Scimitar Propellers

Total Page:16

File Type:pdf, Size:1020Kb

Load more

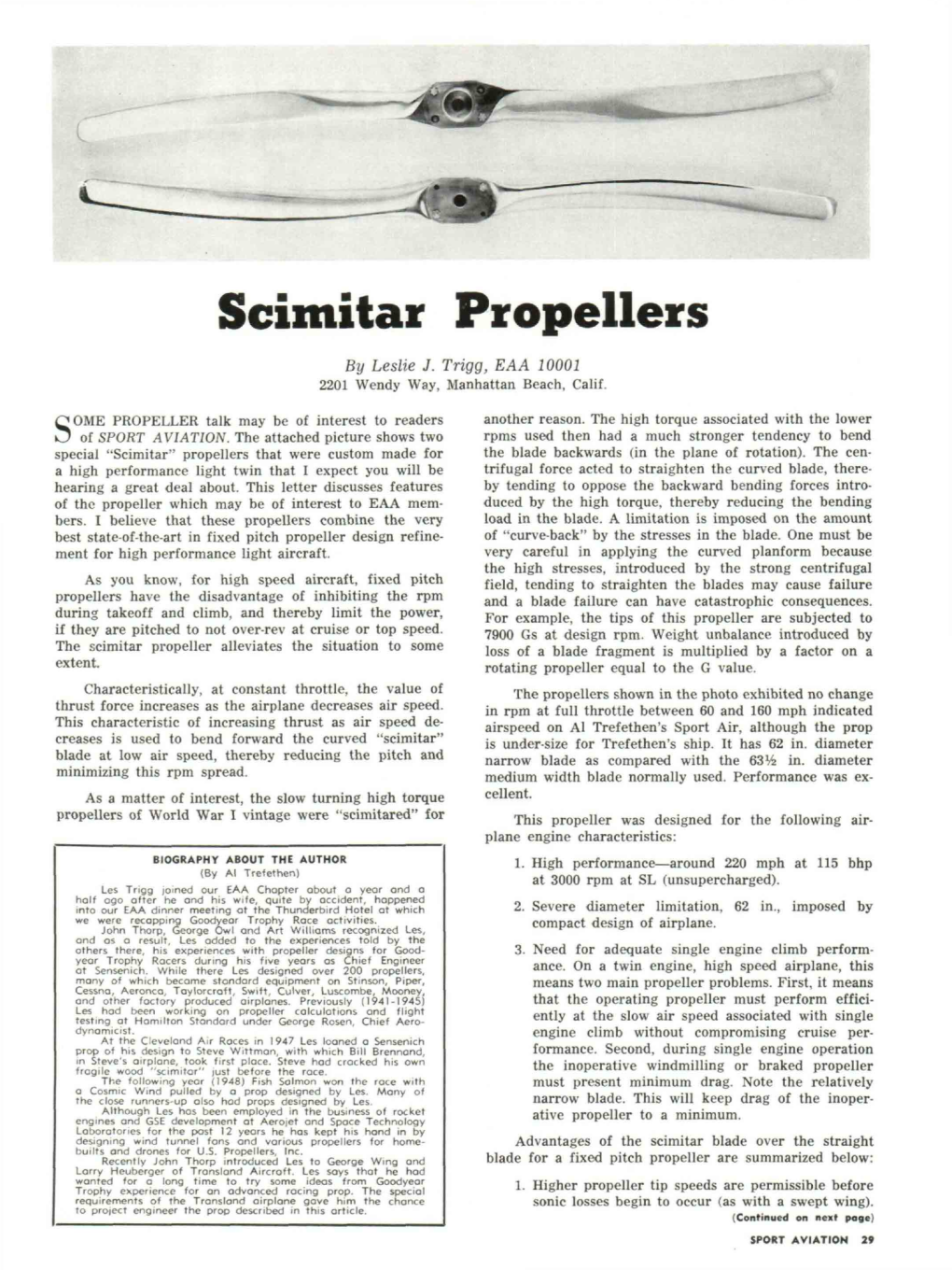

Recommended publications

-

Propeller Aerodynamics CONSTANT-SPEED PROPELLER

Constant-speed propeller Centrifugal twisting force. This is the opposing force to the aerodynamic twist- ing moment. Because this force is greater, it tries to move the blades toward a reduced blade angle. A propeller is designed to withstand the effect of these forces, but the forces are nonetheless important factors in design and operation. The effect of these forces accu- mulates across the length of the blade with the greatest stress at the hub. As the rota- tional speed of the propeller increases, so too do the stresses acting upon it. Given the various forces acting upon a propeller, it is not difficult to understand the serious prob- lem associated with even small nicks or scratches that could weaken the integrity of the propeller. Propeller aerodynamics To understand how a propeller moves an aircraft through the air, it is necessary to look at it from an aerodynamic rather than a mechanical perspective. Figure 5-6 depicts the side view of a propeller detailing the blade path, blade chord, and relative wind. The illustration reveals two types of motion associated with the propeller blades: rota- tional and forward. As a blade moves downward, it simultaneously moves forward. This has a significant effect on the relative wind making it strike the blade at an angle that is between straight ahead and straight down. This angle that the relative wind strikes the blade is called the angle of attack. The relative wind hitting the descending blade is deflected rearward causing the dynamic pressure on the engine side of the blade to be greater than the pressure on the back of the blade. -

Propeller Operation and Malfunctions Basic Familiarization for Flight Crews

PROPELLER OPERATION AND MALFUNCTIONS BASIC FAMILIARIZATION FOR FLIGHT CREWS INTRODUCTION The following is basic material to help pilots understand how the propellers on turbine engines work, and how they sometimes fail. Some of these failures and malfunctions cannot be duplicated well in the simulator, which can cause recognition difficulties when they happen in actual operation. This text is not meant to replace other instructional texts. However, completion of the material can provide pilots with additional understanding of turbopropeller operation and the handling of malfunctions. GENERAL PROPELLER PRINCIPLES Propeller and engine system designs vary widely. They range from wood propellers on reciprocating engines to fully reversing and