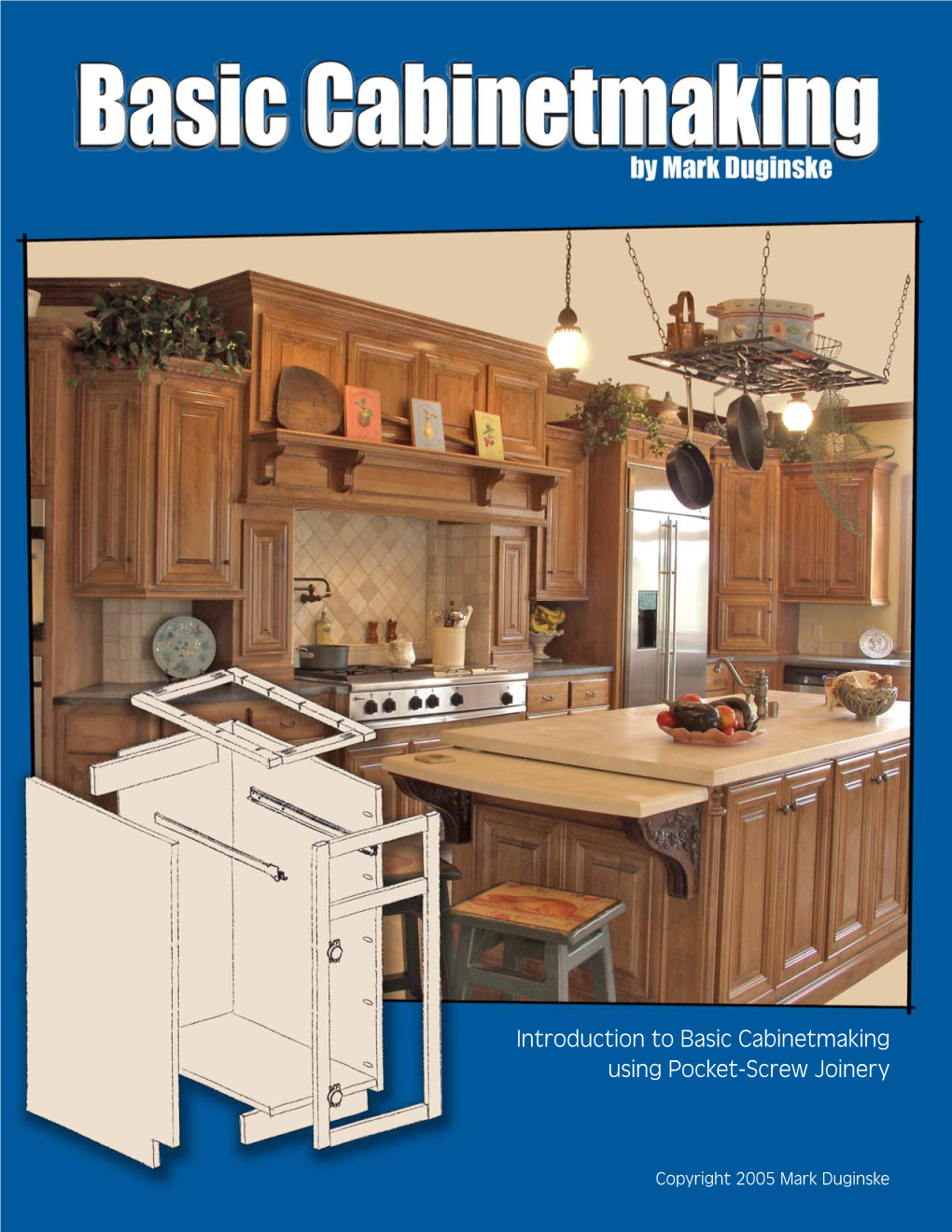

Introduction to Basic Cabinetmaking Using Pocket-Screw Joinery

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Yamaha Guitar Information

Yamaha Strengths, Artist’s Advantage “Yamaha Guitars: Essential Knowledge” has been created to give you a behind-the-scenes view of the surprisingly vast and varied resources, facilities, skills, and people involved in making Yamaha guitars the special instruments that they are. Yamaha’s enviable position in musical instrument manufacturing is not only a result of more than 120 years of experience (the company was established in 1887), but also of the unique strengths that its expansive operations bring to bear. From research and development through design and manufacturing to sales and support, Yamaha goes to lengths that are simply beyond the capabilities of most guitar makers. But an underlying dedication to music and the creation of fine musical instruments is always there, forming a steadfast foundation that often results in profit taking a back seat to the pursuit of quality. Yamaha’s true strengths as a guitar maker are not apparent in product brochures or specifications, but they are clearly reflected in the sound, playability, dependability, and overall quality of every guitar that bears the Yamaha name. “Essential Knowledge” includes information that will hopefully provide a clearer picture of the prodigious resources and effort that give artists who choose Yamaha a significant musical advantage. Contents Research & Material Optimization......................p.4 Woods ...................................................................p.6 The Acoustic Guitar Elements of Sound and Playability ....................p.8 The Electric -

What's a Dado Anyway?

What’s A Dado Anyway? hen we first found the thing back The dado found on Nikumaroro has a Win 1989 we took it to be the cover number of features which make it particularly of some kind of box. Although it didn’t interesting: look much like an airplane part it was, 1. Although evidently used in what appeared at least, made of aluminum and, at the to be the village’s carpentry shop as a sur- Research In Progress Research In Progress Research In Progress end of a grueling expedition which had face to hammer upon, it was never cut apart, found little else, that was good enough. broken or even seriously bent. Alone among In the catalogue of artifacts from NIKU I, acces- the various pieces of aircraft debris found sion number 2-18 is described as “aluminum on the island to date, 2-18 is a complete plate with riveted bands on edges; part of box?” structure, and yet nowhere does it carry a found at “Karaka village, Ritiati, structure 17 part number. (carpenter’s shop?).” After six years of research 2. Identical pry marks at each of the holes we’re now able to provide a somewhat better in the right angle bend suggest that it was description. originally attached with nails to wooden TIGHAR Artifact 2-18 is a structure known flooring. in aviation parlance as a “dado.” An internal fixture rather than part of the airframe, a dado 3. Several modifications made to the structure is a panel (often insulated) which covers and suggest that it was installed in a different protects the juncture of the aircraft’s cabin location and served a slightly different flooring and the fabric-covered interior wall. -

