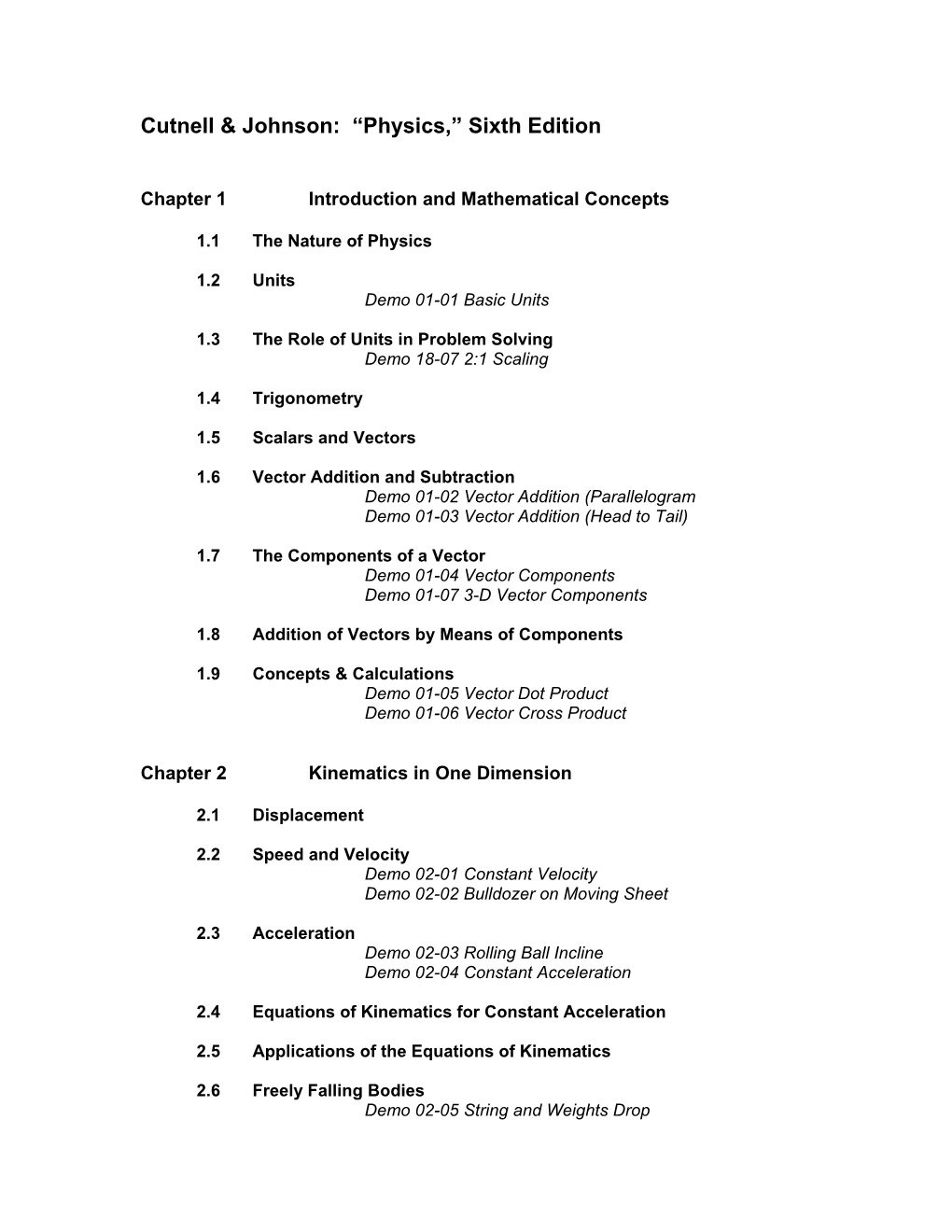

Cutnell & Johnson: “Physics,” 6Th Ed

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

A Catechism of the Steam Engine by John Bourne</H1>

A Catechism of the Steam Engine by John Bourne A Catechism of the Steam Engine by John Bourne Produced by Robert Connal and PG Distributed Proofreaders from images generously provided by the Digital & Multimedia Center, Michigan State University Libraries. A CATECHISM OF THE STEAM ENGINE IN ITS VARIOUS APPLICATIONS TO MINES, MILLS, STEAM NAVIGATION, RAILWAYS, AND AGRICULTURE. WITH PRACTICAL INSTRUCTIONS FOR THE MANUFACTURE AND MANAGEMENT OF ENGINES OF EVERY CLASS. BY page 1 / 559 JOHN BOURNE, C.E. _NEW AND REVISED EDITION._ [Transcriber's Note: Inconsistencies in chapter headings and numbering of paragraphs and illustrations have been retained in this edition.] PREFACE TO THE FOURTH EDITION. For some years past a new edition of this work has been called for, but I was unwilling to allow a new edition to go forth with all the original faults of the work upon its head, and I have been too much engaged in the practical construction of steam ships and steam engines to find time for the thorough revision which I knew the work required. At length, however, I have sufficiently disengaged myself from these onerous pursuits to accomplish this necessary revision; and I now offer the work to the public, with the confidence that it will be found better deserving of the favorable acceptation and high praise it has already received. There are very few errors, either of fact or of inference, in the early editions, which I have had to correct; but there are many omissions which I have had to supply, and faults of arrangement and classification which I have had to rectify. -

Chapter 1. Introduction

1 Introduction 1.1 Introduction Control systems are ubiquitous. They appear in our homes, in cars, in industry and in systems for communication and transport, just to give a few examples. Control is increasingly becoming mission critical, processes will fail if the control does not work. Control has been important for design of experimental equipment and instrumentation used in basic sciences and will be even more so in the future. Principles of control also have an impact on such diverse fields as economics, biology, and medicine. Control, like many other branches of engineering science, has devel- oped in the same pattern as natural science. Although there are strong similarities between natural science and engineering science it is impor- tant to realize that there are some fundamental differences. The