feathering constant- speed propellers on turbine engines. Each of these propulsion systems has the similar basic function of producing thrust to propel the airplane, but with different control and operational requirements. Since the full range of combinations is too broad to cover fully in this summary, it will focus on a typical system for transport category airplanes - the constant speed, feathering and reversing propellers on turbine engines. Major propeller components The propeller consists of several blades held in place by a central hub. The propeller hub holds the blades in place and is connected to the engine through a propeller drive shaft and a gearbox. There is also a control system for the propeller, which will be discussed later. Modern propellers on large turboprop airplanes typically have 4 to 6 blades. Other components typically include: The spinner, which creates aerodynamic streamlining over the propeller hub. The bulkhead, which allows the spinner to be attached to the rest of the propeller. -

Epic Performance for Tнe Entire King Air 200 Family

BEECHCRAFT KING AIR B200GT EPIC PERFORMANCE FOR THE B200 ENTIRE KING AIR 200 FAMILY... 200 ...utilizing Swept Blade Technology Simply more of what you bought your King Air for! THE ELEMENTS OF RAISBECK’S 200-SERIES EPIC PERFORMANCE PACKAGE (Elements available separately) SWEPT BLADE TURBOFAN PROPELLERS RAM AIR RECOVERY SYSTEM ENHANCED PERFORMANCE LEADING EDGES DUAL AFT BODY STRAKES HIGH FLOTATION GEAR DOORS OPTIONAL CROWN WING LOCKERS Diaphragm Seal Particle Separator with flap Ice Shedder Turning Vane Flap Bypass Door Seal Benefits Benefits Benefits Benefits Benefits Benefits • Stunning ramp presence • Significantly increases climb and cruise • Cruise speeds and range are increased • Passenger ride quality is improved • Climb and cruise performance of standard- • FAA-certified to carry 600 pounds total cargo in • Quiet and virtually vibrationless operation performance in both normal and anti-ice • Stall speeds and characteristics are improved • Pilot control and handling qualities are gear King Airs is restored 17 cubic feet of luggage space from takeoff to touchdown operating modes • Air conditioning and cooling are more efficient enhanced • Cruise speed is increased 8 to 12 knots • Returns your cabin to your passengers • Certified around the world to meet the most • Protects against FOD—deployable for all • Outboard wing fatigue life is inherently • Air Minimum Control Speed is inherently depending on altitude • Handles skis, snowboards, camping and stringent regulations and noise requirements ground, takeoff and landing operations -

