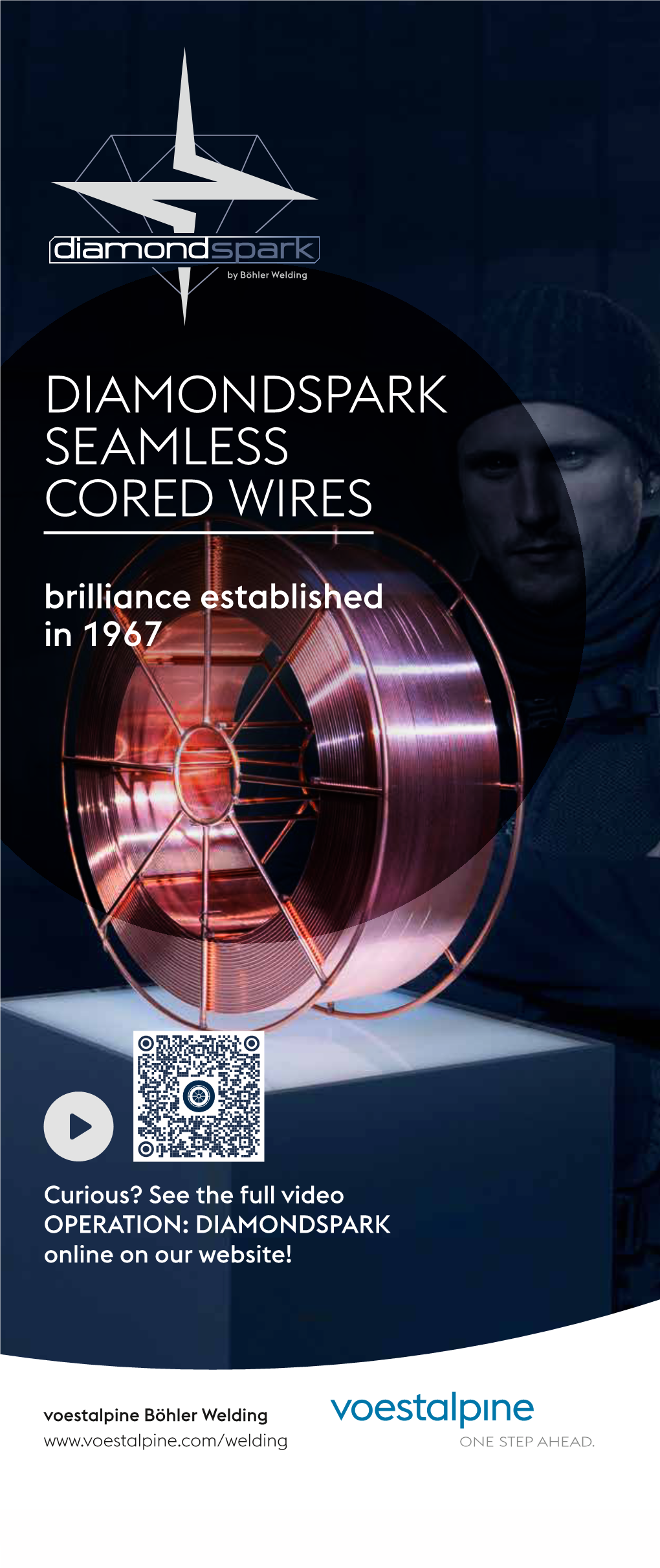

DIAMONDSPARK SEAMLESS CORED WIRES Brilliance Established in 1967

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

VMAA-Performance-Sta

Revised June 18, 2019 U.S. Department of Veterans Affairs (VA) Veteran Monthly Assistance Allowance for Disabled Veterans Training in Paralympic and Olympic Sports Program (VMAA) In partnership with the United States Olympic Committee and other Olympic and Paralympic entities within the United States, VA supports eligible service and non-service-connected military Veterans in their efforts to represent the USA at the Paralympic Games, Olympic Games and other international sport competitions. The VA Office of National Veterans Sports Programs & Special Events provides a monthly assistance allowance for disabled Veterans training in Paralympic sports, as well as certain disabled Veterans selected for or competing with the national Olympic Team, as authorized by 38 U.S.C. 322(d) and Section 703 of the Veterans’ Benefits Improvement Act of 2008. Through the program, VA will pay a monthly allowance to a Veteran with either a service-connected or non-service-connected disability if the Veteran meets the minimum military standards or higher (i.e. Emerging Athlete or National Team) in his or her respective Paralympic sport at a recognized competition. In addition to making the VMAA standard, an athlete must also be nationally or internationally classified by his or her respective Paralympic sport federation as eligible for Paralympic competition. VA will also pay a monthly allowance to a Veteran with a service-connected disability rated 30 percent or greater by VA who is selected for a national Olympic Team for any month in which the Veteran is competing in any event sanctioned by the National Governing Bodies of the Olympic Sport in the United State, in accordance with P.L. -

ELIGIBILITY Para-Cycling Athletes: Must Be a United States Citizen With

ELIGIBILITY Para-cycling Athletes: Must be a United States citizen with a USA racing nationality. LICENSING National Championships: Riders may have a current International or Domestic USA Cycling license (USA citizenship) or Foreign Federation license showing a USA racing nationality to register. World Championships Selection: Riders must have a current International USA Cycling license with a USA racing nationality on or before June 20, 2019 in order to be selected for the Team USA roster for the 2019 UCI Para-cycling Road World Championships. Selection procedures for the World Championships can be found on the U.S. Paralympics Cycling Website: https://www.teamusa.org/US- Paralympics/Sports/Cycling/Selection-Procedures REGULATIONS General: All events conducted under UCI Regulations, including UCI equipment regulations. Road Race and Time Trials: • No National Team Kit or National championship uniforms are allowed. • For