Chrysler Electronic Ignition in a Prestolite Distributor (Copyright 1987, C.M

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

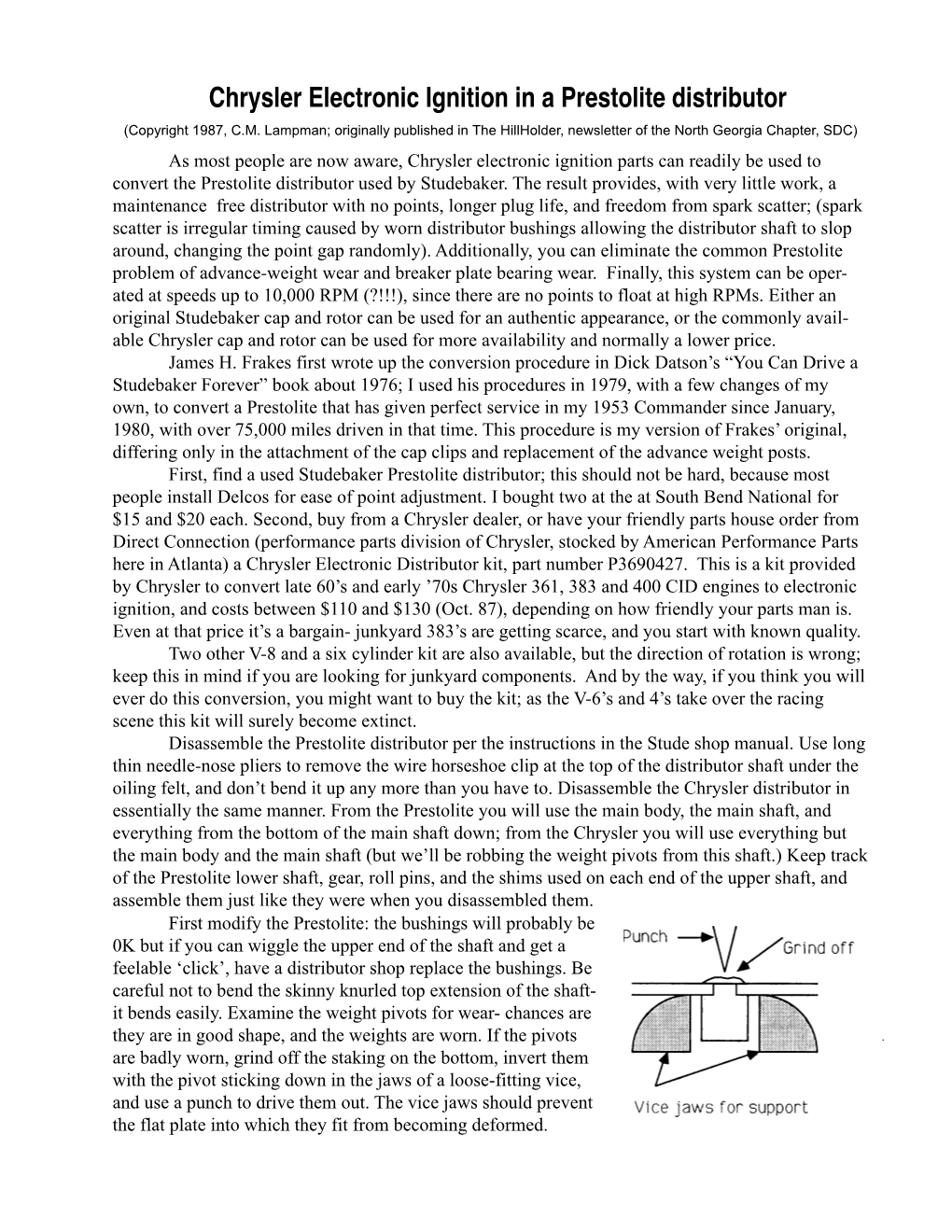

-

Studebaker-Packard Corporation

STUDEBAKER-PACKARD CORPORATION SOUTH BEND 27, INDIANA TWIN-TRACTION LUBRICANT All Twin-Traction type rear axle assemblies in- STUDEBAKER PAGE stalled in Studebaker passenger cars and trucks at the AIR CONDITIONING COMPRESSOR SUCTION VALVE- factory use a special Twin-Traction lubricant. 1959-61 Lark Models............................... 5 ALTERNATOR FAN AND PULLEY, LEECE-NEVILLE......... 3 The Twin-Traction axle assembly requires a special ALUMINUM CONNECTING ROD AND MAIN BEARINGS lubricant and only Studebaker-Packard Twin-Trac- FOR THE 6-170 ENGINE HEAVY-DUTY PASSENGER CAR AND TRUCK SERVICE.......................... 4 tion lubricant is recommended when adding or chang- BACK-UP LIGHT SWITCH-1961 Lark LHC Models With ing the lubricant. This is so stated in the current Pas- Std. ond O.D. Transmissions...............3 senger Car Shop Manual and in the Owner’s Guide BRAKE PEDAL SHAFT END PLAY-1961 Lark Models with which comes in each vehicle. Flightomatic Transmission ......................1 CLIMATIZER FRESH AIR CONTROL-1961 Lark Models...... 5 Studebaker-Packard Twin-Traction lubricant is CLUTCH AND BRAKE PEDALS RELOCATED-1961 Lark LHC the very best lubricant that can be used in any Stude- Models................................... 2 COOLING SYSTEM THERMOSTATS-1961 V Models........ 3 baker axle whether it is the Twin-Traction or Stand- CONVERTIBLE TOP PROTECTIVE COVER-1961 Models......6 ard type., In view of the high percentage of Twin-Trac- DIRECTIONAL SIGNAL SWITCH-1961 Models...............3 tion axles being used in production and to avoid in- DIRECT READING AMMETER AND OIL PRESSURE GAUGES . 7 stallation of the incorrect lubricant, we urge all dealers ENGINE DIESELINGG ................................... 4 FRONT DOOR INNER PANELS-1955-58 Models-D and F to use Studebaker-Packard Twin-Traction lubricant in Body Types....................................... -

