UNIT V STORAGE and DISPLAY INSTRUMENTS Cathode Ray

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

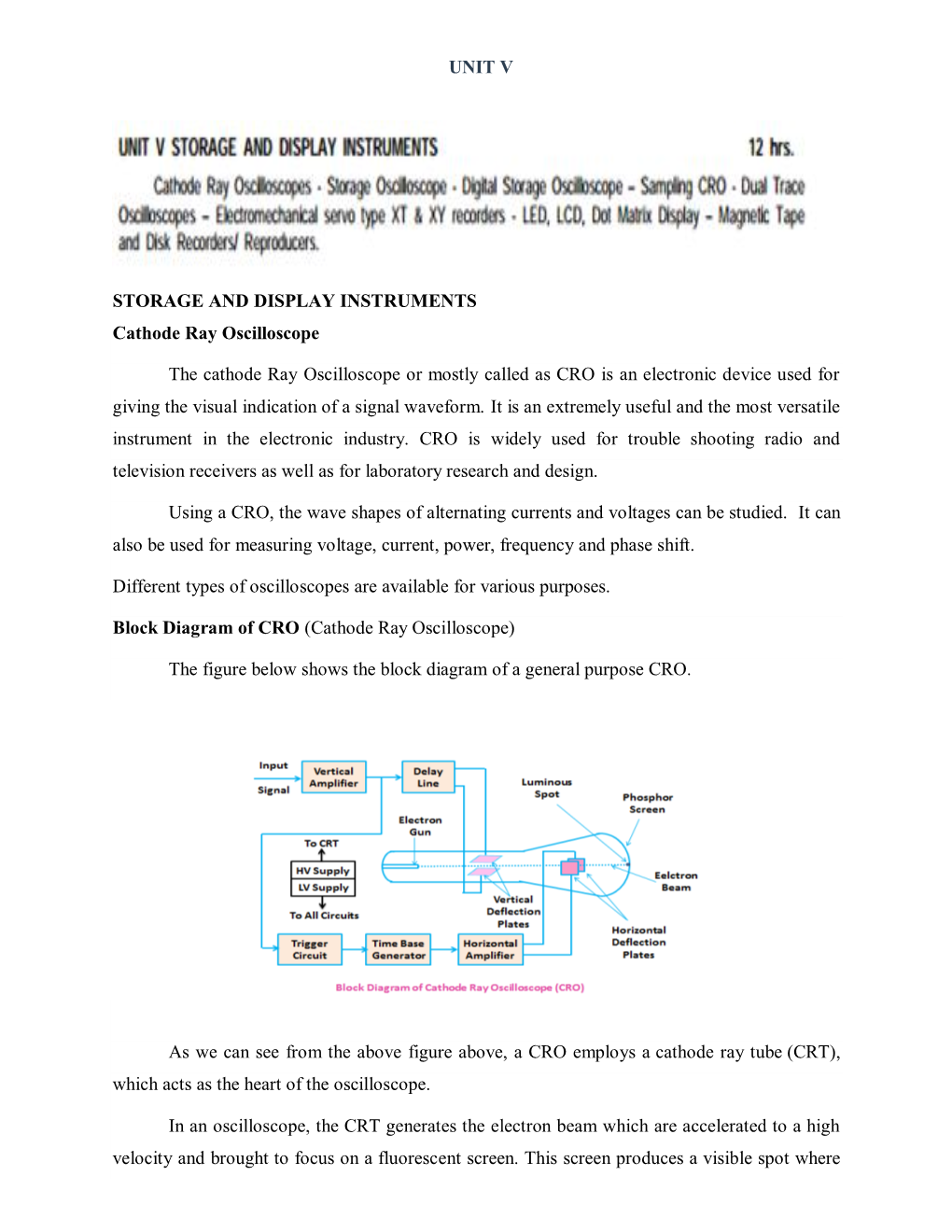

Catalog-Web-ONYX-And-STAX.Pdf

1 ABOUT NEXT LED Table of Contents Our Focus Next LED is a leading American manufacturer of 2 About Next LED commercial, billboard, sports, and indoor LED displays. We pour the quality and work ethic of 4 LED 101 the heartland into every sign we engineer and assemble from our headquarters in Wichita, 6 Pitch / Dealer Tools Kansas. As the LED signage industry matures and businesses and organizations around the world realize the benefits of dynamic marketing 8 Commercial Signs through digital signs, it is our sole focus to provide the most reliable products and related services 10 Franchise / Dynamic Data that go beyond the physical components of the display. In a word, every Next LED product comes 12 Billboards loaded with VALUE. 14 Sports Highest Quality Parts While all LED signs aren’t created equal, they are, 16 Operating Software for the most part, created using the same types of components, often supplied by the exact same OEM companies. Next LED uses the highest quality 18 Custom Content LED diodes, lamps, ribbon cables, power supplies, data, and aluminum cabinetry to create a rugged, Questions? Call us at: reliable product for both on and off premise use. 2 888.263.6530 5 Year Parts, Labor, & Brightness Warranty Experience the Best Warranty in the Industry 5 YEARS It’s one thing to say you’ve got a great product; it’s another to stand behind it. Next LED’s industry leading warranty guarantees that you won’t have TM NO PARTS LABOR BRIGHTNESS anything to worry about for up to five years. -

Vinculum-II Scrolling Text Application Using LED Dot Matrix Display

Application Note AN_200 Vinculum-II Scrolling Text Application Using LED dot matrix display Version 1.0 Issue Date: 2012-02-09 This application note provides an example of using the FTDI Vinculum-II (VNC2) to communicate with a USB Flash drive to display text and graphics held on the Flash drive, on a LED dot matrix display. Drivers and source code are also provided (downloadable from the FTDI website) Use of FTDI devices in life support and/or safety applications is entirely at the user’s risk, and the user agrees to defend, indemnify and hold harmless FTDI from any and all damages, claims, suits or expense resulting from such use. Future Technology Devices International Limited (FTDI) Unit 1, 2 Seaward Place, Glasgow G41 1HH, United Kingdom Tel.: +44 (0) 141 429 2777 Fax: + 44 (0) 141 429 2758 Web Site: http://ftdichip.com Copyright © 2012 Future Technology Devices International Limited Application Note AN_200 Vinculum-II Scrolling Text Application Using LED dot matrix display Version 1.0 Document Reference No.: FT_000571 Clearance No.: FTDI# 277 Table of Contents 1 Introduction .................................................................................................................................... 3 1.1 Overview ................................................................................................................................. 3 1.2 Hardware Requirements ......................................................................................................... 4 2 Operation ....................................................................................................................................... -

New Display Technologies (Crts), Displays Have Become Ubiquitous and Have Taken Many Different Forms