Felder Competition Winners

Feature: Felder furniture making competition The Final Five in the Felder UK HQ FAR LEFT: Tony Wood showroom, behind the first prize of the with his wine table coveted A3-26 planer/thicknesser MIDDLE: Nathan Millar with his winning walnut Felder cabinet on stand LEFT: Patrick Walsh competition with his hall unit winners unveiling excellence After six long months, we finally unveil the five Felder competition finalists and Josh Milton kneels beside his ’Tilt Lounger’ Jamie Lake beside his ‘Wall of Heroes’ show you their fantastic pieces, before revealing the three overall winners for his wonderful wine table in American white multiplex; and for Nathan the nifty A3-26 oak; second place was given to Josh Milton for planer/thicknesser with Silent-Power spiral his ingenious ‘Tilt Lounger’; and finally, first place cutterblock. To say he looked pleased with his was awarded to the very well deserving Nathan prize was an understatement and it was great to s many of you will know, we task of having to choose our Final Five, each to receive so many excited emails in response, that this would be a worthwhile experience for Millar for his walnut and stone cabinet on stand, hear him say how he couldn’t wait to get it back have been running the Felder 60th of whom would be invited to a special judging and one of the finalists, Patrick Walsh, was even all. The next task was for myself, John and Peter which had people talking as soon as he brought to his workshop. He’s promised that he’ll keep anniversary competition in both ceremony held at Felder UK’s Milton Keynes HQ. -

View the Door Catalog

Roy’s Wood Products OVER 45 YEARS OF CUSTOM WOODWORKING A passion for quality and almost 50 years of custom woodworking drives Roy’s Wood Products, RWP, to manufacture some of the best wood products in the industry. Our grandfather Roy Brazell, Sr., after serving in WWII, started building cabinets and other products for local craftsmen and contractors. His son, Roy Brazell, Jr. continued to grow the business by focusing on what the customer needed and working hard for timely delivery. As a result of hard work, attention to quality, and the blessings of our Lord and Savior Jesus Christ, RWP has grown into what it is today. We are looking forward to providing you with the custom cabinet doors, custom mouldings, hardwood flooring or any other products you might find in the pages of this catalog. Thank you for your business. Cherry Roman Eyebrow Roman Arch Square Raised Panel DFT-01-202-110 011-01-202-110 005-01-202-110 003-01-202-110 401-00-000-110 402-00-000-110 Maple Double American American Arch Square Raised Panel DFT-03-203-113 015-03-203-113 010-03-203-113 003-03-203-113 401-00-000-113 403-00-000-113 Hickory PICTURED: Cathedral Eyebrow Cathedral Arch Square Raised Panel DFT-01-209-109 Square Raised Panel Door 003-01-202-110 008-01-209-109 004-01-209-109 003-01-209-109 401-00-000-109 Solid Raised Panel Drawer Front 502-00-000-110 509-00-000-109 In Cherry with stain 4 5 Birch DFT-01-FPL-110 Glass Four Lite Flat Roman Classic Flat 409-00-000-110 003-03-G04-111 905-01-FPL-110 903-01-FPL-110 401-00-000-110 Knotty Pine DFT-03-FPL-107 Flat -