Death of John W. Studebaker P97 John W

Volume 37, Issue 4 Collecting, recording and sharing the genealogical history of family groups Fall 2002 Death of John W. Studebaker P97 John W. had married Hannah Ulery, sister to Mary, wife of his brother David, thus making these two families particularly close. John became a 'Visiting Brother" in the Church. He continued to buy and sell land after he came to Ohio. His health must not have been good, as he made his will April 23, 1832 and revised it that June when he was only 45 years old. He died the following January, leaving 14 living children, 7 of whom were minors. Hannah Ulery had her hands full, but with the help of her older children, managed to keep the family together. Both she and her sister were strong characters. I found no record of any of John's children being apprenticed. Perhaps John and Hannah did not approve of how Abraham handled the guardianship of David's offspring. The two Ulery sisters, now both relatively young widows By Miriam Owen Irwin with large families, had the advantage of being born into two P984-611 fine, supportive families. They were daughters of Elder Samuel Ulery and his wife, Mary Elizabeth Brumbaugh. John and Hannah's oldest son, Samuel [+P971] was 25 and married to Elizabeth Minnich when John W. died. As his inheritance, he received a farm called the Knoop place. Later they moved to Clark County, Ohio. We have not been able to follow the genealogy of Samuel's eight children. Mary Studebaker [+P972] had married Eli Gump before her father died. -

What Is a Studebaker?

