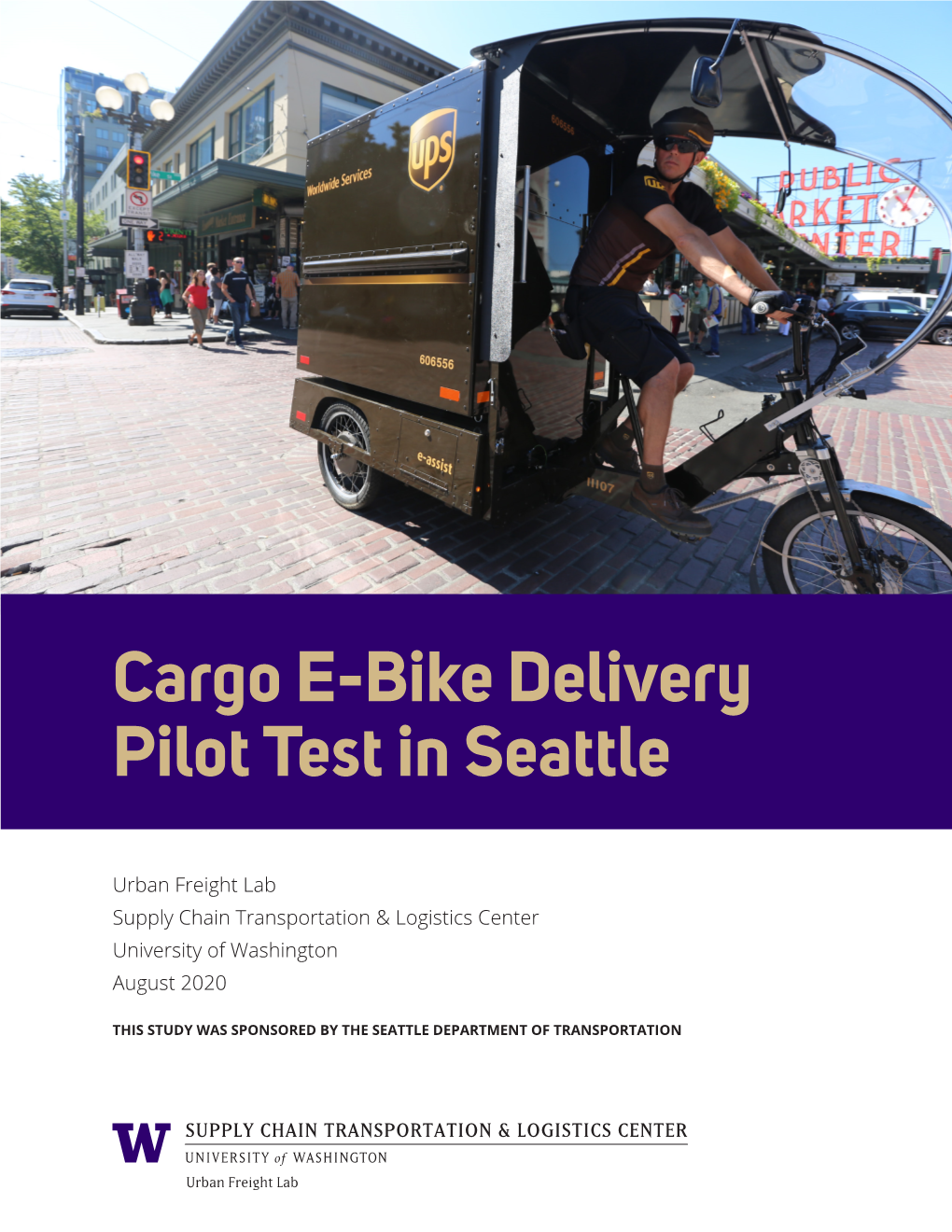

Cargo E-Bike Delivery Pilot Test in Seattle

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Scope of Using Autonomous Trucks and Lorries for Parcel Deliveries in Urban Settings

