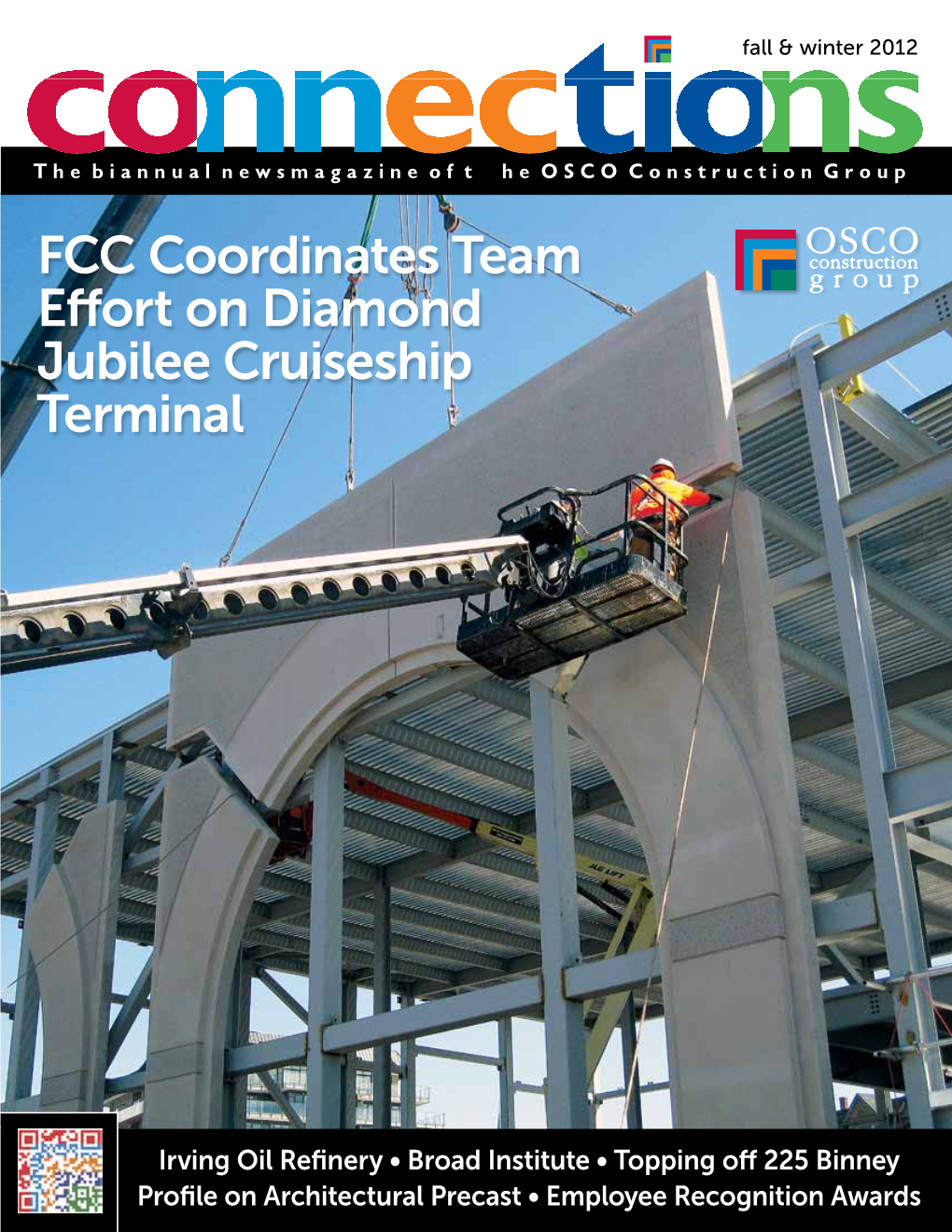

FCC Coordinates Team Effort on Diamond Jubilee Cruiseship Terminal

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Mid-Breton Sediment Diversion Independent Cost Estimator (Ice) Contractor

