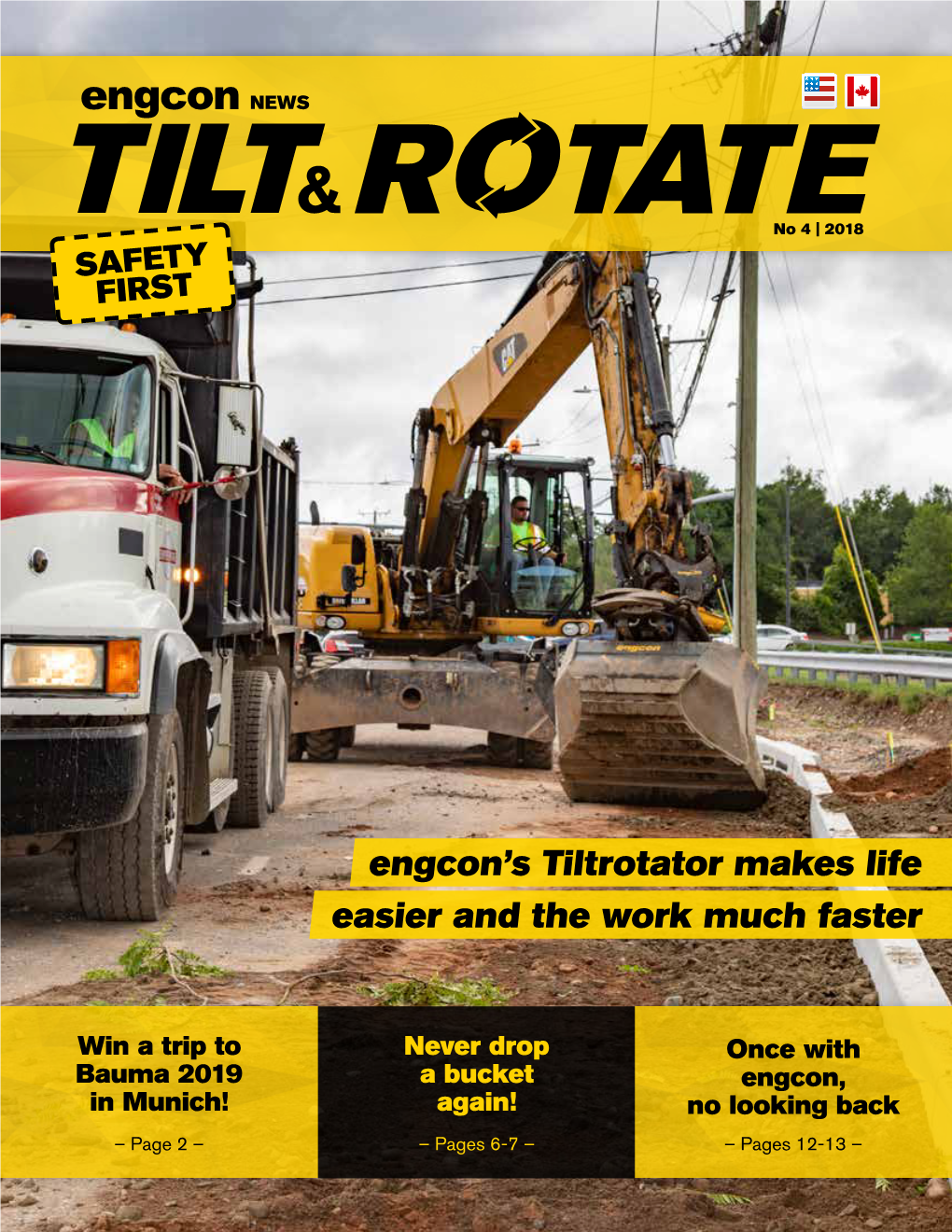

Easier and the Work Much Faster Engcon's Tiltrotator Makes Life

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Tiltrotator Delivers Speed and Precision for Cenex