ALL THINGS STUDEBAKER! What is a Studebaker? For those who do not know . it is a vehicle officially produced, in various forms, since 1852. The Studebaker Drivers Club is one of the largest single-marque car clubs in the world, in existence since 1962. The Studebaker Drivers Club holds an International Meet annually and the 55th is in Mansfield, Ohio. The Studebaker Extravaganza is open to the public on SATURDAY, SEPTEMBER 14, 9 am until 3 pm at the Richland County Fairgrounds. There will be not one, but TWO electric Studebaker buggies dating to 1908, campers, fire trucks, hot rods and modifieds, classics, possibly a wagon (Studebaker manufactured them for the US Army during the Civil War), parts vendors, a Studebaker band performance and more! Studebaker produced military trucks, aircraft engines and the Weasel, a tracked carrier, during World War II. Studebaker has owned Packard, Pierce-Arrow, STP, Gravely, Clarke, Onan, Empire-Detroit steel mill, and was absorbed by the McGraw-Edison Company which was acquired by Cooper Industries. Look further . the Studebaker Extravaganza flyer is included! Please share this with your friends. Saturday, September 14, 2019 Mansfield, Ohio ALL THINGS STUDEBAKER! Fire trucks, classics, campers, modified/hot rods, race cars, parts, Studebaker Band performance 1908 Electric Studebakers Studebaker-family members invited, Parts vendors will be open 9 am to Noon such as Packard, Everett-Metzger- 1908 Electrics will be on display until Noon Flanders (EMF), Richland County Fairgrounds Pierce Arrow 750 North Home Rd, Mansfield, Ohio 44906 Contact: Dave Hamblin $10 per person [email protected] 419.947.1360 Age 15 and younger FREE www.sdcmeet.com/extra . -

Engine Engine

Engine From Hillsboro, Ohio, Randy Wilkin’s 1946 truck ENGINE SECTION GLOssARY Engine Identification Charts for 1939-54 Champion or Commander ..............160 1955-64 Car .................................................161 Trucks: 1941-56 ............................................162 Trucks: 1957-63 ...........................................163 Cylinder Heads & Gaskets ...........................164 Motor Mounts & Kits ...........................164-165 McKinnon Engine Gaskets & Seals ..............166 Crankshaft ........................................... 168-169 Camshaft ......................................................169 Main Bearings & Rods .................................170 Pistons ..........................................................171 Oil Pumps & Related Parts .................. 172-173 Valves ................................................... 174-175 Manifold & Exhaust ............................ 176-177 Gasket & Seal Sets ................................ 178-179 Blocks & Frame Brackets ..............................180 159 Major & Minor Rebuild Kits ............... 181-182 The following charts are designed to help you identify the type of engine in your car. At the top of each chart is “where to look” directions to help you locate the serial & engine numbers. If you’re unsure what year or model your car is, then use the starting engine numbers listed below. 1939-42 & 1946 CHAMPION CAR SERIAL NUMBER PLATE: 1939 ChampioN: Under the front fender, left side of frame 1940 ChampioN: Either on the left front door -

Studebaker V-8 Engine Identification

Studebaker V-8 Engine Identification Compiled by Skip Lackie from parts books, service letters, and other documentation Starting Engine Number Year and Model Used Displacement Notes* B-1 1964 R3/4 Paxton aftermarket 304 JT-1,001 1963 Lark/Hawk 63V w/R1 289 3 JTC-1,001 1963 Lark/Hawk 63V w/R1 (Canada) 289 3 JTS-1,001 1963 Lark/Hawk 63V w/R2 supercharged 289 3 JTSC-1,001 1963 Lark/Hawk 63V w/R2 supercharged (Canada) 289 3 K-1,001 1956 Golden Hawk 56J w/OD 352 1 L-101 1958 Packard 58L 289 LS-101 1957 Clipper 57L supercharged 289 LS-5,201 1958 Packard Hawk 58L-K9 supercharged 289 P-101 1955 President 6H 259 P-22,001 1956 President/Pinehurst/Sky Hawk 56H 289 P-39,601 1957 President/Broadmoor/Silver Hawk 57H 289 P-60,701 1958 President/Marshall/Silver Hawk 58H 289 P-70,501 1960 Hawk 60V 289 2 P-74,701 1961 Hawk/Cruiser/Marshall 61V 289 P-79,801 1962 Lark/Hawk 62V 289 P-93,601 1963 Lark/Hawk 63V 289 3 PC-101 1955 President 6H (Canada) 259 PC-601 1956 President 56H (Canada) 289 PC-1,501 1957 President 57H (Canada) 289 PC-2,001 1958 President 58H (Canada) 289 PC-2,201 1960 Hawk 60V (Canada) 289 PC-2,501 1961 Hawk/Cruiser/Marshall 61V (Canada) 289 PC-2,801 1962 Lark/Hawk 62 V (Canada) 289 PC-3,401 1963 Lark/Hawk 63V (Canada) 289 3 PL-101 1955 President 6H (Los Angeles plant) 259 PL-2,701 1956 President 56H (Los Angeles plant) 289 PS-1,001 1957 Golden Hawk 57H-K7 supercharged 289 PS-5,501 1958 Golden Hawk 58H-K7 supercharged 289 R-1,001 1963 Avanti w/R1 289 RS-1,001 1963 Avanti w/R2 supercharged 289 R3S-H320 1964 Avanti/Hawk/Lark-type w/R3 supercharged -