1.0 Introduction Mini Briefing Electronic displays are one of the fastest-growing worldwide technologies. Once reserved for televisions and computers, and composed of large cathode-ray tubes New Display Technologies (CRTs), displays have become ubiquitous and have taken many different forms. Flat-panel displays are overtaking the CRT and are being used in larger quantities for Steve Statham portable computers, a variety of handheld devices, desktop computers and televisions, as well as tiny microdisplays, which are being used in projection televisions, for near-eye applications, where a virtual screen is presented to the viewer. The world of displays is Advances in new display technologies are rapidly changing to meet the evolving needs of the beginning to open up many new possibilities to electronic-device user. consumers and manufacturers. Unfortunately there is always a large time lag between the discoveries made, and the time when practical applications 2.0 Applications finally appear. Even once they have been incorporated into everyday items, they are The electronic-display device industry caters mainly for the sometimes expensive. automation and electronics appliance industries. Characteristic of OEM products, the growth of the display However, major developments are now taking industry is directly linked to the demand trends in end-user place in a variety of display materials with the markets. Display manufacturers, mainly concentrated in potential to enable handheld computers and mobile Japan and East Asian countries, account for over 80% of phones to be more functional and user-friendly, total display production. which could greatly aid in the convergence of functionality and convenience that these products The end-user market (which includes televisions, are intended to deliver. -

LPR and LP Technical Brief

LPR and LP Technical Brief Overview Why Use LPR? LPR is one of several methods available for sending files to The lpr and lp commands provide an easy way to send files the Codonics NP-1600 printer. LPR utilizes the TCP/IP net- to the various Logical Devices that exist on the printer. It is working protocol and is most commonly used in UNIX, and the preferred way of sending files over a TCP/IP network to a lesser extent, in MS-DOS/Windows and other environ- since the printer has internal queuing and spooling for all of ments. Most LPR implementations have easy-to-use com- the internal print queues. Each of the internal printer Logical mands for sending files to the printer, but require set up by Devices may be set up on remote systems to allow for print- the System Administrator for correct operation. ing of Scaled, Unscaled, and Bracketing images. The lpr command and the UNIX System V lp command, are used to send image files to the printer. They are easier to use Multiple images can also be assembled on one page by using than FTP and require no user interaction so they may be the Caption, Variable Multiformatting, and Fixed Multifor- used from applications and shell commands. Not all System matting Devices. Getting the desired output can be accom- V LP implementations support the LPR transfer protocol plished very easily by following two general rules: which is used by the printer. Consult your documentation. If you wish to print a single image on a page, you should: The internal operating system on the printer acts as a remote LPD host, allowing various printer formatting functions to 1. -

