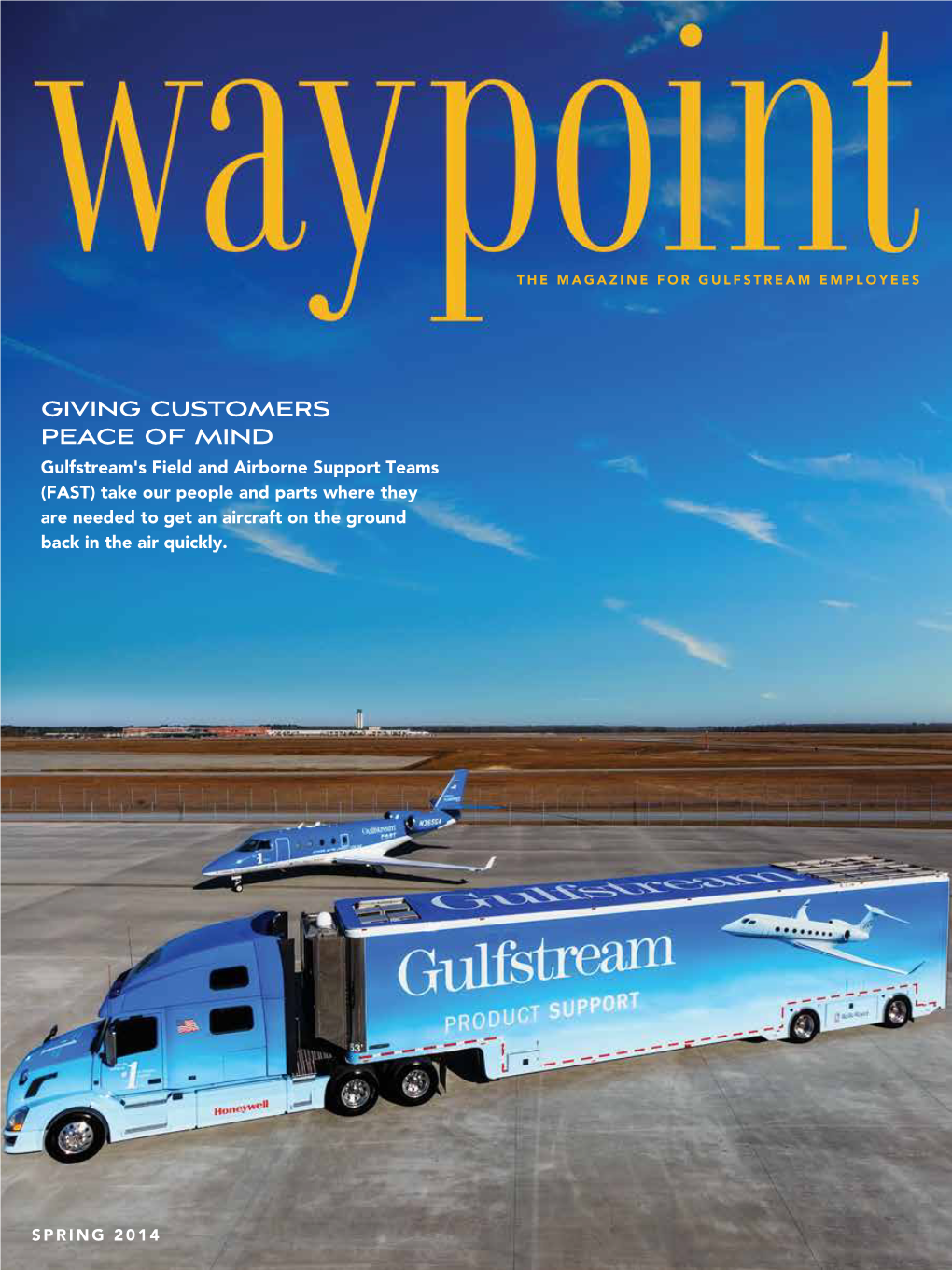

Giving Customers Peace of Mind

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Repair Capabilities List

Repair Capabilities List Eaton P/N Customer P/N Nomenclature Aircraft Usage Repair Capabilities Comments 100000-14 N/A Linear Actuator Lockheed C-130 Yes 100000-29 N/A Actuator Embraer EMB120 Yes 100000-60 N/A Linear Actuator Fokker F28 MK0070; F28 MK0100 Yes 100000-77 2045352 Actuator, Embraer EMB-500 Yes Electromechanical Linear 100100-1 030A-989504-1 Actuator Aileron Mitsubishi MU-2B, -26A, -36A, -40, -60 Yes 102000-1 N/A Actuator Landing Mooney M20 Yes Gear Assembly 102000-2 N/A Actuator, Landing Mooney M20 Yes Gear Wednesday, February 13, 2013 Page 1 of 43 Eaton P/N Customer P/N Nomenclature Aircraft Usage Repair Capabilities Comments 102000-3 560254-503 Actuator Landing Mooney M20 Yes Gear Assembly 102000-4 560254-505 Actuator, Landing Mooney M20 Yes Gear 102000-7 560254-507 Actuator, Landing Mooney M20 Yes Gear 102000-9 N/A Linear Actuator N/A Yes 102000-10 N/A Actuator Assembly, Mooney M20 Yes Linear 102000-12 N/A Actuator Assembly, N/A Yes Main Landing Gear 102000-13 N/A Actuator, Landing Mooney Yes Gear Assembly 104500-1 N/A Linear Actuator Gulfstream Yes Wednesday, February 13, 2013 Page 2 of 43 Eaton P/N Customer P/N Nomenclature Aircraft Usage Repair Capabilities Comments 104500-2 N/A Linear Actuator Gulfstream Yes 105900-2 159SCC100-23 Trim Control Linear Gulfstream GIII, GIV, and GV Yes Actuator 114000-1 N/A Actuator, Rotary Cessna Citation Yes Approved through Direct Shipment Authorization - Expires 9/14/13 114000-3 N/A Actuator, Rotary Cessna Citation Yes 116900-2 N/A Linear Actuator Fokker F27 MK050 Yes 116900-3 N/A Door -

