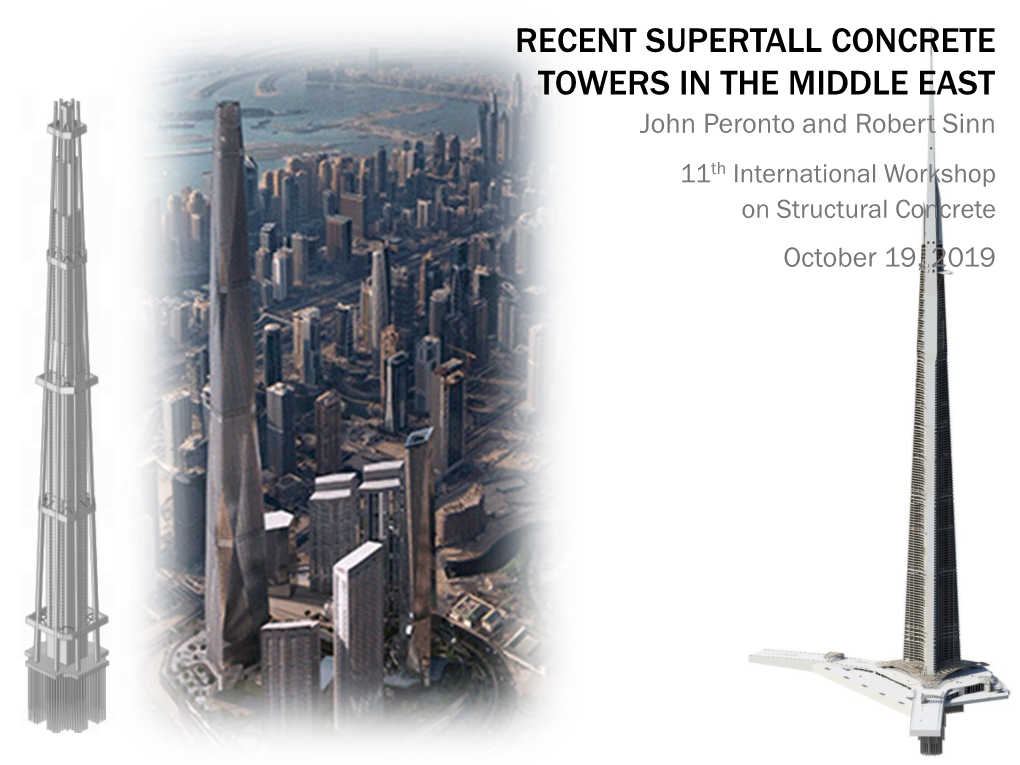

Recent Supertall Concrete Towers in the Middle East

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

CTBUH Journal

About the Council The Council on Tall Buildings and Urban Habitat, based at the Illinois Institute of Technology in CTBUH Journal Chicago and with a China offi ce at Tongji International Journal on Tall Buildings and Urban Habitat University in Shanghai, is an international not-for-profi t organization supported by architecture, engineering, planning, development, and construction professionals. Founded in 1969, the Council’s mission is to disseminate multi- Tall buildings: design, construction, and operation | 2014 Issue IV disciplinary information on tall buildings and sustainable urban environments, to maximize the international interaction of professionals involved Case Study: One Central Park, Sydney in creating the built environment, and to make the latest knowledge available to professionals in High-Rise Housing: The Singapore Experience a useful form. The Emergence of Asian Supertalls The CTBUH disseminates its fi ndings, and facilitates business exchange, through: the Achieving Six Stars in Sydney publication of books, monographs, proceedings, and reports; the organization of world congresses, Ethical Implications of international, regional, and specialty conferences The Skyscraper Race and workshops; the maintaining of an extensive website and tall building databases of built, under Tall Buildings in Numbers: construction, and proposed buildings; the Unfi nished Projects distribution of a monthly international tall building e-newsletter; the maintaining of an Talking Tall: Ben van Berkel international resource center; the bestowing of annual awards for design and construction excellence and individual lifetime achievement; the management of special task forces/working groups; the hosting of technical forums; and the publication of the CTBUH Journal, a professional journal containing refereed papers written by researchers, scholars, and practicing professionals. -