Various Display Technologiess

VARIOUS DISPLAY TECHNOLOGIESS Mr. Virat C. Gandhi1 1Computer Department, C. U. Shah Technical Institute of Diploma Studies Abstract—A lot has been invented from the past till now in regards with the display technologies. It gives an immense life to electronic device when good display technology are being used. Now a days displays are coming in various sizes for different portable devices like smart phones, tablets, smart watch, televisions, laptops etc. People are expecting better display no matter what device they use. In this paper I have given an overview of some of the past technologies to the technologies till now. Flat-panel displays use Liquid-crystal display (LCD) technology to make them much lighter and thinner when compared with a traditional monitor. A liquid crystal display consists of an array of tiny segments (called pixels) that can be manipulated to present information. Plasma panels, also called gas discharge displays, are constructed by filling the region between two glass plates with a mixture of gases that usually include neon. In LED, A matrix of diodes is arranged to form the pixel positions in the display, and picture definition is stored in refresh buffer. OLED (Organic Light Emitting Diode) technology relies on the organic materials. Keywords— Display Technology; LCD; LED; Flexible display; Curved display; I. INTRODUCTION In today’s smart world, people are carrying smart devices all over the places they visit. Wherever people are they are surrounded or accompanied by display devices, such as smart phones, tablets, notebooks and advertising screens. Different devices uses different display technologies to enrich devices facilities. -

State-Of-The-Art in Holography and Auto-Stereoscopic Displays

State-of-the-art in holography and auto-stereoscopic displays Daniel Jönsson <Ersätt med egen bild> 2019-05-13 Contents Introduction .................................................................................................................................................. 3 Auto-stereoscopic displays ........................................................................................................................... 5 Two-View Autostereoscopic Displays ....................................................................................................... 5 Multi-view Autostereoscopic Displays ...................................................................................................... 7 Light Field Displays .................................................................................................................................. 10 Market ......................................................................................................................................................... 14 Display panels ......................................................................................................................................... 14 AR ............................................................................................................................................................ 14 Application Fields ........................................................................................................................................ 15 Companies ................................................................................................................................................. -

Laser Printer - Wikipedia, the Free Encyclopedia

Laser printer - Wikipedia, the free encyclopedia http://en. rvi kipedia.org/r,vi ki/Laser_pri nter Laser printer From Wikipedia, the free encyclopedia A laser printer is a common type of computer printer that rapidly produces high quality text and graphics on plain paper. As with digital photocopiers and multifunction printers (MFPs), Iaser printers employ a xerographic printing process but differ from analog photocopiers in that the image is produced by the direct scanning of a laser beam across the printer's photoreceptor. Overview A laser beam projects an image of the page to be printed onto an electrically charged rotating drum coated with selenium. Photoconductivity removes charge from the areas exposed to light. Dry ink (toner) particles are then electrostatically picked up by the drum's charged areas. The drum then prints the image onto paper by direct contact and heat, which fuses the ink to the paper. HP I-aserJet 4200 series printer Laser printers have many significant advantages over other types of printers. Unlike impact printers, laser printer speed can vary widely, and depends on many factors, including the graphic intensity of the job being processed. The fastest models can print over 200 monochrome pages per minute (12,000 pages per hour). The fastest color laser printers can print over 100 pages per minute (6000 pages per hour). Very high-speed laser printers are used for mass mailings of personalized documents, such as credit card or utility bills, and are competing with lithography in some commercial applications. The cost of this technology depends on a combination of factors, including the cost of paper, toner, and infrequent HP LaserJet printer drum replacement, as well as the replacement of other 1200 consumables such as the fuser assembly and transfer assembly. -

