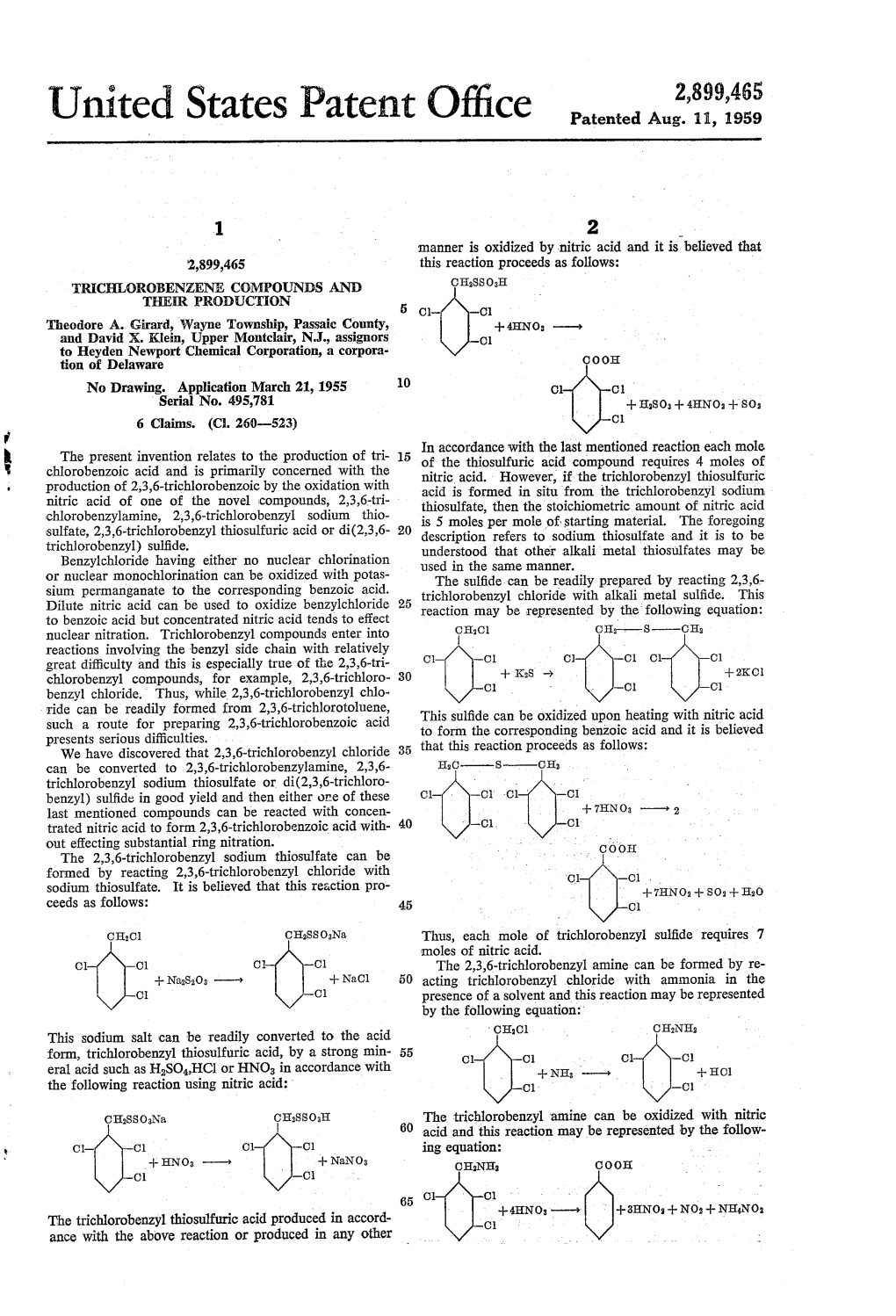

U +4Hnose-—' O+3HN02+NOB+NH4NO2

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Hemoglobin, Myoglobin and Neuroglobin in Endogenous Thiosulfate Production Processes