INTERNATIONAL No 1 | 2019 TILTROTATOR DELIVERS SPEED AND PRECISION FOR CENEX Welcome engcon’s Standardised to engcon lighter locking and safe & Bauma pallet fork quick hitches – Page 4 – – Page 5 – – Pages 2, 3, 12, 13 – Everyone talks about zero tolerance for accidents, but few dare do anything about it SAFETY And so it’s happened again. Since my last editorial just before Christmas, which addressed safety levels on excavator quick hitches, yet another fatal accident has occurred. This time it happened in Sweden. I don’t know all the circumstances surrounding the accident, but they’re probably not all that important for the people who lost a family member, friend or workmate. I suffer with everybody who loses someone close in an accident, no matter where or how it happens. But beyond that, I also think of the person at the controls or behind the steering wheel. Whether the operator had a part in the accident or not, sentence has already been passed. Spending the rest of one’s life wrestling with what might have been done differently is something I would wish on no one. I dare say the operator never wants to see an excavator again. And making the usual trite comment that it’s all down to the human factor will do nothing to stop the next accident. All of the excavators at our workplaces today are built according to the same established principles and standards. What’s worse, almost all of the machines supplied today work in the same way. Well, is this enough? If it is, all of the incidents and fatal accidents have been in vain. -

Excavators Engcon | Attachment Catalogue 2010 Develop Your Business Concept up to 32 Tons

ATTACHMENT CATALOGUE 2010 Excavators engcon | Attachment catalogue 2010 Develop your business concept up to 32 tons New functions for excavators – new contracts for companies Do you want to work more efficiently and find new business opportunities? Tiltrotators and attachments from the world’s leading manufacturers make digging a work of art. By using System engcon and EC-Oil hydraulic quick hitches, you can quickly change tasks and increase both the efficiency and profitability of your excavator or backhoe loader. Our new tiltrotators EC02B, EC10B, EC15B and EC20B have been upgraded to handle greater machine weights and have been developed together with EC-Oil – engcon’s quick hitch with automatic oil couplings. EC-Oil simplifies changes between your hydraulic attachments, for example between grabs and engcon’s completely new vibratory soil com- pactor PP3200. The vibratory soil compactor has variable working width and is driven via an extra coupling on the tiltrotator, thus avoiding external hoses. You can control all your attachments simply and accurately using our proportional control system Microprop. The products in System engcon are adapted to each other and convert your excavator to a multipurpose tool for all sorts of tasks. We invite you to investigate the widest tiltrotator program on the market for machines between 1,5 and 32 tons at our showrooms. 2 | Intro Attachment catalogue 2010 | engcon Product overview 2010 04 System engcon NEWS 06 Tiltrotators Upgraded tiltrotators EC02B: 1.5–3.5 tons 7 EC02B, EC10B, EC15B, EC05B: 3–7 tons 7 EC20B for excavators EC10B: 6–14 tons 8 from 1.5 tons. -

Product Catalogue Content

PRODUCT CATALOGUE CONTENT OQ 4 OQTR 24 Control systems 31 Grapple module 32 OQL 34 OQT 42 OQC 50 Grab John 52 OQC40M 53 OQLS 54 OEM 55 System solution 56 CE marking 57 Service & quality 58 ISO 9001 & environment 59 Contact 60 Social media 63 A modern technology and sales company OilQuick AB specialises in fully automatic attachment coupler systems for excavators, wheel loaders, forklift trucks, material handling machines and cranes. The products are marketed and sold under the OilQuick brand. For the past 25 years the company has also sold Grab John pole-planting buckets, which are well-renowned in overhead line construction. Since the beginning of the 1990s the company has focused on the development, manufacture and sale of automatic quick coupler systems for different types of tool carrier. OilQuick offers rational and effective method solutions for construction and industry. Hydraulic attachments can be switched in just 10 seconds directly from the cab. OilQuick has patent protection in Japan, North America and most European countries. OQ Switch hydraulic attachments in 10 seconds! OilQuick is an automatic quick coupler system for excavators that can couple hydraulic attachments directly from the cab. The operator can rapidly switch between different types of attachment, such as hydraulic hammers, steel and concrete shears, sorting grapples, hydraulic magnets, compactors, sorting buckets, tilt buckets, tiltrotators and more. This means always using the right attachment for the job. OilQuick is the most advanced quick coupler system on the market and is available for excavators between 1 and 120 tonnes. The OilQuick system makes your excavator and your company more versatile, more competitive and more profitable! 4 OQ - Quick couplers for excavators 5 OQ 40/24 OQ 40/24 is a fully automatic quick coupler system suitable for all mini excavators weighing 1-5 tonnes and enables rapid attachment switching between mechanical and hydraulic attachments. -