JAKO201834663385082.Pdf

International Journal of High-Rise Buildings International Journal of September 2018, Vol 7, No 3, 197-214 High-Rise Buildings https://doi.org/10.21022/IJHRB.2018.7.3.197 www.ctbuh-korea.org/ijhrb/index.php Developments of Structural Systems Toward Mile-High Towers Kyoung Sun Moon† Yale University School of Architecture, 180 York Street, New Haven, CT 06511, USA Abstract Tall buildings which began from about 40 m tall office towers in the late 19th century have evolved into mixed-use megatall towers over 800 m. It is expected that even mile-high towers will soon no longer be a dream. Structural systems have always been one of the most fundamental technologies for the dramatic developments of tall buildings. This paper presents structural systems employed for the world’s tallest buildings of different periods since the emergence of supertall buildings in the early 1930s. Further, structural systems used for today’s extremely tall buildings over 500 m, such as core-outrigger, braced mega- tube, mixed, and buttressed core systems, are reviewed and their performances are studied. Finally, this paper investigates the potential of superframed conjoined towers as a viable structural and architectural solution for mile-high and even taller towers in the future. Keywords: Tall buildings, Tallest buildings, Core-outrigger systems, Braced megatubes, Mixed systems, Buttressed core systems, Superframed conjoined towers, Mile-high towers 1. Introduction and the height race was culminated with the 381 m tall 102-story Empire State Building of 1931 also in New York. Tall buildings emerged in the late 19th century in New Due to the Great Depression and Second World War, dev- York and Chicago. -

Read Book Skyscrapers: a History of the Worlds Most Extraordinary

SKYSCRAPERS: A HISTORY OF THE WORLDS MOST EXTRAORDINARY BUILDINGS PDF, EPUB, EBOOK Judith Dupre, Adrian Smith | 176 pages | 05 Nov 2013 | Black Dog & Leventhal Publishers Inc | 9781579129422 | English | New York, United States Skyscrapers: A History of the Worlds Most Extraordinary Buildings PDF Book By crossing the boundaries of strict geometry and modern technologies in architecture, he came up with a masterpiece that has more than a twist in its tail. Item added to your basket. Sophia McCutchen rated it it was amazing Nov 27, The lowest-priced brand-new, unused, unopened, undamaged item in its original packaging where packaging is applicable. Standing meters high and weighing half a million tons, Burj Khalifa towers above its city like a giant redwood in a field of daisies. The observation deck on the 43rd floor offers stunning views of Central, one of Hong Kong's busiest districts. It was the tallest of all buildings in the European Union until London's The Shard bumped it to second in The Shard did it, slicing up the skyline and the record books with its meter height overtaking the Commerzbank Headquarters in Frankfurt by nine meters, to become the highest building in the European Union. That it came about due to auto mogul Walter P. Marina Bay Sands , 10 Bayfront Ave. Heather Tribe rated it it was amazing Dec 01, Standing 1, feet tall, the building was one of the first to use new advanced structural engineering that could withstand typhoon winds as well as earthquakes ranging up to a seven on the Richter scale. Construction — mainly using concrete and stone — began around 72AD and finished in 80AD. -

