The Water Facility

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Download Brochure

Lindahl Marine Putting Customers First Since 1974 Our Experience... Runs Deep www.LindahlMarine.comwww.LindahlMarine.com Since 1974, Lindahl Marine has provided maintenance and diving services for the nation’s industries, including steel mills, power plants, municipalities, and governmental agencies. Lindahl Marine: Lindahl Marine divers raising sunken tug boat • Completes all projects on time, on or below budget • Provides exceptional service • Has the people and resources to complete any project, large or small • Completes projects in all weather conditions • Has no “failed outages” • Has a 4 Hour Emergency Response Equipped to handle anything. On site with dive gear, Time pumping equipment and Outage Support Trailer • Works across the United States • Has better, more experienced personnel Lindahl Marine has performed miles of underwater tunnel inspections. We have pumped over 50,000 cubic yards of concrete, and removed over 200,000 yards of sediment on dams, caissons, steel mills and power plant construction and refurbishment projects. Lindahl Marine diver entering icy water Drawing upon this experience, Lindahl Marine has developed a staff of professionals with particular expertise in all areas of underwater problems. “Major cell repairs completed 'accident free.' Lindahl Marine's underwater and topside welding has withstood the test of time." Yankeetown Dock Newburgh, Indiana Working outdoors in cold conditions. Dive Unit along with an Outage Support Trailer About Lindahl Marine A Full-Service Diving Company Our Safety Standards -

BEAUMONT-CHERRY VALLEY WATER DISTRICT AGENDA REGULAR MEETING of the BOARD of DIRECTORS 560 Magnolia Avenue, Beaumont, CA 92223 W

BEAUMONT-CHERRY VALLEY WATER DISTRICT AGENDA REGULAR MEETING OF THE BOARD OF DIRECTORS 560 Magnolia Avenue, Beaumont, CA 92223 Wednesday, October 9th, 2013 Regular Session 7:00 p.m. Call to Order, President Woll Pledge of Allegiance, Director Slawson Invocation, Director Ball Roll Call Public Input PUBLIC COMMENT: At this time, any person may address the Board of Directors on matters within its jurisdiction which is not on the agenda. However, any non- agenda matters that require action will be referred to Staff for a report and possible action at a subsequent meeting. To provide comments on specific agenda items, please complete a speaker’s request form and provide the completed form to the Board Secretary prior to the Board meeting. Please limit your comments to three minutes. Sharing or passing time to another speaker is not permitted. ACTION ITEMS 1. Adoption of the Agenda (pages 1-2) 2. Consent Calendar: All matters listed under the Consent Calendar are considered by the Board of Directors to be routine and will be enacted in one motion. There will be no discussion of these items prior to the time the Board considers the motion unless members of the Board, the administrative staff, or the public request specific items to be discussed and/or removed from the Consent Calendar. a. August 2013 Budget Variance Report Review** (pages 3-7) b. August 31st, 2013 Cash/Investment Balance Report** (page 8) c. September 2013 Check Register Review** (pages 9-24) d. September 2013 Invoices Pending Approval** (pages 25-29) e. Minutes of the Regular Meeting of September 11th, 2013** (pages 30-32) f. -

Brochure.Pdf

C&W Diving Services, Inc. (C&W) and West Diving Services, Inc. (union side) is a San Diego Bay based marine contractor with a reputation for providing professional personnel, quality performance and value engineering in performance of commercial marine engineering, construction and vessel services. C&W continues in business with an experienced cadre of long time employed management and administrative staff, as well as, production personnel. Incorporated in 1979, C&W is a Service Disabled Veteran- Owned Business. C&W’s owner and president, Frederick West served in the United States Navy as a Seal Team 1 Operative and formerly the President of the San Diego Oceans Foundation. C&W has over 33 years of experience supporting the US Navy, US Coast Guard, Military Sealift Command and MSR within our Ship Husbandry Division; The US Bureau of Reclamation, Army Corps of Engineers, and local, state and federal municipalities throughout the United States within our Civil/Inland Division; Beta Offshore (formerly Pacific Energy Resources), SCE (San Onofre Nuclear Generating Facility), SDG&E and several other companies in the offshore and oil and gas industry. EXCELLENCE UNDER PRESSURE! C&W has extensive experience working on the water providing vessel support services. C&W’s vessel fleet is deployed along the West Coast of the United States and it’s crews have experienced all weather and sea conditions. In San Francisco Bay, C&W is providing all Tug and Crew/Supply Boat Services during the construction of the Caltrans new Oakland/ San Francisco Bay Bridge. This massive project requires daily scheduling and coordination between C&W Vessel Captains and the many contractors working on the Bridge, Caltrans Engineers and the US Coast Guard. -