the Road Race, only neutral service and official’s cars are allowed in the caravan. • For the Time Trial, bicycles and handcycles must be checked 15 minutes before the athlete’s assigned start time. Courtesy checks will be available from 1 hour before the first start. No follow vehicles are allowed. • For all sport classes in the road race, athletes are required to wear a helmet in the correct sport class color, or use an appropriately color helmet cover, as follows: RED MC5, WC5, MT2, MH4, WH4, MB WHITE MC4, WC4, MH3, WH3, WB, WT2 BLUE MC3, WC3, MH2, WT1 BLACK MH5, WH5, MC2, WC2, MT1 YELLOW MC1, WC1, WH2 GREEN MH1 ORANGE WH1 Handcycle Team Relay (TR): New National Championship event run under UCI and special regulations below: • Team Requirements: Teams eligible for the National Championship Team Relay, must be respect the following composition: o Teams of three athletes o Using the table below, the total of points for the three TR athletes may not be more than six (6) points which must include an athlete with a scoring point value of 1. -

The Intentions of International Tourists to Attend the 2016 Rio Summer Olympic and Paralympic Games: a Study of the Image of Rio De Janeiro and Brazil

Ann Appl Sport Sci 8(3): e798, 2020. http://www.aassjournal.com; e-ISSN: 2322–4479; p-ISSN: 2476–4981. 10.29252/aassjournal.798 ORIGINAL ARTICLE The Intentions of International Tourists to Attend the 2016 Rio Summer Olympic and Paralympic Games: A Study of the Image of Rio de Janeiro and Brazil Leonardo Jose Mataruna-Dos-Santos* College of Business Administration, American University in the Emirates, Dubai, UAE. Submitted 22 September 2019; Accepted in final form 27 February 2020. ABSTRACT Background. This paper investigates how hosting a mega sports event such as the 2016 Rio Games – Olympic and Paralympic influence the Rio de Janeiro and Brazil image’ like popular destinations among tourists. Objectives. The following hypotheses guided our research to identify the more positive image of Brazil as a tourism destination. Methods. A mixed research design combining both qualitative and quantitative approaches was used. Participants were recruited at the Technische Universität München and in the city center of Munich, Germany. The two dimensions (cognitive and affective) of the tourism destination image were considered to elaborate a questionnaire survey, which mixes both qualitative and quantitative methods. Results. The significant factors influencing the intentions of a person to attend the Games in Brazil are the positive portrayed image of the country and their sport interest. According to the multiple regression conducted, the only variables, which have influenced people’s intention to go to Brazil for the Olympics, were the image of the country as a tourism destination (β = 0.404, p < 0.05) and sports interests (β = 0.259, p < 0.05). -