International Journal of Molecular Sciences Review The Role of Hemoproteins: Hemoglobin, Myoglobin and Neuroglobin in Endogenous Thiosulfate Production Processes Anna Bilska-Wilkosz *, Małgorzata Iciek, Magdalena Górny and Danuta Kowalczyk-Pachel Chair of Medical Biochemistry, Jagiellonian University Collegium Medicum ,7 Kopernika Street, Kraków 31-034, Poland; [email protected] (M.I.); [email protected] (M.G.); [email protected] (D.K.-P.) * Correspondence: [email protected]; Tel.: +48-12-4227-400; Fax: +48-12-4223-272 Received: 5 May 2017; Accepted: 16 June 2017; Published: 20 June 2017 Abstract: Thiosulfate formation and biodegradation processes link aerobic and anaerobic metabolism of cysteine. In these reactions, sulfite formed from thiosulfate is oxidized to sulfate while hydrogen sulfide is transformed into thiosulfate. These processes occurring mostly in mitochondria are described as a canonical hydrogen sulfide oxidation pathway. In this review, we discuss the current state of knowledge on the interactions between hydrogen sulfide and hemoglobin, myoglobin and neuroglobin and postulate that thiosulfate is a metabolically important product of this processes. Hydrogen sulfide oxidation by ferric hemoglobin, myoglobin and neuroglobin has been defined as a non-canonical hydrogen sulfide oxidation pathway. Until recently, it appeared that the goal of thiosulfate production was to delay irreversible oxidation of hydrogen sulfide to sulfate excreted in urine; while thiosulfate itself was only an intermediate, transient metabolite on the hydrogen sulfide oxidation pathway. In the light of data presented in this paper, it seems that thiosulfate is a molecule that plays a prominent role in the human body. Thus, we hope that all these findings will encourage further studies on the role of hemoproteins in the formation of this undoubtedly fascinating molecule and on the mechanisms responsible for its biological activity in the human body. -

APPENDIX G Acid Dissociation Constants

harxxxxx_App-G.qxd 3/8/10 1:34 PM Page AP11 APPENDIX G Acid Dissociation Constants § ϭ 0.1 M 0 ؍ (Ionic strength ( † ‡ † Name Structure* pKa Ka pKa ϫ Ϫ5 Acetic acid CH3CO2H 4.756 1.75 10 4.56 (ethanoic acid) N ϩ H3 ϫ Ϫ3 Alanine CHCH3 2.344 (CO2H) 4.53 10 2.33 ϫ Ϫ10 9.868 (NH3) 1.36 10 9.71 CO2H ϩ Ϫ5 Aminobenzene NH3 4.601 2.51 ϫ 10 4.64 (aniline) ϪO SNϩ Ϫ4 4-Aminobenzenesulfonic acid 3 H3 3.232 5.86 ϫ 10 3.01 (sulfanilic acid) ϩ NH3 ϫ Ϫ3 2-Aminobenzoic acid 2.08 (CO2H) 8.3 10 2.01 ϫ Ϫ5 (anthranilic acid) 4.96 (NH3) 1.10 10 4.78 CO2H ϩ 2-Aminoethanethiol HSCH2CH2NH3 —— 8.21 (SH) (2-mercaptoethylamine) —— 10.73 (NH3) ϩ ϫ Ϫ10 2-Aminoethanol HOCH2CH2NH3 9.498 3.18 10 9.52 (ethanolamine) O H ϫ Ϫ5 4.70 (NH3) (20°) 2.0 10 4.74 2-Aminophenol Ϫ 9.97 (OH) (20°) 1.05 ϫ 10 10 9.87 ϩ NH3 ϩ ϫ Ϫ10 Ammonia NH4 9.245 5.69 10 9.26 N ϩ H3 N ϩ H2 ϫ Ϫ2 1.823 (CO2H) 1.50 10 2.03 CHCH CH CH NHC ϫ Ϫ9 Arginine 2 2 2 8.991 (NH3) 1.02 10 9.00 NH —— (NH2) —— (12.1) CO2H 2 O Ϫ 2.24 5.8 ϫ 10 3 2.15 Ϫ Arsenic acid HO As OH 6.96 1.10 ϫ 10 7 6.65 Ϫ (hydrogen arsenate) (11.50) 3.2 ϫ 10 12 (11.18) OH ϫ Ϫ10 Arsenious acid As(OH)3 9.29 5.1 10 9.14 (hydrogen arsenite) N ϩ O H3 Asparagine CHCH2CNH2 —— —— 2.16 (CO2H) —— —— 8.73 (NH3) CO2H *Each acid is written in its protonated form. -

