Fedden's Forgotten Flat

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Testing the System Page 1 of 4

Testing the system Page 1 of 4 Testing the system Vehicle diagnostic, testing and information system -VAS 5051B- Test sequence Coolant temperature at least 80 °C. Vehicles with automatic gearbox: selector lever in position P or N – Connect vehicle diagnostic, testing and information system -VAS 5051B- and select vehicle system “01 - Engine electronics” from list. Engine must be idling. WARNING Test equipment must always be secured on the rear seat and operated from that position by a second person. If test and measuring instruments are operated from front passenger's seat and the vehicle is involved in an accident, the person sitting in this seat could be seriously injured when the airbag is triggered. Display on -VAS 5051B-: – From list -1- select diagnostic function “04 - Basic setting”. Display on -VAS 5051B-: 1 - Enter display group – Using the keypad -2-, enter “094” to select “Display group 094” and confirm entry with the Q key. vw-wi://rl/A.en-GB.A04.5636.29.wi::37889621.xml?xsl=3 14.01.2014 Testing the system Page 2 of 4 – Activate basic setting by touching key A . Display on -VAS 5051B-: – Increase the engine speed to above 2000 rpm for approx. 10 seconds. – Check specifications in display zones -3- and -4-. Display zones 1234 Display group 94: variable valve timing, bank 1 (right-side) and bank 2 (left-side) Display xxxx rpm --- --- --- Readout Engine speed Variable valve timing Variable valve timing Variable valve timing bank 1 bank 2 Range CS-ctrl ON Test OFF Test OFF CS-ctrl OFF Test ON Test ON Syst. -

Camshaft Deviation Codes.Pdf

AD07.61 -P-4000 -94VA Page 1 of 2 AD07.61-P-4000- Continuous camshaft adjustment - 94VA fault code description ME Angular deviation of camshafts to the crankshaft 1 Fault code 1197 Exhaust camshaft on right cylinder bank, permanent advanced ( Readout on generic scan tool) position (P0017) 1198 Exhaust camshaft on right cylinder bank, permanent retarded position (P0017) 1200 Exhaust camshaft on right cylinder bank, displacement (P0017) 1201 Exhaust camshaft on left cylinder bank, permanent advanced position (P0019) 1202 Exhaust camshaft on left cylinder bank, permanent retarded position (P0019) 1204 Exhaust camshaft on left cylinder bank, displacement (P0019) 1205 Intake camshaft on right cylinder bank, permanent advanced position (P0016) 1206 Intake camshaft on right cylinder bank, permanent retarded position (P0016) 1208 Intake camshaft on right cylinder bank, displacement (P0016) 1209 Intake camshaft on left cylinder bank, permanent advanced position (P0018) 1210 Intake camshaft on left cylinder bank, permanent retarded position (P0018) 1212 Intake camshaft on left cylinder bank, displacement (P0018) 2 Fault storage After expiry of test duration and fault Actuation of engine diagnosis Following two successive driving cycles with faults indicator lamp (EURO4) or CHECK ENGINE (MIL) malfunction indicator lamp 3 Checking frequency Continuous 4 Checked signal or status Comparison of position of the intake camshaft or exhaust camshaft to position of the crankshaft 5 Fault setting conditions 1197, 1201, 1205, 1209 - Permanent advanced position greater than a 20° crank angle 1198, 1202, 1206, 1210 - Permanent retarded position greater than a 20° crank angle 1200, 1204, 1208, 1212 - Fault if after adjustment of a camshaft the new position deviates more than a 9° crank angle from the required value. -

Off-Road Industrial Engines MAN Engines Off-Road Diesel Engines Fordiesel Agricultural and Environmental, Construction and Special Machinery and Special Construction