Aircraft Service Manual

Propeller Technical Manual Jabiru Aircraft Pty Ltd JPM0001-1 4A482U0D And 4A484E0D Propellers Propeller Technical Manual FOR 4A482U0D and 4A484E0D Propellers DOCUMENT No. JPM0001-1 DATED: 1st Feb 2013 This Manual has been prepared as a guide to correctly operate & maintain Jabiru 4A482U0D and 4A484E0D propellers. It is the owner's responsibility to regularly check the Jabiru web site at www.jabiru.net.au for applicable Service Bulletins and have them implemented as soon as possible. Manuals are also updated periodically with the latest revisions available from the web site. Failure to maintain the propeller, engine or aircraft with current service information may render the aircraft un-airworthy and void Jabiru’s Limited, Express Warranty. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. Should you have any questions or doubts about the contents of this manual, please contact Jabiru Aircraft Pty Ltd. This document is controlled while it remains on the Jabiru server. Once this no longer applies the document becomes uncontrolled. ISSUE 1 Dated : 1st Feb 2013 Issued By: DPS Page: 1 of 32 L:\files\Manuals_For_Products\Propeller_Manuals\JPM0001-1_Prop_Manual (1).doc Propeller Technical Manual Jabiru Aircraft Pty Ltd JPM0001-1 4A482U0D And 4A484E0D Propellers 1.1 TABLE OF FIGURES ............................................................................................................................................. 3 1.2 LIST OF TABLES ................................................................................................................................................. -

1976 Cessna T210L Turbo Centurion II for Sale

1976 Cessna T210L Turbo Centurion II Wolfe Aviation Business Aircraft Acquisitions, Appraisals, Sales and Service Verlyn Wolfe, PSCA ASA Accredited Senior Aircraft Appraiser Wolfe Aviation Stockton Metropolitan Airport (KSCK) 2050 East Sikorsky Street, Hangar 7 Stockton, California 95206 P.O. Box 31592, Stockton, California 95213-1592 Telephone: (209) 983-0117 Ext. 233 Cellular: (209) 607-9804 Email: [email protected] Wolfe Aviation believes the following information to be accurate but does not warrant nor guarantee the information accordingly; purchasers should rely upon their own inspection of the aircraft. There shall be no agreement between parties unless set forth in a written contract signed by buyer and seller. 1 Details: • Registration: N2803S • Serial Number: 21061049 • Airframe Time: 2,983 Hours total time since new • Engine: Teledyne Continental Motors TSIO-520-H4B sn: 217325-R; 285 HP 1,005 Hours since factory remanufacture; 1,400 hour TBO Compressions at last annual: #1 68, #2 75, #3 72, #4 68, #5 62, #6 60 Remanufactured by Teledyne Continental Motors 08/30/1994 Turbo overhauled by Main Turbo Systems, Inc. 08/08/2019 @ 83 hours ago 500 Hour magneto inspections c/w 01/26/2018 @ 86 hours ago Knisley Welding exhaust system installed 08/08/2018 • Propeller: Hartzell PHC-J3YF-1RF/F7691 three blade Scimitar propeller 27 Hours since new propeller installed; 2,000 hour TBO Propeller manufactured new by Hartzell Propeller 2018 New McCauley Propeller governor installed 10/21/2019 @ 24 hours ago • Inspection: Annual inspection -

