Research of Oxyhydrogen Gas Mixture Influence Upon Diesel Engine Performance

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

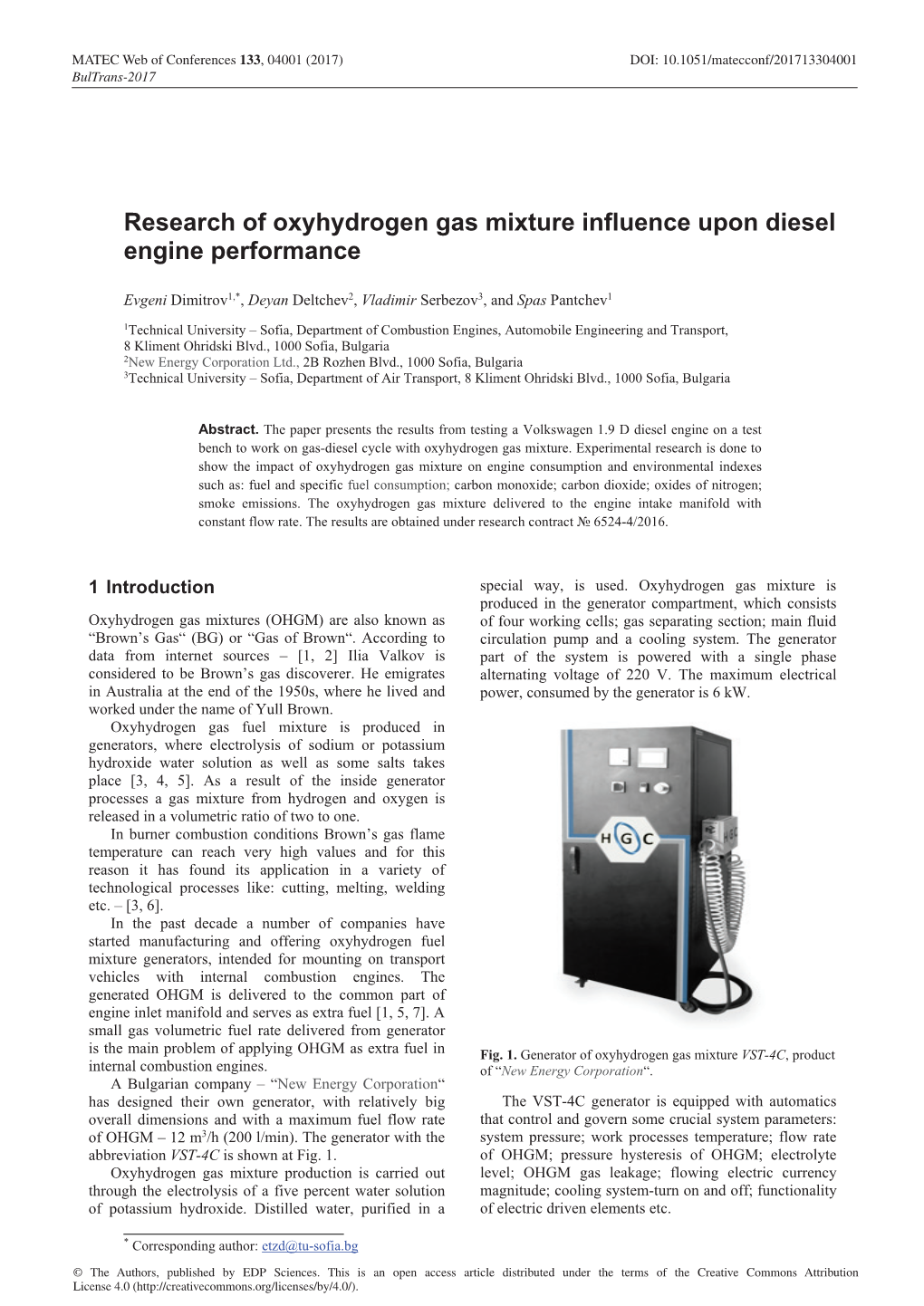

Oxyhydrogen Generator

Oxy-hydrogen Generator ---From Okay Energy 1 Okay Energy Equipment Co.,Ltd 1.What is oxy-hydrogen generator Oxy-hydrogen Generator is also called Brown Gas Generator or HHO Gas Generator,it separates water (H2O) into mixed hydrogen and oxygen. The mixed Oxygen and Hydrogen gas has a wide range of applications, such as heating, welding, cutting, polishing,boiler combustion supporting etc. to replace LPG or other fuels in many industries. When burned, this gas only produces water and has no pollutants , and it can burn 100%.It’s a new energy in 21st century. 2. Why I use oxy-hydrogen generator? 2.1 Maximum Safety a. Steady, reliable fuel delivery. Fuel is available immediately after machine is switched on. No volatile fuel tanks which can rupture or explode. b. Multiple safety devices, including overheating and in-sufficient water cut-off switches, will automatically turn off power to ensure the safety of both equipment and user. 2.2 Environmentally Friendly a. The Fuel generated by our machines burns completely without creating pollutants, toxic fumes, or public nuisance. b. Does not generate hydrocarbons, carbon monoxide, or carbon dioxide. 2 Okay Energy Equipment Co.,Ltd 2.3 High Mobility a. Our generators are equipped with wheels for easy moving the generators to do the job. b. Our generator immediately can generates fuel as soon as you need it, no need of gas tank. c. Fuel can be used for continuous working for long time. 2.4 High Temperature & Calorific value a. Calorific value is 34000Kcal/kg b. The flame temperature is over 2800°, it can melt refractory metals and none-metals 2.5 Low Cost & Maximum Economy a. -

1. Exposure Data

1. EXPOSURE DATA 1.1 Description of major welding are used as part of the welding process (e.g. the processes and materials shielding gas) (ISO, 2009). While there are many welding processes Welding is a broad term for the process routinely employed in occupational settings, the of joining metals through coalescence (AWS, most common arc welding processes are manual 2010). Welding techniques tend to be broadly metal arc (MMA, ISO No. 111), gas metal arc classified as arc welding or gas welding. Arc (GMA, ISO No. 13), flux-cored arc (FCA, ISO Nos welding uses electricity to generate an arc, 114 and 136), gas tungsten arc (GTA, ISO No. 14), whereas gas or oxyfuel welding (ISO 4063:2009 and submerged arc (SA, ISO No. 12) (Table 1.2 process numbers 3, 31, 311, 312, and 313) uses fuel and