NOX Tiltrotators and Accessories NOX TILTROTATORS

NOX Tiltrotators and Accessories NOX TILTROTATORS NOX TILTROTATORS Turn e iciency in With our Tiltrotator, your attachments can be rotated by 360° continuously and tilted by 50° to both sides. Therefore, the eff iciency of your machine will be increased dramatically as time and resources will be saved. your direction! With using the NOX Tiltrotator, you are not only reducing the need for repositioning your excavator and thus sparing FOUR FACTS ABOUT THE USE OF TILTROTATORS: the ground from damage (especially when it comes to landscaping tasks), but you will also speed up your work. PRODUCTIVITY AND PROFITABILITY The attachments can be positioned within the complete MANAGE THE SAME AMOUNT OF WORK IN LESS TIME. reach of the boom to work around obstacles. VISIT OUR WEBSITE: Fast and easy levelling works with a levelling bar SAFETY NOX.KINSHOFER.COM can be realized without repositioning the excavator. THE NOX TILTROTATOR COMPLIES WITH ALL CURRENT SAFETY REGULATIONS AND HELPS THE OPERATOR AND Precise setting of curbstones, dosed and accurate filling SURROUNDING WORKFORCE TO ACHIEVE AN ACCIDENTFREE ENVIRONMENT. of trenches with a bucket turned by 90° as well as the handling of diff erent kinds of materials in narrow areas are no problem with the NOX Tiltrotator. VERSATILTY AND FLEXIBILITY INCREASE THE USE OF YOUR MACHINE DRAMATICALLY AND ACCEPT MORE JOBS. ESPECIALLY IN CONJUNCTION WITH THE NOX. READY FOR THE FUTURE THE NOX TILTROTATOR COMES GPSREADY WITH ITS VERY MODERN NOXPROP+ CONTROL SYSTEM. THE MOST COMMON D MACHINE CONTROL SYSTEMS CAN BE IMPLEMENTED. EVEN RETROACTIVELY. 2 YEARS WARRANTY NOX TILTROTATORS It is our goal that you can always rely on your attachment and make you feel confident of its quality and longevity. -

Training Tomorrow's Operators

NEWS No 1 | 2016 Training tomorrow’s operators MACHINE CONTROL Engcon Want to test an setting up The future excavator and in Holland is here! tiltrotator? – Page 3 – – Pages 7-13 – – Page 7 – Welcome to the first issue of Tilt & Rotate, a new-look In this issue we also tell you about customers using version of our established magazine. We continue excavator guidance systems linked to our tiltrotators. as before with a These are great times for Engcon. fantastic mixture of new products and I would also like to take this opportunity to tell you how Welcome customer reports, we are expanding our operations in Europe. During the but now with a more spring we began our own operation in the Netherlands, personal feel since we expanded in France where we recently opened an to the future each market will have entirely new installation with offices, workshops and its own local features. a warehouse just outside Paris and in collaboration with the British certification body Whenever there is interesting news from other markets, NPORS, we recently launched a you will be able to read about it, too. national tiltrotator safety standard This first edition of the new Tilt & Rotate includes a in the UK. Welcome to Engcon’s report from Bauma, the world’s biggest construction new Tilt & Rotate machinery fair that attracted almost 600,000 visitors. You can read about a number of interesting partnerships Sten Strömgren such as where Pon has selected us as the exclusive Marketing Manager supplier for a major campaign. Engcon Group Grand Opening for Engcon in France At the end of March it was Grand Opening time for Engcon in France. -