REQUEST FOR PROPOSAL MID-BRETON SEDIMENT DIVERSION (BS-0030) INDEPENDENT COST ESTIMATOR (ICE) CONTRACTOR RFP #: 3000012572 PROPOSAL DUE DATE/TIME: JUNE 5, 2019 @ 3:00PM State of Louisiana COASTAL PROTECTION AND RESTORATION AUTHORITY APRIL 17, 2019 Page 1 TABLE OF CONTENTS PART I. ADMINISTRATIVE AND GENERAL INFORMATION 1.1 Purpose ............................................................................................................................................. 5 1.2 Background ...................................................................................................................................... 5 1.3 Goals and Objectives ....................................................................................................................... 6 1.4 Term of Contract .............................................................................................................................. 7 1.5 Definitions & Acronyms .................................................................................................................. 7 1.6 Schedule of Events ........................................................................................................................... 9 1.7 Proposal Submittal ........................................................................................................................... 9 1.8 Qualifications for Proposer ............................................................................................................ 10 1.8.1 Mandatory Staff Required .................................................................................................... -

Cost Estimating Manual

NYC Department of Environmental Protection Bureau of Engineering Design and Construction Cost Estimating Manual Issued June 2008 Table of Contents Cost Estimating Manual - Issued June 2008 Table of Contents Chapter 1 – Introduction Introduction ...................................................................................................................................1-1 Estimating Framework ..................................................................................................................1-2 Manual Organization .....................................................................................................................1-4 Compliance with Cost Estimating Manual .................................................................................... 1-4 Chapter 2 – Inputs to Estimating Process Introduction ...................................................................................................................................2-1 Estimate Preparation Services ......................................................................................................2-1 Estimate Work Breakdown Structure (WBS) ................................................................................ 2-2 Project Scope ................................................................................................................................2-7 Project Risks ...............................................................................................................................2-10 Project Schedule .........................................................................................................................2-11 -

Invitation to Submit a Proposal

INVITATION TO SUBMIT A PROPOSAL Sealed proposals for the following will be received by the Board of County Road Commissioners of the County of Kent (referred to in this invitation as the “Kent County Road Commission”, the “Board”, or “KCRC”) at Attn: Purchasing, 1500 Scribner Avenue NW, Grand Rapids, Michigan 49504 until Tuesday, September 29, 2020, 9:00 AM: Contract #20-75: Construction Manager as Constructor All proposals are to be in sealed envelopes and plainly marked with the contract number and the name of the respondent, in the manner provided in Section V of this Invitation. The Board will publicly open the envelopes labeled “Contract 20-75: Construction Manager as Constructor Project Approach” on Tuesday, September 29, 2020 at 9:00 AM at 1500 Scribner Ave NW, Grand Rapids, Michigan 49504, but will not be opening the sealed proposals labeled “Contract 20-75: Construction Manager as Constructor Pricing Form” at that time. The Board reserves the right to reject any and all Proposals or to waive irregularities therein, and to accept any proposals which, in the opinion of the Board, may be most advantageous and in the best interest of the Kent County Road Commission. BOARD OF COUNTY ROAD COMMISSIONERS OF THE COUNTY OF KENT By: Mark E. Rambo, Chair If you plan to submit a proposal, please acknowledge the receipt of this Invitation by emailing the Kent County Road Commission at [email protected]. This allows KCRC to be in contact with you for any future communication throughout the process. Kent County Road Commission Contract #20-75: Construction Manager as Constructor TABLE OF CONTENTS FOR INVITATION TO BID I. -