Industrial engines Off-Road Off-Road Diesel engines for agricultural and environmental, construction and special machinery MAN Engines Built for everyone who wants to move things in a big way. Contents MAN diesel engines for agricultural and construction machinery Performance spectrum and applications . 4 MAN key technologies . 4 Development to meet operational requirements . 4 Easy system integration . 4 Intelligent service solutions . 4 The shared component concept . 4 Modular exhaust gas treatment kit (AGN kit) . 4 Reliability . 4 Description of engines D0834 and D0836 . 6 D2676 . 8 D3876 . 10 D2868 . 12 D2862 . 14 MAN diesel engines for agricultural and construction machinery Time and cost pressure are increasing, both in agriculture and in the construction industry. This is why reliability and economic efficiency are more important in these businesses than ever before. MAN engines are the constant factor that makes the machines reliable, both in brisk day-to-day business and in their life-cycle costs. Our MAN engines can help you move things in a big way – either as a vehicle operator or as a designer. Performance spectrum and applications MAN off-road engines with a displacement of 4.6 to 24.2 liters come with ratings ranging from 110 kW to 882 kW (150 hp to 1 200 hp). Applications include: nnAgricultural machinery nnCutters and shredders nnSpecial machinery such as nnConstruction machinery nnEnvironmental and recycling snowcats nnMobile cranes and materials technology transport MAN key technologies Development to meet operational Easy system integration Our key to your success: When de signing requirements One name – one system . MAN makes and developing an MAN off-road engine, Our concepts are off-road in the truest use of a single defined engine inter- we rely on innovative technologies such sense of the word, that is to say they face to exchange data and commands as turbo-charging using variable turbine are extraordinary . -

Historical Dictionary of Air Intelligence

Historical Dictionaries of Intelligence and Counterintelligence Jon Woronoff, Series Editor 1. British Intelligence, by Nigel West, 2005. 2. United States Intelligence, by Michael A. Turner, 2006. 3. Israeli Intelligence, by Ephraim Kahana, 2006. 4. International Intelligence, by Nigel West, 2006. 5. Russian and Soviet Intelligence, by Robert W. Pringle, 2006. 6. Cold War Counterintelligence, by Nigel West, 2007. 7. World War II Intelligence, by Nigel West, 2008. 8. Sexspionage, by Nigel West, 2009. 9. Air Intelligence, by Glenmore S. Trenear-Harvey, 2009. Historical Dictionary of Air Intelligence Glenmore S. Trenear-Harvey Historical Dictionaries of Intelligence and Counterintelligence, No. 9 The Scarecrow Press, Inc. Lanham, Maryland • Toronto • Plymouth, UK 2009 SCARECROW PRESS, INC. Published in the United States of America by Scarecrow Press, Inc. A wholly owned subsidiary of The Rowman & Littlefield Publishing Group, Inc. 4501 Forbes Boulevard, Suite 200, Lanham, Maryland 20706 www.scarecrowpress.com Estover Road Plymouth PL6 7PY United Kingdom Copyright © 2009 by Glenmore S. Trenear-Harvey All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior permission of the publisher. British Library Cataloguing in Publication Information Available Library of Congress Cataloging-in-Publication Data Trenear-Harvey, Glenmore S., 1940– Historical dictionary of air intelligence / Glenmore S. Trenear-Harvey. p. cm. — (Historical dictionaries of intelligence and counterintelligence ; no. 9) Includes bibliographical references. ISBN-13: 978-0-8108-5982-1 (cloth : alk. paper) ISBN-10: 0-8108-5982-3 (cloth : alk. paper) ISBN-13: 978-0-8108-6294-4 (eBook) ISBN-10: 0-8108-6294-8 (eBook) 1. -