logistics Article Scope of Using Autonomous Trucks and Lorries for Parcel Deliveries in Urban Settings Evelyne Tina Kassai, Muhammad Azmat * and Sebastian Kummer Welthandelsplatz 1, Institute for Transport and Logistics Management, WU (Vienna University of Economics and Business), 1020 Vienna, Austria; [email protected] (E.T.K.); [email protected] (S.K.) * Correspondence: [email protected] Received: 17 June 2020; Accepted: 21 July 2020; Published: 7 August 2020 Abstract: Courier, express, and parcel (CEP) services represent one of the most challenging and dynamic sectors of the logistics industry. Companies of this sector must solve several challenges to keep up with the rapid changes in the market. In this context, the introduction of autonomous delivery using self-driving trucks might be an appropriate solution to overcome the problems that the industry is facing today. This paper investigates if the introduction of autonomous trucks would be feasible for deliveries in urban areas from the experts’ point of view. Furthermore, the potential advantages of such autonomous vehicles were highlighted and compared to traditional delivery methods. At the same time, barriers that could slow down or hinder such an implementation were also discovered by conducting semi-structured interviews with experts from the field. The results show that CEP companies are interested in innovative logistics solutions such as autonomous vans, especially when it comes to business-to-consumer (B2C) activities. Most of the experts acknowledge the benefits that self-driving vans could bring once on the market. Despite that, there are still some difficulties that need to be solved before actual implementation. -

Expedited Delivery: How Transportation Companies Can Thrive with Blockchain

Expedited delivery IBM Institute for Business Value survey conducted by How transportation companies can thrive with blockchain The Economist Intelligence Unit Executive Report Transportation In this report How blockchain technology can help transportation companies increase How IBM can help security, trust in data and logistics management As one of the world’s leading research organizations, and one of the world’s top contributors to open source projects, IBM is How transportation companies will committed to fostering the collaborative effort required to use blockchain to improve existing transform how people, governments and businesses transact operational processes and interact. IBM provides clients the blockchain technology How blockchain can reduce frictions fabric, consulting and systems integration capabilities to design that impede progress and rapidly adopt distributed ledgers, digital identity, blockchain solutions and consortia. IBM helps clients leverage the global Recommendations about how to start scale, business domain expertise and deep cloud integration implementing blockchain experience required for the application of these technologies. Learn more at ibm.com/blockchain. To succeed in today’s hyper-competitive world, travel and transportation companies need to solve increasingly complex problems and seize new and exciting opportunities faster than their competitors. They must continue to drive operational excellence and enable collaboration across enterprise functions and between members of emerging ecosystems. Above all, industry leaders must run the business well amidst constant change. The IBM Travel and Transportation practice understands these challenges and brings its extensive industry experience, business insight and technical prowess to bear on them. For more information, visit ibm.com/industries/traveltransportation 1 Full speed ahead The transformational potential of blockchain Few industries can benefit more from blockchain The transportation industry has a long history of resisting all but the most essential than transportation. -

No One Knows E-Commerce Like We Do Vision

NO ONE KNOWS E-COMMERCE LIKE WE DO VISION “To be the best and set the pace in the express air and integrated transportation and distribution industry, with a business and human conscience. We commit to develop, reward and recognize our people who, through high quality and professional service, and use of sophisticated technology, will meet and exceed customer and stakeholder expectations profitably”. Passionately crafted by over 600 managers in 1993 5 KEY DRIVERS FOR E-COMMERCE GROWTH THE BLUE DART ADVANTAGE LARGEST & MOST SUCCESSFUL EXPRESS 1 High Domestic Consumption PLAYER Digital Adoption growing at a exponential pace 2 IN ACTIVE INVESTMENT MODE TO MAKE INDIA’S E- Shopping On-line becoming a way of life 3 COMMERCE SUCCESSFUL 4 Tier III / IV and rural India FLEXIBLE ENVIRONMENT; CONTINOUS PROCESS RE- 5 Reliable, agile and large national level express logistics players will be able to sustain this growth ENGINEERING needs BEST SERVICE PARAMETER DELIVERABLES OVER 34 YEARS INDIA’S MOST AWARDED & INNOVATIVE EXPRESS LOGISTICS 4 PILLARS OF COMPANY DIFFERENTIATION Everything we do is part of our vision to: VALUE HIGH & CONSISTENT SERVICE EXPERIENCE 1 Make our customers’ business successful PRODUCTS 2 Activate, engage and inspire our employees to play their part EXPRESS DISTRIBUTION FROM A DOCUMENT TO A CHARTER LOAD 3 Provide high quality solutions TECHNOLOGY Offer great customer experience, more choice, 4 CUSTOMER APIs, REAL-TIME TRACK & convenience and control TRACE, SUPERIOR VISIBILITY & CONTROLS CREATE POWER FOR YOUR BUSINESS 5 Deliver products to millions with expertise, efficiency, innovation and customer centricity LEADERSHIP BRAND VALUES, PASSIONATE PEOPLE- FORCE, UNMATCHED INFRASTRUCTURE AND CONTINOUS INNOVATIONS DRIVE EXPERIENCE BLUE DART’S E-COMMERCE A FULLY INTEGRATED E-COMMERCE SOLUTION PRODUCT PORTFOLIO We offer world-class logistics services focusing on three product lines: Domestic Delivery, Fulfillment and Cross Border BLUE DART’S E-COMMERCE PRODUCT PORTFOLIO Domestic Cross Fulfillment Delivery Border .Cash on Delivery . -