inspi- ration for natural science is to understand phenomena in nature. This has led to a strong emphasis on analysis and isolation of specific phe- nomena, so called reductionism. A key goal of natural science is to find basic laws that describe nature. The inspiration of engineering science is to understand, invent, and design man-made technical systems. This places much more emphasis on interaction and design. Interaction is a key feature of practically all man made systems. It is therefore essential to replace reductionism with a holistic systems approach. The technical systems are now becoming so complex that they pose challenges compa- rable to the natural systems. A fundamental goal of engineering science is to find system principles that make it possible to effectively deal with complex systems. Feedback, which is at the heart of automatic control, is an example of such a principle. -

Technical Standards and Safety Authority ACTIVE Code Adoption Documents, Guidelines, Advisories, Director's Orders & Directo

ACTIVE Code Adoption Documents, Guidelines, Advisories, Director's Orders & Director's Safety Orders as of December 1, 2020 Elevating and Amusement Devices Safety Program Technical Standards and Safety Authority This file contains documents (or regulatory instruments) that form part of Ontario's Elevating Devices Regulatory Landscape. The documents enclosed are those which are considered to be in Active status as of the date of this publishing. For historic and archived versions please refer to the ARCHIVED Regulatory Documents Binder (ED-SKI). Technical Standards & Safety ACTIVE Code Adoption Documents, Guidelines, Advisories, Director's (Safety) Orders Authority This file contains current Active regulatory communucation tools ID No. Date Active Is Past Due? Enforcement that form part of Ontario's Elevating Devices Regulatory Landscape ID No. Date CODE ADOPTION DOCUMENT Status1 Status2 Enforcement 277/19 Feb‐01‐19 ED CAD Amendment ‐ Updated to Parts 1,2,4,5,8, Re‐Issue Parts 3,6,7 Active Mandatory 272/18 amendment Mar‐30‐20 SLM Continuing Education Requirements Active Mandatory 272/18 May‐16‐18 SLM Continuing Education Requirements Active see temporary amendment Mandatory 268/14 Dec‐05‐14 Requirements for Transport Platforms Active Mandatory 265/14 Jan‐07‐14 Construction Hoist Interlocks Active Mandatory 194/08 Oct‐08‐08 Regulation of Parking Garage Lifts Active Mandatory ID No. Date GUIDELINES Status1 Status2 Enforcement 257/12 Sep‐14‐12 Guideline ‐ Construction Hoist Operator Logs Active Mandatory 256/12 Sep‐14‐12 Guideline ‐ Construction -