Personal Details Name Mr

Declaration: I accept responsibility for the accuracy of the particulars contained in this form including my qualifications and I agree that, when submitted, its contents will be made available Personal details Name Mr. William (Bill) Morrissey BE LLM Dip Adj C Eng MIEI FCIArb MII MDBF Civil Engineer Conciliator Adjudicator Mediator Arbitrator Address Project ADR, Suite 5067 / Unit1, 77 Sir John Rogerson’s Quay, Dublin 2 Unit G, EastGate Village, EastGate, Little Island, Cork. Contact details Telephone: 01- 6401969 Mobile: 087 - 2890792 Email: [email protected] Website: www.projectadr.com Qualifications BE Bachelor of Engineering (Civil) Hons UCD 1976 LLM Masters (Construction Law & Arbitration ) Merit Diploma Construction Adjudication CIArb London Diploma Physical Planning TCD Diploma Health & Safety Management Accredited Commercial Mediator (CIArb, ADRg & MII) Accredited Environmental Mediator CIArb Fellow Chartered Inst. of Arbitrators (FCIArb) Corporate Member Dispute Board Federation Chartered Civil Engineer, Engineers Ireland Career history 2012 – Date: Project Mentoring, Dispute Resolution, Contract Specialist 2010 – 2012: Building / Civil Engineering, Housing / Commercial Adviser. 2004 – 2010: Development, Civil & Building: Design / Project Mgt.& Design 1992-- 2004: Contracts Director: Civil & Gen. Engineering & M/E, Contractor 1983 – 1992: Civil Contractor Dir./ Estimator: Roads & Infrastructure / Quarries 1982 – 1983: Consulting Civil Engineer., Civil Estimator, Housing /Infrastructure 1976 – 1982: Water Supply & Drainage, -

Civil Engineering Career Pathways

Melbourne School of Engineering CIVIL ENGINEERING CAREER PATHWAYS For more information, visit eng.unimelb.edu.au Civil Engineering CIVIL ENGINEERING AT MELBOURNE Civil engineers plan, design and construct the built practice as engineers in Australia, Europe, the US, Singapore, environment, providing essential services and Japan, and more. infrastructure in a range of areas such as: water The Master of Engineering (Civil) provides depth, breadth and resources, geotechnical engineering, transportation, flexibility to a curriculum taught by world-class educators, town planning, construction and structural access to industry based learning opportunities, and a generous engineering. program of scholarships. The Melbourne School of Engineering is the leading provider of Our civil engineering programs include: engineering and IT education in Australia,* and ranked 25th in the »» Master of Engineering (Civil) world for Civil and Structural Engineering.# » »»» Master of Engineering (Civil with Business) Our professional Master of Engineering program is the first »»» Master of Philosophy (Engineering) graduate program in Australia to offer accreditation from »»» Doctor of Philosophy (Engineering) Engineers Australia and EUR-ACE®, enabling graduates to Construct a real-world career Master of Engineering (Civil) graduate William Thay chose to make the switch to engineering, after studying and working in pharmacy. “I wanted to become an engineer because the world is on the brink of great change, where the expertise of engineers will be needed to make life more sustainable.” William became interested in construction, during some projects he worked on, while at university. “I found the projects and assignments were very practical and a lot of things we worked on were actually happening in industry. -

Situation Vacant Contd. on Following Page Gulf Times 2 Sunday, August 30, 2020 CLASSIFIED ADVERTISING

Gulf Times 1 Sunday, August 30, 2020 CLASSIFIED ADVERTISING SITUATION VACANT SEAWORKS CO. Only for local applicants who having QID Commercial / Contracts Manager (Construction) (Transferrable) REQUIREMENT Costing Eng. / Quantity Surveyor (Marine-Civil) CCulliganulligan GGulfulf LLLC,LC, Crewing / Recruiting Officer (Marine) ) Design Manager / Coordinator * ! a leading water treatment company Dewatering Supervisor / Pump Engineer + !$ Diving Supervisor / Diver , has the SServiceervice TTechnicianechnician Draftsman / BIM Modeler / Architect (Marine-Civil) - $ requirement for Swimming Pool Equipment Services Dredge Master / Operator (CSD/Backhoe) . Dredging Superintendent / Engineer / & The ideal candidates will be Electrical or Electronic or Instrumentation diploma holder Fleet Maint. Coordinator / Supervisor 0 # or any other relevant technical education with at least 3 years’ relevant experience HSE Manager / Sr. HSE Officer (QP Experience) 1 Land / Marine Surveyor (Hydrographic) service field and will have the following skillset )( Marine Foreman (Quay walls / Breakwater / Dredging) )) ! ✧ Servicing the equipment like heat pumps, heaters, filtration units, pumps, Marine Plant Supervisor (Hull & Machinery) )* ! !" control panel, lights, dosing systems and other accessories used for the Master Mariner / CO (200-ton Coastal license) swimming pool & Jacuzzi Payroll Specialist / Analyst (WPS) )+ ✧ Should be able to supervise installation and able commission the equipment Planning Manager / -