Automated Delivery Vehicle State of the Practice Scan

Emerging Automated Urban Freight Delivery Concepts: State of the Practice Scan www.its.dot.gov/index.htm Final Report – November 20, 2020 FHWA-JPO-20-825 Produced by Volpe National Transportation Systems Center U.S. Department of Transportation Office of the Assistant Secretary for Research and Technology Intelligent Transportation Systems Joint Program Office Notice This document is disseminated under the sponsorship of the Department of Transportation in the interest of information exchange. The United States Government assumes no liability for its contents or use thereof. The U.S. Government is not endorsing any manufacturers, products, or services cited herein and any trade name that may appear in the work has been included only because it is essential to the contents of the work. Technical Report Documentation Page 1. Report No. 2. Government Accession No. 3. Recipient’s Catalog No. FHWA-JPO-20-825 4. Title and Subtitle 5. Report Date Emerging Automated Urban Freight Delivery Concepts: State of the Practice November 20, 2020 Scan 6. Performing Organization Code 7. Author(s) 8. Performing Organization Report No. Joshua Cregger: ORCID 0000-0002-6202-1443; Elizabeth Machek: ORCID DOT-VNTSC-FHWA-21-01 0000-0002-2299-6924; Molly Behan: ORCID 0000-0002-1523-9589; Alexander Epstein: ORCID 0000-0001-5945-745X; Tracy Lennertz: ORCID 0000-0001-6497-7003; Jingsi Shaw: ORCID 0000-0002-3974-5304; Kevin Dopart: ORCID 0000-0002-0617-8278 9. Performing Organization Name and Address 10. Work Unit No. (TRAIS) U.S. Department of Transportation Volpe National Transportation Systems Center 55 Broadway, 11. Contract or Grant No. Cambridge, MA 02142 12. -

Grocery Delivery MAY / 2O19

1 RETAIL Grocery Delivery MAY / 2O19 As global online grocery sales could reach as high as $334 billion by 2022,1 grocers are evolving delivery services and experimenting with innovative technologies to meet demand. 1 Forrester Research — The State of Global Online Grocery Retail, 2018 2 EVOLVING DELIVERY ——— Consumer expectations for quick and convenient shopping — and fast, fresh delivery — are adding pressure to the already expensive supply chain. In a low-margin industry like grocery, the substantial increase in logistics costs creates a major challenge — leading grocers to experiment with different delivery models to lower costs. Some are partnering with third-party logistics specialists (as Kroger has done with Ocado in the U.S.), while others are building their own logistics capabilities (as Ahold Delhaize has done since its 2001 purchase of Peapod). Others are blending third- party logistics with in-house capabilities. As grocery delivery gains popularity, we will see a proliferation of new models and technologies that aim to lower costs while meeting consumer demands. 3 REAL ESTATE IMPACT ——— Increased Urban Retailers Will Focus on Environments Convert a Greater Curbside Will Drive Portion of Store Pickup in the Growth in Home Space to Service Suburbs Delivery Delivery In lower-density suburban Given the high cost of last-mile Grocery retailers recognize the markets, distribution costs will food delivery, e-commerce delivery importance of having a large store be higher for retailers. As a result, options will grow faster in denser footprint that can be leveraged by retailers will focus their efforts urban markets, where distribution their delivery services. -

