate), including purification through recrystallization, and to prepare chromium-aluminum alum by replacement. Lab techniques Weighing chemicals. Operating of gravity filtration, suction filtration, and crystallization. Introduction I. Synthesizing alum Although aluminum is an active metal, but it reacts slowly with dilute acids because its surface is protected by a thin layer of aluminum oxide. However, alkaline solutions may dissolve the oxide layer and then react with the metal quickly. - Aluminum is oxidized by excess alkali to tetrahydroxoaluminate(III) anion, Al(OH)4 (7-1), which is soluble in solution. When acid is added slowly to the solution containing this complex anions, one of the OH- is removed, then a flocculent white Al(OH)3 appears (7-2). While continuous addition of acid, the hydrated aluminum 3+ cations, [Al(H2O)6] , are formed and the white precipitate Al(OH)3 is dissolved (7-3). Aluminum hydroxide which may react with acid and base (7-4) simultaneously is said to be amphoteric. + - 2Al(s) + 2KOH(aq) + 6H2O(l) → 2K (aq) + 2Al(OH)4 (aq) + 3H2(g) (7-1) - + Al(OH)4 (aq) + H (aq) → Al(OH)3(s) + H2O(l) (7-2) + 3+ Al(OH)3(s) + 3H (aq) → Al (aq) + 3H2O(l) (7-3) - - Al(OH)3(s) + OH (aq) → Al(OH)4 (aq) (7-4) In the experiment, recycled aluminum can is used to react with potassium hydroxide and sulfuric acid in sequence in order to prepare alum and observe the amphoteric property of aluminum. -

Chromium Contamination in Tannery Effluent Toxicology and Potential Interventions

8/8/2019 Chromium Contamination in Tannery Effluent Toxicology and Potential Interventions CIVE 480B Final Report Liam Downey, V00846518 UVIC CIVIL ENGINEERING STUDENT Jordan Gough, V00865608 UVIC CIVIL ENGINEERING STUDENT Timothy Berntsen, V00839469 UVIC CIVIL ENGINEERING STUDENT Executive Summary Leather tanning has been practiced by humans for thousands of years. Animal hides are subject to putrefaction and when wet, and are tough and useless for practical purposes when dried. The process of tanning replaces the water molecules in collagen, the main protein in animal skin, with new molecules. Prior to the Industrial Revolution, vegetable tanning was primarily how leather was tanned. Animal hides are soaked in a vegetable tannin bath, which is usually made from tree bark extracts. In 1859, two technologists invented the process of mineral tanning. This process is very similar, but usually uses chromium ions instead of vegetable tannins to displace and replace water molecules in the collagen. Chrome tanning is quicker, easier, and results in leather that is softer and suppler than vegetable-tanned leather. Currently the leather tanning industry is valued at 100 billion USD, and 80-90% of leather is chrome-tanned. Chromium mainly exists in nature in two oxidation states – chromium (III) and chromium (VI). Chromium (III) is what is used in chrome tanning, but chromium (VI) can also be present in the watershed through errors in the salt manufacturing and oxidation by natural compounds. Chromium (VI) is much more toxic, causing a plethora of both acute and chronic toxic effects. These effects include dermal and respiratory damage to tannery workers, and gastrointestinal effects from chromium entering drinking water. -

Chemical Resistance Chart Version 11/2018 | PDF Only | Bürkert Applied Marketing & Design Applied Marketing 11/2018 | PDF Only Bürkert Version