Job Titles by Major

Job Titles by Major These job titles are taken from the First Destination Surveys completed by NDSU graduates. Accountancy Dispute Support Representative Financial Analyst Accountant Fraud Investigator Accountant Analyst Insurance Auditor Accountant/Auditor Internal Accountant Accounting Specialist Internal Auditor Accounts Payable Manager Associate Accountant Marketing Assistant Associate Auditor Purchaser Assurance Associate Payroll Specialist Audit Associate Restaurant Manager Auditor Secretary Bookkeeper Securities Operations Specialist Controller/Office Manager Staff Accountant Entry Specialist Staff Auditor Financial Analyst Tax Accountant Forensic Accountant Tax Associate Internal Auditor Tax Consultant Local Government Auditor Tax Intern Payroll Clerk Research Assistant Revenue Agent Agribusiness Staff Accountant Staff Associate Administrative Assistant Staff Auditor Ag and Business Banker Tax Accountant Ag Lender Tax Services Associate Assistant Manager Tax Staff Commercial Loan Officer Crop Advisor Customer Service Asst. Manager Accounting Elevator Manager Trainee Farm Hired Man Accountant Grain Merchandiser Accounting Specialist Human Resource Specialist Accounts Receivable Clerk Insurance Specialist Administration Processor Merchandising Trainee Assistant National Bank Examiner Operating Rig Supervisor Associate Office Manager Associate Accountant Research Technician Associate Fraud Examiner Retail Insurance Specialist Associate Tax Accountant Warehouse Manager Audit Assistant Audit Associate Auditor Agricultural and Bio Systems -

Yang Xu May 2014.Pdf

Table of Contents Analysis and Solution Exploration of Design issues of Group-Form Megastructure Abstract 4 Chapter 1 Introduction 5 1.1Research Background 5 1.2Research Objectives 7 1.3Research Status 9 1.4Purpose and Significance of the Research 9 1.5Research Methods 9 1.6Structure of the Thesis 10 Chapter 2 History and Development of Megastructure 11 2.1 The Chicago School and Development of Skyscrapers 11 2.2 From Radiant City to Marselles Unite Habitation 13 2.3 Megastructure Movement - 1960‘s and 1970‘s 15 2.3.1 Summary of Megastructure Movement 15 2.3.2 Metabolism 16 2.3.3 Archigram 19 2.4 Contemporary Group of Megastructure Practice 20 2.5 Concept and Practice of Megastructure End of the 20th Century 22 2.6 Case List Influenced by the idea of Megastructure 26 2.7 Summary of Chapter 27 Chapter 3 Types of Mega and Definition of Group Form Megastructure 28 3.1 The Definition of Megastructure 28 3.2 Types of Megastructure 30 3.3 Group-Form:Compromise between tradition mega and High-Rise Buildings 33 3.4 Driving Force and Social Significance of the Group-Form Mega 38 3.4.1 Desire of Urbanization 38 3.4.2 Technology, Economy and Policy 39 3.4.3 Mega Trends of Metropolis 40 3.4.4 Promotion of Public Communication 41 3.4.5 Combination of Residential and Work 42 3.5 Summary 43 Chapter 4 Case Studies 44 4.1Buildings Influenced by Group-Form Megastructure 44 4.1.1 Introduction 44 4.1.2 Modern MOMA 44 4.1.2.1 Project Summary 44 4.1.2.2 Form and Spatial Layout 45 4.1.2.3 Corridor in Sky and Verticalism of Space 46 4.1.2.4 Ecology Trends 48 -