Entuitive Tall Buildings

TALL BUILDINGS HIGH PERFORMANCE ENTUITIVE IS COLLABORATING WITH DEVELOPERS, ARCHITECTS AND BUILDERS TO DESIGN AND ENGINEER HIGH PERFORMANCE TALL BUILDINGS THAT ARE DEFINING CITY SKYLINES Urban centres around the globe are experiencing unprecedented growth. With limited land resources, cities are increasingly building towers – both for commercial and residential developments. Entuitive’s Tall Buildings team consists of structural engineers, building envelope specialists and technologists with decades of experience in delivering high-rise buildings through innovative and value driven solutions. DELIVERING VALUE It’s our ambition to help clients realize the best performing buildings that support their vision and commercial objectives. Through a holistic, integrated and highly collaborative approach, we draw on the wide-range of expertise wielded by Entuitive’s professionals to develop advanced structural and envelope solutions that deliver multiple dimensions of building performance with greater life-cycle economies. OPTIMIZING PERFORMANCE With extensive experience in tall buildings, deep knowledge of the latest building materials and construction methods, and sophisticated modeling techniques, our engineers and building envelope specialists focusing on solutions that enhance building performance. We strive to deliver a high degree of occupant comfort by mitigating the effects of wind-induced vibration. Our designs consider building resilience to natural and man-made events including seismic, extreme weather and blast. And we consistently optimize our structural and envelope solutions with an eye to improving efficiency at every stage while minimizing costs. AN ADVANCED APPROACH We use BIM and the latest technologies to enhance collaboration and coordination in order to deliver projects on-time and on- budget. We also go beyond BIM and utilize computational design and parametric modelling to assist architects in unleashing their creativity while optimizing the building structure – affording greater constructability, cost-savings and reduced time to market. -

Structural Developments in Tall Buildings: Current Trends and Future Prospects

© 2007 University of Sydney. All rights reserved. Architectural Science Review www.arch.usyd.edu.au/asr Volume 50.3, pp 205-223 Invited Review Paper Structural Developments in Tall Buildings: Current Trends and Future Prospects Mir M. Ali† and Kyoung Sun Moon Structures Division, School of Architecture, University of Illinois at Urbana-Champaign, Champaign, IL 61820, USA †Corresponding Author: Tel: + 1 217 333 1330; Fax: +1 217 244 2900; E-mail: [email protected] Received 8 May; accepted 13 June 2007 Abstract: Tall building developments have been rapidly increasing worldwide. This paper reviews the evolution of tall building’s structural systems and the technological driving force behind tall building developments. For the primary structural systems, a new classification – interior structures and exterior structures – is presented. While most representative structural systems for tall buildings are discussed, the emphasis in this review paper is on current trends such as outrigger systems and diagrid structures. Auxiliary damping systems controlling building motion are also discussed. Further, contemporary “out-of-the-box” architectural design trends, such as aerodynamic and twisted forms, which directly or indirectly affect the structural performance of tall buildings, are reviewed. Finally, the future of structural developments in tall buildings is envisioned briefly. Keywords: Aerodynamics, Building forms, Damping systems, Diagrid structures, Exterior structures, Interior structures, Outrigger systems, Structural performance, Structural systems, Tall buildings Introduction Tall buildings emerged in the late nineteenth century in revolution – the steel skeletal structure – as well as consequent the United States of America. They constituted a so-called glass curtain wall systems, which occurred in Chicago, has led to “American Building Type,” meaning that most important tall the present state-of-the-art skyscraper. -

Jeddah Tower for Web.Indd

Jeddah Tower Jeddah, Saudi Arabia Jeddah Tower Jeddah, Saudi Arabia At over 1,000 meters (3,280 feet) and a total construction area of 530,000 square meters (5.7 million square feet), Jeddah Tower— formerly known as Kingdom Tower—will be the centerpiece and first construction phase of the $20 billion Kingdom City development in Jeddah, Saudi Arabia, near the Red Sea. SERVICES Expected to cost $1.2 billion to construct, Jeddah Tower will be a mixed-use building featuring a luxury hotel, office Architecture space, serviced apartments, luxury condominiums and the world’s highest observatory. Jeddah Tower’s height will be Interior Design at least 173 meters (568 feet) taller than Burj Khalifa, which was designed by Adrian Smith while at Skidmore, Owings Master Planning & Merrill. CLIENT AS+GG’s design for Jeddah Tower is both highly technological and distinctly organic. With its slender, subtly Jeddah Economic Company asymmetrical massing, the tower evokes a bundle of leaves shooting up from the ground—a burst of new life that FUNCTION heralds more growth all around it. This symbolizes the tower as a catalyst for increased development around it. Mixed use The sleek, streamlined form of the tower can be interpreted as a reference to the folded fronds of young desert plant FACTS growth. The way the fronds sprout upward from the ground as a single form, then start separating from each other at 1,000+ m height the top, is an analogy of new growth fused with technology. 530,000 sm area While the design is contextual to Saudi Arabia, it also represents an evolution and a refinement of an architectural continuum of skyscraper design. -