Gulfstream's History

BACKGROUNDER The Gulfstream Fleet Gulfstream’s comprehensive product line offers an exceptional combination of safety, comfort, performance and value in each segment of the mid- to ultra-large-cabin business-jet market. The Gulfstream G650 and G650ER have the largest purpose-built business-jet cabins, offering passengers wider seats, more aisle room, 16 panoramic windows and the lowest cabin altitude of any business jet. The cabins also feature the quietest cabin sound levels, 100 percent fresh air and in-flight connectivity. Both aircraft can accommodate passengers and crew in conference, dining and entertainment areas with sleeping for up to 10. The G650ER, the company’s flagship, is the world’s longest-range business jet and provides outstanding mission flexibility. On one of its earliest flights, the aircraft flew nonstop from Los Angeles International Airport to Tullamarine Airport in Melbourne, Australia, in just under 15 hours at an average speed of Mach 0.86. The G650 and the G650ER combined hold more than 60 city-pair records and can both traverse the world in practically one stop. Current G650 owners and order-holders can upgrade their aircraft to a G650ER. Powered by Rolls-Royce engines, the G650 and G650ER travel at speeds up to Mach 0.925, more than nine-tenths the speed of sound, and can fly far above airline-traffic congestion and adverse weather, resulting in smoother flights and fewer delays. The aircraft feature the most technologically advanced PlaneViewTM II flight deck with intuitive systems that ease pilots’ workload and enhance safety. In 2015, the G650 was awarded the 2014 Robert J. -

