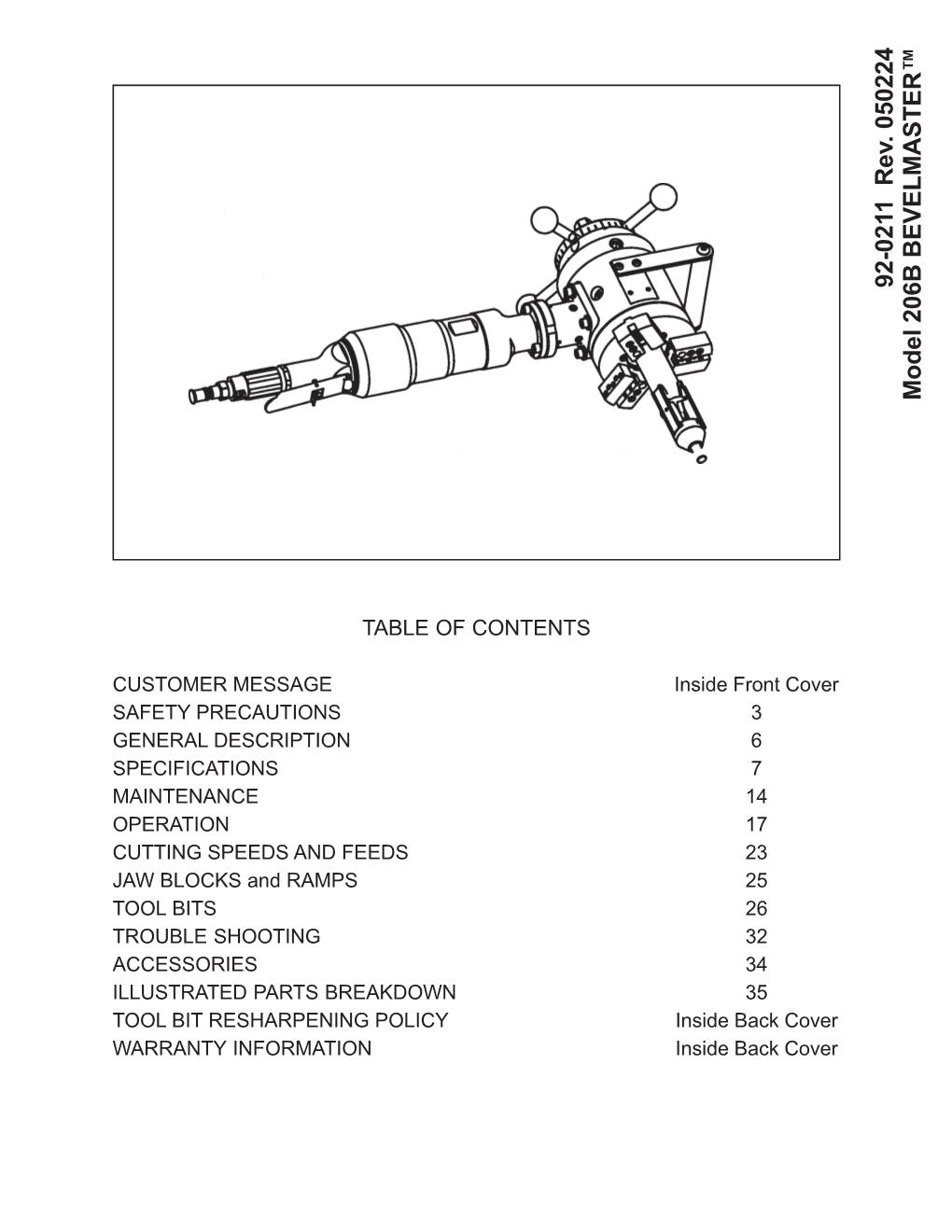

92-0211 Rev. 050224 Model 206B BEVELMASTER™ Copyright 2005 Proprietary Property of TRI TOOL Inc

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

ROUTER BIT GEOMETRY Feed the Router Bit in Such a Manner So That in Moving Through the Terms Work It Has a Chance to Bite Or Cut Its Way Freely