Asendia USA COVID-19 Update March 5 2021 V2.Xlsx

Status Key On Schedule Expect Delays Service Suspended Inbound Transportation to Asendia USA Facilities: Facility Transportation Status Date Updated Daily Updates/Comments New York - Hauppauge On Schedule 3/5/2021 Pennsylvania - Folcroft On Schedule 3/5/2021 Florida - Miami On Schedule 3/5/2021 Illinois - Elk Grove Village On Schedule 3/5/2021 California - Bell On Schedule 3/5/2021 California - Hayward On Schedule 3/5/2021 Operational Processing @ Asendia USA Facilities: Facility Processing Status Date Updated Daily Updates/Comments New York - Hauppauge On Schedule 3/5/2021 Pennsylvania - Folcroft On Schedule 3/5/2021 Florida - Miami On Schedule 3/5/2021 Illinois - Elk Grove Village On Schedule 3/5/2021 California - Bell On Schedule 3/5/2021 California - Hayward On Schedule 3/5/2021 USPS International Service Centers: Facility Processing Status Date Updated Daily Updates/Comments USPS reported that Canada Post has informed that they have recovered their operations in Toronto and that USPS can begin to initiate normal flow of mail from LAX and SFO to Toronto effective March 1 (vs. diverting to Vancouver). - Iceland Post has notified that there were missing EDI messages but USPS not sure it is impacting any of its volume. Claire was awaiting further clarification from ISC New York (JFK) Expect Delays 3/5/2021 Iceland Post and would update if it were at all an impact. - SFO to French Polynesia had a slight delay, with oldest mail Feb. 13, but not huge volume impact. - Antigua and Barbuda – USPS just got word that they are closing due to COVID but not sure if that will lead to an embargo, no word yet and not on the list at moment. -

Fuel Cell Hybrid Electric Delivery Van Project Project ID: TA016

Fuel Cell Hybrid Electric Delivery Van Project Project ID: TA016 Jason Hanlin Center for Transportation and the Environment (CTE) 2019 DOE Annual Merit Review May 1, 2019 This presentation does not contain any proprietary, confidential, or otherwise restricted information. Overview 2 Timeline Barriers Project Start: 7/15/2014 Technology Validation Project End: 04/30/2022 A. Lack of Fuel Cell Electric Vehicle Performance and Durability Data Budget Market Transformation Total Project Budget: $ 11,264,505 D. Market uncertainty around the Total Recipient Share: $ 8,282,434 need for hydrogen infrastructure Total Federal Share: $ 2,982,071 versus timeframe and volume of Total DOE Funds Spent: $ 1,034,573* commercial fuel cell applications *as of Feb. 2019 F. Inadequate user experience for many hydrogen and fuel cell applications Partners US DOE, CARB, CEC, SCAQMD: Project Sponsors UPS: Commercial Fleet Partner and Operator CTE: Prime Contractor and Project Manager Hydrogenics, UES, UT-CEM, Lithium-Werks: Subcontractors 3 Relevance – Project Objectives Overall Objectives • Substantially increase the zero emission driving range and commercial viability of electric drive medium-duty trucks – Phase 1: develop a demonstration vehicle in order to prove its viability to project sponsors, commercial fleet partner (UPS), and other stakeholders [Barriers A & F] – Phase 2: build and deploy a pre-commercial volume (15) of the same vehicle for at least 5,000 hours of in-service operation [Barriers A & F] • Develop an Economic & Market Opportunity Assessment -

A Study of Road Autonomous Delivery Robots and Their Potential Impacts on Freight Efficiency and Travel