Investor Day Presentation

Meggitt Investor Day Stephen Young, Chief Executive 19 April 2016 Disclaimer This presentation is not for release, publication or distribution, directly or This presentation includes statements that are, or may be deemed to be, indirectly, in or into any jurisdiction in which such publication or distribution is “forward-looking statements”. These forward-looking statements can be unlawful. identified by the use of forward-looking terminology, including the terms This presentation is for information only and shall not constitute an offer or “anticipates”, “believes”, “estimates”, “expects”, “aims”, “continues”, “intends”, solicitation of an offer to buy or sell securities, nor shall there be any sale or “may”, “plans”, “considers”, “projects”, “should” or “will”, or, in each case, their purchase of securities in any jurisdiction in which such offer, solicitation or sale negative or other variations or comparable terminology, or by discussions of would be unlawful prior to registration or qualification under the securities laws of strategy, plans, objectives, goals, future events or intentions. These forward- any such jurisdiction. It is solely for use at an investor presentation and is looking statements include all matters that are not historical facts. By their provided as information only. This presentation does not contain all of the nature, forward-looking statements involve risk and uncertainty, because they information that is material to an investor. By attending the presentation or by relate to future events and circumstances. Forward-looking statements may, reading the presentation slides you agree to be bound as follows:- and often do, differ materially from actual results. This presentation has been organised by Meggitt PLC (the “Company”) in order In relation to information about the price at which securities in the Company to provide general information on the Company. -

Corporate Aviation

FT SPECIAL REPORT Corporate Aviation Tuesday November 17 2015 www.ft.com/reports | @ftreports Inside Helicopters: need for Industry outlook remains cloudy speed is overtaken Manufacturers should be used to ups and Manufacturers’ “There’s still an intra-continental requirementforsomeusers,”MrAnder- downs conflicting messages son says. “North American users who Page 2 reflect mixed fortunes, still have local requirements can very well utilise the midsize and light jet air- Embraer reports Robert Wright craft.” How the Brazilian The smallest light-jet segment, which wasonceexpectedtoboomasaseriesof aircraft maker turned a or anyone seeking to under- manufacturers launched very cheap dream into reality stand the state of the business models, looks set to remain a modest Page 3 jet market, the three weeks at part of the market. JetCraft says very the end of April and start of light, light and superlight jets will F Maywereaconfusingtime. account for only $25bn of the $271bn On April 29, Phebe Novakovic, chief revenuethatitprojectstheindustrywill executive of General Dynamics, earnfromnewjetsuptotheendof2024. expressed cautious but unmistakable Alain Bellemare, Bombardier’s chief optimism about prospects for the US executive, cited the “very soft” market aerospace and defence company’s Gulf- for smaller jets as the reason for cancel- streambusinessjetoperationasshedis- ling the midsize Learjet 85 programme cusseditsfirst-quarterresults. altogether,after the project was initially “We always pull production down in putonholdinJanuary. Large-cabin -

November 2020 Vol

BUSINESS & COMMERCIAL AVIATION OPERATORS SURVEY GULFSTREAM G500 AIREON IN SERVICE ADJUSTING APPROAC NOVEMBER 2020 $10.00 AviationWeek.com/BCA Business & Commercial Aviation OPERATORS SURVEY Gulfstream G500 A step change in aircraft design H SPEED NOVEMBER 2020 VOL. 116 NO. 10 H SPEED NOVEMBER 2020 VOL. 116 NO. ALSO IN THIS ISSUE Aireon in Service Winter Ground Ops Adjusting Approach Speed Flying Petri Dish C&C: Stop. Look. Think. Digital Edition Copyright Notice The content contained in this digital edition (“Digital Material”), as well as its selection and arrangement, is owned by Informa. and its affiliated companies, licensors, and suppliers, and is protected by their respective copyright, trademark and other proprietary rights. Upon payment of the subscription price, if applicable, you are hereby authorized to view, download, copy, and print Digital Material solely for your own personal, non-commercial use, provided that by doing any of the foregoing, you acknowledge that (i) you do not and will not acquire any ownership rights of any kind in the Digital Material or any portion thereof, (ii) you must preserve all copyright and other proprietary notices included in any downloaded Digital Material, and (iii) you must comply in all respects with the use restrictions set forth below and in the Informa Privacy Policy and the Informa Terms of Use (the “Use Restrictions”), each of which is hereby incorporated by reference. Any use not in accordance with, and any failure to comply fully with, the Use Restrictions is expressly prohibited by law, and may result in severe civil and criminal penalties. Violators will be prosecuted to the maximum possible extent. -