Compression Spiral ROUTER BIT GEOMETRY Feed the router bit in such a manner so that in moving through the Terms work it has a chance to bite or cut its way freely. If the feedrate is too Helix Angle- Angle of the cutting flute, it is measured relative to the axis fast, strain and deflection will occur. If it is too slow, friction and of the cutting toot. burning will occur. Both too fast and too slow will decrease its life and cause breakage. Flute Fadeout- The length between the end of the cutting length and the begin of the shank length The router mechanism must be well maintained for any cutting tool to perform properly. Check the collet for wear regularly. Inspect tools for CEL- Cutting edge length. collet marks indicating slipping due to wear or dust build up. Check Shank Length- The length of the cutter shank that can be inserted into spindle on a dial indicator for run-out. Collet and run-out problems cause the collet. premature toot failure and associated production difficulties. Do not use OAL- Overall cutter length. adaptor bushings to reduce size of the collet on a routing or production basis. Tools will not perform properly in bushings over an extended CED- Cutting edge diameter. period of time. Bushings are for prototype, experimentation, test and Shank Diameter- The diameter of the shank to be inserted into the collet. evaluation and not for production. Single Flute Wherever possible, use a coolant when routing. Heat caused by Use for faster feed rates in softer materials. -

Milling Speeds & Feeds

MADE IN USA MILLING SPEEDS & FEEDS Carbide Tipped Speeds & feeds are starting recommendations only. Factors such as machine, fixture and tooling rigidity, horsepower available, coolant application and others will affect the performance significantly. Please read machine operators instructions and use all safety shields and glasses before performing these operations. Use these charts for carbide tipped milling cutters. IPT = Inches Per Tooth IPM = Inches Per Minute RPM = Rotations Per Minute SFPM = Surface Feet Per Minute Cutter Diameter = Diameter of the cutter in inches RPM=SFPM*3.82/CUTTER DIAMETER IPM=IPT*RPM*#TEETH APPLICATION - MILLS AND SAWS CLASS OF MATERIAL SURFACE FEET INCHES PER MATERIALS BRINELL PER MINUTE TOOTH (SFPM) (IPT) 30-150* ALUMINUM ALLOY - WROUGHT 1000-2000 .004-.008 (500kg) MAGNESIUM ALLOY 50-90* 750-1500 .004-.008 NON-FERROUS (SOFT) LEAD ALLOY 10-20* 300-1000 .004-.008 NON-METAL AND PLASTIC – 1500-3000 .004-.008 ZINC ALLOY - DIE CAST 80-100 750-1500 .005-.010 ALUMINUM BRONZE 40-175 200-600 .003-.006 BRASS ALLOY - LEADED AND 10-100Rb 400-800 .004-.008 NON-FERROUS FREE CUTTING (HARD) NICKEL SILVER 10-100Rb 200-400 .003-.006 COPPER ALLOY - TOUGH 40-200* 200-500 .004-.008 DUCTILE CAST IRON - AUSTENITIC 120-275 75-150 .002-.004 DUCTILE CAST IRON - FERRITIC 140-270 250-400 .003-.006 DUCTILE CAST IRON - MARTENSITIC 270-400 200-300 .003-.006 CAST IRON GRAY - PEARLITIC 220-320 120-300 .002-.004 GRAY - FERRITIC 110-240 250-425 .003-.006 MALLEABLE CAST IRON - 200-320 130-225 .002-.004 MARTENSITIC LOW AND MEDIUM CARBON STEEL -

Machining of Aluminum and Aluminum Alloys / 763

ASM Handbook, Volume 16: Machining Copyright © 1989 ASM International® ASM Handbook Committee, p 761-804 All rights reserved. DOI: 10.1361/asmhba0002184 www.asminternational.org MachJning of Aluminum and AlumJnum Alloys ALUMINUM ALLOYS can be ma- -r.. _ . lul Tools with small rake angles can normally chined rapidly and economically. Because be used with little danger of burring the part ," ,' ,,'7.,','_ ' , '~: £,~ " ~ ! f / "' " of their complex metallurgical structure, or of developing buildup on the cutting their machining characteristics are superior ,, A edges of tools. Alloys having silicon as the to those of pure aluminum. major alloying element require tools with The microconstituents present in alumi- larger rake angles, and they are more eco- num alloys have important effects on ma- nomically machined at lower speeds and chining characteristics. Nonabrasive con- feeds. stituents have a beneficial effect, and ,o IIR Wrought Alloys. Most wrought alumi- insoluble abrasive constituents exert a det- num alloys have excellent machining char- rimental effect on tool life and surface qual- acteristics; several are well suited to multi- ity. Constituents that are insoluble but soft B pie-operation machining. A thorough and nonabrasive are beneficial because they e,,{' , understanding of tool designs and machin- assist in chip breakage; such constituents s,~ ,.t ing practices is essential for full utilization are purposely added in formulating high- of the free-machining qualities of aluminum strength free-cutting alloys for processing in alloys. high-speed automatic bar and chucking ma- Strain-hardenable alloys (including chines. " ~ ~p /"~ commercially pure aluminum) contain no In general, the softer ailoys~and, to a alloying elements that would render them lesser extent, some of the harder al- c • o c hardenable by solution heat treatment and ,p loys--are likely to form a built-up edge on precipitation, but they can be strengthened the cutting lip of the tool. -