Portland State University PDXScholar Civil and Environmental Engineering Faculty Publications and Presentations Civil and Environmental Engineering 2020 A Study of Road Autonomous Delivery Robots and Their Potential Impacts on Freight Efficiency and Travel Dylan Jennings Portland State University Miguel A. Figliozzi Portland State University, [email protected] Follow this and additional works at: https://pdxscholar.library.pdx.edu/cengin_fac Part of the Transportation Engineering Commons Let us know how access to this document benefits ou.y Citation Details Jennings, Dylan and Figliozzi, Miguel A., "A Study of Road Autonomous Delivery Robots and Their Potential Impacts on Freight Efficiency andr T avel" (2020). Civil and Environmental Engineering Faculty Publications and Presentations. 549. https://pdxscholar.library.pdx.edu/cengin_fac/549 This Pre-Print is brought to you for free and open access. It has been accepted for inclusion in Civil and Environmental Engineering Faculty Publications and Presentations by an authorized administrator of PDXScholar. Please contact us if we can make this document more accessible: [email protected]. Jennings, Figliozzi 1 A STUDY OF ROAD AUTONOMOUS DELIVERY ROBOTS AND THEIR POTENTIAL IMPACTS ON FREIGHT EFFICIENCY AND TRAVEL Dylan Jennings Student Researcher Transportation Technology and People (TTP) Lab Department of Civil and Environmental Engineering Portland State University PO Box 751—CEE Portland, OR 97207-0751 Email: [email protected] Miguel Figliozzi Director Transportation Technology and People (TTP) Lab Department of Civil and Environmental Engineering Portland State University PO Box 751—CEE Portland, OR 97207-0751 Phone: 503-725-4282 Fax: 503-725-5950 Email: [email protected] PLEASE CITE AS Jennings, D. and Figliozzi, M., 2020. -

A Metro-Based System As Sustainable Alternative for Urban Logistics in the Era of E-Commerce

sustainability Article A Metro-Based System as Sustainable Alternative for Urban Logistics in the Era of E-Commerce Rafael Villa 1,* and Andrés Monzón 2 1 School of Technology and Science, Camilo José Cela University, 28692 Madrid, Spain 2 Transport Research Centre (TRANSyT), Universidad Politécnica de Madrid, 28040 Madrid, Spain; [email protected] * Correspondence: [email protected] Abstract: Business to consumer e-commerce (B2C) has increased sharply in recent years driven by a growing online population and changes in consumer behavior. In metropolitan areas, the “Amazon effect” (online retailers’ vast selection, fast shipping, free returns, and low prices) has led to an increased use of light goods vehicles. This is affecting the rational functioning of the transport system, including a high degree of fragmentation, low load optimization, and, among other externalities, higher traffic congestion. This paper investigates the potential of a metro system, in a big city like Madrid, to provide delivery services by leveraging its existing carrying capacity and using the metro stations to collect parcels in lockers. It would be a new mixed distribution model for last-mile deliveries associated with e-commerce. To that end, the paper evaluates the cost and impacts of two alternative scenarios for managing the unused space in rolling stock (shared trains) or specific full train services (dedicated trains) on existing lines. The external costs of the proposed scenarios are Citation: Villa, R.; Monzón, A. A compared with current e-commerce delivery scenario (parcel delivery by road). The results show Metro-Based System as Sustainable that underground transport of parcels could significantly reduce congestion costs, accidents, noise, Alternative for Urban Logistics in the GHG emissions, and air pollution. -

Restaurant Delivery + Delivery Automation

1 RETAIL Restaurant Delivery + Delivery Automation As remote diners become more prevalent in today’s culture, restaurants are racing to serve them. 2 FOOD AT HYPERSPEED ——— Restaurants must solve the delivery equation in order to be competitive and capture increasing consumer demand for remote dining. Restaurants rely on either direct delivery or partnering with third-party providers, both of which are costly. While direct delivery offers a more unified brand experience, it involves significant investment in physical and technological infrastructure. Third-party delivery is often the preferred solution, as those providers reach a broader customer base. However, the fees and commissions paid for those services cut into already narrow profit margins and are a growing concern industrywide. 3 This incredible shift in preference from in-store dining to at-home delivery opens up enormous opportunity for restaurants everywhere. Like guests at a masquerade ball, these restaurants can become whoever and whatever they want in the digital world, regardless of their location, financing, or physical footprint. It’s exciting! Jay Coldren Managing Director, Eat + Drink Streetsense 4 Delivery Pillars RETAIL Last-Mile Technology + Delivery Automation Welcome to Retail Innovation Watch, a collaboration between CBRE and Streetsense thought leaders. The series highlights key trends across the consumer and retail sectors, Partner- Ghost current examples of industry innovation, and ships Kitchens forward-looking predictions for what’s next. 5 PILLAR 1: ——— LAST-MILE DELIVERY In a product’s journey from warehouse shelf to customer doorstep, the “last mile” of delivery is the final step of the process — the point at which the package finally arrives at the buyer’s door. -