United States Patent 19 11 4,289,699 Oba Et Al

United States Patent 19 11 4,289,699 Oba et al. 45 Sep. 15, 1981 54 PROCESS FOR THE PRODUCTION OF Primary Examiner-Donald G. Daus N-(HYDROXYPHENYL) MALEIMEDES Assistant Examiner-D. B. Springer 75 Inventors: Masayuki Oba; Motoo Kawamata; Attorney, Agent, or Firm-Fisher, Christen & Sabol Hikotada Tsuboi; Nobuhito Koga, all 57 ABSTRACT of Yokohama, Japan N-(hydroxyphenyl) maleimides of the general formula 73 Assignee: Mitsui Toatsu Chemicals, Incorporated, Tokyo, Japan 21 Appl. No.: 88,825 (22 Filed: Oct. 26, 1979 N CO-m-CH Related U.S. Application Data (HO) 62) Division of Ser. No. 956,971, Nov. 2, 1978, Pat. No. 4,231,934. where R' stands for H, CH3, C2H5, F, Cl, Br or I and in 30 Foreign Application Priority Data is an integer of 1-5 are produced by treating the corre sponding maleamic acid or by treating the ester of said Nov. 2, 1977 (JP) Japan ................................ 52-130905 N-(hydroxyphenyl) maleimide at a temperature of Nov. 4, 1977 (JP Japan ................................ 52-3504 0-150° C. in the presence of at least one dehydrating 51) Int. Cl. .......................................... C07D 207/.452 agent selected for the group consisting of oxides and (52) U.S. Cl. .......................................... 260/326.5 FM oxyacids of sulfur or phosphorus and alkali metal and 58) Field of Search .............................. 260/326.5 FM alkaline earth metal salts of the said oxyacids. The cor responding maleamic acid can be obtained by reacting 56) - References Cited an aminophenol having one or more hydroxyl groups U.S. PATENT DOCUMENTS on its phenyl nucleus with maleic anhydride. -

Recent Developments on the Origin and Nature of Reductive Sulfurous Off-Odours in Wine

fermentation Review Recent Developments on the Origin and Nature of Reductive Sulfurous Off-Odours in Wine Nikolaus Müller 1,* and Doris Rauhut 2 1 Silvanerweg 9, 55595 Wallhausen, Germany 2 Department of Microbiology and Biochemistry, Hochschule Geisenheim University, Von-Lade-Straße 1, 65366 Geisenheim, Germany; [email protected] * Correspondence: [email protected]; Tel.: +49-6706-913103 Received: 9 July 2018; Accepted: 3 August 2018; Published: 8 August 2018 Abstract: Reductive sulfurous off-odors are still one of the main reasons for rejecting wines by consumers. In 2008 at the International Wine Challenge in London, approximately 6% of the more than 10,000 wines presented were described as faulty. Twenty-eight percent were described as faulty because they presented “reduced characters” similar to those presented by “cork taint” and in nearly the same portion. Reductive off-odors are caused by low volatile sulfurous compounds. Their origin may be traced back to the metabolism of the microorganisms (yeasts and lactic acid bacteria) involved in the fermentation steps during wine making, often followed by chemical conversions. The main source of volatile sulfur compounds (VSCs) are precursors from the sulfate assimilation pathway (SAP, sometimes named as the “sulfate reduction pathway” SRP), used by yeast to assimilate sulfur from the environment and incorporate it into the essential sulfur-containing amino acids methionine and cysteine. Reductive off-odors became of increasing interest within the last few years, and the method to remove them by treatment with copper (II) salts (sulfate or citrate) is more and more questioned: The effectiveness is doubted, and after prolonged bottle storage, they reappear quite often. -

SAFETY DATA SHEET According to Safe Work Australia Printing Date 13.06.2013 Revision: 13.06.2013