RFP) #WTP18-01 INTERIOR CLEANING & INSPECTION of WATER STORAGE TANK(S) Issue Date: August 7, 2018 Due Date: September 21, 2018 at 2:00PM EST

TOWN OF AMHERST, VIRGINIA DEPARTMENT OF PLANTS REQUEST FOR PROPOSALS (RFP) #WTP18-01 INTERIOR CLEANING & INSPECTION OF WATER STORAGE TANK(S) Issue Date: August 7, 2018 Due Date: September 21, 2018 at 2:00PM EST Point of Contact: Gary S. Williams, Director of Plants Email: [email protected] Phone: 434-946-5769 Fax: 434-946-2087 Mailing Address: Town of Amherst Gary S. Williams P.O. Box 280 Amherst, Virginia 24521 The Town of Amherst will accept proposals until 2:00PM, September 7,2018 to provide for the interior cleaning and inspection of two (2) one-million gallon water storage tanks and one (1) fifty- two thousand gallon clear-well in accordance with all specifications and conditions herein. Proposers should carefully examine the specifications and fully inform themselves as to all conditions and matters which could in any way affect the equipment/material/service or the cost thereof. Should a proposer find discrepancies in, or omissions from, the specifications or invitation for bids or should he be in doubt as to their meaning, he should notify the Town of Amherst and obtain clarification prior to submitting any proposal. Clarifications, if any, will be made via addendum to this RFP which will be made available no later than August 27. Proposers are responsible for obtaining copies of any addenda prior to proposing. Proposals may be submitted by mailed, emailed or faxed. The Town reserves the right to reject any and all proposals, to waive any technicalities in quotations received, to negotiate any proposer, and to authorize a contract which best serves the interest of the Town. -

REQUEST for QUOTATIONS TIME: 5:00 P.M

RFQ: BCVWD-S-2018-005 BEAUMONT-CHERRY VALLEY WATER DISTRICT QUOTATIONS DUE: 10/25/2018 REQUEST FOR QUOTATIONS TIME: 5:00 p.m. This is an invitation to submit quotation for Furnishing Reservoir Inspection Services as Identified on Attachment “A”, “B”, and “C” and in accordance with the attached Specification Section 09911 included in Attachment “D” and draft contract requirements included in Attachment “E”. This Project is subject to Prevailing Wage Requirements. Instructions to Bidders Quotation must be made on the attached Quotation Form (Attachment “C”) included in this Request for Quotations, and all requested attachments must be submitted with the completed Quotation Form. Failure to comply with all requirements may result in a determination that the bidder is non-responsive. Vendor shall field verify all reservoir dimensions identified in the specifications (Attachment "D" Table 2) and shall provide inspection and cleaning services, as necessary for actual reservoir sizes for reservoirs identified on Bid Sheets included as Attachment “C”. Vendor will be required to execute the District’s standard “Contract for Public Work”. A draft of the District’s standard contract is provided as Attachment “E”. Vendor shall provide quotes for inspection services, cleaning services, and minor repairs with the requirements set forth on Attachment “A”, “B”, “C”, “D”, and “E”. Questions should be addressed in writing to: James Bean, [email protected]: Quotation must be submitted to the Beaumont-Cherry Valley Water District (BCVWD) by the due date and time indicated in the upper right corner of this page. Quotation may be transmitted by facsimile machine to 951-845- 0159; by e-mail to [email protected] by mail to 560 Magnolia Avenue, Beaumont, CA 92223, or by delivery service or in person to the District Office located at 560 Magnolia Avenue, Beaumont, CA 92223. -

International Consensus Standards for Commercial Diving and Underwater Operations