Diesel Mechanics: Fuel Systems

DOCUMENT RESUME ED' 220 6,31 CE 033 516 AUTHOR Foutes, William TITLE Diesel Mechanics: 9uel Systems. INSTITUTION Mid-America Vocational Curriculum Consortium, Stillwater, Okla. PUB DATE 82 NOTE 284p.; For related documents see tb 149 162 and CE 033 514-515. AVAILABLE FROMMid-America Vocational Cuiriculum Consortium, 1515 West Sixth Avenue, Stillwater, OK 74074. EDRS PRICE MF01 Plus Postage. PC Not Available fromEDRS. DESCRIPTORS *Auto-. Mechanics; Behavioral Objectives; Curriculbm Guides; *Diesel Engines; Job Skills; Learning Activities; Performance Tests; Postsecondary Education; Trade and Industrial Education; Transparencies IDENTIFIERS *Fuel Systems ABSTRACT This publication is the third in a series of three texts for a diesel mechanics curriculum. Its purpose is to teach the concepts related to fuel injection systems in a diesel trade. The text contains eight units. Each instructional unit irjcludes some or all of these basic components: unit and specific (fiFtormance) objectives, suggested activities for teachers and students, information sheets, transparency masters, assignment sheets, answers to assignment sheets, job sheets, pencil-paper and performance tests, and answers to tests. Introductory matei.ia,ls include description of unit components, instructional/task analysis (psychomotor and cognitive skills to be learned), listing of needed tools and equipment, and reference list. Unit titles are Introduction to Fuel Injection Systems, Fuel System Components, Distributor Type Injection Pump, In-Line Injection Pump, Unit Injector, Pressure Time (PT) Fuel Systems, Injection Nozzles, and Governors. (YLB) *********************************************************************** Reproductions supplied by EDRS are the best that can be made from the original document. *********************************************************************** DIESEL MECHANICS : FUEL SYSTEMS by William Foutes' revised by Bill Guynes Joe Mathis Marvin Kukuk Developed by the Mid-America Vocational Curriculum Consortium, Inc. -

Bulletin 173 Plate 1 Smithsonian Institution United States National Museum

U. S. NATIONAL MUSEUM BULLETIN 173 PLATE 1 SMITHSONIAN INSTITUTION UNITED STATES NATIONAL MUSEUM Bulletin 173 CATALOG OF THE MECHANICAL COLLECTIONS OF THE DIVISION OF ENGINEERING UNITED STATES NATIONAL MUSEUM BY FRANK A. TAYLOR UNITED STATES GOVERNMENT PRINTING OFFICE WASHINGTON : 1939 For lale by the Superintendent of Documents, Washington, D. C. Price 50 cents ADVERTISEMENT Tlie scientific publications of the National Museum include two series, known, respectively, as Proceedings and Bulletin. The Proceedings series, begun in 1878, is intended primarily as a medium for the publication of original papers, based on the collec- tions of the National Museum, that set forth newly acquired facts in biology, anthropology, and geology, with descriptions of new forms and revisions of limited groups. Copies of each paper, in pamphlet form, are distributed as published to libraries and scientific organi- zations and to specialists and others interested in the different sub- jects. The dates at which these separate papers are published are recorded in the table of contents of each of the volumes. Tlie series of Bulletins, the first of which was issued in 1875, contains separate publications comprising monographs of large zoological groups and other general systematic treatises (occasionally in several volumes), faunal works, reports of expeditions, catalogs of type specimens and special collections, and other material of simi- lar nature. The majority of the volumes are octavo in size, but a quarto size has been adopted in a few instances in which large plates were regarded as indispensable. In the Bulletin series appear vol- umes under the heading Contrihutions from the United States Na- tional Eerharium, in octavo form, published by the National Museum since 1902, which contain papers relating to the botanical collections of the Museum. -

Chapter One Introduction

Chapter One Introduction Feedback is a central feature of life. The process of feedback governs how we grow, respond to stress and challenge, and regulate factors such as body temperature, blood pressure and cholesterol level. The mechanisms operate at every level, from the interaction of proteins in cells to the interaction of organisms in complex ecologies. M. B. Hoagland and B. Dodson, The Way Life Works, 1995 [99]. In this chapter we provide an introduction to the basic concept of feedback and the related engineering discipline of control. We focus on both historical and current examples, with the intention of providing the context for current tools in feedback and control. Much of the material in this chapter is adapted from [155], and the authors gratefully acknowledge the contributions of Roger Brockett and Gunter Stein to portions of this chapter. 1.1 What Is Feedback? A dynamical system is a system whose behavior changes over time, often in response to external stimulation or forcing. The term feedback refers to a situation in which two (or more) dynamical systems are connected together such that each system influences the other and their dynamics are thus strongly coupled. Simple causal reasoning about a feedback system is difficult because the first system influences the second and the second system influences the first, leading to a circular argument. This makes reasoning based on cause and effect tricky, and it is necessary to analyze the system as a whole. A consequence of this is that the behavior of feedback systems is often counterintuitive, and it is therefore necessary to resort to formal methods to understand them. -