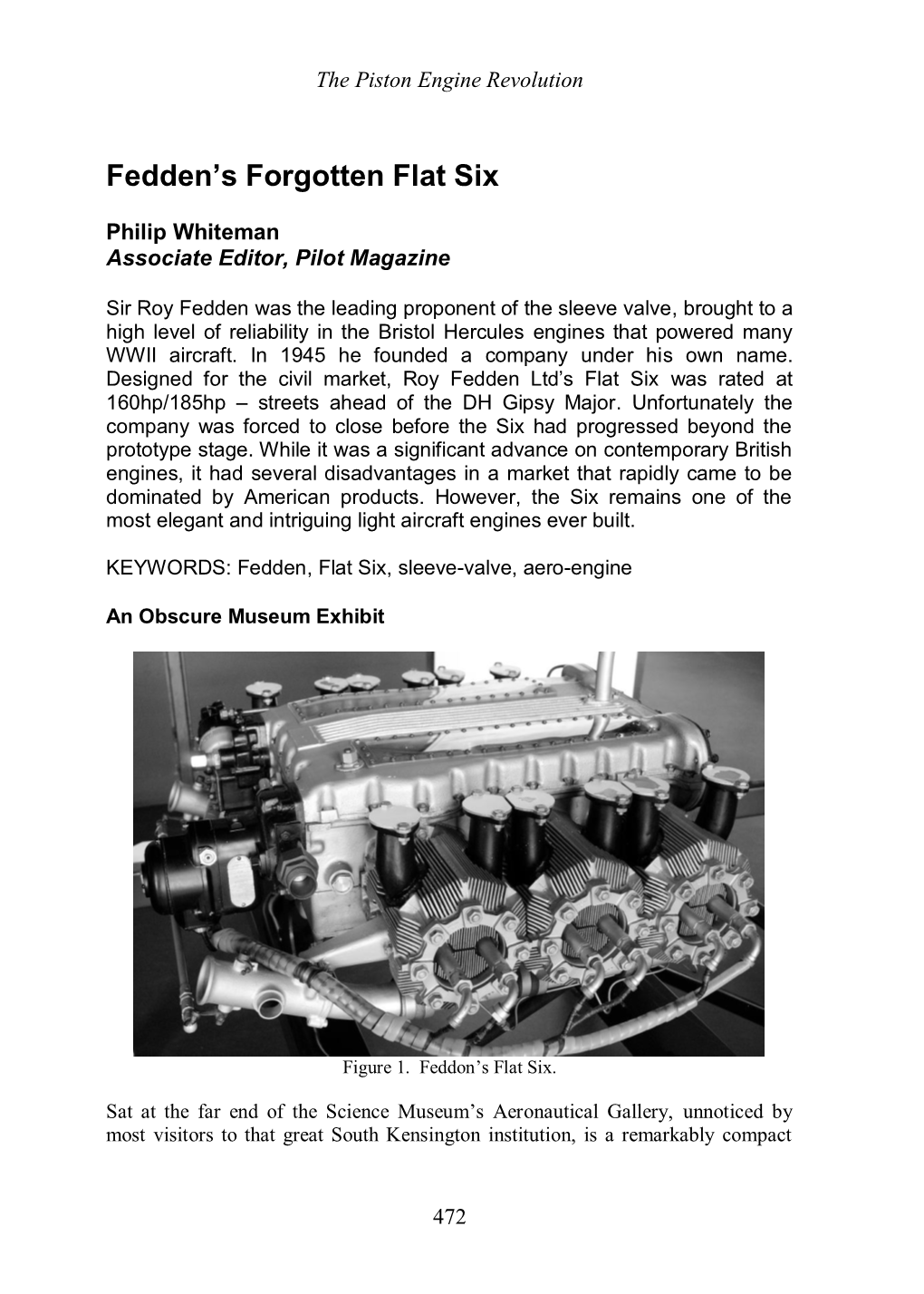

Sir A. H. Roy Fedden

Daniel Guggenheim Medal MEDALIST FOR 1938 For contributions to the development of aircraft engine design and for the specific design of the sleeve-valve aircraft engine. SIR A. H. ROY FEDDEN The advancement of aeronautics in the 20’s and 30’s was a triumph of mingled daring, skill, science, engineering, construction; and not least, the rapid development of better, more powerful, more reliable engines. To the latter art one of the principal contributors was Alfred Hubert Roy Fedden, born in Bristol, England, on June 6, 1885; in his time to become one of the world’s leading authorities on aircraft power plants. He was knighted in 1942 for his contributions to aeronautics. Fedden was educated at Clifton College, and took the engineering course at Bristol Merchant Venturers Technical College. In 1906, at the age of 21, he joined Brazil Staker and Company, Fishponds, Bristol, and for two years was in charge of touring car design. From 1909 to 1914 he was Chief Engineer; in 1914 he became Director and was in charge of engineering on internal combustion engines. In the period from 1915 until the end of World War I he was engaged in aircraft engine manufacture, producing the Rolls-Royce, Hawke and Falcon liquid-cooled engines and the 8- cylinder Renault air-cooled engine. In 1920 the Bristol Aeroplane Company appointed him Chief Engineer of its Engine Department, a position he held until 1942. Here he completed development of the Jupiter engine, which earned world-wide recognition for reliability and efficiency. With restless eagerness for improvement, he continued to develop new and successful air-cooled engines, including the Lucifer, Mercury, Cherub and Pegasus. -