BAND SAW BLADES Welcome to ARNTZ Your Cutting Expert for the Entire World of Metals

2021 Edition FactBook BAND SAW BLADES Welcome to ARNTZ Your cutting expert for the entire world of metals. 225 years of manufacturing, 225 years of tools, 225 years of passion: We are proudly looking back on a long tradition while facing the future with excitement. Complex materials are opening up new markets and alloys are developing along with higher requirements of their products behind. This requires new and innovative cutting solutions. Our specialists are being challenged with the demands of many different markets – daily. We are familiar with the materials and their cross sections – over all industries and down to the detail. Our operational structures allow us to quickly and indivi- dually address the individual need of our customers and develop optimal solutions close to you. We will assist you from the first question up to fine-tuning. Even at your site if required. Saw blades from ARNTZ are high-performance tools – economical, precise and perfectly matched to the relevant application. Our actions are guided by our high quality standards and our passion for what we do. We deliver sawing technology „Made in Germany“ that you can depend on worldwide – promised ! Innovative cutting technology. Optimized operating processes and certified quality Our experienced service technicians provide in-depth expert controls are the foundation of ARNTZ’s high-end saw knowledge that has been adapted to fit your exact require- blades. Every single step in the production process goes ments. Alongside telephone assistance and on-site support, through our multilayered control system to guarantee we also offer training modules targeted to your require- our quality standards. -

Helical's Machining Guidebook

Helical MACHINING GUIDEBOOK Quick Reference eBook for CNC Milling Practices & Techniques 1 | Machining Guidebook | © 2016 Helical Solutions, LLC Helical Contents Milling Techniques & Strategies Terminology & Common Calculations 01 | Milling Techniques . 3 04 | End Mill Construction . 37 Types of Tool Entry . 4 Geometry Definitions . 38 Ramping . 6 End Mill Construction . 40 Thin Wall Milling . 8 End Mill Anatomy . 42 Deep Pocket Milling . 10 05 | Common Calculations . 51 Finishing . 11 Decimal Conversion Chart . 52 Ball Nose Strategy . 13 Common Milling Calculations . 53 Corner Engagement . 17 Speeds & Feeds . 54 Angle Engagement . 19 Conventional vs Climb Milling . 20 06 | Tool Holding . 55 Chip Thinning . 22 Tool Holding . 56 Preventing Tool Pull Out . 58 02 | High Efficiency Milling . 23 High Efficiency Milling . 24 HEM Tooling . 25 Troubleshooting 03 | Depth of Cut . 26 07 | Troubleshooting . 60 Depth of Cut . 27 Troubleshooting Chart . 61 Depth of Cut - Peripheral . 28 Tool Wear . 65 Depth of Cut - Slotting . 34 Tool Deflection . 69 Copyright © 2016 by Helical Solutions, LLC . All rights reserved . This book or any portion thereof may not be reproduced or used in any manner whatsoever without the express written permission of Helical Solutions . 2 | Machining Guidebook | © 2016 Helical Solutions, LLC Helical 01 Milling Techniques Types of Tool Entry . 4 Ball Nose Strategy . 13 Ramping . 6 Corner Engagement . 17 Thin Wall Milling . 8 Angle Engagement . 19 Deep Pocket Milling . 10 Conventional vs Climb Milling . 20 Finishing . 11 Chip Thinning . 22 3 | Machining Guidebook | © 2016 Helical Solutions, LLC Helical Types of Tool Entry The type of part entry that is programmed has a lot of influence on the tool’s success and is one of the most punishing Theoperations type of part for entry a cutter programmed . -

Sawing Basics V63WCWO3 Operator Variables That Aid Sawing Performance When Making Blade Recommendations, There Are a Few Questions We Need to Answer