Electrowetting Using a Microfluidic Kelvin Water Dropper

micromachines Article Electrowetting Using a Microfluidic Kelvin Water Dropper Elias Yazdanshenas 1, Qiang Tang 1,2 and Xiaoyu Zhang 1,* 1 Department of Mechanical & Aerospace Engineering, Old Dominion University, Norfolk, VA 23529, USA; [email protected] (E.Y.); [email protected] (Q.T.) 2 State Key Lab of Mechanics and Control of Mechanical Structures, Nanjing University of Aeronautics & Astronautics, Nanjing, Jiangsu 210016, China * Correspondence: [email protected]; Tel.: +1-757-683-4913 Received: 16 December 2017; Accepted: 22 February 2018; Published: 25 February 2018 Abstract: The Kelvin water dropper is an electrostatic generator that can generate high voltage electricity through water dripping. A conventional Kelvin water dropper converts the gravitational potential energy of water into electricity. Due to its low current output, Kelvin water droppers can only be used in limited cases that demand high voltage. In the present study, microfluidic Kelvin water droppers (MKWDs) were built in house to demonstrate a low-cost but accurately controlled miniature device for high voltage generation. The performance of the MKWDs was characterized using different channel diameters and flow rates. The best performed MKWD was then used to conduct experiments of the electrowetting of liquid on dielectric surfaces. Electrowetting is a process that has been widely used in manipulating the wetting properties of a surface using an external electric field. Usually electrowetting requires an expensive DC power supply that outputs high voltage. However, in this research, it was demonstrated that electrowetting can be conducted by simply using an MKWD. Additionally, an analytic model was developed to simulate the electrowetting process. Finally, the model’s ability to well predict the liquid deformation during electrowetting using MKWDs was validated. -

Steam Engine Collection

STEAM ENGINE COLLECTION The New England Museum of Wireless And Steam Frenchtown Road ~ East Greenwich, R.I. International Mechanical Engineering Heritage Collection Designated September 12, 1992 The American Society of Mechanical Engineers INTRODUCTION It has been said that an operating steam engine is ‘visual music’. The New England Museum of Wireless and Steam provides the steam engine enthusiast, the mechanical engineer and the public at large with an opportunity to experience the ‘music’ when the engines are in steam. At the same time they can appreciate the engineering skills of those who designed the engines. The New England Museum of Wireless and Steam is unusual among museums in its focus on one aspect of mechanical engineering history, namely, the history of the steam engine. It is especially rich in engines manufactured in Rhode Island, a state which has had an influence on the history of the steam engine in the United States out of all proportion to its size and population. Many of the great names in the design and manufacture of steam engines received their training in Rhode Island, most particularly in the shops of the Corliss Steam Engine Co. in Providence. George H. Corliss, an important contributor to steam engine technology, founded his company in Providence in 1846. Engines that used his patent valve gear were built in large numbers by the Corliss company, and by others, both in the United States and abroad, either under license or in various modified forms once the Corliss patent expired in 1870. The New England Museum of Wireless and Steam is particularly fortunate in preserving an example of a Corliss engine built by the Corliss Steam Engine Company. -

Engine Reassembly and Break-In

This sample chapter is for review purposes only. Copyright © The Goodheart-Willcox Co., Inc. All rights reserved. CHAPTER 19 Engine Reassembly and Break-In Learning Objectives Key Terms After studying this chapter, you will be able to: assembly lube break-in • Summarize the steps in reassembling L-head bearing crush dampening coils and overhead valve engines. bearing spread • Explain how crankshafts and camshafts should be reinstalled. • Summarize the steps in reassembling a piston and rod assembly and installing rings. • Explain the purpose of ring end gap. • Describe methods of adjusting crankshaft endplay. • Summarize what happens during piston ring wear-in. Introduction Reinstalling Internal Engine After the engine has been disassembled and all Components the parts have been cleaned, inspected, and recon- ditioned as needed, the engine must be properly The steps followed to reassemble an engine are reassembled. Always reassemble the engine in a essentially the reverse of the steps used to disas- clean work area. If dirt or other abrasives get into semble it. Begin by making sure that all bearings the engine during reassembly, it can undo all of the or bushings are properly installed in the crankcase hard work that went into the engine rebuild. and crankcase cover. Next, install replacement oil Have all of the necessary repair parts, supplies, seals in the crankcase and crankcase cover. Apply and instructions handy and well organized. Read sealant around the outside of the shell of the seal through the manufacturer’s instructions for reas- before pressing it in place. Often, seals can be sembling the engine and be sure you understand replaced by tapping them into the bore with a seal them before beginning. -