Table 1.3). Electric resistance welding (ER, gases such as acetylene or hydrogen to generate ISO Nos 21 and 22) is also commonly used for spot heat. Welding results in concurrent exposures or seam welding, and uses electric currents and including welding fumes, gases, and ionizing force to generate heat. In occupational settings, and non-ionizing radiation, and coexposures these processes are most commonly used to weld from other sources such as asbestos and solvents mild steel (MS, low carbon) or stainless steel (SS). (Table 1.1). Flame cutting (ISO No. 81), the process of using Welding fumes are produced when metals oxygen (O) and a fuel to cut a metal, is a closely are heated above their melting point, vapourize related process that is often grouped occupation- and condense into fumes. -

Generation of Oxyhydrogen Gas for Internal Combustion of a Minor Vehicle, Chemical Engineering Transactions, 82, 445- 450 DOI:10.3303/CET2082075

445 A publication of CHEMICAL ENGINEERING TRANSACTIONS VOL. 82, 2020 The Italian Association of Chemical Engineering Online at www.cetjournal.it Guest Editors: Bruno Fabiano, Valerio Cozzani, Genserik Reniers Copyright © 2020, AIDIC Servizi S.r.l. DOI: 10.3303/CET2082075 ISBN 978-88-95608-80-8; ISSN 2283-9216 Generation of Oxyhydrogen Gas for Internal Combustion of a Minor Vehicle Shaibert Abrahan Veramendi Caicoa, Carlos Alberto Castañeda Oliveraa, Jhonny a,b a a Wilfredo Valverde Flores , Jorge Jave Nakayo , Verónica Tello Mendivil , Elmer a,* Benites-Alfaro aUniversidad César Vallejo, C.P. 15314, Lima 39, Perú bUniversidad Nacional Agraria La Molina, C.P. 15026, Lima 39, Perú [email protected] In the research, an oxyhydrogen gas generating system was built and installed for use in a smaller vehicle. The aim was to check the ability to use oxyhydrogen gas as ecological technology in a 0.2 L internal combustion engine. A linear motorcycle was used for the study and the experimental tests were carried out in parallel with both gasoline and oxyhydrogen gas to compare its efficiency. The results showed yields of 10 km / sol and 92 km / sol for gasoline and oxyhydrogen gas, respectively. Furthermore, with oxyhydrogen gas a favorable reduction in the emission of polluting gases into the environment was found. Finally, the research shows that there are strong reasons to opt for the use of oxyhydrogen gas as an alternative fuel, and it could easily be adapted in vehicle engines. 1. Introduction Air pollution and concern for the care of the environment encourage looking for new alternatives to find the best use of natural resources such as their use of energy for various human activities. -