Sawing Basics V63WCWO3 Operator Variables That Aid Sawing Performance When making blade recommendations, there are a few questions we need to answer: • Which blade do we use? • Which tooth pitch do we use? • Which blade speed should we use? • Which feed rate should we use? • What is the relationship between feed & speed? • Why do we need a cutting fluid? • Why do we need blade break‐in? Which blade do we use? Items that influence selection • Machine type—Low cost, low performance machines will not allow a band saw blade to function optimally. • For low performance machines, select blades that can withstand higher shock, chatter, or • The better the feed system on a machine, the higher performance blade that can be used effectively. • Production Rate– The more cuts per hour or the longer the run time the higher the performance blades will be needed. • Cost Per Cut‐To lower the cost per cut, move to a higher performance blade. What Blade Do We Use? Items That Influence Selection Material Machinability‐ Machinability is generally rated from 0 to 100% (SAE1112, rated at 100%, is considered free cutting) • Alloy type (Carbon vs. Nickel‐based, etc.), hardness (Heat‐Treated or aged), and material shape all affect material machinability • The higher the alloy, the lower the machinability rating • The higher the material hardness, the lower the machinability • Complex material shapes will lower the machinability rating due to increase shock Abrasiveness‐ Abrasive material or coatings will reduce the life of a band saw blade‐ consider carbide tipped -

Antares, Inc. Fact Sheets Rotary Engraving © 2011 - Antares, Inc

Antares, Inc. Fact Sheets Rotary Engraving © 2011 - Antares, Inc. Description Rotary engraving is the term used to describe engraving done with a rotating cutting tool in a motorized spindle. The tool, or cutter, cuts into the surface of the material to a predetermined depth and produces a groove of the same shape and dimension of the cutter. Rotary engraving can be performed on a wide variety of materials with plastic, brass, and aluminum being the most common in the awards industry. Rotary engraving can be done using the simplest pantographs to the most complex computerized engrav- ing machines. The principles are the same on all. On a pantograph, the operator lowers the cutter into the material and then forms the character by tracing a master (copy type, template, etc.). On a computerized machine, the cutter spindle (Z-axis) is lowered mechanically and then is moved laterally (X-axis / Y-axis) by stepper motors to form the characters. Engraving Cutters The tools used for rotary engraving are generally referred to as “cutters.” Cutters are manufactured from different materials and are produced in a variety of configurations specific for certain applications and materi- als. Most engraving cutters are “half-round” tools which means the blank is split or halved on center produc- ing a “single-lip” tool which is one of having only one cutting edge. This configuration affords a significant amount of clearance and allows the tool to run at relatively high speeds to maximize material removal and produce good finishes. Some cutters are also made as “quarter-round” tools which allow even greater clear- ance, but they are inherently weaker and are recommended for specific applications. -

TIVAR Fabrication & Machining

TIVAR Fabrication & Machining TIVAR can be efficiently machined using conventional Turning (cont.) machine tools and woodworking machinery. It is often necessary to run at reduced RPMs to enable the operator to keep chips clear of the machine. Care must Cutting tools should have high rake angles and sufficient be taken: it is easy to get hands caught in the machinery chip clearance to prevent clogging. If the above criteria are and debris. met, cutting speeds of up to 5,000 surface feet per minute are practical. Feed rates should be high, so that minimum Milling time is allowed for the cutting tool to heat the material by Carbide cutters designed for machining aluminum give friction. the best results. Conventional high-speed steel end mills and Very high surface finishes can be obtained by using cutters designed for machining steel can be used, but they proper cutting tools. Attempts to improve poor finishes by do not have sufficient rake angle or chip clearance for filling or sanding usually result in worsening the appearance. efficient stock removal. Cutting fluids should not be necessary, but a blast of Router bits work well for slotting and light milling. For compressed air will sometimes aid in chip removal. cutting deep slots and T-slots, it is essential that compressed air be used to blow chips away from the cutter. Sawing For circular sawing, course tooth carbide-tipped blades Planing give the best results. An 8 diameter blade should have Wood planers will readily reduce the thickness and approximately 12 teeth with lots of clearance. A number of true up the surface of TIVAR. -

