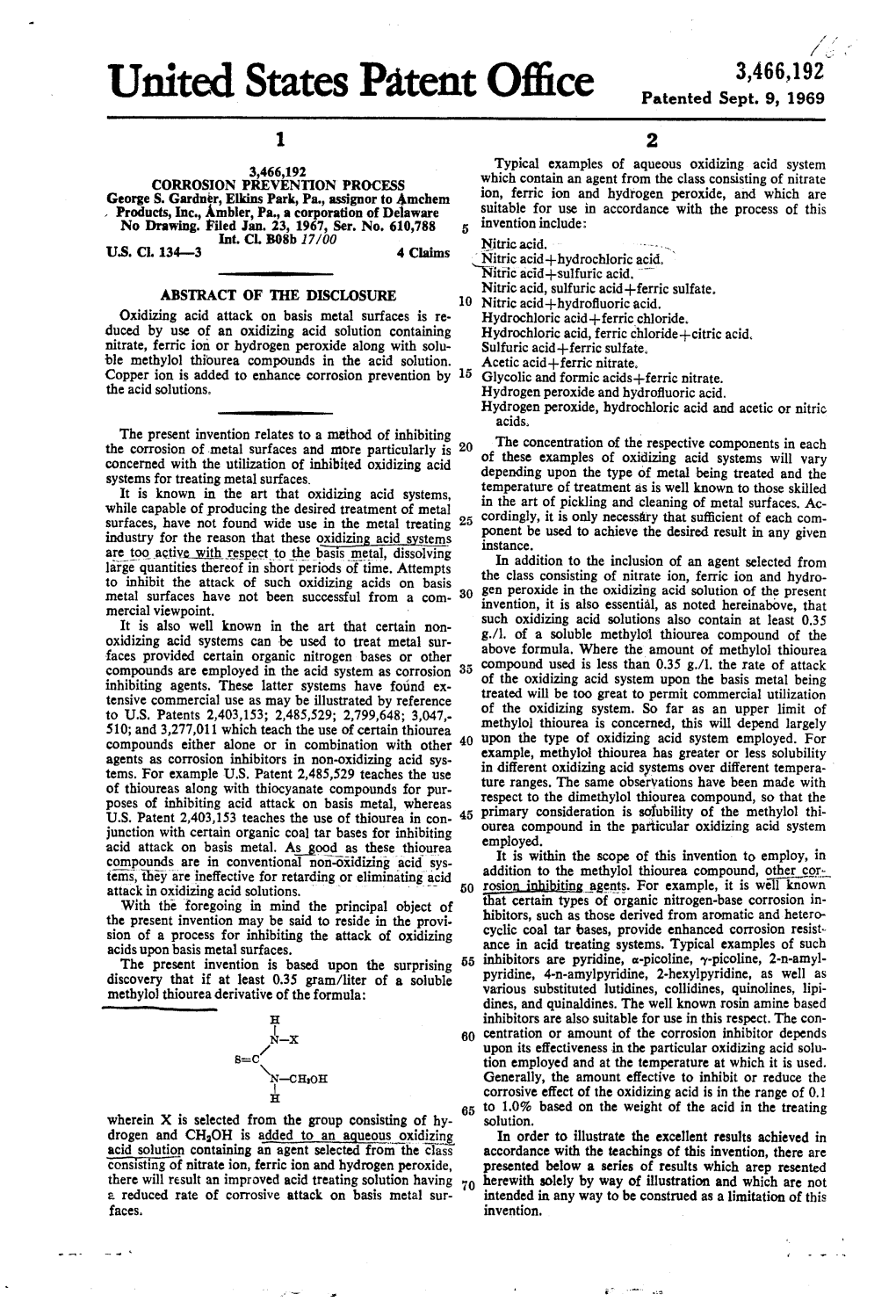

United States Patent Office Patented Sept

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Guidelines for Using Perchloric Acid