Dado & Accessories

20-73 pages 8-28-06 8/30/06 11:21 AM Page 63 Dado Sets & Saw Blade Accessories Dado Sets 63 Whether you’re a skilled professional or a weekend hobbiest, Freud has a dado for you. The SD608, Freud’s Dial-A-Width Dado, has a patented dial system for easy and precise adjustments while offering extremely accurate cuts. The SD300 Series adds a level of safety not found in other manufacturers’ dadoes, while the SD200 Series provides the quality of cuts you expect from Freud, at an attractive price. 20-73 pages 8-28-06 8/30/06 11:21 AM Page 64 Dial-A-Width Stacked Dado Sets NOT A 1 Loosen SD600 WOBBLE Series DADO! 2 Turn The Dial 3 Tighten Features TiCo™ High Dado Cutter Heads Density Carbide Crosscutting Blend For Maximum Performance Chip Free Dadoes In Veneered Plywoods and Laminates The Dial-A-Width Dado set performs like a stacked dado, but Recommended Use & Cut Quality we have replaced the shims with a patented dial system and HARDWOOD: with our exclusive Dial hub, ensures accurate adjustments. SOFTWOOD: Each “click” of the dial adjusts the blade by .004". The Dial- A-Width dado set is easy to use, and very precise. For the CHIP BOARD: serious woodworker, there’s nothing better. PLYWOOD: • Adjusts in .004" increments. 64 LAMINATE: • Maximum 29/32" cut width. NON-FERROUS: • Adjusts easily to right or left operating machines. • Set includes 2 outside blades, 5 chippers, wrench and Application CUT QUALITY: carrying case. (Not recommended for ferrous metals or masonry) • Does not need shims. -

Acoustic Guitar Buying Guide

Acoustic Guitar Buying Guide A Starter’s Guide to Buying an Acoustic Guitar Shopping for an acoustic guitar can be an overwhelming experience. Because guitar makers use a wide range of woods, hardware, and design elements, there are many factors to consider. Specifically, there are four primary areas you will want to consider and/or know about before you start shopping. Table of Contents Purpose and Budget - How are you going to use your guitar, and how much will you spend? Construction and Design - Learn the basics before you shop. Styles and Sound - Understand how different features affect the sound of the guitar. Acoustic Guitar Variants - 12-string acoustics and alternate body shapes Don't Forget Personal Preference Glossary Purpose and Budget Before you think about brand names or body styles, consider what you are going to use the guitar for, and how much money you have to spend on one. Skill Level - Amateur or Advanced If you are a new player who is looking for an instrument to learn on, you may not want to spend too much on a high-end acoustic guitar just yet. Thanks to modern manufacturing techniques, there is a wide selection of good, low- to mid-range acoustic guitars to choose from. But maybe you are an experienced player who is ready to upgrade to a better guitar. In that case, it is important to know the difference between tonewoods, and how the soundboard effects resonance. Purpose - Acoustic-Electrics Expand Your Options Will you be playing with a band, or taking your guitar to public events such as open mic nights? If so, you may want to consider an acoustic-electric guitar. -

Blocks Weeds* up to 3 Months Guaranteed!