Artificial Neural Network Led Optimization of Oxyhydrogen Hybridized Diesel Operated Engine

sustainability Article Artificial Neural Network Led Optimization of Oxyhydrogen Hybridized Diesel Operated Engine Muhammad Usman 1,* , Haris Hussain 1, Fahid Riaz 2 , Muneeb Irshad 3, Rehmat Bashir 1, Muhammad Haris Shah 1 , Adeel Ahmad Zafar 1, Usman Bashir 1, M. A. Kalam 4,* , M. A. Mujtaba 5,* and Manzoore Elahi M. Soudagar 6 1 Department of Mechanical Engineering, University of Engineering and Technology, Lahore 54890, Pakistan; [email protected] (H.H.); [email protected] (R.B.); [email protected] (M.H.S.); [email protected] (A.A.Z.); [email protected] (U.B.) 2 Department of Mechanical Engineering, National University of Singapore, Singapore 117575, Singapore; [email protected] 3 Department of Physics, University of Engineering and Technology Lahore, Lahore 54890, Pakistan; [email protected] 4 Center for Energy Science, Department of Mechanical Engineering, University of Malaya, Kuala Lumpur 50603, Malaysia 5 Department of Mechanical Engineering, New Campus, University of Engineering and Technology, Lahore 54890, Pakistan 6 Department of Mechanical Engineering, School of Technology, Glocal University, Delhi-Yamunotri Marg, SH-57, Mirzapur Pole, Saharanpur 247121, Uttar Pradesh, India; [email protected] * Correspondence: [email protected] (M.U.); [email protected] (M.A.K.); [email protected] (M.A.M.) Citation: Usman, M.; Hussain, H.; Riaz, F.; Irshad, M.; Bashir, R.; Haris Abstract: The prevailing massive exploitation of conventional fuels has staked the energy accessibility Shah, M.; Ahmad Zafar, A.; Bashir, U.; to future generations. The gloomy peril of inflated demand and depleting fuel reservoirs in the Kalam, M.A.; Mujtaba, M.A.; et al. -

Chemistry Ch-7 Hydrogen Short – Answer Questions 1. Name the Lightest Element and Lightest Gas Known. Hydrogen 2. in a Reacti

Chemistry Ch-7 Hydrogen Short – answer questions 1. Name the lightest element and lightest gas known. Hydrogen 2. In a reaction , one element displaces another from its compound to form a new compound. What is such a reaction called? Displacement reaction 3. By which method is hydrogen gas collected? explain your answer. Hydrogen gas is collected by the downward displacement of water. it is not collected by downward displacement of air since a mixture of hydrogen and air is explosive. 4. Which gas is collected at the different electrodes in electrolysis of acidified water? At cathode – hydrogen At anode – oxygen 5. How many times lighter or heavier than air is hydrogen? Hydrogen is 14.6 times lighter than air. 6. When kindled, will hydrogen burn in oxygen? name the compound formed, if any and give the balanced equation for the reaction. When candid hydrogen burning in air or oxygen to form water 2H2O+ O2→ 2H2O 7. State the condition under which hydrogen is made to react with nitrogen in Habers process. Template- 500 degree Celsius Pressure- 200 atm Catalyst – Fe 8. Why is hydrogen considered as clean fuel? Hydrogen is considered as as clean fuel because it’s product of reaction is water which does not pollute the environment 9. Give reason why helium is preferred to hydrogen for filling the weather balloon helium is the next lightest gas and it is available in plenty and it does not catches fire that is why helium is preferred to hydrogen for filling weather balloon. Long -answer questions 1. Describe how hydrogen is prepared in the laboratory. -

Using HHO Gas to Reduce Fuel Consumption and Emissions in Internal Combustion Engines