Hydromatic Propeller

HYDROMATIC PROPELLER International Historic Engineering Landmark Hamilton Standard The American Society of A Division of United Technologies Mechanical Engineers Windsor Locks, Connecticut November 8, 1990 Historical Significance The text of this International Landmark Designation: The Hamilton Standard Hydromatic propeller represented INTERNATIONAL HISTORIC MECHANICAL a major advance in propeller design and laid the groundwork ENGINEERING LANDMARK for further advancements in propulsion over the next 50 years. The Hydromatic was designed to accommodate HAMILTON STANDARD larger blades for increased thrust, and provide a faster rate HYDROMATIC PROPELLER of pitch change and a wider range of pitch control. This WINDSOR LOCKS, CONNECTICUT propeller utilized high-pressure oil, applied to both sides of LATE 1930s the actuating piston, for pitch control as well as feathering — the act of stopping propeller rotation on a non-functioning The variable-pitch aircraft propeller allows the adjustment engine to reduce drag and vibration — allowing multiengined in flight of blade pitch, making optimal use of the engine’s aircraft to safely continue flight on remaining engine(s). power under varying flight conditions. On multi-engined The Hydromatic entered production in the late 1930s, just aircraft it also permits feathering the propeller--stopping its in time to meet the requirements of the high-performance rotation--of a nonfunctioning engine to reduce drag and military and transport aircraft of World War II. The vibration. propeller’s performance, durability and reliability made a The Hydromatic propeller was designed for larger blades, major contribution to the successful efforts of the U.S. and faster rate of pitch change, and wider range of pitch control Allied air forces. -

Design Study of Technology Requirements for High Performance Single-Propeller- Driven Business Airplanes

3 1176 01346 2362 ! NASA Contractor Report 3863 NASA-CR-386319850007383 Design Study of Technology Requirements for High Performance Single-Propeller- Driven Business Airplanes David L. Kohlman and James Hammer CONTRACT NAS1-16363 JANUARY 1985 N/ A NASA Contractor Report 3863 Design Study of Technology Requirements for High Performance Single-Propeller- Driven Business Airplanes David L. Kohlman and James Hammer Flight Research Laboratory University of Kansas Center for Research, Inc. Lawrence, Kansas Prepared for Langley Research Center under Contract NAS1-16363 N/ A National Aeronautics and Space Administration Scientific and Technical InformationBranch 1985 TABLE OF CONTENTS Page i. INTRODUCTION .............................................. 1 2. NOMENCLATURE .............................................. 5 3. BASELINE CONFIGURATION ANALYSIS ........................... 7 3.1 Description of Baseline Configuration ................ 7 3.2 Effect of Aspect Ratio ............................... ii 3.3 Effect of Wing Loading ............................... 12 3.4 Effect of Wing Natural Laminar Flow .................. 15 3.5 Effect of Fuselage Drag .............................. 19 4. PROPULSION SYSTEM ANALYSIS ................................. 31 4.1 GATE Engine ........................................... 32 4.1.1 Description of Engine .......................... 32 4.1.2 GASP Engine Routine ............................ 33 4.2 Very Advanced Reciprocating Engine (Spark Ignited), (SIR) ............................... 36 4.3 Very Advanced Diesel -