International Consensus Standards FOR COMMERCIAL DIVING AND UNDERWATER OPERATIONS 6.2 EDITION ASSOCIATION OF DIVING CONTRACTORS INTERNATIONAL International Consensus Standards For Commercial Diving And Underwater Operations INTERNATIONAL CONSENSUS STANDARDS FOR COMMERCIAL DIVING AND UNDERWATER OPERATIONS 6.2 EDITION ASSOCIATION OF DIVING CONTRACTORS INTERNATIONAL, INC. Safety • Education • Communication i International Consensus Standards For Commercial Diving And Underwater Operations No responsibility is assumed by the Association of Diving Contractors International, Inc. (ADCI), its members, board of directors, officers or publisher for any injury and/or damage to persons or property as a matter of liability, negligence or otherwise, or from any use or operation of any methods, product, instruction, standards, rules or ideas contained in the material herein. No suggested test or procedure should be carried out unless, in the reader’s judgment, its risk is justified and the reader assumes all responsibility. All rights reserved. No part of this book may be reproduced, stored in a retrieval system or transmitted in any form or by any means (electronic, mechanical, photocopying, microfilming, recording or otherwise) without written per mission from the Association of Diving Contractors International, Inc. Copyright © Association of Diving Contractors International, Inc. Printed and bound in the United States of America. International Standard Book Number: 0-941332-45-4. Library of Congress control number: 95-077534. Published by: Association of Diving Contractors International, Inc. 5206 FM 1960 West, Suite 202 Houston, TX 77069 www.adc-int.org Third Edition 1991 Fourth Edition 1992 Fifth Edition 2004 Sixth Edition 2011 Sixth Edition 2014 (Revision 6.1) Sixth Edition 2016 (Revision 6.2) ii International Consensus Standards For Commercial Diving And Underwater Operations The Mission of the ADCI is: • To promote the highest possible level of safety in the practice of commercial diving and underwater operations. -

The Divers Logbook Free

FREE THE DIVERS LOGBOOK PDF Dean McConnachie,Christine Marks | 240 pages | 18 May 2006 | Boston Mills Press | 9781550464788 | English | Ontario, Canada Printable Driver Log Book Template - 5+ Best Documents Free Download A dive log is a record of the diving history of an underwater diver. The log may either be in a book, The Divers Logbook hosted softwareor web based. The log serves purposes both related to safety and personal records. Information in a log may contain the date, time and location, the profile of the diveequipment used, air usage, above and below water conditions, including temperature, current, wind and waves, general comments, and verification by the buddyinstructor or supervisor. In case of a diving accident, it The Divers Logbook provide valuable data regarding diver's previous experience, as well as the other factors that might have led to the accident itself. Recreational divers are generally advised to keep a logbook as a record, while professional divers may be legally obliged to maintain a logbook which is up to date and complete in its records. The professional diver's logbook is a legal document and may be important for getting employment. The required content and formatting of the professional diver's logbook is generally specified by the registration authority, but may also be specified by an industry association such as the International Marine Contractors Association IMCA. A more minimalistic log book for recreational divers The Divers Logbook are only interested in keeping a record of their accumulated experience total number of dives and total amount of time underwatercould just contain the first point of the above list and the maximum depth of the dive. -