Technical Bulletins

Technical Bulletins Gulfstream Aerospace Corporation Report Created On: 30 Mar 2020 G650 N47TR S/N: 6101 Regulation: PART 91.409(F)(3) Phone: +1-912-298-1304 Airworthiness Date: 13 Aug 2014 Fax: 1-912-963-0265/1-800-944-1775 Analyst: Richard Rayburn Projected Through Airframe & Component Times Total Time Logbook Position Description Serial No. Log Date Hours Cycles Hours Cycles GULFSTREAM AEROSPACE CORPORATION Airframe 6101 13 Mar 2020 1240.5 504 G650 ROLLS-ROYCE DERBY PLC BR725A1-12 Engine 1 25317 13 Mar 2020 1240.5 504 (G650) ROLLS-ROYCE DERBY PLC BR725A1-12 Engine 2 25316 13 Mar 2020 1240.5 504 (G650) APU HONEYWELL RE220 (G650) P-209 07 Jan 2020 1257.5 0 TYP C/W Source Code Description Effectivity ATA Status Logbook Work Order HRS LDG Date C/I MM REF M HRS Maintenance Notes CSB 016 G650 GULFSTREAM CABIN 34 N/A 1082.3 436 24-May-2019 C AIRFRAME MANAGEMENT SYSTEM (GCMS 2) FIRMWARE UPDATE CSB 016 (CE-CSB-6016) # 3202908- HONEYWELL SB 3202908-36- 36 C/W SAVANNAH - 529.6 192 15-Aug-2016 C 36-1912 1912 - REWORK RIGHT FOUR- GR4R216M AIRFRAME INCH DIAMETER CHECK VALVE, PN 3202908-1 TO PN 3202908-2, USED ON THE GULFSTREAM G650. SB 3202908- HONEYWELL SB 3202908-36- 36 C/W SAVANNAH - 529.6 192 15-Aug-2016 C - - 36-1912 1912 - REWORK LEFT FOUR- GR4R216M - - AIRFRAME INCH DIAMETER CHECK VALVE, PN 3202908-1 TO PN 3202908-2, USED ON THE GULFSTREAM G650. SB 49-7933 APU - SB 49-7933R5 APU 49 N/A 0 29-Jan-2016 C - - APU R05 APPROVED OILS THIS CODE HAS BEEN CANCELLED. -

ICAO Version Finale

Thales Presentation > ICAO NGAP Symposium March 2010 Francis ARCHAMBAULT – Director, Marketing and Product Policy Benoît THUBERT – Advance Project Design Authority Aerospace Agenda THALES Avionics system development in recent History AIRBUS, BOMBARDIER, GULFSTREAM, ATR, EMBRAER, SUKHOI Interactive Cockpit Display Systems, Flight Management Systems, Integrated Modular Avionics, Electronic Flight Controls Computers, Head-Up Displays, Enhanced Vision Systems, IFE. THALES Innovation NEW TECHNOLOGIES Flight Deck Innovation Strategy, Global Environment – Thales actions & major Industry initiatives, R&D and emerging technologies – some considerations, Avionics evolving Business Model, New generation of flight crew & new approach to develop flight deck, Competency and training methods, Bridging the gap between pilots and systems, New interaction languages, Helping pilots to handle complexity. March 2010 March THALES Training Technologies 2 This document is the property of Thales Group and may not be copi ed or communicated without written consent of Thales > Thales Recent Avionics developments Aerospace Thales - intelligence onboard Connectivity - SATCOM Integrated Modular Avionics Cockpit Display + HUD + EVS Electrical Power Flight Guidance Generation / Conversion Flight Management Communication, Navigation, Surveillance Flight Controls Utilities: Braking Steering Fuel Engine Controls In-Flight Entertainment Systems Doors & Slides Cabin lighting March 2010 March Integrated Maintenance Cabin interiors floor to floor 4 This document -