Police Fail Either to Criticize Or to Praise New Traffic

VOLUME 47: No 14. South Amboy, N. J., Friday, July 8, 1927. Price Four Cents. POLICE FAIL EITHER TO CRITICIZE OR BUY TICKETS ! BOYS ENJOY NINE FIREMEN SLIGHTLY INJURED JN ADVANCE OVERSIGHT HIKE TO PRAISE NEW TRAFFIC SIGNAL LIGHT For Legion Excunion Ai Capacity Of Preibyterian Boy< and Pastor Camp WHEN TRUCK STRIKES LIGHT POLE Boat Is Limited Beyond Spotswood. Policemen Meeting With Mayor Kvist Give Indieations At an unusually enthusiastic meet- Dr. G. E. Sehlbrede, Pastor of Driver Of Protection Apparatus Unable To Make Turn ing of Lufce A. Lovely Post of the the First Presbyterian; Church, to- ', That More, Extensive Tests Are Needed—Many Are American Legion, the final plans for gether witih Messrs. Everitt Sheppard From Feltus Street Into Bordentown Avenue—Claims tho Moonlight Excursion of the Post and LaiMont ilnjrraham, took the boy Fined Heavily For passing Red Signal—More Tonight as outlined by Chairman Downs, were members of the Children's Bible To Have Done All Possible To Swing Heavy Machine. approved, and everything is now set Study Class to a point beyond Spots- Traffic conditions at the corner of States to permit right hand turns to for the big day. The boys all have wood on an overnight camiping trip, instructions to, loot for a clear day, Turning into Bordentown avenue somewhat sharp swerve at the first Main street and Stevens avenue over be made in the tfiaee of a stop signal leaving this city Thursday just after out of Ketlus street last Monday af- part o't the turn, felt his truck sway the week end and holiday were seem- indication, here such turns are not al- and tho committee .has very thorough- noon, and returning Saturday aboqt ly investigated a number oif alman- ternoon the big Mack .pumper iire over somewhat and :eased off a little ingly neither any better nor worse lowed. -

Studebaker's 1956 Golden Hawk by Frank Ambrogio Studebaker's 1956 Golden Hawk by Frank Ambrogio