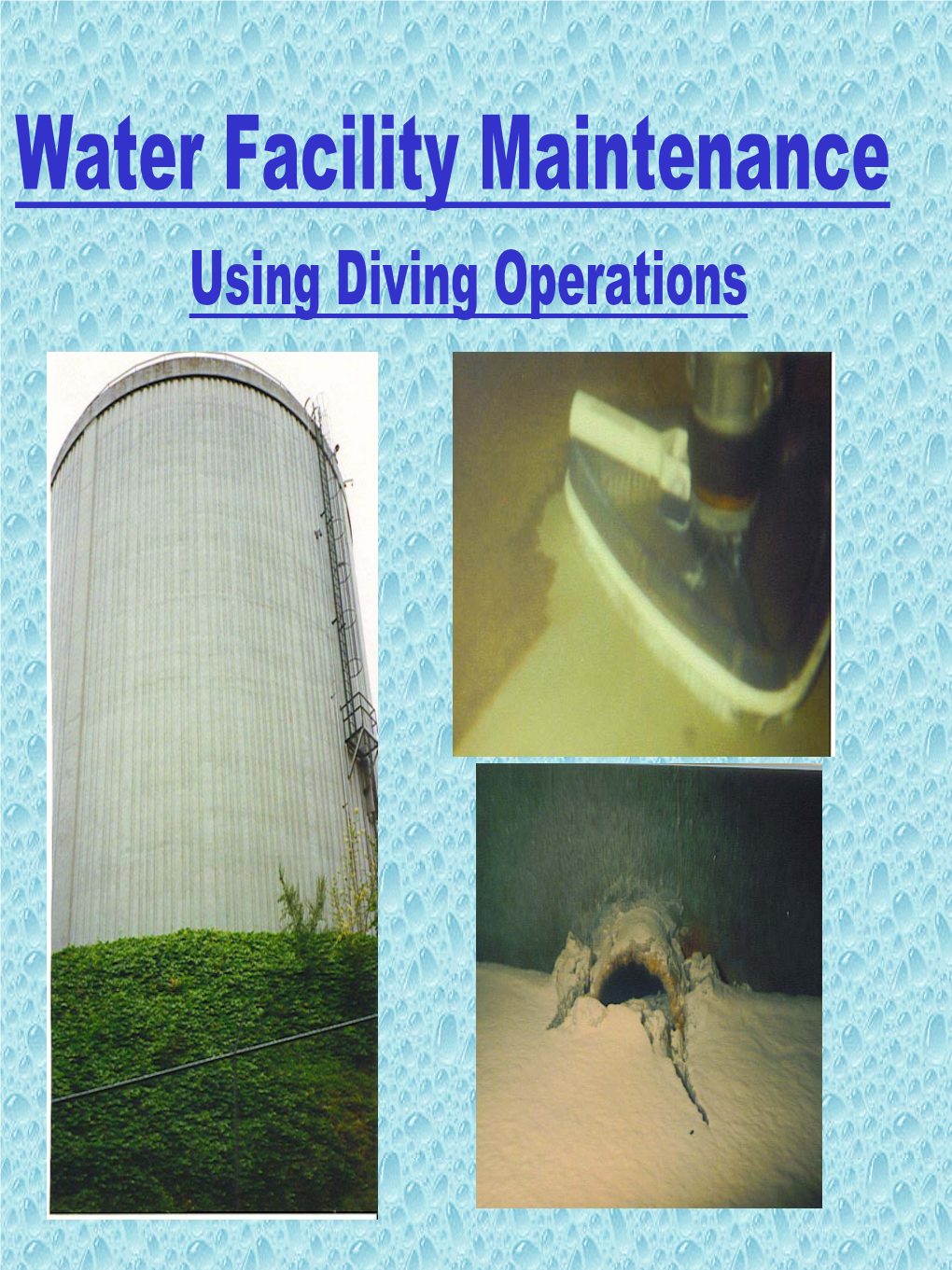

Into the Belly of the Beast: Maintaining Water Quality in Elevated Water Storage Tanks

Into the Belly of the Beast: Maintaining Water Quality in Elevated Water Storage Tanks By the Water Quality & Health Council We hear much about the vast, leaky water distribution system below our feet, but not much about some of the more highly visible, towering components of this system. These are the elevated water storage tanks that dot our landscape, looking like odd, other-worldly creatures. Elevated water storage tanks are a source of pressurized drinking water for communities. Situated hundreds of feet above sea level, these storage tanks help maintain a steady pressure and flow of safe drinking water to consumers, augmenting the H2O supply during times of high use, fire, or power failures. As part of a potable water delivery system, they require maintenance. And maintenance requires entering the “belly of the beast.” Inspecting the Belly of the Beast According to an article in Municipal Sewer & Water Magazine, routine inspection and cleaning are key to preventing corrosion and sediment build-up in water storage tanks. Remote sensing equipment helps ease the inspection process. Visual inspections may be carried out without draining the water storage tank by using a remote-controlled underwater video camera. The camera is first sanitized with a 200 parts per million chlorine solution to prevent contamination, and then placed in the tank. The camera may be tethered to a cable, for example, that controls the location, orientation and operation of the camera to record images of the ceiling, walls and floor of the tank. Remotely operated vehicle (ROV) cameras, also prepped by sanitizing, are another option for inspecting water tank interiors. -