SIRS High Technology Participants

2012 US Mercer SIRS® Benchmark Survey – High Technology Industry Participant List High Technology – Aerospace and Defense Develops, delivers, and supports advanced integrated aerospace and defense systems and products. Aerojet Sacramento L3 Communications – Electrodynamics, Inc. Alliant Techsystems Inc. L3 Communications – ESSCO AIRINC Incorporated L3 Communications – Fuzing & Ordnance Systems B&W Y–12, LLC L3 Communications – Integrated Systems B/E Aerospace L3 Communications – Link Simulation & Training BAE Systems, Inc. L3 Communications – Linkabit Ball Corporation – Aerospace & Technologies Corp. L3 Communications – Ocean Systems Boeing Defense, Space and Security L3 Communications – PHOTONICS Cobham North America L3 Communications – Power Paragon, Inc. Corsair Engineering L3 Communications – Space and Navigation DRS Technologies L3 Communications – Telemetry West Eclipse Aerospace L3 Communications – Unmanned Systems Federal Aviation Administration L3 Communications – Westwood Corporation General Dynamics Corporation L3 Communications Corporation GKN Aerospace North America Division L3 Communications, Wescam Sonoma Operations Goodrich ISR Systems Lockheed Martin Honeywell Lockheed Martin – Space Systems INSITU, INC. MDA Information Systems, Inc L3 Communications – Aerospace Electronics Moog Inc. L3 Communications – Applied Signal & National Security Technologies, LLC Image Technology Nordam Group, The L3 Communications – Applied Technologies Northrop Grumman Corporation Pulse Sciences Northrop Grumman Corporation – Enterprise Shared -

Fly-By-Wire: Getting Started on the Right Foot and Staying There…

Fly-by-Wire: Getting started on the right foot and staying there… Imagine yourself getting into the cockpit of an aircraft, finishing your preflight checks, and taxiing out to the runway ready for takeoff. You begin the takeoff roll and start to rotate. As you lift off, you discover your side stick controller is not responding correctly to your commands. Panic sets in, and you feel that you’ve lost total control of the aircraft. Thanks to quick action from your second in command, he takes over and stabilizes the aircraft so that you both can plan to return to the airport under reversionary mode. This situation could have been a catastrophe. This happened in August of 2001. A Lufthansa Airbus A320 came within less than two feet and a few seconds of crashing during takeoff on a planned flight from Frankfurt to Paris. Preliminary reports indicated that maintenance was performed on the captain’s sidestick controller immediately before the incident. This had inadvertently created a situation in which control inputs were reversed. The case reveals that at least two "filters," or safety defenses, were breached, leading to a near-crash shortly after rotation at Frankfurt’s Runway 18. Quick action by the first officer prevented a catastrophe. Lufthansa Technik personnel found a damaged pin on one segment of the four connector segments (with 140 pins on each) at the "rack side," as it were, of the avionics mount. This incident prompted an article to be published in the 2003 November-December issue of the Flight Safety Mechanics Bulletin. The report detailed all that transpired during the maintenance and subsequent release of the aircraft. -

INTRODUCING the ALL-NEW GULFSTREAM G500 and G600 When You Start with a Clean Sheet, the Opportunities Are Boundless

THE MAGAZINE FOR GULFSTREAM EMPLOYEES INTRODUCING THE ALL-NEW GULFSTREAM G500 AND G600 When you start with a clean sheet, the opportunities are boundless. Gulfstream and its employees celebrate the next generation of aircraft – the G500 and G600. SPECIAL ISSUE | JANUARY 2015 the president’s JANUARY 2015 SPECIAL ISSUE corner Waypoint is published for employees of Gulfstream Aerospace Corporation. The magazine’s mission is to LARRY FLYNN inform and entertain; to bring together people from our many sites, teams, disciplines and interests; and to instill a sense of company pride. It also seeks to provide thoughtful, in-depth articles on GULFSTREAM IS our company’s people, programs and initiatives PHOTO: KATHY ALMAND in an effort to strengthen our common bond BOUNDLESS and adhere to our corporate vision. Since Grumman introduced the Gulfstream I VICE PRESIDENT TECHNICAL MARKETING & in 1958, Gulfstream has grown its reputation COMMUNICATIONS Steve Cass through a history of industry firsts, record-set- EDITORIAL DIRECTOR ting aircraft, technological innovations, global Philip Hanyok service and support initiatives and an expand- EDITOR Laura Wentz ing worldwide customer base. Oct. 14, 2014, PHOTOGRAPHY EDITORS was yet another extraordinary day in our sto- Matthew Stephan Beth Getman ried history. PHOTOGRAPHY On that day, we ushered in a new era for Kathy Almand Paul Bowen Gulfstream by introducing the all-new G500 and G600, helping us further our vision John Dibbs Lori Dynan to create and deliver the world’s finest aviation experience. Stephanie Lipscomb These clean-sheet aircraft reflect an optimal combination of form, function and Josh Triplett efficiency, with wide cabins, advanced-technology flight decks and high-speed perfor- GRAPHIC DESIGN Chic Graphic Design mance. -