Feeds and Speeds Charts

888-680-4466 • ShopBotTools.com Selecting the Right Bit/ Feeds and Speeds Charts © Copyright 2016 ShopBot Tools, Inc. page 1 Selecting the Right Bit/Feeds and Speeds Charts • October 20, 2016 © Copyright 2016 ShopBot Tools, Inc. page 2 Selecting the Right Bit/Feeds and Speeds Charts • October 20, 2016 Table of Contents Introduction .............................................................................................................................................5 Selecting the Right Bit for the Job ..........................................................................................................5 What’s the Difference Between a Square-End Bit and an End Mill? ..............................................6 Calculating Feeds/Speed with Chip Load ......................................................................................6 Feeds and Speeds ..................................................................................................................................6 Manufacturer settings for bits .................................................................................................................7 Chip load calculator ................................................................................................................................8 Feeds and speeds charts ......................................................................................................................11 Soft wood ..............................................................................................................................................11 -

Machine Tool Speeds and Feeds

Machine Tool Speeds and Feeds Recommended Speeds (sfpma) Material Drill Lathe Mill Magnesium 300 400-800 200-400 Aluminum 250 350-700 250-500 Brass & Bronze 200 250-500 150-450 Copper 70 100-250 100-200 Cast Iron (soft) 120 100-250 80-120 Cast Iron (hard) 80 50-150 50-100 Mild Steel 110 100-250 70-120 Cast Steel 50 70-150 80-100 Alloy Steels (hard) 60 50-150 30-60 Tool Steel 60 50-150 40-70 Stainless Steel 30 60-180 30-60 Titanium 30 90-200 40-60 High Manganese Steel 15 40-100 20-40 aIn surface feet per minute at the periphery of the tool for HSS (high-speed-steel) tools. For carbide-tipped tools, speeds can be twice those given. Carbide-tipped tools do not operate properly at low speeds; operate at or above the minimum speed if possible. To calculate rpm from sfpm: 3.8 × speed 4 × speed rpm = ∼ d d where speed is given in sfpm and d is the diameter of the tool (mill or drill) or workpiece (lathe) in inches. Suggested Depth of Cut in Inches Lathe Mill Material HSS Carbide HSS Carbide Aluminum 0.05 0.07 0.05 0.05 Plain Carbon Steel 0.03 0.05 0.03 0.03 Alloy Steels 0.025 0.045 0.025 0.025 Stainless Steel 0.03 0.05 0.03 0.03 Brass 0.05 0.07 0.05 0.05 1 Recommended Feeds for Turning (lathe) Tool Feed (iprb) Material Rough Cut Finish Cut Magnesium 0.015-0.025 0.005-0.010 Aluminum 0.015-0.025 0.005-0.010 Brass & Bronze 0.015-0.025 0.003-0.010 Copper 0.010-0.020 0.004-0.008 Cast Iron (soft) 0.015-0.025 0.005-0.010 Cast Iron (hard) 0.010-0.020 0.003-0.010 Mild Steel 0.010-0.020 0.003-0.010 Cast Steel 0.010-0.020 0.003-0.010 Alloy Steel (hard) 0.010-0.020 0.003-0.010 Tool Steel 0.010-0.020 0.003-0.010 Stainless Steel 0.010-0.020 0.003-0.010 Titanium 0.010-0.020 0.003-0.010 High Manganese Steel 0.010-0.020 0.003-0.010 bIn inches per revolution of the spindle. -