The Connection

The Connection ROYAL AIR FORCE HISTORICAL SOCIETY 2 The opinions expressed in this publication are those of the contributors concerned and are not necessarily those held by the Royal Air Force Historical Society. Copyright 2011: Royal Air Force Historical Society First published in the UK in 2011 by the Royal Air Force Historical Society All rights reserved. No part of this book may be reproduced or transmitted in any form or by any means, electronic or mechanical including photocopying, recording or by any information storage and retrieval system, without permission from the Publisher in writing. ISBN 978-0-,010120-2-1 Printed by 3indrush 4roup 3indrush House Avenue Two Station 5ane 3itney O72. 273 1 ROYAL AIR FORCE HISTORICAL SOCIETY President 8arshal of the Royal Air Force Sir 8ichael Beetham 4CB CBE DFC AFC Vice-President Air 8arshal Sir Frederick Sowrey KCB CBE AFC Committee Chairman Air Vice-8arshal N B Baldwin CB CBE FRAeS Vice-Chairman 4roup Captain J D Heron OBE Secretary 4roup Captain K J Dearman 8embership Secretary Dr Jack Dunham PhD CPsychol A8RAeS Treasurer J Boyes TD CA 8embers Air Commodore 4 R Pitchfork 8BE BA FRAes 3ing Commander C Cummings *J S Cox Esq BA 8A *AV8 P Dye OBE BSc(Eng) CEng AC4I 8RAeS *4roup Captain A J Byford 8A 8A RAF *3ing Commander C Hunter 88DS RAF Editor A Publications 3ing Commander C 4 Jefford 8BE BA 8anager *Ex Officio 2 CONTENTS THE BE4INNIN4 B THE 3HITE FA8I5C by Sir 4eorge 10 3hite BEFORE AND DURIN4 THE FIRST 3OR5D 3AR by Prof 1D Duncan 4reenman THE BRISTO5 F5CIN4 SCHOO5S by Bill 8organ 2, BRISTO5ES -

Table of Contents S65B40 Engine

Table of Contents S65B40 Engine Subject Page Crankcase and Crankshaft Drive . .3 Engine Block with Bedplate Construction . .3 Crankshaft . .4 Connecting Rods . .4 Pistons . .5 Oil Supply . .6 Oil Supply Hydraulic Circuit Diagram . .8 Valvetrain . .10 Cylinder Head . .10 Hydraulic Bucket Tappet . .11 CamshaftDrive................................................12 VANOS . .13 Belt Drive . .16 Air Supply . .17 Air Intake Guide/Oil Separator/Secondary Air System . .17 Oil Separators . .18 Secondary Air System . .18 Individual Throttle Butterfly System . .19 Idle Control System . .20 Fuel Supply . .21 Cooling System . .22 Exhaust System . .24 Initial Print Date: 1/08 Revision Date: S65B40 Engine Model: E90 M3, E92 M3 Production: 2/2008 After completion of this module you will be able to: Identify the components of the S65B40 engine Identify the difference between the S85B50 and S65B40 engines Explain the oil supply system of the engine 2 S65B40 Engine Crankcase and Crankshaft Drive Engine Block with Bedplate Construction The construction and materials are identical to the S85; the upper low-pressure die-cast crankcase is made from an aluminum-silicon alloy. The cylinder bores are formed using exposed hard silicon crystals, rendering the use of cylinder liners redundant. The lower crankcase (bedplate) is also constructed using die-cast aluminum. Due to the extreme forces, grey cast iron inlays are used to reinforce the bedplate construction. These also limit crankshaft bearing clearances over a greater temperature range and thus have a positive effect on the oil flow rate. S65B40 Engine block with bedplate construction Index Explanation 1 Engine block (upper section) 2 Grey cast iron inlays 3 Bedplate construction (lower section) 3 S65B40 Engine Crankshaft The five-bearing crankshaft is forged from a single piece, including the two double-chain wheels for driving the valve gear. -