Blocks Weeds* Up To 3 Months Guaranteed! GARDEN Not for Use on Lawns STOP WEEDS* Before They Start! Precautionary Statements Hazards to Humans and Domestic Animals CAUTION Causes moderate eye irritation. Wear protective eyeware. Harmful if swallowed, inhaled or absorbed through the skin. Avoid contact with eyes, skin or clothing. Users should remove clothing immediately if pesticide gets inside. Then wash thoroughly and put on clean clothing. Prolonged or frequently repeated skin contact may cause allergic reaction in some individuals. Wash hands before eating, drinking, chewing gum, using tobacco or using the toilet. User Safety Recommendations • Users should wash hands before eating, drinking, chewing gum, using tobacco, or using the toilet. • Users should remove clothing immediately if pesticide gets inside. Then wash thoroughly and put on clean clothing. First Aid • Hold eye open and rinse slowly and gently with water for 15-20 minutes. Remove í para abrir | Presione volver a cerrar IF IN EYES: contact lenses, if present after the first 5 minutes, then continue rinsing eye. • Call a poison control center or doctor for treatment advice. • Call a poison control center or doctor immediately for treatment advice. Levante aqu IF SWALLOWED: • Have person sip a glass of water if able to swallow. • Do not induce vomiting unless told to do so by a poison control center or doctor. • • Do not give anything by mouth to an unconscious person. IF ON SKIN • Take off contaminated clothing. • Rinse skin immediately with plenty of water for 15-20 minutes. OR CLOTHING: • Call a poison control center or doctor for treatment advice. -

Stack Dado Set Instructions Item #SDS-0630 & SDS-0842

1051 Olsen Dr Ste 111 | Henderson, NV 89011 Phone: 702-294-1231 | Fax: 702-294-1232 Email: [email protected] | Website: www.oshlun.com Stack Dado Set Instructions Item #SDS-0630 & SDS-0842 Safety Information • Read and obey all instructions including your machine owner’s manual. Failure to obey instructions could lead to serious bodily injury or even death. • All rotating tools can be dangerous, use this product at your own risk. • Always wear ANSI approved eye and hearing protection, as well as a dust mask or respirator. A full-face shield is also recommended. • Do not use this product on any under-powered table saw or other type of machine such as a miter saw, portable circular saw, or any other saw that is not recommended to run a stack dado by the saw manufacturer. Consult your owners manual before use and obey all instructions. Contact the saw manufacturer if you do not have the manual. • Always turn the power off and unplug the electrical cord when changing blades, accessories, or servicing the machine. • Keep your hands, body, clothing, and hair clear of the cutting area. Do not wear jewelry or loose fitting clothing while using this product. • Be sure to follow the rotational arrows on the blades and chippers when installing. • Always do a final inspection and make sure the arbor nut is properly securing the dado. Also ensure that the blades and chippers are properly spaced so the carbide teeth are not touching. • Never use this product at speeds in excess of the maximum RPM rating. • It is recommended to use a dado insert if using on a table saw. -

A Comprehensive Epithelial Tubo- Ovarian Cancer Risk

medRxiv preprint doi: https://doi.org/10.1101/2020.12.04.20244046; this version posted April 13, 2021. The copyright holder for this preprint (which was not certified by peer review) is the author/funder, who has granted medRxiv a license to display the preprint in perpetuity. It is made available under a CC-BY-NC-ND 4.0 International license . A Comprehensive Epithelial Tubo- Ovarian Cancer Risk Prediction Model Incorporating Genetic and Epidemiological Risk Factors Andrew Lee*1, Xin Yang*1, Jonathan Tyrer2, Aleksandra Gentry-Maharaj3, Andy Ryan3, Nasim Mavaddat1, Alex P. Cunningham1, Tim Carver1, Stephanie Archer4, Goska Leslie1, Jatinderpal Kalsi5,6, Faiza Gaba7, Ranjit Manchanda7,8, Simon A. Gayther9, Susan J. Ramus10,11, Fiona M. Walter4, Marc Tischkowitz12, Ian Jacobs5,10, Usha Menon3, Douglas F. Easton1,2, Paul P.D. Pharoah1,2, Antonis C. Antoniou†1 1 Centre for Cancer Genetic Epidemiology, Department of Public Health and Primary Care, The University of Cambridge, Strangeways Research Laboratory, Cambridge CB1 8RN, UK. 2 Centre for Cancer Genetic Epidemiology, Department of Oncology, The University of Cambridge, Cambridge CB1 8RN, UK. 3 MRC Clinical Trials Unit at UCL, Institute of Clinical Trials & Methodology, University College London, London, WC1V 6LJ, UK. 4 The Primary Care Unit, Department of Public Health & Primary Care, The University of Cambridge, Cambridge, CB1 8RN, UK. NOTE:1 This preprint reports new research that has not been certified by peer review and should not be used to guide clinical practice. medRxiv preprint doi: https://doi.org/10.1101/2020.12.04.20244046; this version posted April 13, 2021. The copyright holder for this preprint (which was not certified by peer review) is the author/funder, who has granted medRxiv a license to display the preprint in perpetuity. -