(Exact Name of Registrant As Specified in Its Charter) Delaware 13

U NITED STATES SECURITIES AND EXCHANGE COMMISSION Washington, D.C. 20549 FORM 10-K (Mark One) [X] ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 For the fiscal year ended December 31, 2018 OR [ ] TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 For the transition period from _______ to _______ Commission File Number 1-3671 GENERAL DYNAMICS CORPORATION (Exact name of registrant as specified in its charter) Delaware 13-1673581 State or other jurisdiction of incorporation or organization IRS Employer Identification No. 2941 Fairview Park Drive, Suite 100 Falls Church, Virginia 22042-4513 Address of principal executive offices Zip code Registrant’s telephone number, including area code: (703) 876-3000 Securities registered pursuant to Section 12(b) of the Act: Title of each class Name of exchange on which registered Common stock, par value $1 per share New York Stock Exchange Securities registered pursuant to Section 12(g) of the Act: None Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ü No ___ Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ___ No ü Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. -

Service Center Full Capabilities List

AMETEK Part Number OEM Number Description Platforms Location Contact Number 182936 10-60735-1 OXYGEN PRESSURE INDICATOR BOEING 727 / 737 Binghamton, NY 607-763-4708 182972 10-60735-2 OXYGEN PRESSURE INDICATOR BOEING 727/737/747/757/777/P-8 Binghamton, NY 607-763-4708 253884 10-60775-6 SURFACE POSITION INDICATOR BOEING 737 Binghamton, NY 607-763-4708 260456 N/A DC VOLTMETER INDICATOR NOT IDENTIFIED Binghamton, NY 607-763-4708 260457 N/A DC AMMETER NOT IDENTIFIED Binghamton, NY 607-763-4708 260461 60B00120-1 OXYGEN PRESSURE INDICATOR BOEING 747-100,-200,-300 Binghamton, NY 607-763-4708 260516 60B00120-2 DUAL OXYGEN PRESSURE INDICATOR BOEING 747-400 Binghamton, NY 607-763-4708 260519 60B92012-1 FUEL TEMPERATURE INDICATOR BOEING B747/B767 Binghamton, NY 607-763-4708 520445 671788-101 ENGINE VIBRATION MONITOR UNIT LOCKHEED L1011 Binghamton, NY 607-763-4708 520467 60B00108-7 COMP DUCT TEMPERATURE INDICATOR BOEING 747 Binghamton, NY 607-763-4708 520487 60B00126-4 APU TACHOMETER INDICATOR BOEING 747-100,-200,-300 Binghamton, NY 607-763-4708 520549 672449-101 AIR TURBINE TACHOMETER INDICATOR LOCKHEED Binghamton, NY 607-763-4708 520616 01-3621-9-0001 PNEUMATIC PRESSURE INDICATOR MCDONNELL DOUGLAS DC10 Binghamton, NY 607-763-4708 520690 672490-101 RAM AIR INDICATOR LOCKHEED L1011 Binghamton, NY 607-763-4708 521314 60B00117-5 CSD OIL TEMPERATURE INDICATOR BOEING 747 Binghamton, NY 607-763-4708 521394 5940-00-901-8270 COMPARTMENT TEMPERATURE INDICATOR E-3/E-6/E-8 Binghamton, NY 607-763-4708 521396 60B00108-10 SUPPLY AIR TEMPERATURE INDICATOR E-3/E-6/E-8