M62 Engine Details (PDF)

TABLE OF CONTENTS Subject Page M62TU Engine . .. .. 2 Vanos Operation . .3-12 Engine Cooling System. 13 IHKA System Auxilary Pump. 14 DME-ME 7.2 Engine Management. 15 IPO ME 7.2. 16 Integral Electronic Throttle System (EML). .17 Input Signal/Components. .19 Camshaft Position Sensors. 19 Hot Film Air Mass Sensor (HFM 5). 20 Integrated Ambient Barometeric Pressure Sensor. .21 Radiator Outlet Temperature Sensor. 22 DSC III Road Speed Signal. 22 Accelerator Pedal Sensor (PWG). 23 EDK Throttle Position Feedback Signal. 24 MFL Cruise Control Data Signal. .25 Brake Light Switch. 25 Can Bus. .26 Output Control Functions. .. .27 E-Box. .27 Secondary Air Injection. .28 Auxiliary Fan Control. .29 Electric Throttle Control. 30 DM-TL. .. 31 Leak Diagnosis Test Precondition. 34 M62TU Engine / ME7.2 The 4.4i X5 is equipped with the M62 TU B44 (4.4 liter) engine. Features of the M62 TU engine include: • Digital motor Electronics Control ME 7.2. • Variable positioned intake camshaft VANOS system. • “EML” Electronic Throttle Control System identified as EDK. • Compact water cooled generator (F-alternator). • Thermostat controlled transmission fluid/engine coolant heat exchanger system for automatic transmission equipped vehicles. • Non Return Fuel Rail (Running Loss Compliance). • IHKA Auxillary Water Pump. 2 M62 TU VANOS OVERVIEW The variable intake valve timing system on the M62 TU continues to be identified as VANOS. This acronym comes from the German words; VAriable NOckenwellen Steuerung, which means Variable Camshaft Control. The M62 TU VANOS system is a new variant providing stepless VANOS functionality on each intake camshaft. The system is continuously variable within its range of adjustment providing optimized camshaft positioning for all engine operating conditions. -

(12) United States Patent (10) Patent N0.: US 6,321,698 B1 Rau Et Al

US006321698B1 (12) United States Patent (10) Patent N0.: US 6,321,698 B1 Rau et al. (45) Date of Patent: Nov. 27, 2001 (54) INTERNAL COMBUSTION ENGINE 1024825 * 4/1953 (FR). 121605A * 5/1919 (GB) ................................. .. 123/551 (75) Inventors; Erhard Rau, We?heim; Wilhelm 97/40267 * 10/1997 (WO) ..................................... .. 75/22 Huettner, Waiblingen; Joerg Abtho?', Pluederhausen, all of (DE) OTHER PUBLICATIONS (73) Assignee; Daimlerchrysler AG, Stuttgart (DE) “18—Zylinder von Volkswagen”, Autos Test Technik, mot No. 11, ISSN 0027—1462, pp. 16—23, (May 15, 1998). ( * ) Notice: Subject to any disclaimer, the term of this patent is extended or adjusted under 35 * cited by examiner U.S.C. 154(b) by 0 days. Primary Examiner—Noah P. Kamen (21) Appl- NOJ 09/369,225 Assistant Examiner—Hai Huynh (22) Filed Aug 5 1999 (74) Attorney, Agent, or Firm—Kenyon & Kenyon . , _ _ (57) ABSTRACT Related US. Application Data (60) Provisional application No. 60/095,774, ?led on Aug. 7, An internal combustion engine having four individual cyl 1998- inder banks, in each case tWo cylinder banks being arranged (51) Int. c1.7 .................................................... .. F02B 75/22 in a V-éharw With respect to one another in such a Way that (52) us CL 123/54_4 the cylinder banks forming a V are disposed on both sides (58) Field of i i i i i i 4 1 54 4 of one engine plane E de?ned by a vertical aXis H that 123/54 8 55 1 54 6 54 7 54 2 symmetrically divides the internal combustion engine and ' ’ ' ’ ' ’ ' ’ ' by a longitudinal aXis L of the internal combustion engine, (56) References Cited one cylinder bank of the cylinder banks that are associated With one another in a V-shape being con?gured closer to the US. -