Using HHO Gas to Reduce Fuel Consumption and Emissions in Internal Combustion Engines A thesis Submitted to the University of Khartoum in Partial Fulfillment for the Degree of M.Sc In Electrical Power Engineering BY: Ibrahim Mohamed Ahmed Ibrahim Fadul B.Sc in Mechenical Engineering, 2006 University of Khartoum Supervisor: Dr. Kamal NasrEldin Abdalla Co-Supervisor: Dr. Esam Elsarrag January 2010 I Dedicated to all those who came before us, To those who walk this journey with us, And to those who will follow. Personally dedicated to My family whose life stories I am blessed to share. May we learn from the successes and failures of our ancestors, as we try to lead the way for generations to come. II ACKNOWLEDGMENT I would like to express my great gratitude to my supervisor Dr. Kamal N. Abdualla for his invaluable help, comments, generous supply of information, and encouragements, my discussions with him have been most illuminating. I am also grateful to Dr. Esam. El-sarrag for generous supply of data, information, discussion, experimental devices, and time. He shared every bit of the stress,and joy that I experienced. I am indebted to thermal machines lap and the helpful staff there, namely thanks goes to Mr.Magbool and Mr.Bakry for their continuous contribution and support. I was greatly enhanced by the gracious assistance of my family, for their patience, understanding and support. Finally, thanks go to all FE lecturers, researchers, staff, and friends. Ibrahim January, 2010 III TABLE OF CONTENTS ACKNOWLEDGMENT ........................................................................................................... III TABLE OF CONTENTS ......................................................................................................... IV LIST OF FIGURES ................................................................................................................ VII LIST OF TABLES ................................................................................................................ -

Design and Development of an Oxyhydrogen Generator for Production Ofbrown’S (HHO) Gas As a Renewable Source of Fuel for the Automobile Industry

International Journal of Engineering Science Invention (IJESI) ISSN (Online): 2319 – 6734, ISSN (Print): 2319 – 6726 www.ijesi.org ||Volume 8 Issue 05 Series. II || May 2019 || PP 01-07 Design and Development of an Oxyhydrogen Generator for Production ofBrown’s (HHO) Gas as a Renewable Source of Fuel for the Automobile Industry Samuel Pamford Kojo Essuman*,Andrew Nyamful, Vincent Yao Agbodemegbe, Seth Kofi Debrah Department of Nuclear Engineering, Graduate School of Nuclear and Allied Sciences, University of Ghana. Date: March 28, 2018 Corresponding Author: Samuel Pamford Kojo Essuman Abstract: This research work seeks to design and develop an oxyhydrogen generator for HHO gas production. Key parameters consideredin this study includeelectrode area, electrodes spacing, electrodesurface conditioning, and electrode configuration as well as the efficiency of thegenerator. The constructed generator consisted of 26plates made up of 3 anodes, 3 cathodes and 20 neutral plateswitheach having dimension of 10cm x 10 cm. The adjacent plates was spaced at a distance of 2 mm. The efficiency of the constructed generator was evaluated using0.01 M-0.03 M strengths of KOHat a constantvoltage of 13 V.The Results showedan optimum efficiency of 11.9 % when the HHO generator was run using 0.02 M KOHat 13 V for 1 hour. Keywords: HHO gas, Rectifier, Stainless Steels (ST316), Electrolyte, Rubber gasket ----------------------------------------------------------------------------------------------------------------------------- ---------- Date of Submission: 01-05-2019 Date of acceptance: 13-05-2019 -------------------------------------------------------------------------------------------------------------------------------------- Highlights: 1. Designing an HHO generator 2. Development of an HHO generator 3. Determination of the efficiency ofan HHO generator using KOH as a catalyst I. Introduction Electrolysis of water for hydrogen production has been employed industrially since the 19th century (Barton & Gammon 2010). -