PRICELIST 2019 EUROPE Pricelist 2019 Euro

PRICELIST 2019 EUROPE Pricelist 2019 Euro SMP Tiltrotator Page Models ST6 / ST10 / ST12 / S15 / ST18 / ST22 / ST28 1 to 7 Quick Couplers Page SMP Hydraulic Quick Coupler SMP35 - SMP205 8 SMP Mechanical Quick Coupler SMP4 - SMP100 9 SMP Hydr./Mech. Quick Coupler Type S30 - S100 10 SMP Hydr./Mech. Quick Coupler Type S1 - S2 - S3 / B20 - B27 - B30 11 Converting Kits Page Converting Plate / Kit SMP Quick Couplers 12 Converting Bracket Type S30 - S100 13 Converting Plate / Kit Type S1 - S2 - S3 / B20 - B27 - B30 14 Buckets Page Backhoe Buckets, Mini / Comp. Excavators 55 - 400L/sae 15 HDR Bucket 500 - 1000L/sae 16 HDR/HDS Bucket 1050 - 2500L/sae 17 HDR/HDS Bucket 2700 - 4400L/sae 18 HDR/HDS Buckets Options / Extensions 19 Grading Bucket Hydr. Operation 55 - 2500L/sae Horizontal cylinders 20 Grading Bucket Hydr. Operation 1000 - 2500L/sae Vertical cylinders 21 Grading Bucket Standard 55 - 1800L/sae 22 Grading Bucket Tiltrotator 150 - 1800L/sae 23 Cable Bucket 30 - 800L/sae 24 Sorting Bucket 55 - 1800L/sae 25 Combi-Grab Bucket 350 - 1000L/sae 26 VA-Bucket 500 - 1000L/sae 26 Plainfront for Backhoe & HDR/HDS Buckets 27 Grading Bucket Wheeloader 2000mm - 3400mm 28 Sort- & Grab Bucket With & Without rotator 29 Average products Page Ripper 50 - 1100kg 30 Asphaltcutter / Levelling rollerbar Width 2300 - 2700mm. 31 Adaptorplates For hammers, crushers etc. 32 Pallet Forkstand - Excavator & Wheelloaders Carrier 2,5 - 5,0 tonnes 33 Crushing Pin 34 Tree Cutter 35 Sales, Warranty & Deliveryterms ● Prices may vary depending designs. ● Prices and deliveryterms in offers are valid 1 week. ● Transportcosts, pallets/packaging will be charged. -

Attachments for Construction Machines

Attachments for Construction Machines www.hks-partner.com The Best for Every Challenge NO LIMITS TO INDIVIDUALITY Each application is different and requires different tools as well. For this purpose, HKS has the largest market range of turning and swiveling tools, which ideally covers every application. Whether only simple pivoting or rotating, or both at once. We develop, design and produce according to your ideas and thus achieve the best for you and your excavator. Our design team adapts each product individually to your excavator, so the kinematics remain in the best possible way and the volume of each bucket can be utilized maximally. › Improved accessibi- lity of operating po- Convince yourself of our solutions, likewise as well sitions by tilting directly on site. › Easy handling of works on embankments Trust in HKS with over 45 years experience in the field of hydraulic and pneumatic rotary actuators and fif- teen years of successful products for the Constructi- on Technology segment. 2 › Best possible accessibility of operating positions thanks to simultaneous tilting and rotating › Spatial positioning enables previously impossible areas of application for your at- tachments › Improved accessibility of operating positions due to endless rotation › Immediate changeo- ver from backhoe to face bucket by means of simple rotation 3 Further intermediate tilt angles available upon request. Combination Sandwich-Solution With adapter to dipperstick With quick-coupler adapter connection and quick coupler and quick coupler Combination Sandwich-Solution With adapter to dipperstick With quick-coupler adapter connection and quick coupler and quick coupler With Lugs Combination With lugs for direct With permanent shaft connection. -