Page 1/5 SAFETY DATA SHEET According to Safe Work Australia Printing date 13.06.2013 Revision: 13.06.2013 1 . IDENTIFICATION: PRODUCT IDENTIFIER AND CHEMICAL IDENTITY Product Name: POOL PRO CHLORINE OUT Other Name: Sodium hyposulphite Recommended Use of the Chemical and Restriction on Use: Laboratory reagent, de-chlorinating agent and chrome tanning. Details of Manufacturer or Importer: The POPS Group Pty Ltd as Trustee for The Pool Shops Trust 10-12 Cairns Street Loganholme QLD 4129 Phone Number: 07 3209 7884 1800 143 788 Emergency telephone number: 1800 033 111 +61 3 9663 2130 International 2 . HAZARDS IDENTIFICATION Hazardous Nature: The product is not classified according to the Globally Harmonized System (GHS). Label Elements Signal Word Void Hazard Statements Void 3 . COMPOSITION AND INFORMATION ON INGREDIENTS Chemical Characterization: Mixtures Description: Mixture of substances listed below with nonhazardous additions. Hazardous Components: 10102-17-7 Thiosulfuric acid (H2S2O3), disodium salt, pentahydrate 99% 4 . FIRST AID MEASURES Inhalation: If inhaled, remove to fresh air. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. Seek medical attention if symptoms persist. Skin Contact: Remove contaminated clothing and wash affected areas with soap and water. Seek medical attention if symptoms persist. Launder clothing before reuse. Eye Contact: In case of eye contact, check for and remove any contact lenses. Immediately irrigate eyes with plenty of running water for at least 15 minutes, keeping eyelids open. Seek immediate medical attention. Ingestion: Wash mouth with water. Do not induce vomiting. Never give anything by mouth to an unconscious person. Seek medical attention. Information for Doctor Treat symptomatically. -

(CDR) by CASRN Or Accession Number

List of Chemicals Reported for the 2012 Chemical Data Reporting (CDR) by CASRN or Accession Number For the 2012 CDR, 7,674 unique chemicals were reported by manufacturers (including importers). Chemicals are listed by CAS Registry Number (for non-confidential chemicals) or by TSCA Accession Number (for chemicals listed on the confidential portion of the TSCA Inventory). CASRN or CASRN or ACCESSION ACCESSION NUMBER CA INDEX NAME or GENERIC NAME NUMBER CA INDEX NAME or GENERIC NAME 100016 Benzenamine, 4-nitro- 10042769 Nitric acid, strontium salt (2:1) 10006287 Silicic acid (H2SiO3), potassium salt (1:2) 10043013 Sulfuric acid, aluminum salt (3:2) 1000824 Urea, N-(hydroxymethyl)- 10043115 Boron nitride (BN) 100107 Benzaldehyde, 4-(dimethylamino)- 10043353 Boric acid (H3BO3) 1001354728 4-Octanol, 3-amino- 10043524 Calcium chloride (CaCl2) 100174 Benzene, 1-methoxy-4-nitro- 100436 Pyridine, 4-ethenyl- 10017568 Ethanol, 2,2',2''-nitrilotris-, phosphate (1:?) 10043842 Phosphinic acid, manganese(2+) salt (2:1) 2,7-Anthracenedisulfonic acid, 9,10-dihydro- 100447 Benzene, (chloromethyl)- 10017591 9,10-dioxo-, sodium salt (1:?) 10045951 Nitric acid, neodymium(3+) salt (3:1) 100185 Benzene, 1,4-bis(1-methylethyl)- 100469 Benzenemethanamine 100209 1,4-Benzenedicarbonyl dichloride 100470 Benzonitrile 100210 1,4-Benzenedicarboxylic acid 100481 4-Pyridinecarbonitrile 10022318 Nitric acid, barium salt (2:1) 10048983 Phosphoric acid, barium salt (1:1) 9-Octadecenoic acid (9Z)-, 2-methylpropyl 10049044 Chlorine oxide (ClO2) 10024472 ester Phosphoric acid, -

On the Reactivity of Nanoparticulate Elemental Sulfur

ON THE REACTIVITY OF NANOPARTICULATE ELEMENTAL SULFUR: EXPERIMENTATION AND FIELD OBSERVATIONS Fotios Christos Kafantaris Submitted to the faculty of the University Graduate School in partial fulfillment of the requirements for the degree Doctor of Philosophy in the Department of Earth Sciences, Indiana University December 2017 ii Accepted by the Graduate Faculty of Indiana University, in partial fulfillment of the requirements for the degree of Doctor of Philosophy. Doctoral Committee ___________________________ Gregory K. Druschel, PhD, Chair ___________________________ Kevin Mandernack, PhD ___________________________ William P. Gilhooly III, PhD ___________________________ Gabriel Filippelli, PhD ___________________________ Steven E. Lacey, PhD October 2, 2017 ___________________________ Brandy M. Toner, PhD iii © 2017 Fotios Christos Kafantaris iv DEDICATION I would like to dedicate this work to three women. The first one is the Most Holy Theotokos and Ever-Virgin Mary, the most precious individual the human race has and will ever have, the Bridge from earth to Heaven and the Gate to Paradise. Through Her intercessions to the Holy Trinity I am still alive and safe. The second woman is my mother, Eleni, who is the angel-on-earth that protects, nourishes, teaches, provides, inspires and guides me in life. Words would be poor to attempt to describe her and her virtues in an accurate manner. My mother is the main contributor of what I have become so far in life. The third woman is my σύζυγος (spouse) Diana, who has given me life, as well as meaning for life. Diana is the main contributor of what I will hopefully do in life from this point onward, and through her help I will hopefully manage to be with the other two forever. -

Are Strong Brønsted Acids Necessarily Strong Lewis Acids?