International Consensus Standards for Commercial Diving and Underwater Operations

International Consensus Standards FOR COMMERCIAL DIVING AND UNDERWATER OPERATIONS 6.2 EDITION ASSOCIATION OF DIVING CONTRACTORS INTERNATIONAL International Consensus Standards For Commercial Diving And Underwater Operations INTERNATIONAL CONSENSUS STANDARDS FOR COMMERCIAL DIVING AND UNDERWATER OPERATIONS 6.2 EDITION ASSOCIATION OF DIVING CONTRACTORS INTERNATIONAL, INC. Safety • Education • Communication i International Consensus Standards For Commercial Diving And Underwater Operations No responsibility is assumed by the Association of Diving Contractors International, Inc. (ADCI), its members, board of directors, officers or publisher for any injury and/or damage to persons or property as a matter of liability, negligence or otherwise, or from any use or operation of any methods, product, instruction, standards, rules or ideas contained in the material herein. No suggested test or procedure should be carried out unless, in the reader’s judgment, its risk is justified and the reader assumes all responsibility. All rights reserved. No part of this book may be reproduced, stored in a retrieval system or transmitted in any form or by any means (electronic, mechanical, photocopying, microfilming, recording or otherwise) without written per mission from the Association of Diving Contractors International, Inc. Copyright © Association of Diving Contractors International, Inc. Printed and bound in the United States of America. International Standard Book Number: 0-941332-45-4. Library of Congress control number: 95-077534. Published by: Association of Diving Contractors International, Inc. 5206 FM 1960 West, Suite 202 Houston, TX 77069 www.adc-int.org Third Edition 1991 Fourth Edition 1992 Fifth Edition 2004 Sixth Edition 2011 Sixth Edition 2014 (Revision 6.1) Sixth Edition 2016 (Revision 6.2) ii International Consensus Standards For Commercial Diving And Underwater Operations The Mission of the ADCI is: • To promote the highest possible level of safety in the practice of commercial diving and underwater operations. -

Inspection and Cleaning of Water Reservoirs (This Is Not an Order) PLEASE FAX/EMAIL YOUR QUOTE TO: Please Respond with Current Pricing

2874 9 RFQ No. 1 of Request for Quotation No. 2874 Page Inspection and Cleaning of Water Reservoirs (This is not an order) PLEASE FAX/EMAIL YOUR QUOTE TO: Please respond with current pricing. Be sure Send your quote to: Theresa Hernandez Inspection and Cleaning of Beattie Reservoir to supply part/catalog numbers. Follow the [email protected] form below. FAX Number: (805) 735-7628 Phone Number: (805) 875-8020 By: May 10, 2018 at 2:00 pm PDT Qty UOM Description Extended Price 1 JOB In-service cleaning and inspection of the City of Lompoc, “Beattie Water Reservoir” utilizing commercial divers trained in potable water operations TOTAL Delivery ARO: Days FOB: DESTINATION Payment Terms: Net 30 Discount for Payment in 20 Days: % Estimated Start Date: Estimated Completion Date: We hereby certify that: • This bid was not made in the interest of or on behalf of any undisclosed person, partnership, association or corporation. • This bid is genuine and not collusion or sham; and that we did not, directly or indirectly, induce or solicit anyone else to submit a false or sham bid. • We have not, directly or indirectly, by agreement, communication or conference with anyone attempted to induce action prejudicial to the interest of the City of Lompoc, or any other bidder or anyone else interested in the proposed contract; and further, • Did not, in any manner, directly or indirectly, seek by agreements, communications, or conference with anyone to raise or fix any overhead, profit, or cost element of this bid price, or that of anyone else. (Please type or print) Company Name Signature Of Authorized Representative Address Name And Title (Please Print) City, State And Zip Code Email Address Phone Number Fax Number Date Web Site Address I Registered Bidder Sheet Request for Quotation No. -

• Looth Anniversary of the Russian Navy Diving School• • Russian Helmets • HDS Russia • • Henri Delauze • Libby Langstoth • HDS Mexico • Pioneer Diver Capt