Diagnosis and Prognosis of Fuel Injectors Based on Control Adaptation

Diagnosis and Prognosis of Fuel Injectors based on Control Adaptation Azeem Sarwar1, Chaitanya Sankavaram2, and Xiangxing Lu3 1,2,3 Vehicle Health Management Group, Vehicle Systems Research Laboratory, General Motors Company, 30565 William Durant Blvd, Warren, MI, USA [email protected] [email protected] [email protected] ABSTRACT 54.5 mpg by 2025 (Ferguson & Kirkpatrick, 2015). Follow- ing the stricter requirements, the emission level of current in- Spark Ignition Direct Injection (SIDI) technology enables ternal combustion engines has decreased to about 5% of the better fuel economy and tail pipe emissions in vehicles emission levels that were prevalent 40 years ago (Ferguson & equipped with gasoline engines. The SIDI technology de- Kirkpatrick, 2015). pends on the ability of the system to deliver fuel at high pres- sure directly into the combustion chamber, hence making the Up until 1990s, Port Fuel Injection (PFI) Engines reflected fuel injectors key subcomponents. Reliable performance of state of the art for production gasoline engines (C¸elik & fuel injectors is vital as it directly relates to the operability of Ozdalyan, 2010). Advancement in computer-based con- the vehicle, and hence customer satisfaction in case of failure. trol made it possible to deliver gasoline precisely through It, therefore, becomes very important to devise a scheme that solenoid-based fuel injectors, just upstream or at the back of can effectively diagnose and prognose such a component. In each cylinder’s intake valve. The fuel then mixes with the this article, algorithm development for diagnosis and a path- incoming air, and gets pulled into the combustion chamber way to prognosis of fuel injectors is presented. -

Piston Engine Fundamentals TC010-05-01S

LEVEL F PPiissttoonn EEnnggiinnee FFuunnddaammeennttaallss TTCC001100--0055--0011SS Mazda Motor Corporation Technical Service Training Piston Engine Fundamentals CONTENTS TC010-05-01S 1 – INTRODUCTION ............................................................................1 Course Overview ..................................................................................1 Audience and Purpose...................................................................1 Course Content and Objectives .................................................2 How to Use This Guide .........................................................................3 Section Objectives .........................................................................3 Text and Illustrations......................................................................3 Review Exercises ..........................................................................4 2 – BASIC OPERATION.......................................................................5 Objectives .............................................................................................5 How Power is Developed......................................................................6 Harnessing Power..........................................................................6 Controlling Combustion..................................................................7 The Four-Stroke Cycle..........................................................................9 Intake Stroke............................................................................... -

ENGINEERS' WALK in BRISTOL (Blue Plaques)

Supplement to the Histelect News No. S75 August 2020 ENGINEERS’ WALK IN BRISTOL (Blue Plaques) - Part 1 by John Coneybeare There were three reasons why I suggested that the Retired Professional Engineers Club (now sadly closed) should set this up. a) In Sydney I saw the recently commenced series of pavement mounted plaques, celebrating famous Australian Writers at Circular Quay. b) The Retired Chartered Engineer’s Club in Exeter had already erected wall mounted plaques in their city and kindly showed me around. c) Bristol was planning to celebrate the bi-centenary of Isambard Kingdom Brunel’s birth in 2006. There are now 15 plaques erected on walls belonging to a science museum in Bristol called ‘We the Curious’. We are indebted to this museum for their great support. The following are mini biographies but you can see more by visiting engineerswalk.co.uk. _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Samuel Plimsoll (1824 – 1898) Mr John Chambers, of a mine owning family, gave him another chance. Following the Plimsoll was born in Bristol but by his teens dismissal of corrupt staff there was the family lived in Sheffield. He wanted to be cooperation between GNR and Plimsoll. a coal merchant exporting coal to Kings Plimsoll designed and built a revolutionary Cross, London by rail.