CESSNA 180-SCIMITAR.Pdf

T O P P R Cessna 180 (Land or Amphibian) O With O-470-A, -J, -K, -L, -R, -S, -U engine P P E R F O R M A N C E C Basic Kit: 180 with the O-470-A, -J, -K, -L, -R, -S engine Part Number: C3F00025STP O 1 3-Bladed Propeller: PHC-C3YF-1RF/F7691 1 Polished Spinner: C-3535-1P N 1 STC Document Set: SA00852AT V Basic Kit: 180 with the O-470-U engine E Part Number: C3F00025STP*1 1 3-Bladed Propeller: PHC-C3YF-1RF/F7691 R 1 Polished Spinner: C-3535-1P 1 STC Document Set: SA00852AT S I O __________________________________________________________________________________________________ Aircraft Serial and registration numbers required when ordering N All Prices FOB Hartzell Propeller Inc. Prices do not include Ohio State Sales Tax Installation and Dynamic Balancing available at an additional charge S Telephone: (937) 778-5726 Option 2 / (800) 942-7767 Option 2 Fax: (937) 778-4215 Internet: www.hartzellprop.com Email: [email protected] T O P P R O CESSNA 180 P Applicable Models: All models (Land or Amphibian) *Note: a governor change may be required in some cases P Specifications: 78 inch diameter 3-bladed, scimitar, aluminum hub propeller 2400 hour / 6 year TBO E 75 pounds (propeller and spinner) Diameter reduction allowable to 77 inches R Replaces: Hartzell 82XF- 84 or 88 inch dia., 2-bladed steel hub prop F Diameter reduction allowable to 82.5 or 86 inches 1000 hours / 5 year TBO O McCauley 2A36C - 82 or 88 inch diameter 2-bladed propeller R Diameter reduction allowable to 80 or 86 inches 1000-1500 hours / 5 year TBO M McCauley 2A34C - 82 -

Speed, Power and Control Depend on Innovation

Discover Speed, Power and Control Depend on Innovation he latest innovation from Lancair is a new T2-seat “little brother” to the groundbreaking Mako — the Barracuda. Establishing a new standard for value, Barracuda offers high per- formance, operational economy and Lancair’s trademark aerodynamic style in a cost-effective package for two. nnounced at EAA AirVenture 2018, Barracuda is the latest design from Lancair’s legendary innovators. AA beautiful 2-place composite single with exceptional performance and style at an affordable price point. Speed, Power and Control Barracuda Specifications Start with Innovation. Base Engine Continental IO-550-N Horsepower 310 Power to climb. Speed to take you to new places. Innovation that Hartzell Propeller 3-blade “Scimitar” only Lancair can bring you. Three decades after revolutionizing the Landing Gear (Base Configuration) Fixed Mains, Retractable Nose world of two-seat aircraft, a rich history of unparalleled innovation Useable Fuel 65 gal and record-setting performance continues with the Lancair Gross Weight (lb) 2200 Barracuda. Updated and optimized from tip to tail, Barracuda is Empty Weight (lb) 1450 faster, more agile and quicker to build than its predecessors. Useful Load (lb) 750 Full Fuel Payload (lb) 360 It’s All About The Options. Glass Panel G3X Touch AmSafe Seat Belts optional You’ll enjoy a wealth of options to customize your Barracuda. Speed Brakes optional Speed Brakes from Precise Flight, Wheel Brakes from Beringer and Built-in Oxygen optional convenient access to the baggage area via an openable rear window Wingspan 25.5 ft are just a sample. Choose a Hartzell 3-blase ‘Scimitar’ propeller to Length 22 ft boost performance. -

Fire and Ice

Volume 12 Number 3 Summer 2003 Fire and Ice by Robert Mills Page 30 America’s Ancient City: St. Augustine A Pre-Convention Tour by Jeff Schweitzer Page 42 Representing Owners and Pilots of High Performance Single Engine Pressurized Aircraft Worldwide Trade-in and land an incredible deal on a Meridian. Deal your way into a Piper Meridian. Now with 15% MORE useful load. There are more reasons than ever to get a new Piper Meridian • Now with up to 1740 pounds of useful load • Optional Honeywell Integrated Hazard (15% more!) Avoidance System (IHAS) 8000 • New cutting edge digital Magic 1500 autopilot – Weather uplink – Traffic avoidance designed especially for the Meridian – Color moving map – L3 WX-500 Stormscope • Piper Insurance and Financial Services – Terrain awareness – Weather radar display standing by to work for you • 2 year Factory Warranty Now that’s freedom. There’s never been a better time to buy! Take advantage of this limited time offer today. To find out more, call Piper at 866-648-1945 or visit www.newpiper.com ™ The New Piper Aircraft, Inc. Table of Contents ... 6 Letter From the Editor by Jeff Schweitzer 10 Malibu Maintenance by Kevin Mead 12 Aviation News by Doug Leet 14 Note from the President by Richard Bynum 15 Coats Corner by David Coats M.D. 18 Malibu Trivia Q & A by Mary Bryant 21 Piper Perspective: The View From Vero Beach by Chuck Suma 24 Views from a JetProp by Robert Conrad 27 Turbine Times by Cody Ramsey 52 Notes from M-MOPA Headquarters by Russ Caauwe 57 M•MOPA Classifi eds 62 Advertising Rates 62 Calendar 62 Training Update FEATURE ARTICLES 30 Alaska Adventure by Robert Mills 42 America’s Ancient City: St. -