Structural Design Challenges of Shanghai Tower

Structural Design Challenges of Shanghai Tower Author: Yi Zhu Affiliation: American Society of Social Engineers Street Address: 398 Han Kou Road, Hang Sheng Building City: Shanghai State/County: Zip/Postal Code: 200001 Country: People’s Republic of China Email Address: [email protected] Fax: 1.917.661.7801 Telephone: 011.86.21.6057.0902 Website: http://www.thorntontomasetti.com Author: Dennis Poon Affiliation: Council on Tall Buildings and Urban Habitat Street Address: 51 Madison Avenue City: New York State/County: NY Zip/Postal Code: 10010 Country: United States of America Email Address: [email protected] Fax: 1.917.661.7801 Telephone: 1.917.661.7800 Website: http://www.thorntontomasetti.com Author: Emmanuel E. Velivasakis Affiliation: American Society of Civil Engineers Street Address: 51 Madison Avenue City: New York State/County: NY Zip/Postal Code: 10010 Country: Unites States of America Email Address: [email protected] Fax: +1.917.661.7801 Telephone: +1.917.661.8072 Website: http://www.thorntontomasetti.com Author: Steve Zuo Affiliation: American Institute of Steel Construction; Structural Engineers Association of New York; American Society of Civil Engineers Street Address: 51 Madison Avenue City: New York State/County: NY Zip/Postal Code: 10010 Country: United States of America Email Address: [email protected] Fax: 1.917.661.7801 Telephone: 1.917.661.7800 Website: http://www.thorntontomasetti.com/ Author: Paul Fu Affiliation: Street Address: 51 Madison Avenue City: New York State/County: NY Zip/Postal Code: 10010 Country: United States of America Email Address: [email protected] Fax: 1.917.661.7801 Telephone: 1.917.661.7800 Website: http://www.thorntontomasetti.com/ Author Bios Yi Zhu, Senior Principal of Thornton Tomasetti, has extensive experience internationally in the structural analysis, design and review of a variety of building types, including high-rise buildings and mixed-use complexes, in both steel and concrete. -

MEETING AGENDA High Rise Building Safety Advisory Committee

MEETING AGENDA High Rise Building Safety Advisory Committee Teleconference/Web Meeting October 9, 2014 1. Call to Order. Call the meeting to order by Chair, Jim Quiter, at 1:00 pm EDT on Thursday, October 9, 2014. 2. Introduction of Attendees. For a current committee roster. See pg. 02. 3. Review of Agenda. 4. Approval of Minutes. Approve the minutes of the 2014 May 13-14 meeting. See pg. 03. 5. Status of NFPA 1/101/5000 and next revision schedule. 6. Residential EAP Guide. 7. Update on standard for professional practices for facility fire safety planning and fire safety directors. 8. Future HRBSAC Action Items and Updates. 9. New Business. 10. Next Meeting. 11. Adjournment. Address List No Phone 09/29/2014 Kristin Bigda High Rise Building Safety Advisory Committee HRB-TAC James R. Quiter SE 9/30/2004 Geoff Craighead SE 7/19/2005 Chair HRB-TAC Principal HRB-TAC Arup Universal Protection Service 560 Mission Street, Floor 7 1551 North Tustin Avenue, Suite 650 San Francisco, CA 94105 Santa Ana, CA 92705 Safety to Life Correlating Committee Jon D. Magnusson SE 9/30/2004 John P. Miller L 4/22/2005 Principal HRB-TAC Principal HRB-TAC Magnusson Klemencic Associates Los Angeles City Fire Department 1301 Fifth Avenue, Suite 3200 Battalion 17 "A" Platoon Seattle, WA 98101-2699 200 North Main Street National Council of Structural Engineers Assns. Los Angeles, CA 90012 Jack J. Murphy U 9/30/2004 Jake Pauls C 9/30/2004 Principal HRB-TAC Principal HRB-TAC Fire Safety Directors Association of Greater New York Jake Pauls Consulting Services 236 Overlook Avenue 255 Glenlake Avenue, Suite 2207 Leonia, NJ 07605-1519 Toronto, ON M6P 1G2 Canada Fire Safety Directors Association of Greater New York American Public Health Association Sally Regenhard C 9/30/2004 James P. -