Centrifugal Governors

UNIT V MECHANISMS FOR CONTROL Governors - Types - Centrifugal governors – Porter, Proel and Hartnell Governors – Characteristics –Sensitivity– Stability – Hunting – Isochronisms – equilibrium speed - Effect of friction - Controlling Force Introduction The function of a governor is to regulate the mean speed of an engine, when there are variations in the load e.g. when the load on an engine increases, its speed decreases, therefore it becomes necessary to increase the supply of working fluid. On the other hand, when the load on the engine decreases, its speed increases and thus less working fluid is required. The governor automatically controls the supply of working fluid to the engine with the varying load conditions and keeps the mean speed within certain limits. A little consideration will show, that when the load increases, the configuration of the governor changes and a valve is moved to increase the supply of the working fluid ; conversely, when the load decreases, the engine speed increases and the governor decreases the supply of working fluid. Types of Governors The governors may, broadly, be classified as 1. Centrifugal governors, 2. Inertia governors. Centrifugal Governors The centrifugal governors are based on the balancing of centrifugal force on the rotating balls by an equal and opposite radial force, known as the controlling force*.It consists of two balls of equal mass, which are attached to the arms as shown in Fig. 1. These balls are known as governor balls or fly balls. The balls revolve with a spindle, which is driven by the engine through bevel gears. The upper ends of the arms are pivoted to the spindle, so that the balls may rise up or fall down as they revolve about the vertical axis. -

DOCUMENT RESUME TITLE Basic Principles of Marine Diesel.Engines, 8-2. Military Curriculum Materials for Vocational and Technical

DOCUMENT RESUME ED 223 901 CE 034 541 TITLE Basic Principles of Marine Diesel.Engines, 8-2. Military Curriculum Materials for Vocational and Technical Education. INSTITUTION Army Transportation School, Fort Eustic, VA.;Ohio State Univ., Columbus. National Center for Research in Vocational Edudation. SPONS AGENCY Office of Education (DHEW), Washington, D.C. PUB DATE 78 NOTE 110p. PUB TYPE Guides - Classroom Use Materials (For Learner) (051) EDRS PRICE MF01/PC05 Plus Postage. DESCRIPTORS Behavioral Objectives; *Diesel Engines; Individualized Instruction; Learning Activities; *Mechanics (Process); Pacing; Postsecondary Education; Secondary Education; Tests; Textbooks; *Trade and Industrial Education IDENTIFIERS *Marine Equipment; Military Curriculum Project ABSTRACT This volume of student materials for a secondary/postsecondary level course in principles of marine diesel engines is,one of a number of.military-developed curriculumpackages selected for adaptation to vocational instruction andcurriculum development in a civilian setting. The purpose of theindividualized, self-paced course is to acquaint students with theoperating cycles and systems that make ,up a diesel engine. Itprovides theory that is useful in laboratory and on-the-job learningexperiences. The course is divided into two lessons: Diesel EngineConstruction, Principles, and Structural Parts; and Valve Gear, FuelInjection, and Governors. These materials are included: the reference text,"Basic Principles of Marine Diesel Engines" (five chapters and anappended glossary); and -

Tom & Measurement Lab Manual

Tom & Measurement Lab Manual 4th Sem Mech engg Lab manual ON THEORY OF MACHINE & MEASUREMENT LAB For 4TH SEM MECHANICAL ENGG (SCTE&VT SYLLABUS) Prepared by Dr Niharika Mohanta Lecturer Mechanical Engg OSME KEONJHAR 1 Prepared by Dr Niharika Mohanta OSME Keonjhar Tom & Measurement Lab Manual 4th Sem Mech engg INDEX Exp. Date Experiment Name Page Remark no no 1 To Determine the centrifugal force of watt/Porter/ Proell 3 /hartnell Governor 2 Study & demonstration of static balancing apparatus 10 3 To determine the pressure distribution of lubricating oil at 12 various load and speed of a Journal Bearing 4 Study of different types of Cam and followers 19 5 Study & demonstration of epicyclic gear train 22 6 24 Determination of the thickness of ground M.S flat to an accuracy of 0.02mm using Vernier Caliper 7 28 Determination of diameter of a cylindrical component to an accuracy of 0.01mm using micrometer 8 Determine the heights of gauge blocks or parallel bars to 30 accuracy of 0.02mm using Vernier height gauge 9 Determination the thickness of M.S. Plates using slip 33 gauges. 10 Determination of angel of Machined surfaces of 35 components using sin bar with slip gauge 2 Prepared by Dr Niharika Mohanta OSME Keonjhar Tom & Measurement Lab Manual 4th Sem Mech engg EXPERIMENT NO: 01 GOVERNOR AIM: To Determine the centrifugal force of watt/Porter/ Proell /hartnell Governor THEORY: The function of a governor is to regulate the mean speed of an engine, when there are variations in the load e.g. when the load on an engine increases, its speed decreases, therefore it becomes necessary to increase the supply of working fluid.