Guidelines for Using Perchloric Acid Perchloric acid (HClO4) is a strong mineral acid. Under some circumstances it may act as an oxidizer and/or present an explosion hazards. These guidelines present information on how to handle and store perchloric acid safely. Please notify EH&S at 8-8182 if you are using perchloric acid in your laboratory. Using Perchloric Acid (< 72%) at Room Temperature At room temperature, perchloric acid up to concentrations of 72% has properties similar to other strong mineral acids. It is a highly corrosive substance and causes severe burns on contact with the eyes, skin, and mucous membranes. When used under these conditions, perchloric acid reacts as a strong non-oxidizing acid. The following precautions should be taken when using perchloric acid under these conditions: · Substitute with less hazardous chemicals when appropriate. Use dilute solutions (< 60%) whenever possible. · Conduct operations involving cold perchloric acid in a properly functioning chemical fume hood with current EH&S certification. If operations are conducted frequently or in large quantities contact EH&S to determine if a specially designed fume hood dedicated to perchloric acid use is required. · Always use impact-resistant chemical goggles, a face shield, neoprene gloves, and a rubber apron when handling perchloric acid. · When using or storing even dilute perchloric acid solutions avoid contact with strong dehydrating agents (concentrated sulfuric acid, anhydrous phosphorous pentoxide, etc.). These chemicals may concentrate the perchloric acid and make it unstable. · Always transfer perchloric acid over a sink or other suitable containment in order to catch any spills and afford a ready means of cleanup and disposal. -

Hazardous Materials Management Plan

The George Washington University Hazardous Materials Management Plan Introduction The George Washington University is committed to providing a safe laboratory environment for its faculty, staff, students and visitors. The goal of the Hazardous Materials Management Plan (HMMP) is to minimize the risk of injury or illness to laboratory workers by ensuring that they have the training, information, support and equipment needed to work safely in the laboratory. The HMMP is comprised of two main elements. The first part describes potential hazards of hazardous materials found in a laboratory and reviews safe laboratory practices. The second part describes the hazardous materials stored in laboratories at GW, including intended storage and use areas and chemical inventory. March 27, 2006 Table of Contents 1.1 Chemical and Hazard Identification .....................................................................................3 1.1.1 Labels.................................................................................................................................3 1.1.2 Material Safety Data Sheets................................................................................................3 1.2 Laboratory Basics.................................................................................................................3 1.3 Chemical Storage..................................................................................................................4 1.3.1 General Considerations ......................................................................................................4 -

Corrosion Control Tactics –

110.pdf A SunCam online continuing education course Corrosion Control and Tactics By Gerald O. Davis, P.E. Davis Materials & Mechanical Engineering, Inc. 110.pdf Corrosion Control and Tactics A SunCam online continuing education course Introduction Corrosion in its several forms is a well-known problem that occurs in many applications. The associated costs are many and widespread in scope. These corrosion-induced costs may include customer dissatisfaction with deteriorated appearance or function of consumer products, serious personnel injury due to material failures, large financial losses from litigation that may follow personnel injuries or fatalities or extended shutdowns of continuous operating manufacturing plants due to corrosion. In the latter case the cost of repair or replacement of the specific corroded equipment often is minor compared to the cost of lost production caused by the shutdown. It has been estimated that the direct cost of corrosion across all U.S. industries in 1998 was $276 billion (that’s billion with a B), or more than 3% of the country’s gross domestic product in that year, Reference 1. Many research and development efforts have been and are in progress in universities and industries to combat corrosion by various approaches. This work includes gaining more complete basic understanding of the several specific mechanisms of corrosion through their electrochemical and metallurgical aspects; developing and adequately testing new metallic alloys that combine good resistance and other needed characteristics; applying nanotechnology to anticorrosion coatings, developing fundamentally different and reliable corrosion sensors; etc. All these efforts are justified and potentially can provide big payoffs. While R&D concerning new approaches to control corrosion is proceeding there are many methods and tactics that are well established and effective those, unfortunately, are not always used. -