Chemical Resistance Chart Version 11/2018 | PDF only | Bürkert Applied Marketing & Design Applied Marketing 11/2018 | PDF only Bürkert Version Check chemical resistance online. Download our mobile resistApp for free: Click to start the resistApp! Bürkert Fluid Control Systems Christian-Bürkert-Straße 13 -17 74653 Ingelfingen Germany Tel.: +49 7940 10 0 Fax: +49 7940 10 91204 [email protected] www.burkert.com Introduction 3 Introduction When dealing with aggressive fluids the user is continuously faced with the problem of finding compatible materials. In order to simplify the selection of suitable materials when using Bürkert products for aggressive fluids, the following tables provide useful information on the optimal choice of housing and gasket materials for a multitude of media. Since corrosion performance is influenced by several factors, the information contained Content in this brochure should be treated only as a guide and is not necessarily valid for all op- erating conditions. Increased temperatures, higher concentrations, and the inadvertent 3 Introduction ingress of water in originally pure chemicals can all lead to accelerated corrosion. 4 Structure and content of the chemical resistance charts Dependent on the purity of the fluid as well as the compounding and nature of vulca- 5 Interpretation of Symbols nisation of the gasket materials, deviations can result which affect the suitability and durability of the plastics and elastomers. 5 References 6 Overview The information quoted in this guide does not consider the effect of mechanical load- ing, which may also have a bearing on the material performance in the fluid. In cases 8 Resistance in basic chemicals of doubt when considering our products, we strongly recommend the prior testing of 32 Resistance in commercial products samples with various material combinations, in order to establish and check their suit- ability under the actual operating conditions of the application. -

Locating and Estimating Air Emissions from Sources of Chromium

United States Office of Air Quality EPA-450/4-84-007g Environmental Protection Planning And Standards Agency Research Triangle Park, NC 27711 July 1984 AIR EPA LOCATING AND ESTIMATING AIR EMISSIONS FROM SOURCES OF CHROMIUM L &E EPA-450/4-84-007G July 1984 Locating and Estimating Air Emissions From Sources of Chromium U.S ENVIRONMENTAL PROTECTION AGENCY Office of Air and Radiation Office of Air Quality Planning and Standards Research Triangle Park, North Carolina, NC 27711 This report has been reviewed by the Office of Air Quality Planning and Standards, U.S. Environmental Protection Agency, and has been approved for publication as recieved from Radian Corporation. Approval does not signify that the contents necessarily reflect the views and policies of the Agency, neither does mention of trade names or commercial products constitute endorsement or recommendation for use. TABLE OF CONTENTS Page List of Tables .......................................................... v List of Figures ...................................................... viii 1. Purpose of Document ......................................... 1 2. Overview of Document Contents ............................... 3 3. Background ........................................... 5 Nature of Pollutant ................................... 5 Overview of Production and Use ........................ 9 Chromium production ............................. 9 Chromium uses .................................. 19 References for Section 3 ............................. 27 4. Chromium Emission Sources ................................. -

Safety Data Sheet CS: 1.7.2

Safety Data Sheet CS: 1.7.2 Page: 1 of 4 ™ Infosafe No 1CH93 Issue Date : March 2014 RE-ISSUED by CHEMSUPP Product Name : CHROMIUM (III) POTASSIUM SULFATE Dodecahydrate Classified as hazardous 1. Identification GHS Product CHROMIUM (III) POTASSIUM SULFATE Dodecahydrate Identifier Company Name CHEM-SUPPLY PTY LTD (ABN 19 008 264 211) Address 38 - 50 Bedford Street GILLMAN SA 5013 Australia Telephone/Fax Tel: (08) 8440-2000 Number Fax: (08) 8440-2001 Recommended use Tanning (chrome-tan liquors), textile dye (mordant), photography (fixing bath), ceramics, rendering glue of the chemical and and gum insoluble, waterproofing fabrics, manufacture of ink and other chromium salts laboratory restrictions on use reagent. Other Names Name Product Code CHROMIUM POTASSIUM SULFATE Dodecahydrate LR CL039 Chrome Alum, Chrome Potash Alum, Potassium Chromium Sulfate, Alum Chrome, Potassium chromium (III) sulfate Other Information EMERGENCY CONTACT NUMBER: +61 08 8440 2000 Business hours: 8:30am to 5:00pm, Monday to Friday. Chem-Supply Pty Ltd does not warrant that this product is suitable for any use or purpose. The user must ascertain the suitability of the product before use or application intended purpose. Preliminary testing of the product before use or application is recommended. Any reliance or purported reliance upon Chem-Supply Pty Ltd with respect to any skill or judgement or advice in relation to the suitability of this product of any purpose is disclaimed. Except to the extent prohibited at law, any condition implied by any statute as to the merchantable quality of this product or fitness for any purpose is hereby excluded. This product is not sold by description.