Are Strong Brønsted Acids Necessarily Strong Lewis Acids? K. Gupta1,2, D. R. Roy1, V. Subramanian3,* and P. K. Chattaraj1,* 1Chemistry Department, Indian Institute of Technology, Kharagpur-721302, India 2On leave from Department of Chemisty, Ramananda College, Bishnupur-722122, Bankura, India. 3Chemical Laboratory, Central Leather Research Institute, Adyar, Chennai- 600 020, India. E-mail: [email protected], [email protected] Abstract The Brønsted and Lowry acid-base theory is based on the capacity of proton donation or acceptance (in the presence/absence of a solvent) whereas the Lewis acid- base theory is based on the propensity of electron pair acceptance or donation. We explore through DFT calculation the obvious question whether these two theories are in conformity with each other. We use pKa as the descriptor for the Brønsted and Lowry acidity. The DFT descriptors like ionization potential, electron affinity, electronegativity, hardness and global electrophilicity are computed for 58 organic and inorganic acids. The fractional electron transfer, ΔN and the associated energy change, ΔE for the reaction of these acids with trimethyl amine (a strong base) are used as the possible descriptors for the Lewis acidity. A near exponential decrease in ΔN and (–ΔE) values is observed in general with an increase in pKa values. The findings reveal that a stronger Brønsted acid in most cases behaves as a stronger Lewis acid as well. However it is not necessarily true for all acids. Keywords DFT, Brønsted acids, Lewis acids, pKa, electron transfer 1 Introduction Brønsted and Lowry1 suggested that any substance that acts as a proton donor should be classified as an acid and any substance that accepts a proton should be classified as a base. -

United States Atent Thee July 5, 1195

227E254? United States atent thee July 5, 1195 ing at the same time, the evidence for this reaction mech anism is extremely strong and, therefore, although it is 2,712,547 not desired to limit the invention to any particular theory, the evidence is so strong that the mechanism has a high PREPARATION or s-AnYL-TmosULFURIc ACIDS Lil degree of probability. We have determined that the Hans Z. Lecher, Plain?eld, and Elizabeth M. Hardy, second reaction, namely oxidation of the thiol by bisul?de, Bound Brook, N. J., assignors to American Cyanamid actually does take place, The oxidation of thiols is Company, New York, N. ‘L, a corporation of Maine not limited to S-nitro‘oenzene thiol and Z-benzoylarnino No Drawing. Application April 7, 1954, benzene thiol but it may take place with any thiol having Serial No. 421,700 a suf?ciently high oxidation-reduction potential, for ex ample Z-naphthalenethiol and benzenethiol. 11 Claims. (Cl. 26tl-—453) The use of bisul?tes in the reaction of the present invention is a very critical factor. Sulfurous acid will not produce the results of the present invention although This invention relates to an improved process of pre it has been used with aryl-disul?des having basic sub paring salts of certain S-aryl-thiosulfuric acids often re stituents which are, of course, entirely different from ferred to as Bunte salts. More speci?cally it relates to those with which the present invention deals. Sul?tes an improved process of preparing water-soluble salts of are also not useful. -

AP Chemistry Summer Assignment 2021

AP Chemistry Information and Summer assignment Overview of Course Expectations: AP Chemistry is a college level course. Students can earn up to 8 hours college credit for successful completion of this course and a good score on the AP Exam. It is a time-consuming and challenging, yet extremely rewarding, course. This course moves at a very fast pace and classroom attendance is a MUST. Students will be prepared to do college level work of any type upon completion of this course due to the thought processes used and the discipline/work habits required. The course covers two semesters of college chemistry. We will complete many hours of lab work. To have success on the AP exam, students will need to spend on average five to ten additional hours per week outside of class working on AP chemistry. This time will be spent on homework assignments, pre-labs, lab reports, problem sets, etc. There will be times that students will be able to complete things during class if they use their time efficiently. These statements are not meant to discourage, but to point out and state the truth to avoid any misconceptions about the high expectations for this course. I will do my very best to provide a college level course/experience which not only prepares you for the AP exam, but provides a solid foundation in chemistry. I also intend for it to be fun!! You are fortunate to be able to take this type of college level course in the high school setting as part of a small class. -