High-Performance Alloys for Resistance to Aqueous Corrosion

High-Performance Alloys for Resistance to Aqueous Corrosion Wrought nickel products The INCONEL® Ni-Cr, Ni-Cr-Fe & Ni-Cr-Mo Alloys The INCOLOY® Fe-Ni-Cr Alloys The MONEL® Ni-Cu Alloys 63 Contents Corrosion Problems and Alloy Solutions 1 Corrosion-Resistant Alloys from the Special Metals Group of Companies 4 Alloy Selection for Corrosive Environments 11 Corrosion by Acids 12 Sulfuric Acid 12 Hydrochloric Acid 17 Hydrofluoric Acid 20 Phosphoric Acid 22 Nitric Acid 25 Organic Acids 26 Corrosion by Alkalies 28 Corrosion by Salts 31 Atmospheric Corrosion 35 Corrosion by Waters 37 Fresh and Process Waters 37 Seawater and Marine Environments 38 Corrosion by Halogens and Halogen Compounds 40 Fluorine and Hydrogen Fluoride 40 Chlorine at Ambient Temperature 41 Chlorine and Hydrogen Chloride at High Temperatures 41 Metallurgical Considerations 44 Appendix 49 Corrosion Science and Electrochemistry 50 References 60 Publication number SMC-026 Copyright © Special Metals Corporation, 2000 INCONEL, INCOLOY, MONEL, INCO-WELD, DURANICKEL, 625LCF, 686CPT, 725, 864 and 925 are trademarks of the Special Metals group of companies. Special Metals Corporation www.specialmetals.com Corrosion Problems and Alloy Solutions Due to their excellent corrosion resistance and good mechanical properties, the Special Metals nickel-based alloys are used for a broad range of applications in an equally broad range of industries, including chemical and petrochemical processing, pollution control, oil and gas extraction, marine engineering, power generation, and pulp and paper manufacture. The alloys' versatility and reliability make them the prime materials of choice for construction of process vessels, piping systems, pumps, valves and many other applications designed for service in aqueous and high-temperature environments. -

3-4 E 9%-4 a 77OARWAY CORROSION-RESISTANT ALLOYS Filed June 18, 1959 2

Nov. 13, 1962 M, STERN 3,063,835 CORROSION-RESISTANT ALLOYS Filed June l8, 1959 2 Sheets-Sheet OOOO O - 3%% HC O,OOO O - 5% HC - O2, HC 4,000 OOO O O% BOING, HC oo: \\ e E 400 s t 5%. BOLING HC H O s \\ He: 2 2 as - O aw O u? ov 2 2 OCa 2/ g U O 3%. BOLNG HC U O O. O O. O2 O.3 0.4 O.5 .O.6 O7 PER CENT PALLADIUM 36/f INVENTOR. MILTON STERN /3-4 e 9%-4 a 77OARWAY CORROSION-RESISTANT ALLOYS Filed June 18, 1959 2. Sheets-Sheet 2 40,000 O - 4% H2SO4. 40,000 O-5% H2SO4. OOO 0 - 40%H2SO4 IO 400 O2 BOILING H2SO4. s f s E O O O 100 rg a/ O 5% BOILING H2SO4. asa Ol d 2 2 O 9. o O 3 2 R O oa sa da OU y O c S. O % BOILNG H2SO4. O O. O O. O.2 O3 O.4 O.5 PER CENT PLATINUM 12 2d2 INVENTOR. MILTON STERN BY /2414-6A 77OAWAY 2-y 3,063,835 United States Patent Office Patented Nov. 13, 1962 2 3,063,835 It is also an object of this invention to provide a meth CORROSION-RESESTANT ALLCYS od for increasing the resistance to non-oxidizing corrosive Milton Stern, Tonawanda, N.Y., assignor to Union Car media of the metals titianum, chromium, and their alloys. bide Corporation, a corporation of New York Other aims and advantages of this invention will be Fied June 18, 1959, Ser. -