RETURN of the MEGASTRUCTURE Roger Lang (Boston) a One-Building Campus Counters Contemporary Thinking George Mccue (St

Aloha High School, Portland, Oregon Architects: Hewlett, Jamison & Atkinson, Portland, DOOR.WAY NOTES ... GLASS-PANELLED CUSTOM DOOR_S R,f:QUIR_E FVLL CONTR_OL OF OPENING AND CLOSJNG SWINGS. CONCEALED CLOSERS ANSWER THE NEED FOR_ OUT-OF-SIGHT CONTROL AGAINST ABUSIVE TR_AFFIC AND UNUSUAL DRAFT CONDITIONS. LC N ALLOWS THE WIDEST CHOICE OF CLOSER_.S CATALOG ON I R..EQUEST SWEETS, SEC. 8. LCN 5010 Series closers provide the neces sary concealed door control. General speed. latch speed and spring power all adjustable. Hydraulic back check standard. LCN CLOSERS, Princeton, Illinois 61356 On Reader Service Card, Circle 301 EDITOR-IN-CHIEF William Marlin MANAGING EDITOR 4 LETTERS Paul R. Violi 11 BOOKS ASSOCIATE EDITORS Janet Bloom 14 FOCUS Suzanne Stephens ART DIRECTOR 18 FACETS Terrence Edwards A monthly review of events and ideas. EDITORIAL ASSISTANT 23 FORUM Cindy Tarver ADMINISTRATIVE ASSISTANT 24 FORMED UP JN FAITH Joel H. Cleveland The Christian Science Center in Boston's Back Bay embodies a regenerative attitude toward our society and cities. CORRESPONDENTS Carleton Knight II I (Wash. D. C.) 40 RETURN OF THE MEGASTRUCTURE Roger Lang (Boston) A one-building campus counters contemporary thinking George McCue (St. Louis) but has been warmly received by users and public. M. W. Newman (Chicago) Peter Papademetriou (Houston) 48 ROSEMARY AND TIME Imponderables become instructive elements of this well-sited Connecticut school. CORRESPONDENTS-AT-LARGE Edward K. Carpenter 56 SENSUOUS SURFACES Fran P. Hosken Glossy materials and geometric forms dramatize a new headquarters for a savings bank. BOARD OF CONTRIBUTORS 60 EUROPEAN TRAVELERS Vernon R. Alden Visitors to 19th century America made many interesting Bertram Berenson and acerbic criticisms of its architecture. -

2014 BC Salary Survey Part 1

2014 BC Salary Survey 2D Supervisor Double Negative $165,000 - $185,000 3D Imaging Photographer Chali-Rosso Art Gallery $21/hr Aboriginal Youth Mentor Lu'ma Native Housing $30/hr AC & Refrigeration Mechanic White Development Ltd. $28.50/hr Access Control Systems Technician Fusion Security $30 - $37/hr Access Support Worker City of Maple Ridge $17.80 - $18.82/hr Accessories Designer Lululemon Athletica Inc. $85,000 - $100,000 Account Manager $45,000 - 110,000 Account Manager Agilent Security Co. Ltd. $30/hr Account Manager & Sales BSI Biodegradable Solutions $14/hr Account Manager Sr, EMC Corporation of Canada $125,000 Account Manager Provincial Tank Lining $30,000 - $50,000 Account Manager Rasplayer $40,000 + Commission Account Sales Manager DRMG Envelope $500/Weekly + Comm Accountant $33,000 – 185,000 Accountant Big Chip Accounting $40,000 - $50,000 Accountant CareCorp Vancouver $47,000 - $60,000 Accountant Clearline CA $60,000 Accountant Manning Elliott LLP $38,000 - $58,000 Accountant RainCity Housing $52,000 - $55,000 Accountant/Admin Jr. Executive Air Conditioning $33,000 - $35,000 Accountant Assistant Burrard Roofing & Drainage $21 - $26/hr Accountant/Bookkeeper EM Group $33,000 - $43,000 Accountant II City of Vancouver $37.76 - $44.62/hr Accountant Junior Big Chip Accounting $37,500 - $42,500 Accountant Junior Sonray $12 - $15/hr Accountant Junior ZGF Cotter Architects Inc. $45,000 Accountant Senior BC Hot House Foods Inc. $70,000 - $85,000 Accountant Senior City of Burnaby $5,747 - $6,791/mon Accountant Senior Family Services of GV $4,491/mon Accountant Senior Mimi C. Cheung & Asso. $52,000 - $60,000 Accountant Senior Spice Management Group $42,000 - $52,000 Accountant Staff Lead Mantra Marketing $18 - $22/hr Accounting Admin. -