The Quick Coupling System Saves Time Engcon Fills Lots of Gaps in Holland

An informative magazine • 2004 edition Page 5 The quick coupling system saves time Page 9 engcon fills lots of gaps in Holland Two companies with New challenges big resources and continued development rom the time the engcon company started in 1990, it was We are strengthening our presence on several of the European for your help with machining, F and still is emphatically linked to one man, Stig Engström, markets. We have, for example, a new subsidiary in Gt. Britain, its managing director and a major driving force behind the engcon UK. Countries such as Germany, Holland, Belgium and company’s fabulous success during the past decade. Now that Italy have turned out to be important markets for the engcon’s welding and assembling Stig has decided to hand over the MD role to me, many people continued growth. We have a solid network of dealers who con- have wondered, and rightly so, what this will mean for the futu- tribute with their unique know-how on their respective markets re development of the company. Stig has chosen to return to do and who are important to our customer service. what he really enjoys most – the nuts and bolts of product deve- During 2004, engcon will be more visible than previously. lopment and the seeking out of fresh challenges related to new Among other things we intend participating in many of the customer segments and markets. The purpose of his altered role branch exhibitions that are being held all over Europe. Chances will be that the company should increase growth further, and are very good that you will come across us and our tiltrotators not let development to come to a halt. -

Engcon Visits Varbergs Schakt Swedish Machine O

engcon magazine 2005 edition Mikko Lyytinen – a well-known name in Finland “I bought a Rolls Royce” – engcon visits Varbergs Schakt Swedish Machine Operating Champion – 25 and already a veteran A whole work team in a single cab – a Danish sensation A genuine Stradivarius – Björn Viken from Trondheim waxes lyrical Page 4 Mikko Lyytinen – a well-known name in Finland Page 6 A Rolls Royce in Varberg – Roger Serholt made his choice back in 1995 Page 7 engcon expands – renovations for 6 million SEK Page 8 Putting operational safety first – EAG 5 Entreprenad – one of Jämtland’s leaders Page 9 Success in Norway – another Volvo on its way Page 9 Swedish champion – 25 years old 8 and already at the top Page 10 A whole work team in a single cab – an unusual sight in Munke Bjergby of Denmark Page 11 Computer-controlled working speed 9 – proportional control adapts implement functions Page 12 The perfect couple – EC20 + engcon SK stone and scrap handling grab Page 13 Grab gets praise in Finland 12 Page 14 A genuine Stradivarius – dulcet tones from Trondheim Page 15 Three Gazelle companies 14 – with engcon as a common denominator engcon nordic ab Box 111 SE-833 22 Strömsund, Sweden Tel +46 670-178 00 Fax +46 670-178 28 [email protected] www.engcon.se Official publisher: Sten Strömgren. Production: Syre Reklambyrå. Photography: Sten Strömgren, Ellen Kirkevold, Hydrex and Jocke Prager. Printing: PA Group 2005. 2 | engcon LEADING ARTICLE A NEW EXCITING YEAR We are embarking on a new, exciting year. Demand for our will help us achieve our goal of ensuring that customers are products continues to increase, while the expansion of our always satisfied with us. -

An Ideal Solution for Engcon Tiltrotator Remote Rail Projects

INTERNATIONAL No 4 | 2018 SAFETY FIRST engcon tiltrotator an ideal solution for remote rail projects “We can’t afford Never drop Win a trip to any more a bucket Bauma 2019! accidents” again! – Page 2 – – Pages 3-5 – – Pages 6-7 – Zero tolerance for dropped buckets They say that politics is wanting to get zero achieved so far is a concrete result more importantly, safety efforts focused something done. I believe the same to from the discussions. Not much has hap- on the right things, namely the elimination be true of entrepreneurship. We create pened in our niche business – excavators of the human factor that is behind the companies because we want to get and quick hitches – either. This could be overwhelming majority of traffic accidents. something done. down to a number of issues - exhaust- We can also learn from this. The tiltrotator that was the start of engcon ing decision-making processes, inertia in In launching the “responsible quick back in 1990 came about because I the companies that are involved in them hitch”, engcon seeks to do everything it wanted to solve a technical problem. and diversity of opinions. But we cannot can to drive developments towards zero Looking back a few decades later I can allow the lack of consensus to create un- tolerance of workplace accidents involving see that a great deal has happened in the necessary deadlocks that constantly slow excavators. In the system engcon has development of the Group, its business development if we really want to make developed, the quick hitch does for the solutions and the product systems we progress. -