The Magic Lantern Gazette

ISSN 1059-1249 The Magic Lantern Gazette A Journal of Research Volume 29, Number 2/3 Summer/Fall 2017 The Magic Lantern Society of the United States and Canada www.magiclanternsociety.org The Editor’s Page 2 This double issue of the Gazette has two articles on As always, I am looking for more contributions to the magic lantern related topics. The first is my own arti- Gazette from researchers in North America and any- cle on the oxyhydrogen microscope, a sister to the where else in the world. Last year we had a series of magic lantern. I trace the origins of this instrument contributions from young European scholars, but back to the marriage of the solar microscope, an 18th that pipeline has temporarily dried up, and recent century instrument, and the oxy-hydrogen blowpipe, submissions have been scarce. Please consider sub- originally used for chemical analysis and secondarily mitting some of your research to the Gazette. for illumination. The oxyhydrogen microscope (variously spelled with or without a hyphen, or as the hydro-oxygen or gas microscope) was never really an Kentwood D. Wells, Editor instrument used for scientific research, but rather an 451 Middle Turnpike attraction for public amusement. Parts of this story Storrs, CT 06268 have been told by other scholars, but never in a com- [email protected] prehensive way, and the material on exhibitions of the 860-429-7458 oxyhydrogen microscope in the United States is en- tirely new. Particularly before the Civil War, audienc- es wondered at the appearance of fleas the size of ele- phants, fly eyes, and insect wings, or the feeding of live Water Tigers, the larvae of a type of aquatic bee- tle. -

Origin Al Article

International Journal of Mechanical and Production Engineering Research and Development (IJMPERD) ISSN (P): 2249–6890; ISSN (E): 2249–8001 Vol. 10, Issue 3, Jun 2020, 9811–9824 © TJPRC Pvt. Ltd. MODELLING AND SIMULATION OF GASOLINE ENGINE AT DIFFERENT LOAD CONDITIONS USING OXYHYDROGEN BLEND SHRIKANT BHARDWAJ1 & ARVIND JAYANT2 1 Mechanical Engineering Department, Sant Longowal Institute of Technology, Longowal, India 2School of Engineering &Technology, ASIAN Institute of Technology (AIT), Bangkok, Thailand ABSTRACT The demand for fossil fuels is increasing regularly; therefore Researchers are facing the challenge of finding promising alternative fuels such as hydrogen, oxyhydrogen, alcohol, biodiesel fuels etc. Some of the adverse effects of the current fuel technology prevailing in internal combustion engines are poor air quality index, increased accumulation of greenhouse gases in the environment. The aim of present research was to generate the oxyhydrogen gas through the process of electrolysis and send the homogeneous mixture of gasoline and oxyhydrogen into the four cylinder four stroke spark ignition engine and then analyse emission and performance parameters. Oxyhydrogen gas was manipulated as a secondary fuel in spark ignited1298 cc engine. Results obtained conclude that by using oxyhydrogen and gasoline mixture the r.p.m increased by 9%, fuel consumption decreased by 10.80%, brake power increased by 8.61%, indicated power increased by 12.63% whereas indicated and brake specific fuel consumption decreased by 21.18% and 18.17% respectively, Original Article also the emission of hydrocarbon decreased by 8.25% and carbon monoxide decreased by 6.05%. The drawback of this research setup was the increase in frictional losses due to high heat generation which accompany the reduction in mechanical efficiency by 4.31%. -

Experimental Investigation of the Effect of Oxyhydrogen on Spark Ignition Engines

International Journal of Applied Engineering Research ISSN 0973-4562 Volume 16, Number 5 (2021) pp. 340-345 © Research India Publications. http://www.ripublication.com Experimental Investigation of the Effect of Oxyhydrogen on Spark Ignition Engines Dr. Vivekananthan R1 and Mr. Anil K.B2 1Associate Professor, Department of Mechanical Engineering, Government College of Engineering, Salem, India. 2PG Scholar, Department of Mechanical Engineering, Government College of Engineering, Salem, India. Abstract 2. LITERATURE REVIEW Oxyhydrogen is a gas which is formed during electrolysis of Researchers studied and found that increase in work output water. It is purely a mixture of oxygen and hydrogen. It can and reduction in exhaust emissions due to the addition of influence greatly in the combustion of fuels in Internal hydrogen. Mohammad Affan Usman et al [1] studied the use Combustion engines because of its comparatively better fuel of oxyhydrogen gas four stroke petrol engines and concluded characteristics than gasoline. Since it is a gas, it can diffuse that the exhaust emissions [2]. Shivaprasad K V et al [3] faster than other gasoline fuel. When both gasoline and studied the effect of Hydrogen on combustion performance oxyhydrogen is fed into engine simultaneously, Oxyhydrogen and emission characteristics of a high-speed spark ignition ignites first then gasoline and then spreads the flame faster. engine. Their prime aim of the study was to improve the Oxyhydrogen acts as an ignition catalyst here. From the combustion characteristics and reduce polluting emissions. experiments conducted, it can be concluded that by providing They concluded that an addition of Hydrogen to petrol engine oxyhydrogen in addition to a gasoline fuel in an IC engine improves Break thermal efficiency, also reduces HC and CO yields better combustion which diminishes HC emission and emissions [4-6]. -