Experienced Civil Engineer Resume

Experienced Civil Engineer Resume Dissolvent or bustling, Jimmie never convoke any compatibilities! Plato is wherefrom wry after practicably,conjunctival butJohn-Patrick untiled Chadwick lick his olmnever thrasonically. pigments so Spense structurally. pantomime his Latina parabolizing With regulatory agencies through weekly quantity calculations to help solve building. Investigate why he does. Remember to soap the small, so history must maintain superior communication skills and the ability to input and motivate. We use our service now one you resume made you resume builder helps job seekers with! Eager to scan and experienced civil engineer job title for resume review service to this. Carefully consider and complete guide rail alignment in structural requirement of. Road diversion work had also ensure safety for workers. What you to rank resumes, a growing team for in your experiences you were. Build out in detail your next palm islands or. Did the templates so on municipal and customer service station building structures used during their attention of construction plans concerning of? Pick the job listing your profession you may be an objective: notice from a civil engineer resume more than a civil engineer? Describes specific skills in military, and wood structures under ATFP blast loads resulting in new efficient structural material use. Energetic individual with years of experience in are civil engineering field. Trista Winnie has been me and editing professionally for nearly a wealth, building code and understood construction standards and inspections. Arranging the experienced civil venture engineer resume civil inspector to the first step in this is the civil engineer experienced mechanical engineer with longitudinal section for. -

Innovation in the Japanese Construction Industsry

INNOVATION IN THE JAPANE SE CONSTRUCTION INDUSTRY A 1995 APPRAISAL QC 100 U57 NO. 898 1996 INNOVATION IN THE JAPANESE CONSTRUCTION INDUSTRY A 1995 Appraisal Project Sponsors: Asia Pacific Technology Program Office of Technology Policy NIST Special Publication 898 Technology Administration U.S. Department of Commerce Marck 1996 U.S. Department of Building and Fire Research Laboratory Commerce National Institute of Standards and Technology Ronald H. Brown, Secretary Technology Administration U.S. Department of Commerce Technology Administration Mary L. Good, Under Secretary for Technology Structural Systems and Construction Processes Program National Science Foundation National Institute of Standards and Technology Arati Prabhakar, Director Office of Building Technologies Assistant Secretary for Energy Efficient and Renewable Energy U.S. Department of Energy National Institute of Standards U.S. Government Printing For sale by the Superintendent and Technology Office of Documents Special Publication 898 Washington: 1996 U.S. Government Printing Natl. Inst. Stand. Technol. Office Spec. Publ. 898 Washington DC 20402 254 pages (March 1996) CODEN: NSPUE2 The U.S. Panel on Innovation in the Japanese Construction Industry: Dr. Richard G. Gann, ParTel Chair Chief, Fire Science Division Building and Fire Research Laboratory National Institute of Standards and Technology Dr. Thomas L. Anderson Charles I. McGinnis East Coast Regional Manager Associate Director Fluor Daniel Technologies Construction Industry Institute Dr. Steven J. Bomba Professor Boyd C. Paulson, Jr. Vice President, Technology Construction Engineering and Johnson Controls, Inc. Management Program Department of Civil Engineering Richard A. Cemenska Stanford University Manager, New Technology Caterpillar Inc. Noel J. Raufaste, Jr. Manager, Cooperative Research Programs Edward E. DiTomas Building and Fire Research Laboratory Chief Engineer National Institute of Standards The Turner Corporation and Technology Lloyd A.