Para Cycling Information Sheet About the Sport Classification Explained

Para cycling information sheet About the sport Para cycling is cycling for people with impairments resulting from a health condition (disability). Para athletes with physical impairments either compete on handcycles, tricycles or bicycles, while those with a visual impairment compete on tandems with a sighted ‘pilot’. Para cycling is divided into track and road events, with seven events in total. Classification explained In Para sport classification provides the structure for fair and equitable competition to ensure that winning is determined by skill, fitness, power, endurance, tactical ability and mental focus – the same factors that account for success in sport for able-bodied athletes. The Para sport classification assessment process identifies the eligibility of each Para athlete’s impairment, and groups them into a sport class according to the degree of activity limitation resulting from their impairment. Classification is sport-specific as an eligible impairment affects a Para athlete’s ability to perform in different sports to a different extent. Each Para sport has a different classification system. Standard Classification in detail Para-Cycling sport classes include: Handcycle sport classes H1 – 5: There are five different sport classes for handcycle racing. The lower numbers indicate a more severe activity limitation. Para athletes competing in the H1 classes have a complete loss of trunk and leg function and limited arm function, e.g. as a result of a spinal cord injury. Para athletes in the H4 class have limited or no leg function, but good trunk and arm function. Para cyclists in sport classes H1 – 4 compete in a reclined position. Para cyclists in the H5 sport class sit on their knees because they are able to use their arms and trunk to accelerate the handcycle. -

RHS Hardiness Ratings (H1-H4) Which Are Not the Direct Equivalents of the New Ratings

HARDINESS RATINGS RHS Registered Charity No: 222879/SC038262 Rating Temperature Category Definition USDA ranges (°C) H1a >15 Heated greenhouse Under glass all year. 13 – tropical H1b 10 – 15 Heated greenhouse Can be grown outside in the summer in hotter, sunny and 12 – subtropical sheltered locations (such as city centre areas), but generally perform better under glass all year round. H1c 5 – 10 Heated greenhouse Can be grown outside in the summer throughout most of 11 – warm temperate the UK while day-time temperatures are high enough to promote growth. (Most bedding plants, tomatoes and cucumbers). H2 1– 5 Tender – cool or Tolerant of low temperatures, but not surviving being 10b frost-free greenhouse frozen. Except in frost-free inner-city areas or coastal extremities requires glasshouse conditions. Can be grown outside once risk of frost is over. (Most succulents, many subtropical plants, annual bedding plants, many spring-sown vegetables). H3 1 – -5 Half hardy – unheated Hardy in coastal and relatively mild parts of the UK except 9b/10a greenhouse/mild in severe winters and at risk from sudden (early) frosts. winter. May be hardy elsewhere with wall shelter or good microclimate. Likely to be damaged or killed in cold winters, particularly with no snow cover or if pot grown. Can often survive with some artificial protection in winter. (Many Mediterranean-climate plants, spring sown vegetables for later harvesting). H4 -10 – -5 Hardy – average Hardy though most of the UK apart from inland valleys, at 8b/9a winter altitude and central/northerly locations. May suffer foliage damage and stem dieback in harsh winters in cold gardens. -