Nitric Acid - Wikipedia, the Free Encyclopedia

Nitric acid - Wikipedia, the free encyclopedia http://en.wikipedia.org/wiki/Nitric_acid Nitric acid From Wikipedia, the free encyclopedia Nitric acid Nitric acid (HNO3), also known as aqua fortis and spirit of nitre, is a highly corrosive and toxic strong acid. Colorless when pure, older samples tend to acquire a yellow cast due to the accumulation of oxides of nitrogen. If the solution contains more than 86% nitric acid, it is referred to as fuming nitric acid. Fuming nitric acid is characterized as white fuming nitric acid and red fuming nitric acid, depending on the amount of nitrogen dioxide present. At concentrations above 95% at room temperature, it tends to develop a yellow color due to decomposition. An alternative IUPAC name is oxoazinic acid. Contents IUPAC name Nitric acid 1 Properties Other names 1.1 Acidic properties Aqua fortis 1.2 Oxidizing properties Spirit of nitre 1.2.1 Reactions with metals Salpetre acid 1.2.2 Passivation Hydrogen Nitrate 1.2.3 Reactions with Azotic acid Identifiers non-metals CAS number 7697-37-2 1.3 Xanthoproteic test PubChem 944 2 Grades ChemSpider 919 EC number 231-714-2 3 Industrial production UN number 2031 4 Laboratory synthesis ChEBI 48107 5 Uses RTECS number QU5775000 5.1 Elemental analysis Properties 5.2 Woodworking Molecular formula HNO 3 5.3 Other uses Molar mass 63.012 g/mol 6 Safety Appearance Clear, colorless liquid 7 References Density 1.5129 g/cm3 8 External links Melting point -42 °C, 231 K, -44 °F Properties 1 of 8 6/3/10 6:08 PM Nitric acid - Wikipedia, the free encyclopedia http://en.wikipedia.org/wiki/Nitric_acid Pure anhydrous nitric acid (100%) is a colorless Boiling point mobile liquid with a density of 1.522 g/cm3 which 83 °C, 356 K, 181 °F (bp solidifies at −42 °C to form white crystals and of pure acid. -

Chemical Storage Guidelines

Chemical Storage Guidelines Use these guidelines to determine appropriate storage locations for the chemicals in your area. The tables below show examples of chemicals within each group, but are NOT all inclusive. For more information about storing chemicals, refer to your Safety Data Sheets, the Laboratory Safety Manual, or contact an EH&S Laboratory Safety Specialist. Acids (pH < 7.0) Mineral acid Organic acid Oxidizing acid Hydrochloric acid Acetic acid Nitric acid Phosphoric acid Formic acid Perchloric acid Storage: Store in a corrosives cabinet, if available, or in compatible secondary containment. Incompatibility information: Acids should be segregated from bases and flammables. Oxidizing acids are incompatible with most chemicals, especially organics. Specific combinations to avoid: • Acetic acid with chromic acid, nitric acid, hydroxyl compounds, ethylene glycol, perchloric acid, peroxides, or permanganates • Chromic acid with acetic acid, naphthalene, camphor, glycerin, turpentine, alcohol, (especially ethanol) or flammable liquids • Nitric acid with acetic acid, aniline, chromic acid, hydrocyanic acid, hydrogen sulfide, flammable liquids, flammable gases, copper, brass, or any heavy metals • Perchloric acid with acetic acid, acetic anhydride, bismuth and its alloys, alcohol, paper, wood, ether, oils or grease Bases (pH > 7.0) Inorganic base Organic base Potassium hydroxide Diethylamine Sodium hydroxide Piperidine Storage: Store in a corrosives cabinet, if available, or in compatible secondary containment. Incompatibility information: Bases should be segregated from acids, flammables, and reactives. Environmental Health and Safety | 2408 Wanda Daley Drive | Ames, IA 50011-3602 | Ph: (515) 294-5359 | www.ehs.iastate.edu Reviewed 2018 1 Flammables Flammable liquid Flammable solid Acetone Napthalene Ether Paraformaldehyde Storage: Flammable liquids totaling more than 10 gallons must be stored in a flammable cabinet. -

Engineer's Guide to Corrosion-Causes, Protection and Control Eight (8) Continuing Education Hours Course #ME1112