Engcon's EC226 Tiltrotator for Larger Excavators Gets an Upgraded Lifting Hook – Now Approved for 8 Ton Lifting

Mar 04, 2021 10:40 GMT Engcon's EC226 tiltrotator for larger excavators gets an upgraded lifting hook – now approved for 8 ton lifting Engcon’s EC226, the second largest tiltrotator for excavators in the 19-26 tonne weight class, now has a more powerful lifting hook that is approved for 8 tons, according to EN 474-1: 2006 + A6: 2019 ANNEX E. The upgrade applies to the directly attached tiltrotators. ”It’s thanks to an upgraded top with more powerful side plates that made the upgrade possible”, says Göran Kron, constructor at Engcon. The more powerful lifting hook can handle three tons more than the previous model, and with a larger diameter it can hold more robust chains or lifting straps. ”Yes, it has also been a wish as some drivers use reinforced lifting straps for heavy lifting,” Göran Kron continues. Göran Kron also says that the lifting hook has a CE mark like all the other lifting hooks that Engcon mounts on its tiltrotators. The EC226 upgrade applies with immediate effect, and the 8-ton hook is already in production and delivered as standard on all directly attached EC226 tiltrotators. About engcon Engcon, founded in 1990, is the world leader in the manufacture of tiltrotators and their attachments, which increase the efficiency, profitability and safety of excavators. The parent company is located in Strömsund in northern Sweden. Through its local sales companies supplies products and services in Finland, Norway, Denmark, France, North America (US and Canada), Benelux, UK, Germany and most recently in Korea and Australia. Engcon also exports tiltrotators worldwide from Sweden. -

Mini Excavators P35

CONSTRUCTION THE MAGAZINEMAGAZINE FORFOR EUROPE’SEUROPE’SS CCONSTRUCTIONONSTRUCCTIONCT INDUSTRYINDUSTRY www.construction-europe.comwww.constru i A KHL Group publication May 2014 Volume 25 Number 4 Components p27 Samoter p23 Mini excavators p35 CE 05 2014 Front Cover.indd 1 28/04/2014 10:02:18 UNDERNEATH IT ALL CONFIDENCE Machine Drive Power (MDP) is a new, innovative soil MDP measures closer to the depth of the lift with less compaction measurement technology available only from variability than accelerometer-based systems, even on Caterpillar. cohesive soils. That gives you confidence that the soil you are compacting will support the load. Machine Drive Power Accelerometer-based Feature (MDP) Compaction Measurement Measurement Depth* 30 - 60 cm (12 - 24 in) 1 - 1.2 m (3.3 - 4 ft) Can be correlated with plate load test 3 Usable with smooth drum, padfoot, or padfoot shell kit 3 Usable on granular or cohesive material 3 Measures with vibratory system on or off 3 Exclusive Cat® technology 3 * Dependent on soil type, moisture and other factors. Ask your local Cat dealer about rental and purchase options for your next soil compaction job. Find us online at www.cat.com/paving facebook.com/CATPaving youtube.com/CATPaving R QEXC1769-02 © 2014 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, BUILT FOR IT, their respective logos, “Caterpillar Yellow,” the “Power Edge” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. Full page.indd 1 28/04/2014 10:54:33 CONTENTS CONSTRUCTION IN THIS ISSUE Volume 25 Number 4 MAY 2014 REGULARS CONSTRUCTION THE MAGAZINEMAGAZINE FORFOR EUROPE’SEUROPE’SS CONSTRUCTIONCONSTRUCCTIONCT INDUSTRYINDUSTRY www.construction-europe.comwww.constru i A KHL Group publication May 2014 Volume 25 Number 4 Components NEWS & BUSINESS 4 ON THE COVER p27 Samoter p23 ISSN 0964–0665 A 2.6 tonne Bobcat © Copyright KHL Group 2014 WORLD NEWS 9 E25 owned by R Durtnell & Sons.