Federal Aviation Administration, DOT § 25.925

Federal Aviation Administration, DOT § 25.925 speed of the engines, following the § 25.907 Propeller vibration and fa- inflight shutdown of all engines, is in- tigue. sufficient to provide the necessary This section does not apply to fixed- electrical power for engine ignition, a pitch wood propellers of conventional power source independent of the en- design. gine-driven electrical power generating (a) The applicant must determine the system must be provided to permit in- magnitude of the propeller vibration flight engine ignition for restarting. stresses or loads, including any stress (f) Auxiliary Power Unit. Each auxil- peaks and resonant conditions, iary power unit must be approved or throughout the operational envelope of meet the requirements of the category the airplane by either: for its intended use. (1) Measurement of stresses or loads [Doc. No. 5066, 29 FR 18291, Dec. 24, 1964, as through direct testing or analysis amended by Amdt. 25–23, 35 FR 5676, Apr. 8, based on direct testing of the propeller 1970; Amdt. 25–40, 42 FR 15042, Mar. 17, 1977; on the airplane and engine installation Amdt. 25–57, 49 FR 6848, Feb. 23, 1984; Amdt. for which approval is sought; or 25–72, 55 FR 29784, July 20, 1990; Amdt. 25–73, (2) Comparison of the propeller to 55 FR 32861, Aug. 10, 1990; Amdt. 25–94, 63 FR similar propellers installed on similar 8848, Feb. 23, 1998; Amdt. 25–95, 63 FR 14798, airplane installations for which these Mar. 26, 1998; Amdt. 25–100, 65 FR 55854, Sept. 14, 2000] measurements have been made. -

Variable Pitch Propeller for UAV-Experimental Tests

energies Article Variable Pitch Propeller for UAV-Experimental Tests Maciej Pods˛edkowski 1,*, Rafał Konopi ´nski 1, Damian Obidowski 2 and Katarzyna Koter 1 1 Institute of Machine Tools and Production Engineering, Lodz University of Technology, 90924 Łód´z,Poland; [email protected] (R.K.); [email protected] (K.K.) 2 Institute of Turbomachinery, Lodz University of Technology, 90924 Łód´z,Poland; [email protected] * Correspondence: [email protected] Received: 1 September 2020; Accepted: 3 October 2020; Published: 10 October 2020 Abstract: Growth in application fields of unmanned aerial vehicles (UAVs) and an increase in their total number are followed by higher and higher expectations imposed on improvements in UAV propulsion and energy management systems. Most commercial vertical takeoff and landing (VTOL) UAVs employ a constant pitch propeller that forces a mission execution tradeoff in the majority of cases. An alternative solution, presented here, consists of the use of a variable pitch propeller. The paper summarizes experimental measurements of the propulsion system equipped with an innovative variable pitch rotor. The investigations incorporated characteristics of the rotor for no wind conditions and a new approach to optimize pitch settings in hover flight as a function of UAV weight and energy consumption. As UAV battery capacity is always limited, efficient energy management is the only way to increase UAV mission performance. The study shows that use of a variable pitch propeller can increase the maximal takeoff weight of the aircraft and improve power efficiency in hover, especially if load varies for different missions. The maximal thrust measured was 31% higher with respect to the original blade settings.