J. Rohonczy: Inorganic Chemistry I

Dr. János Rohonczy Lecture Notes Eötvös Loránd University, Budapest Faculty of Sciences Dr. János Rohonczy INORGANIC CHEMISTRY I. Lecture Notes Eötvös Loránd University Faculty of Sciences BUDAPEST 2017. János Rohonczy: Inorganic Chemistry I. Lecture Notes. Copyright © 2017 Dr. János Rohonczy, Eötvös Loránd University, Budapest, Faculty of Sciences All Right are Reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means: electronic, electrostatic, magnetic tape, mechanical, photographical, photocopying, recording or otherwise, without permission in writing form the publisher. This book is written utilized the lecture notes of the Inorganic Chemistry lectures of the author at the Department of Inorganic Chemistry of Eötvös Loránd University, Budapest. Revised, and the fullerene and boron cluster topics remarked by Dr. Béla Csákvári professor emeritus. First edition 2017 Edited and cover page made by Dr. János Rohonczy Publisher: Eötvös Loránd University, Faculty of Sciences ISBN: 978-963-284-853-2 DOI: 10.21862/ 3 Table of Contents Introduction 7 1. Hydrogen 8 1.1. Hydrogen compounds 9 2. Halogens: F, Cl, Br, I, At 10 2.1. Hydrogen halides 13 2.2. Interhalogens 14 2.3. Polyhalogen and interhalogen ions, organic derivatives 16 3. (16th column) O, S, Se, Te, Po 17 3.1. Oxygen (O) 17 3.1.1. Oxygen compounds 19 3.1.2. Halogen oxides and oxygen halides 21 3.1.3. Halogen oxoacids and their salts 24 3.1.4. Halogen oxofluorides and fluorinated oxoacids 28 3.2. Sulfur(S) 29 3.2.1. Sulfur containing compounds 31 3.2.2. -

01 Excipients Prelims 1..9

Sodium Thiosulfate 1 Nonproprietary Names SEM 1: Excipient: sodium thiosulfate; magnification: 100Â; voltage: 10 kV. BP: Sodium Thiosulphate JP: Sodium Thiosulfate Hydrate PhEur: Sodium Thiosulfate USP-NF: Sodium Thiosulfate 2 Synonyms Ametox; disodium thiosulfate; disodium thiosulfate pentahydrate; natrii thiosulfas; natrium thiosulfuricum; sodium hyposulfite; sodium subsulfite; Sodothiol; Sulfothiorine; thiosulfuric acid disodium salt. 3 Chemical Name and CAS Registry Number Sodium thiosulfate anhydrous [7772-98-7] Sodium thiosulfate pentahydrate [10102-17-7] 4 Empirical Formula and Molecular Weight Na2S2O3 158.11 (for anhydrous) Na2S2O3Á5H2O 248.2 (for pentahydrate) Table I: Pharmacopeial specifications for sodium thiosulfate. 5 Structural Formula Test JP XV PhEur 6.0 USP32–NF27 Identification þþþ Characters — þ — pH 6.0–8.0 6.0–8.4 — Appearance of solution þþ— Water — — 32.0–37% Calcium þ — þ Heavy metals 420 ppm 410 ppm 40.002% Arsenic 45 ppm — — Loss on drying þ —— 6 Functional Category Sulfides — þ — Sulfates and sulfites — 40.2% — Antioxidant. Assay (dried basis) 99.0–101.0% 99.0–101.0% 99.0–100.5% 7 Applications in Pharmaceutical Formulation or S Technology Sodium thiosulfate is used as an antioxidant in pharmaceuticals 11 Stability and Storage Conditions (ophthalmic, intravenous, and oral preparations). It has also been Sodium thiosulfate decomposes on heating. The bulk powder used for its antifungal properties(1) and as a reagent in analytical should be stored in a cool place, and the container should be kept chemistry. tightly closed in a dry and well-ventilated place. It should not be stored near acids. 8 Description 12 Incompatibilities Sodium thiosulfate occurs as odorless and colorless crystals, a crystalline powder or granules.