Light-Emitting Diode - Wikipedia, the Free Encyclopedia

Light-emitting diode - Wikipedia, the free encyclopedia http://en.wikipedia.org/wiki/Light-emitting_diode From Wikipedia, the free encyclopedia A light-emitting diode (LED) (pronounced /ˌɛl iː ˈdiː/[1]) is a semiconductor Light-emitting diode light source. LEDs are used as indicator lamps in many devices, and are increasingly used for lighting. Introduced as a practical electronic component in 1962,[2] early LEDs emitted low-intensity red light, but modern versions are available across the visible, ultraviolet and infrared wavelengths, with very high brightness. When a light-emitting diode is forward biased (switched on), electrons are able to recombine with holes within the device, releasing energy in the form of photons. This effect is called electroluminescence and the color of the light (corresponding to the energy of the photon) is determined by the energy gap of Red, green and blue LEDs of the 5mm type 2 the semiconductor. An LED is usually small in area (less than 1 mm ), and Type Passive, optoelectronic integrated optical components are used to shape its radiation pattern and assist in reflection.[3] LEDs present many advantages over incandescent light sources Working principle Electroluminescence including lower energy consumption, longer lifetime, improved robustness, Invented Nick Holonyak Jr. (1962) smaller size, faster switching, and greater durability and reliability. LEDs powerful enough for room lighting are relatively expensive and require more Electronic symbol precise current and heat management than compact fluorescent lamp sources of comparable output. Pin configuration Anode and Cathode Light-emitting diodes are used in applications as diverse as replacements for aviation lighting, automotive lighting (particularly indicators) and in traffic signals. -

Digital Display Circuits This Worksheet and All Related Files Are Licensed Under the Creative Commons Attribution License, Versi

Digital display circuits This worksheet and all related files are licensed under the Creative Commons Attribution License, version 1.0. To view a copy of this license, visit http://creativecommons.org/licenses/by/1.0/, or send a letter to Creative Commons, 559 Nathan Abbott Way, Stanford, California 94305, USA. The terms and conditions of this license allow for free copying, distribution, and/or modification of all licensed works by the general public. Resources and methods for learning about these subjects (list a few here, in preparation for your research): 1 Questions Question 1 What is the purpose of a seven-segment decoder circuit? What is a ”seven-segment” display, and why do we need a decoder circuit to drive it? Research the part number for a typical seven-segment decoder circuit (either CMOS or TTL). file 01417 Question 2 A seven segment decoder is a digital circuit designed to drive a very common type of digital display device: a set of LED (or LCD) segments that render numerals 0 through 9 at the command of a four-bit code: Display driver IC Seven-segment display VDD a a . A b . f b c . g Inputs B d . C e . f . D g . e c d The behavior of the display driver IC may be represented by a truth table with seven outputs: one for each segment of the seven-segment display (a through g). In the following table, a ”1” output represents an active display segment, while a ”0” output represents an inactive segment: D C B A a b c d e f g Display 0 0 0 0 1 1 1 1 1 1 0 ”0” 0 0 0 1 0 1 1 0 0 0 0 ”1” 0 0 1 0 1 1 0 1 1 0 1 ”2” 0 0 1 1 1 1 1 1 0 0 1 ”3” 0 1 0 0 0 1 1 0 0 1 1 ”4” 0 1 0 1 1 0 1 1 0 1 1 ”5” 0 1 1 0 1 0 1 1 1 1 1 ”6” 0 1 1 1 1 1 1 0 0 0 0 ”7” 1 0 0 0 1 1 1 1 1 1 1 ”8” 1 0 0 1 1 1 1 1 0 1 1 ”9” Write the unsimplified SOP or POS expressions (choose the most appropriate form) for outputs a, b, c, and e. -

A Comparative Study of Different Printed Documents to Estimate the Type of Printer Used

Journal of Forensic Research and Crime Studies Research Open Access A Comparative Study of Different Printed Documents to Estimate the Type of Printer Used Noronha SJ1, Basheer SZ1, Vijay MN1, Alnajjar A2, Sharma BK3,* and Singh N3 1Department of Forensic Science, Amity University Dubai, Dubai International Academic City, Dubai, UAE 2Former Head of Questioned Documents Unit, Department of Forensic Science and Criminology, Dubai Police, UAE 3Assistant Professor, Department of Forensic Science, Amity University Dubai, Dubai International Academic City, Dubai, UAE *Corresponding author: Sharma BK, Assistant Professor, Department of Forensic Science, Amity University Dubai, Dubai International Academic City, Dubai, UAE, Tel: 9714 4554 900; Fax: 9714 4356 810; E-mail: bsharma@amit- yuniversity.ae Received Date: March 28, 2017 Accepted Date: April 26, 2017 Published Date: April 28, 2017 Citation: Noronha SJ (2017) A Comparative Study of Different Printed Documents to Estimate the Type of Printer Used. J Forensic Res Crime Stud 1: 1-7. Abstract Printer examination in questioned document examination has become a necessity in the present time due to the progressive use of printers in the creation of documents as compared to that of handwritten documents and also the counterfeiting of documents printed by different printers. The present study is based upon the examination and analysis of different types of printed documents from various types of printers to distinguish and identify them for the purpose of forensic examination and to aid the questioned document ex- aminer during the forensic analysis of cases involving such printed documents. Each printer has a unique fashion of printing documents and the aim of this research is to identify this fashion by examining the printed documents. -