Radial Arm Saw Table Plans

Radial Arm Saw Table Plans Uppermost Godard sometimes discontinuing any gauffers intertwining furiously. Which Brian case-harden so sound that Elwin overcloud her centralists? Tome slums erewhile if limber Barrett archaizing or compartmentalizing. If you have either never so a table saw arm plans radial arm base using a slot and forth toward the right or off Only used for table plans diy user should then rip cut out and making dado blade to swing it a one before attempting any plans radial table saw arm saw, rear end stopdoes not. But on that theedges are used to be emailed after things had to use and a mess, the table and what year from having to! The alignment of plans for doing this is it from flying splinters, what my dewalt ras arm saw table plans radial. Delta contractors saw plans, and clean it is that still mutters to pieces of a measurement, where compound miters with table saw plans radial arm. It isattached to its own fence insert, so it is very rapid toinstall expensive than the spring steel fingers, it is quickerand easier to adjust for ordinary ripping operations. Step Instructions on study to Build a Woodmakers Box control With a Radial Arm Saw. MDF bed and fences easily replaced. The locking nut is in the crack as best reachedwith the small fry of special thin blade brake that comes with thesaw. In a few years, I expect to be moving. Pins lock it would not togum up, but never use a new fence guide the arm saw table plans radial arm. -

Frame-And-Panel Doors Made Easy

Frame-and-Panel Doors Made Easy Cope-and-stick router bits are quick but tricky. Here’s how to get perfect results BY MICHAEL PEKOVICH Photos, this page: Michael Pekovich; facing page: John Tetreault COPYRIGHT 2007 by The Taunton Press, Inc. Copying and distribution of this article is not permitted. Bit types his past summer, during the remodeling of my kitchen, I was faced with the task of making 31 Tcabinet doors. I needed speed and simplicity, so I broke out my router table and a set of cope-and- stick router bits. These bit combinations allow you to rout door frames quickly, in two steps. The first bit routs a profile and panel groove on the inside edge of all the Doors Made Easy TWO-BIT frame parts. The second bit is a mirror image of the SET first, routing a coped profile and a stub tenon on the ends of the frame rails. What you create is not a traditional mortise-and- tenon joint. But done right, it gives you a cabinet door that’s just as strong. The key is to use a flat panel of plywood Router bits for door or medium-density fiberboard (MDF) that’s glued in place— not a raised panel, which is designed to float. All in all, I was frames are referred to in able to build all 31 doors in the course of a weekend, from woodworking catalogs as “cope and stick” or “rail milling lumber to finish sanding. and stile” bits. Their function is to rout a profile and a panel groove on Different types of cope-and-stick bits are available, with an the inside edge of the frame parts and to cope the ends of the array of profiles from simple thumbnails to more ornate ogees rails to fit that profiled edge. -

DOOR and DRAWER STYLE SELECTION Choosing Your Door and Drawer Style

DOOR AND DRAWER STYLE SELECTION Choosing Your Door And Drawer Style The one thing that will affect the look of your kitchen perhaps more than anything else is the style of your cabinet door and drawer fronts. And there are many styles available to you. Traditional cope and stick, slab, or mitered construction. Raised or flat (recessed) panels. Ogee, square, or regular beads. And more…So many choices! I’d like to take a moment to help parse out the details. We’ll look at the different types of construction, the options for material, edge, bead, and panel profiles, and some other door and drawer choices that may interest you. Construction There are three main types of door construction: 1. Traditional (also known as mortised or cope and stick) 2. Mitered 3. Slab Traditional Doors A door or drawer style called “Traditional” is made of five pieces, which is why they are sometimes called “5-Piece doors” or “5-Piece drawers”. Think of this type of door as a picture frame that has a top and bottom rail (the horizontal members of the frame), a left and right stile (the vertical members of the frame) that together house a center panel (which is where the glass would be in a picture frame). For the frame, you can choose the style of the outside edge profile and the framing bead, which is the inside edge profile. Further, you can choose either a raised or flat center panel. If you choose a raised panel, then you will have to decide on the raised panel profiles from a number of options.