(VA) Veteran Monthly Assistance Allowance for Disabled Veterans

Revised May 23, 2019 U.S. Department of Veterans Affairs (VA) Veteran Monthly Assistance Allowance for Disabled Veterans Training in Paralympic and Olympic Sports Program (VMAA) In partnership with the United States Olympic Committee and other Olympic and Paralympic entities within the United States, VA supports eligible service and non-service-connected military Veterans in their efforts to represent the USA at the Paralympic Games, Olympic Games and other international sport competitions. The VA Office of National Veterans Sports Programs & Special Events provides a monthly assistance allowance for disabled Veterans training in Paralympic sports, as well as certain disabled Veterans selected for or competing with the national Olympic Team, as authorized by 38 U.S.C. 322(d) and Section 703 of the Veterans’ Benefits Improvement Act of 2008. Through the program, VA will pay a monthly allowance to a Veteran with either a service-connected or non-service-connected disability if the Veteran meets the minimum military standards or higher (i.e. Emerging Athlete or National Team) in his or her respective Paralympic sport at a recognized competition. In addition to making the VMAA standard, an athlete must also be nationally or internationally classified by his or her respective Paralympic sport federation as eligible for Paralympic competition. VA will also pay a monthly allowance to a Veteran with a service-connected disability rated 30 percent or greater by VA who is selected for a national Olympic Team for any month in which the Veteran is competing in any event sanctioned by the National Governing Bodies of the Olympic Sport in the United State, in accordance with P.L. -

Social Scientists' Satisfaction with Data Reuse

Ixchel M. Faniel OCLC Research Adam Kriesberg University of Michigan Elizabeth Yakel University of Michigan Social Scientists’ Satisfaction with Data Reuse Note: This is a preprint of an article accepted for publication in Journal of the Association for Information Science and Technology copyright © 2015. Abstract: Much of the recent research on digital data repositories has focused on assessing either the trustworthiness of the repository or quantifying the frequency of data reuse. Satisfaction with the data reuse experience, however, has not been widely studied. Drawing from the information systems and information science literatures, we develop a model to examine the relationship between data quality and data reusers’ satisfaction. Based on a survey of 1,480 journal article authors who cited Inter-University Consortium for Political and Social Research (ICPSR) data in published papers from 2008 – 2012, we found several data quality attributes - completeness, accessibility ease of operation, and credibility – had significant positive associations with data reusers’ satisfaction. There was also a significant positive relationship between documentation quality and data reusers’ satisfaction. © 2015 OCLC Online Computer Library Center, Inc. 6565 Kilgour Place Dublin, Ohio 43017-3395 This work is licensed under a Creative Commons Attribution 4.0 International License. http://creativecommons.org/licenses/by/4.0/ Suggested citation: Faniel, I. M., Kriesberg, A. and Yakel, E. (2015). Social scientists' satisfaction with data reuse. Journal of the Association for Information Science and Technology. doi: 10.1002/asi.23480 Social Scientists’ Satisfaction with Data Reuse 1 Introduction In the past decade, digital data repositories in a variety of disciplines have increased in number and scope (Hey, Tansley, & Tolle, 2009). -

SPECTATOR GUIDE U.S. Paralympics Cycling Open Cummings Research Park, Huntsville, Alabama April 17-18, 2021 Come Cheer for Our P

SPECTATOR GUIDE U.S. Paralympics Cycling Open Cummings Research Park, Huntsville, Alabama April 17-18, 2021 Come Cheer for our Paralympic Cyclists! The Huntsville/Madison County community is excited to host U.S. Paralympics Cycling on Saturday and Sunday, April 17-18, 2021 in Cummings Research Park. The U.S. Paralympics Cycling Open presented by Toyota, is one of four domestic cycling events and the second opportunity for Para-cyclists to qualify for the Summer Paralympics in Tokyo this summer. This is also the return to competitive racing for these outstanding athletes who have not competed in over a year due to the ongoing COVID-19 pandemic. In fact, this event has taken on more importance in the qualifying circuit as other international qualifying events have been cancelled due to the pandemic. We expect approximately 100 Para athletes to visit Huntsville. The athletes will compete in three different types of road cycling events including the men’s and women’s road race, individual time trial, and handcycling team relay. Learn more about U.S. Paralympics Cycling here: USParaCycling.org This guide serves as an FAQ. It provides information on how and where you can watch the action during race weekend. Link to: Parking Viewing Restrooms What’s on the Schedule Each Day Show Your Support! Athletes to Watch Page 1 Do I need tickets? No! The public is invited, and this is a free event. The events will happen rain or shine. Bring the family, pack a cooler, bring chairs and a blanket, and come watch along the outside ring of Explorer Boulevard, the loop of Cummings Research Park West. -