Historical Diver, Volume 8, Issue 1 [Number 22], 2000 Item Type monograph Publisher Historical Diving Society U.S.A. Download date 08/10/2021 17:31:07 Link to Item http://hdl.handle.net/1834/30845 The Official Publication of The Historical Diving Societies of Australia & S.E. Asia, Canada, Germany, Mexico and the U.S.A Vol. 8 Issue 1 Winter 2000 • lOOth Anniversary of the Russian Navy Diving School• • Russian Helmets • HDS Russia • • Henri Delauze • Libby Langstoth • HDS Mexico • Pioneer Diver Capt. William H. Tat lor • • HDS/DEMA History of Rebreathers Exhibit • Combined Industry Awards Banquet • HISTORICAL DIVING SOCIETY USA A PUBLIC BENEFIT NONPROFIT CORPORATION 340 S KELLOGG AVE STE E, GOLETACA 93117, U.S.A. PHONE: 805-692-0072 FAX: 805-692-0042 e-mail: [email protected] or HTTP://www.hds.org/ Corporate Members ADVISORY BOARD Sponsors D.E.S.C.O. DIVERS ALERT NETWORK (DAN) Dr. Sylvia Earle Prof. Hans Hass DIVING SYSTEMS INTERNATIONAL Dr. Peter B. Bennett Lotte Hass DIVE COMMERCIAL INTERNATIONAL, INC. Dick Bonin Dick Long INFLATABLE TECHNOLOGIES, INC. MARES Ernest H. Brooks II J. Thomas Millington, M.D. OCEAN FUTURES Scott Carpenter Bob & Bill Meistrell OCEANIC SEA PEARLS Jean-Michel Cousteau Bev Morgan SCUBA TECHNOLOGIES, INC. E.R. Cross Phil Nuytten Henri Delauze Sir John Rawlins Founding Corporations Andre Galeme Andreas B. Rechnitzer, Ph.D. BEST PUBLISHING D.E.S.C.O. Lad Handelman Les Ashton Smith DIVING SYSTEMS INTERNATIONAL MARINE SURPLUS SUPPLY OCEANEERING INTERNATIONAL, INC., WEST COAST SANTA BARBARA CITY COLLEGE SOCIETY BOARD OF DIRECTORS Members Chairman: Lee Selisky, President: Leslie Leaney, Secretary: ADVENTURES IN DIVING James Cunningham, Treasurer: Blair Mott, Directors: Bonnie AMERICAN UNDERWATER CONTRACTORS, INC. -

Request for Quotation No. 2931 Inspection and Cleaning of Water Reservoir (This Is Not an Order)

Request for Quotation No. 2931 Inspection and Cleaning of Water Reservoir (This is not an order) PLEASE FAX/EMAIL YOUR QUOTE TO: Please respond with current pricing. Be sure Send your quote to: Theresa Hernandez to supply part/catalog numbers. Follow the [email protected] form below. FAX Number: (805) 735-7628 Phone Number: (805) 875-8020 By: November 1, 2019 @ 2:00pm PDT Qty UOM Description Extended Price 1 JOB In-service cleaning and inspection of the City of Lompoc, Avalon Water Reservoir utilizing commercial divers trained in potable water operations TOTAL Delivery ARO: Days FOB: DESTINATION Payment Terms: Net 30 Discount for Payment in 20 Days: % Estimated Start Date: Estimated Completion Date: We hereby certify that: This bid was not made in the interest of or on behalf of any undisclosed person, partnership, association or corporation. This bid is genuine and not collusion or sham; and that we did not, directly or indirectly, induce or solicit anyone else to submit a false or sham bid. We have not, directly or indirectly, by agreement, communication or conference with anyone attempted to induce action prejudicial to the interest of the City of Lompoc, or any other bidder or anyone else interested in the proposed contract; and further, Did not, in any manner, directly or indirectly, seek by agreements, communications, or conference with anyone to raise or fix any overhead, profit, or cost element of this bid price, or that of anyone else. (Please type or print) Company Name Signature Of Authorized Representative Address Name And Title (Please Print) City, State And Zip Code Email Address Phone Number Fax Number Date Web Site Address Purchasing Division 1300 West Laurel Avenue Bldg.