The Design of Akhmat Tower

E3S Web of Conferences 33, 01022 (2018) https://doi.org/10.1051/e3sconf/20183301022 HRC 2017 The Design of Akhmat Tower Sara Beardsley1, Alejandro Stochetti1, and Marc Cerone1 1Adrian Smith + Gordon Gill Architecture, 111 West Monroe, Suite 2300, Chicago, Illinois 60603, USA Abstract. Akhmat Tower is a 435m supertall building designed by Adrian Smith + Gordon Gill Architecture. It is currently under construction in the city of Grozny, in the Chechen Republic, in the North Caucasus region of Russia. The design of the tower was done during a collaborative process by a multi-disciplinary architectural and engineering team, based primarily in the United States and Russia. During this process, the designers considered many factors including, most primarily, the cultural and historical context, the structural requirements given the high seismicity of the region, and the client’s programmatic needs. The resulting crystalline-shaped tower is both an aesthetic statement and a performative architectural solution which will be a new landmark for Chechnya. “The Design of Akhmat Tower” describes in detail the design process including structural considerations, exterior wall design, building program, interior design, the tuned mass damper, and the use of building information modeling. 1 Introduction In 2014, Adrian Smith + Gordon Gill Architecture (AS+GG) was commissioned to design a signature tower adjacent to the Suzha river in Grozny, Chechnya - a Republic of Russia located in the north Caucasus region near the Caspian Sea. This tower is to be a new icon specifically for the region – and is named after the first President of Chechen Republic, Akh- mat Haji Kadyrov [1]. The design was done by a team of over one hundred people, based primarily in the United States and Russia, and utilized expertise from architects and engineers with vast experience in super-tall building design. -

An All-Time Record 97 Buildings of 200 Meters Or Higher Completed In

CTBUH Year in Review: Tall Trends All building data, images and drawings can be found at end of 2014, and Forecasts for 2015 Click on building names to be taken to the Skyscraper Center An All-Time Record 97 Buildings of 200 Meters or Higher Completed in 2014 Report by Daniel Safarik and Antony Wood, CTBUH Research by Marty Carver and Marshall Gerometta, CTBUH 2014 showed further shifts towards Asia, and also surprising developments in building 60 58 14,000 13,549 2014 Completions: 200m+ Buildings by Country functions and structural materials. Note: One tall building 200m+ in height was also completed during 13,000 2014 in these countries: Chile, Kuwait, Malaysia, Singapore, South Korea, 50 Taiwan, United Kingdom, Vietnam 60 58 2014 Completions: 200m+ Buildings by Countr5,00y 0 14,000 60 13,54958 14,000 13,549 2014 Completions: 200m+ Buildings by Country Executive Summary 40 Note: One tall building 200m+ in height was also completed during ) Note: One tall building 200m+ in height was also completed during 13,000 60 58 13,0014,000 2014 in these countries: Chile, Kuwait, Malaysia, Singapore, South Korea, (m 13,549 2014 in these Completions: countries: Chile, Kuwait, 200m+ Malaysia, BuildingsSingapore, South byKorea, C ountry 50 Total Number (Total = 97) 4,000 s 50 Taiwan,Taiwan, United United Kingdom, Kingdom, Vietnam Vietnam Note: One tall building 200m+ in height was also completed during ht er 13,000 Sum of He2014 igin theseht scountries: (Tot alChile, = Kuwait, 23,333 Malaysia, m) Singapore, South Korea, 5,000 mb 30 50 5,000 The Council -