Letters to Assessors 2006-010

STATE OF CALIFORNIA BETTY T. YEE STATE BOARD OF EQUALIZATION Acting Member PROPERTY AND SPECIAL TAXES DEPARTMENT First District, San Francisco 450 N STREET, SACRAMENTO, CALIFORNIA PO BOX 942879, SACRAMENTO, CALIFORNIA 94279-0064 BILL LEONARD Second District, Sacramento/Ontario 916 445-4982 FAX 916 323-8765 www.boe.ca.gov CLAUDE PARRISH Third District, Long Beach February 6, 2006 JOHN CHIANG Fourth District, Los Angeles STEVE WESTLY State Controller, Sacramento RAMON J. HIRSIG Executive Director No. 2006/010 CORRECTION TO COUNTY ASSESSORS: REVENUE AND TAXATION CODE SECTION 69.5: PROPOSITIONS 60, 90, AND 110 Section 69.5 was added to the Revenue and Taxation Code1 in 1987 to implement Proposition 60, which amended section 2 of article XIII A of the California Constitution to authorize the Legislature to provide for the transfer of a base year value from a principal residence2 to a replacement dwelling within the same county by a homeowner age 55 and over. Subsequently, section 69.5 was amended to implement Proposition 90, which authorized county boards of supervisors to adopt ordinances allowing base year value transfers between different counties, and Proposition 110, which extended these provisions to severely and permanently disabled persons of any age. After summarizing the key elements of section 69.5, this letter provides answers to frequently asked questions about its application. This letter supersedes Letters To Assessors No. 87/71 (dated September 11, 1987) and No. 88/10 (dated February 11, 1988). SUMMARY OF SECTION 69.5 Section 69.5 allows a homeowner to transfer the existing base year value to a replacement dwelling provided that: • If the replacement property is located in a different county than the original property, then the county in which the replacement dwelling is located must have a current ordinance allowing base year value transfers from other counties. -

Technical Flood Risk Management Guideline: Flood Hazard

Australian Disaster Resilience Handbook Collection GUIDELINE 7-3 Technical flood risk management guideline: Flood hazard © Commonwealth of Australia 2012 second edition Attribution Edited and published by the Australian Institute Where material from this publication is used for any for Disaster Resilience, on behalf of the Australian purpose, it is to be attributed as follows: Government Attorney-General’s Department. Developed by the National Flood Risk Advisory Group a Source: Australian Disaster Resilience Guideline 7-3: reference group of the Australian – New Zealand Technical flood risk management guideline: Flood Emergency Management Committee hazard, 2014, Australian Institute for Disaster Resilience CC BY-NC Edited and published by the Australian Emergency Management Institute, part of the Australian Using the Commonwealth Coat of Arms Government Attorney-General’s Department. The terms of use for the Coat of Arms are available from Editing and formatting by Biotext, Melbourne. the It’s an Honour website (http://www.dpmc.gov.au/ government/its-honour). Copyright The Australian Institute for Disaster Resilience Contact encourages the dissemination and exchange of Enquiries regarding the content, licence and any use of information provided in this publication. this document are welcome at: The Commonwealth of Australia owns the copyright in all The Australian Institute for Disaster Resilience material contained in this publication unless otherwise 370 Albert St noted. East Melbourne Vic 3002 Telephone +61 (0) 3 9419 2388 Where this publication includes material whose copyright www.aidr.org.au is owned by third parties, the Australian Institute for Disaster Resilience has made all reasonable efforts to: • clearly label material where the copyright is owned by Disclaimer a third party The Commonwealth Attorney-General’s Department and • ensure that the copyright owner has consented to the Australian Institute for Disaster Resilience, in this material being presented in this publication. -