Engineer's Guide to Corrosion-Causes, Protection and Control Eight (8) Continuing Education Hours Course #ME1112 Approved Continuing Education for Licensed Professional Engineers EZ-pdh.com Ezekiel Enterprises, LLC 301 Mission Dr. Unit 571 New Smyrna Beach, FL 32170 800-433-1487 [email protected] Engineer's Guide to Corrosion-Causes, Protection and Control Ezekiel Enterprises, LLC Course Description: The Engineer's Guide to Corrosion-Causes, Protection and Control course satisfies eight (8) hours of professional development. The course is designed as a distance learning course that overviews corrosion in metals from its causes and effects into protection and control. Objectives: The primary objective of this course is to enable the student to understand corrosion on a variety of metals and methods to mitigate and control corrosion over the life of a material. Grading: Students must achieve a minimum score of 70% on the online quiz to pass this course. The quiz may be taken as many times as necessary to successful pass and complete the course. A copy of the quiz questions are attached to last pages of this document. ii Engineer's Guide to Corrosion-Causes, Protection and Control Ezekiel Enterprises, LLC Table of Contents Engineer's Guide to Corrosion-Causes, Protection and Control Environments and Their Affects on Corrosion Processes .......... 1 Forms of Corrosion .............................................................. 13 Corrosion Characteristics and Properties of Metals ............... 61 Corrosion Protection and Control Methods -

Atomic Absorption Methods for Analysis of Some Elements in Ores

CONTENTS PRELIMINARY CONSIDERATIONS 5 GENERAL METHODS 7 General Procedure for Acid Decomposition 7 Barium 7 Beryllium 8 Cobalt 9 Copper 9 Iron 10 Lead 10 Nickel 11 Tellurium 11 Zinc 12 SPECIAL METHODS 14 Acid Pressure Decomposition Technique for Silicate Analysis 14 Analysis of Fluorite for Calcium Carbonate and Calcium Fluorite 15 Copper Oxide in Ores and Concentrates 16 Lead and Zinc in High Grade Ores 16 Manganese in Manganese Ores 17 Mercury in Ores and Concentrates 17 Molybdenum in Molybdenite 18 Molybdenum Oxide in Ores and Concentrates 19 Silver in Ores and Concentrates 19 Tin in Ores and Concentrates 20 REFERENCES 22 iv PREFACE Published methods for rock and ore analysis by atomic absorption are fairly extensive, but scattered. This publication is a compilation of some general and specific procedures for application of atomic absorption analysis to rocks and minerals. In this application, the difficulties and problems lie primarily in the dissolution of the sample. Once dissolution has been effected, the actual atomic absorption analysis is usually relatively simple and straightforward. This publication, while not a treatise of atomic absorption theory or technique, provides a collection of dissolution methods for analysis of rocks and minerals with major emphasis on ore and concentrate analysis. No attempt has been made to include all elements that can be analyzed by atomic absorption, but only those elements and/or situations for which atomic absorption is the method of choice in our laboratory. The methods described have been tested and are used by the analytical laboratory at the New Mexico Bureau of Mines & Mineral Resources. -

Corrosivity Background Document and FRN, May 19, 1980

f , c7’m-0003‘p BACKGROUND DOCUMENT RESOURCE CONSERVATION AND RECOVERY ACT SUBTITLE C - HAZARDOUS WASTE MANAGEMENT SECTION 3001 - IDENTIFICATION ARD LISTING OF RAZARDOUS WASTE 5261.22 - Characteristic of Corrosivity MAY 2, 1980 U. S ENVIRONMENTAL PROTECTION AGENCY bc OFFICE OF SOLID WASTE G \ c Table of Contents I. Introduction If. Proposed Regulations 111. Rationale for the Proposed Regulations A. Rationale for Proposing a Corrosiveness Characteristic. B. Rationale for Proposing Definition of Corrosiveness IV. Test Yethods A. pH B. Metal Corrosion V. Comments on the Proposed Regulations VI. Promulgated Regulation Appendix A - Corrosiveness - State Ideatfication Criteria .C* .. Appendix B - Examples in which Corrosive Wastes Caused Tissue Damage Appendix C - Case Xistories of Accidents Caused by Mixing of Incornpatable Wastes Appendix D - Reactions Between Acids or Bases and Other Substances - Possible Adverse Consequences Appendix E - Examples of Corrosive Wastes Causing Damage to Aquatic Life I. Introduction Subtitle C of the Solid Waste Disposal Act, as amended by the Resource Conservation and Recovery Frt of 1976 creates a comprehensive "cradle-to-grave" management control system for - the disposal of hazardous waste designed to protect public health and the environment from the improper disposal of such waste. Section 3001 of that Subtitle requires EPA to identify the characteristics of and list hazardous wastes. Wastes identified or listed as hazardous will be included in the management control system created by Sections 3002-3006 and 3010. Wastes not identified or listed will be subject to the requirements for non-hazardous waste imposed by the States under Subtitle De The Agency has determined that corrosiveness, the property that makes a substance capable of dissolving _-. -