Feeds and Speeds for Drills, Reamers and Taps

Feeds and Speeds for Drills, Reamers and Taps TAPS —SPEED (SFM) DRILLS REAMERS MATERIAL BRINELL THREADS PER INCH HARDNESS SPEED SPEED (BHN) (SFM) POINT FEED (SFM) FEED 3-7¹₂ 8-15 16-24 25-UP Aluminum 99-101 200-250 118° M 150-160 M 50 100 150 200 Aluminum bronze 170-187 60 118° M 40-45 M 12 25 45 60 Bakelite — 80 60°-90° M 50-60 M 50 100 150 200 Brass 192-202 200-250 118° H 150-160 H 50 100 150 200 Bronze, common 166-183 200-250 118° H 150-160 H 40 80 100 150 Bronze, phosphor, 1/2 hard 187-202 175-180 118° M 130-140 M 25 40 50 80 Bronze, phosphor, soft 149-163 200-250 118° H 150-160 H 40 80 100 150 Cast iron, soft 126 140-150 90° H 100-110 H 30 60 90 140 Cast iron, medium soft 196 80-110 118° M 50-65 M 25 40 50 80 Cast iron, hard 293-302 45-50 118° L 67-75 L 10 20 30 40 Cast iron, chilled* 402 15 150° L 8-10 L 5 5 10 10 Cast steel 286-302 40-50* 118° L 70-75 L 20 30 40 50 Celluloid — 100 90° M 75-80 M 50 100 150 200 Copper 80-85 70 100° L 45-55 L 40 80 100 150 Drop forgings (steel) 170-196 60 118° M 40-45 M 12 25 45 60 Duralumin 90-104 200 118° M 150-160 M 50 100 150 200 Everdur 179-207 60 118° L 40-45 L 20 30 40 50 Machinery steel 170-196 110 118° H 67-75 H 35 50 60 85 Magnet steel, soft 241-302 35-40 118° M 20-25 M 20 40 50 75 Magnet steel, hard* 321-512 15 150° L 10 L 5 10 15 25 Manganese steel, 7-13* 187-217 15 150° L 10 L 15 20 25 30 Manganese copper, 30 Mn.* 134 15 150° L 10-12 L — — — — Malleable iron 112-126 85-90 118° H — H 20 30 40 50 Mild steel, .20-.30C 170-202 110-120 118° H 75-85 H 40 55 70 90 Molybdenum steel 196-235 55 125° M 35-45 M 20 30 35 45 Monel metal 149-170 50 118° M 35-38 M 8 10 15 20 Nickel, pure* 187-202 75 118° L 40 L 25 40 50 80 Nickel steel, 3¹₂% 196-241 60 118° L 40-45 L 8 10 15 20 Rubber, hard — 100 60°-90° L 70-80 L 50 100 150 200 Screw stock, C.R. -

Technical Reference for Cutting Tools

Technical Reference for Cutting Tools www.toolmex.com Drills Size Equivalents Drill Size Decimal Equivalent Drill Metric Decimal Drill Metric Decimal Drill Metric Decimal Drill Metric Decimal Size (mm) Equivalent Size (mm) Equivalent Size (mm) Equivalent Size (mm) Equivalent – 0.10 .0039 45 2.08 .0820 4 5.31 .2090 15/32 11.91 .4688 – 0.20 .0079 44 2.18 .0860 3 5.41 .2130 – 12.00 .4724 – 0.25 .0098 43 2.26 .0890 7/32 5.56 .2188 31/64 12.30 .4844 – 0.30 .0118 42 2.37 .0935 2 5.61 .2210 1/2 12.70 .5000 80 0.34 .0135 3/32 2.38 .0938 1 5.79 .2280 – 13.00 .5118 79 0.37 .0145 41 2.44 .0960 A 5.94 .2340 33/64 13.10 .5156 1/64 0.40 .0156 40 2.50 .980 15/64 5.95 .2344 17/32 13.49 .5312 78 0.41 .0160 39 2.53 .0995 – 6.00 .2362 35/64 13.89 .5469 77 0.46 .0180 38 2.58 .1015 B 6.05 .2380 – 14.00 .5512 – 0.50 .0197 37 2.64 .1040 C 6.15 .2420 9/16 14.29 .5625 76 0.51 .0200 36 2.71 .1065 D 6.25 .2460 37/64 14.68 .5781 75 0.53 .0210 7/64 2.78 .1094 1/4 6.35 .2500 – 15.00 .5906 74 0.57 .0225 35 2.79 .1100 E 6.35 .2500 19/32 15.08 .5938 – 0.60 .0236 34 2.82 .1110 F 6.53 .2570 39/64 15.48 .6094 73 0.61 .0240 33 2.87 .1130 G 6.63 .2610 5/8 15.88 .6250 72 0.64 .0250 32 2.95 .1160 17/64 6.75 .2656 – 16.00 .6299 71 0.66 .0260 – 3.00 .1181 H 6.76 .2660 41/64 16.27 .6406 – 0.70 .0276 31 3.05 .1200 I 6.91 .2720 21/32 16.67 .6562 70 0.71 .0280 1/8 3.18 .1250 – 7.00 .2756 – 17.00 .6693 69 0.74 .0292 30 3.26 .1285 J 7.04 .2770 43/64 17.07 .6719 – 0.75 .0295 29 3.45 .1360 K 7.14 .2810 11/16 17.46 .6875 68 0.79 .0310 28 3.57 .1405 9/32 7.14 .2812 45/64 17.86 .7031 1/32