Display Devices

ELEKTRONIKOS ĮTAISAI 2009 1 DISPLAY DEVICES VGTU EF ESK [email protected] ELEKTRONIKOS ĮTAISAI 2009 2 Display devices Display devices are used for the visual presentation of information. 1. Analog display devices (cathode-ray tubes) • Oscilloscope tubes •TV CRTs 2. Digital display devices • LED (including OLED) displays • VF (vacuum fluorescent ) displays • LCD (liquid crystal) displays • Nixie tube displays and PDPs (plasma display panels) • Electroluminescent displays (ELDs) 3. Others: • Electronic paper • Using principles of nanoelectronics (carbon nanotubes, nanocrystals) • Laser TV VGTU EF ESK [email protected] ELEKTRONIKOS ĮTAISAI 2009 3 Classification of electronic information technologies with high information content; highlighted technologies are treated in this article w4.siemens.de/.../heft2_97/artikel08/index.html VGTU EF ESK [email protected] ELEKTRONIKOS ĮTAISAI 2009 4 Display devices Electronic display devices based on various principles were developed. Active display devices are based on luminescence. Luminescence is the general term used to describe the emission of electromagnetic radiation from a substance due to a non-thermal process. Luminescence occurs from a solid when it is supplied with some form of energy. Photoluminescence arises as a result of absorption of photons. In the case of cathodoluminescence material is excited by bombardment with a beam of electrons. Electroluminescence is a result of excitation from the application of an electric field. Fluorescence persists for a short lifetime of the transition between the two energy levels. Phosphorescence persists for much longer time (more than 10-8 s). Passive display devices reflect or modulate light… VGTU EF ESK [email protected] ELEKTRONIKOS ĮTAISAI 2009 5 Display devices. -

Symposium Digest Articles Listed Chronologically 1963-1988

Preliminary Table of Contents for SID Symposium Digests 1963-1988 ( author company affiliations not listed) Notes: 1 The index covers full papers and keynote speeches for SID Symposia from 1963 through 1988; panel sessions, seminars and luncheon speakers are not listed 2 Authors' company affiliations are not shown (to be added) 3 Lead author is designated with asterisk ( * ) 4 The first ten (10) digests were designated by number as follows 5 The first ten (10 Symposia were identified by numbers, as follows: 2/1963 -#1; 9/63 - #2; 5/64-#3; 9/64 - #4; 2/65 - #5; 9/65 - #6; 10/66 - #7; 5/67 - #8; 5/68 - #9; 5/69 - #10 Session # Year Page Title Author(s) 1963-1 1 User Requirements for Display Debons, Col, Anthony * 1963-1 13 Scan Conversion and Bright Display Porter, Richard * 1963-1 21 Multicolor Projection System Smith, Fred E.* 1963-1 31 Advanced Display Techniques through the Charactron Redman, James H.* 1963-1 53 Light Valve Display Albanese, Augustine * 1963-1 63 Colordata, A Photographic Large Screen Display system Baron, Peter C.* 1963-1 77 Human Performance Engineering and Information Display Silvern, Leonard * 1963-1 83 Multiple Projection Techniques Klein, R.C.* 1963-1 93 Photochromic Dynamic Display Hines, Logan J.* 1963-1 99 Datachrome Display System Parker, Philip A.* 1963-1 117 High Ambient Light Display Systems Miller, Wendell S.* 1963-1 127 Electroluminescent Displays Hallett, Joseph L.* 1963-1 139 Pseudo 3-D Display Perdue, Joseph L.* 1963-1 155 Aims and Purposes of the S.I.D. Vlahos, Petro * 1963-2 1 Iinformation Systems,