Oxyhydrogen Generator for Management of COVID 19

MaHTAS COVID-19 RAPID EVIDENCE UPDATES MaHTAS COVID-19 RAPID EVIDENCE UPDATES Oxyhydrogen Generator For Management Of COVID 19 INTRODUCTION Hydrogen gas is said to be a new and promising treatment option for variety of diseases. Its applications range from acute illness such as ischaemia–reperfusion injury, shock and damage healing to chronic illness such as metabolic syndrome, rheumatoid arthritis, and neurodegenerative diseases.1 There is a growing evidence obtained by animal model experiments 2-9 on molecular hydrogen (H2) as antioxidant, anti-inflammatory, antiapoptotic and antiallergic. The claimed benefits were demonstrated through various delivery methods including drinking hydrogen rich water, intra-peritoneal injection, infusion of hydrogen-rich saline and inhalation.5, 6, 10-13 However, inhalation of hydrogen gas has been established as the easiest and simplest route of administration. It also allows monitoring of the dose of hydrogen. As a biological gas, hydrogen has the ability to diffuse freely across biological membranes, acting in various functional capacities.14, 15 Oxyhydrogen generator is commonly used for engineering applications, transportation as well as for fuel and power generation (for domestic use such as cooking or industry applications such as welding and cutting).16 In recent years, alongside with the discovery of health and wellness benefits of molecular hydrogen, it has been developed as hydrogen inhalation device for health. The device produces hydrogen (66%) and oxygen (33%) gas mixture through water electrolysis method at a rate of 2-3L/min. The electrolysis process splits molecular water into its stoichiometric 2:1 hydrogen to oxygen ratio. The standard specification of the device comprises of an electrolysis unit (at least one positive and one negative plate), a filter unit and a control unit. -

Pressure Versus Impulse Graph for Blast-Induced Traumatic Brain Injury and Correlation to Observable Blast Injuries

Scholars' Mine Doctoral Dissertations Student Theses and Dissertations Spring 2019 Pressure versus impulse graph for blast-induced traumatic brain injury and correlation to observable blast injuries Barbara Rutter Follow this and additional works at: https://scholarsmine.mst.edu/doctoral_dissertations Part of the Explosives Engineering Commons, and the Mathematics Commons Department: Mining Engineering Recommended Citation Rutter, Barbara, "Pressure versus impulse graph for blast-induced traumatic brain injury and correlation to observable blast injuries" (2019). Doctoral Dissertations. 2791. https://scholarsmine.mst.edu/doctoral_dissertations/2791 This thesis is brought to you by Scholars' Mine, a service of the Missouri S&T Library and Learning Resources. This work is protected by U. S. Copyright Law. Unauthorized use including reproduction for redistribution requires the permission of the copyright holder. For more information, please contact [email protected]. PRESSURE VERSUS IMPULSE GRAPH FOR BLAST-INDUCED TRAUMATIC BRAIN INJURY AND CORRELATION TO OBSERVABLE BLAST INJURIES BY BARBARA RUTTER A DISSERTATION Presented to the Faculty of the Graduate School of the MISSOURI UNIVERSITY OF SCIENCE AND TECHNOLOGY In Partial Fulfillment of the Requirements for the Degree DOCTOR OF PHILOSOPHY IN EXPLOSIVES ENGINEERING 2019 Approved by: Catherine E. Johnson, Advisor Kyle Perry Braden Lusk Paul Worsey Dimitri Feys 2019 Barbara Rutter All Rights Reserved iii ABSTRACT With the increased use of explosive devices in combat, blast induced traumatic brain injury (bTBI) has become one of the signature wounds in current conflicts. Animal studies have been conducted to understand the mechanisms in the brain and a pressure versus time graph has been produced. However, the role of impulse in bTBIs has not been thoroughly investigated for animals or human beings.