Doping Control Guide for Testing Athletes in Para Sport

DOPING CONTROL GUIDE FOR TESTING ATHLETES IN PARA SPORT JULY 2021 INTERNATIONAL PARALYMPIC COMMITTEE 2 1 INTRODUCTION This guide is intended for athletes, anti-doping organisations and sample collection personnel who are responsible for managing the sample collection process – and other organisations or individuals who have an interest in doping control in Para sport. It provides advice on how to prepare for and manage the sample collection process when testing athletes who compete in Para sport. It also provides information about the Para sport classification system (including the types of impairments) and the types of modifications that may be required to complete the sample collection process. Appendix 1 details the classification system for those sports that are included in the Paralympic programme – and the applicable disciplines that apply within the doping control setting. The International Paralympic Committee’s (IPC’s) doping control guidelines outlined, align with Annex A Modifications for Athletes with Impairments of the World Anti-Doping Agency’s International Standard for Testing and Investigations (ISTI). It is recommended that anti-doping organisations (and sample collection personnel) follow these guidelines when conducting testing in Para sport. 2 DISABILITY & IMPAIRMENT In line with the United Nations Convention on the Rights of Persons with Disabilities (CRPD), ‘disability’ is a preferred word along with the usage of the term ‘impairment’, which refers to the classification system and the ten eligible impairments that are recognised in Para sports. The IPC uses the first-person language, i.e., addressing the athlete first and then their disability. As such, the right term encouraged by the IPC is ‘athlete or person with disability’. -

Use and Occupancy Classifications with Examples

Use and Occupancy Classifications with examples Assembly Uses: • A1 – Theatres and concert halls. • A2 – Restaurants, banquet halls and bars. • A3 – Gyms, churches, bowling alleys and exhibition Halls. • A4 – Indoor arenas, skating rinks, swimming pools and tennis courts. • A5 – Amusement parks, grandstands, stadiums and bleachers. Business Use: • B – Banks, professional offices, barber shops and beauty shops. Educational Use: • E – Schools and day cares, Factory: • F1 – Manufacturing, fabricating and assembling products of moderate hazard. Example: Bakeries, cabinet shops, fry cleaning, food processing, foundries, printing or publishing, refuse incineration. • F2 - Manufacturing or fabricating products of low-hazard. Example: Ceramic products, Brick or masonry, foundries, gypsum, ice. Hazardous: • H1 - detonation hazard. • H2 – deflagration or accelerated burning hazard. • H3 – readily support combustion or pose a physical threat. • H4 – health hazard. • H5 – hazardous production materials. 1 Institutional: • I1 – More than 16 persons on a 24 hour basis Example: Assisted living, alcohol and drug centers, group homes, half-way houses, convalescent facilities. • I2 – More than 5 persons not capable of self-preservation. Example: Hospitals, nursing homes, mental hospitals, detoxification facilities. I3 – more than 5 persons under restraint or security. Example: Prisons, jails, reformatories, detention centers, correctional centers. • I4 – Day Care Facilities for less than 24 hours for more then 5 persons. Example: Adult-care facility and children facility. Mercantile: • M – Drug store, department stores, markets, motor fuel-dispensing facilities, retail or wholesale stores, sales rooms. Residential: • R1 – Boarding houses, hotels, motels. • R2 – Apartments, dormitories, vacation time shares. • R3 – Child or adult care less than 6 persons, no more than 2 dwellings. • R4 – Care assisted occupancies with 6 to 16 occupants excluding staff.