High-Performance Alloys for Resistance to Aqueous Corrosion

High-Performance Alloys for Resistance to Aqueous Corrosion Contents Corrosion Problems and Alloy Solutions 1 Corrosion-Resistant Alloys from the Special Metals Group of Companies 4 Alloy Selection for Corrosive Environments 11 Corrosion by Acids 12 Sulfuric Acid 12 Hydrochloric Acid 17 Hydrofluoric Acid 20 Phosphoric Acid 22 Nitric Acid 25 Organic Acids 26 Corrosion by Alkalies 28 Corrosion by Salts 31 Atmospheric Corrosion 35 Corrosion by Waters 37 Fresh and Process Waters 37 Seawater and Marine Environments 38 Corrosion by Halogens and Halogen Compounds 40 Fluorine and Hydrogen Fluoride 40 Chlorine at Ambient Temperature 41 Chlorine and Hydrogen Chloride at High Temperatures 41 Metallurgical Considerations 44 Appendix 49 Corrosion Science and Electrochemistry 50 References 60 Corrosion Problems and Alloy Solutions Due to their excellent corrosion resistance and good mechanical properties, the Special Metals nickel-based alloys are used for a broad range of applications in an equally broad range of industries, including chemical and petrochemical processing, pollution control, oil and gas extraction, marine engineering, power generation, and pulp and paper manufacture. The alloys' versatility and reliability make them the prime materials of choice for construction of process vessels, piping systems, pumps, valves and many other applications designed for service in aqueous and high-temperature environments. Many variables influence the performance of a specific material in a specific environment. These include concentration, temperature, aeration, liquid or gaseous flow rates, impurities, abrasives, and cycling process conditions. While every attempt has been made to present a broad base of information, more detailed data will often be needed for individual applications and environments. -

Reactions of Common Reagents with Everyday Materials1

CHM 113L-7 Reactions of Common Reagents with Everyday Materials1 Objective: During this laboratory you will investigate the effects of strong acids, strong bases, and acetone on various materials. Background: This lab has a two-fold purpose. You will discover the kinds of reactions that different chemicals can have on everyday materials and also see what effects milder versions of these chemicals can have on our environment. Acid rain is much more dilute an acid than the concentrated acids that you will be investigating, but the reactions are often the same, just not as quickly. Behavior of Strong Acids Acids are well known to be corrosive substances. The potential hazard of a given acid depends on a number of factors including the strength and the concentration of the acid. Acids are most readily defined as proton (H+) donors or electron pair acceptors. The ease with which an acid donates a proton determines its strength. Strong acids are extremely reactive and readily lose a proton (H+) or gain an electron pair. Common examples of strong acids that you will investigate today are nitric acid (HNO3), sulfuric acid (H2SO4), and hydrochloric acid (HCl). The vast majority of acids are weak and do not readily lose H+ or gain electron pairs. Weak acids are commonly used in cooking. For example, vinegar is a 5% (by volume) solution of the weak acid, acetic acid (HC2H3O2), while citric acid is the weak acid that gives the tangy taste to lemons. Acids are usually used as solutions in water and the acid concentration is described using the term molarity (M).