Aesthetics of Chinese Tall Buildings Author

CTBUH Research Paper ctbuh.org/papers Title: Aesthetics of Chinese Tall Buildings Author: Richard Lee, Junior Partner, C.Y. Lee & Partners Architects/Planners Subjects: Architectural/Design History, Theory & Criticism Keyword: Cultural Context Publication Date: 2019 Original Publication: 2019 Chicago 10th World Congress Proceedings - 50 Forward | 50 Back Paper Type: 1. Book chapter/Part chapter 2. Journal paper 3. Conference proceeding 4. Unpublished conference paper 5. Magazine article 6. Unpublished © Council on Tall Buildings and Urban Habitat / Richard Lee Aesthetics of Chinese Tall Buildings Abstract Richard Lee CTBUH Regional Representative Partner While Western aesthetics dominate the world at this time, the rise of the East has led China to re- C.Y. Lee & Partners Architects/ examine its Eurocentric view towards aesthetics. China has been long been a fertile laboratory Planners for foreign architects to create exciting and wild structures, but this explosion has led to an Taipei, Taiwan, China urban landscape littered with tall buildings that have little, if anything to do with the indigenous Richard Lee received a bachelor’s and master’s cultural heritage. This dilemma came to the forefront in Taiwan when it envisioned creating a degree from the University of Pennsylvania. world-class supertall building that would serve as a “coming-out” to the world stage. Instead After graduation, he worked at KPF in New York, followed by Handel Architects. In 2004, Lee moved of employing a foreign architect, they chose a native Chinese architect. Drawing from Chinese to Shanghai to join C.Y. Lee & Partners. After 2006, aesthetics and sensibilities, the resulting TAIPEI 101 showed that a building could resonate with he relocated to the main office in Taipei, where the indigenous population and culture in a deeply spiritual way, while simultaneously instilling a he was promoted to junior partner in 2016. -

Burj Khalifa, the Shard, and Rivals by Eva Bogomil

Burj Khalifa, The Shard, and Rivals by Eva Bogomil Introduction From the early days, we have invariably been interested in the world we live in, exploring, analysing, and altering it at our will. Humanity has gone a long way from caves to modern skyscrapers, aiming for ever greater heights. The power of human ingenuity has conquered the elements to reach the sky and beyond. Nowadays technologies allow us to build skyscrapers that totally change our idea of a modern world. Throughout the centuries brilliant engineers have been inventing more advanced and complex technologies, expanding our abilities. The Acropolis, St Paul’s Cathedral, the Eiffel Tower and the Sydney Opera House are all marvellous buildings that have remained objects of admiration for historians, architects, and artists, as well as a source of inspiration for many generations. Even to the general public the structures appear breathtaking. The 21st century saw the dawn of super-skyscraper construction. The Shard, Taipei 101, the Princess Tower, the Abraj Al-Bait Towers, and the Shanghai Tower are just some of the outstanding examples the modern world can be proud of. Burj Khalifa, currently the tallest building in the world, crowns this list of our achievements (Figure 1.0) which keep attracting people, making them wonder how such structures could have been built. Figure 1.0: Height comparison of some of the tallest buildings in the world This essay will focus mainly on London’s Shard and Dubai’s Burj Khalifa. Both of these skyscrapers are unique in their own way, yet similar. The Shard — currently the tallest building in the United Kingdom — dominates London skyline.