Last Mile Package Delivery Via Rural Transit: Project Summary and Pilot Outcomes

TTI: 0-6891 Last Mile Package Delivery via Rural Transit: Project Summary and Pilot Outcomes Technical Report 0-6891-R1 Cooperative Research Program TEXAS A&M TRANSPORTATION INSTITUTE COLLEGE STATION, TEXAS in cooperation with the Federal Highway Administration and the Texas Department of Transportation http://tti.tamu.edu/documents/0-6891-R1.pdf Technical Report Documentation Page 1. Report No. 2. Government Accession No. 3. Recipient's Catalog No. FHWA/TX-17/0-6891-R1 4. Title and Subtitle 5. Report Date LAST MILE PACKAGE DELIVERY VIA RURAL TRANSIT: Published: January 2019 PROJECT SUMMARY AND PILOT OUTCOMES 6. Performing Organization Code 7. Author(s) 8. Performing Organization Report No. Zachary Elgart, Kristi Miller, and Shuman Tan Report 0-6891-R1 9. Performing Organization Name and Address 10. Work Unit No. (TRAIS) Texas A&M Transportation Institute The Texas A&M University System 11. Contract or Grant No. College Station, Texas 77843-3135 Project 0-6891 12. Sponsoring Agency Name and Address 13. Type of Report and Period Covered Texas Department of Transportation Technical Report: Research and Technology Implementation Office September 2015–August 2017 125 E. 11th Street 14. Sponsoring Agency Code Austin, Texas 78701-2483 15. Supplementary Notes Project performed in cooperation with the Texas Department of Transportation and the Federal Highway Administration. Project Title: Using Public Transportation to Facilitate Last Mile Package Delivery URL: http://tti.tamu.edu/documents/0-6891-R1.pdf 16. Abstract Rural transit districts and intercity bus carriers are an important link within Texas’ multimodal transportation system. Without such service providers, many rural residents that are transit dependent would be forced to either relocate or find other means of transportation. -

Trends in Last Mile Delivery

Mitsui & Co. Global Strategic Studies Institute Monthly Report May 2021 TRENDS IN LAST MILE DELIVERY ― PANDEMIC-DRIVEN GROWTH IN E-COMMERCE MARKET REVEALS THE FUTURE LANDSCAPE OF THE DELIVERY BUSINESS ― Katsuhide Takashima Industrial Research Dept. II, Industrial Studies Div. Mitsui & Co. Global Strategic Studies Institute SUMMARY Rapid growth in the e-commerce market driven by the COVID19 pandemic has created supply and demand pressures for last mile delivery, where brick-and-mortar retailers using stores as distribution sites have rapidly expanded their e-commerce business. Others have adapted through a high prevalence of MFCs (micro-fulfillment centers: small-scale distribution facilities) and by working with tech companies on labor- saving and efficiency improvement. These developments are revealing how efforts by retailers will take shape over the medium to long term, particularly in the expansion of last mile delivery through in-house operation, outsourcing, collaboration, and the proper division of distribution between MFCs and large distribution centers. These efforts should meet the growing demand for last mile delivery while upgrading the quality of distribution services by lowering cost and increasing delivery speed, accuracy, and security. The worldwide rise of the e-commerce (online shopping) market has overwhelmed delivery capacity, creating problems for last mile delivery—the final process needed to put the product into the hands of the consumer. These problems have taken different forms in different countries. For example, Japan has been grappling with more redeliveries for recipients not at home. The US has been suffering from a growing shortage of truck drivers. Retailers have been working to address these problems since before the pandemic by providing drop delivery services, home delivery lockers, and other measures.