Studebaker's 1956 Golden Hawk by Frank Ambrogio Studebaker's 1956 Golden Hawk by Frank Ambrogio The 1956 Studebaker Golden Hawk is a unique car However, this was not always the case . ..1 which never achieved the level of acceptance pre- There was a time when no one seemed to dicted at its introduction. It's the only product of the notice the heavy front end. During its inaugu- Studebaker-Packard Corporation to reflect its dual com- ral year, the 1956 Golden Hawk was given pany heritage. The platform was the 1953 Studebaker high marks in almost every category, includ- Starliner. The engine and automatic transmission, were ing handling. both products of the Packard arm of the corporation. Several magazines of the period, pub- The management of Studebaker-Packard probably felt lished test drive reports. Tom McCahill had the car would appeal to both Studebaker and Packard fans. the only negative commentary on the car's However, the opposite happened. The Packard power handling. Here are some of the comments: plant never generated much interest among most Studebaker fans. The Packard crowd also fai-led to Mechanix Illustrated April 1956 Tom embrace this illegitimate offspring of orphaned parents. McCahill: "Due to the tremendous torque of the engine cornering maneuvers. The ride was comfortable at all As a matter of fact, the old car hobby, in general, has been (380 foot-pounds @ 2800 rpm) and due to the fact that the times." an apathetic audience. Hawk is quite a nose heavy car (because of its heavy Motor Life Oct 1956 Ken Fermoyle: "This car had Yet, the model has a lot going for it. -

Summary of Sexual Abuse Claims in Chapter 11 Cases of Boy Scouts of America

Summary of Sexual Abuse Claims in Chapter 11 Cases of Boy Scouts of America There are approximately 101,135sexual abuse claims filed. Of those claims, the Tort Claimants’ Committee estimates that there are approximately 83,807 unique claims if the amended and superseded and multiple claims filed on account of the same survivor are removed. The summary of sexual abuse claims below uses the set of 83,807 of claim for purposes of claims summary below.1 The Tort Claimants’ Committee has broken down the sexual abuse claims in various categories for the purpose of disclosing where and when the sexual abuse claims arose and the identity of certain of the parties that are implicated in the alleged sexual abuse. Attached hereto as Exhibit 1 is a chart that shows the sexual abuse claims broken down by the year in which they first arose. Please note that there approximately 10,500 claims did not provide a date for when the sexual abuse occurred. As a result, those claims have not been assigned a year in which the abuse first arose. Attached hereto as Exhibit 2 is a chart that shows the claims broken down by the state or jurisdiction in which they arose. Please note there are approximately 7,186 claims that did not provide a location of abuse. Those claims are reflected by YY or ZZ in the codes used to identify the applicable state or jurisdiction. Those claims have not been assigned a state or other jurisdiction. Attached hereto as Exhibit 3 is a chart that shows the claims broken down by the Local Council implicated in the sexual abuse. -

Complete Studebaker Manual 1929-Part1

OWNER'S MANUAL Studebaker President Eight 131 and 121-inch Wheelbase Models THE STUDEBAKER CORPORATION OF AMERICA sotJT1-IBEND, INDIANA, LICENSE DATA Number of cylinders Cylinder Bore 3% inches Stroke inchqs Piston Displacement 336 cubic inches Horse power (N. A. C. C. Rating) Wheelbase 131 and 21 inches Engine Number—On top surface of fan bracket boss. Serial Number—on plate riveted to frame under left front fender. Body Number-—On plate attached to front of dash under hood. on the weight of any model can be ob- tained from the dealer. The Use of This Book For the convenience of the owner we have divided the book into three sections, "Operation," "Care" and "Adjustments." The first section, starting on page 5, contains driving sug- gestions and information on the instruments and controls. This section of the book is of great importanceand should be thoroughly read by every owner no matter how experi- enced a motorist he may be. The second section, starting on page 16, carries instructions on the lubrication and care of the car, including many details which will be of interest to every owner. The third section, starting on page 35, covers in detail a number of adjustment operations. To the car owner who desires to take advantage of the facilities of a Studebaker- Erskine Service Station, this section may not appeal and it need not be read unless desired. The book should always be kept in the car, however, as this section may prove of value, if at any time when touring, it is necessaryto go to a garage not familiar with the car. -

UAW Studebaker-Packard Department Records

THE UAW STUDEBAKER - PACKARD DEPARTMENT COLLECTION Papers, 1950-1962 (Predominantly 1954-1962) 1.5 linear feet Accession Number 42 L.C. Number MS The papers of the UAW Studebaker - Packard Department were deposited in the Archives of Labor and Urban Affairs in October of 1962 by the UAW Solidarity House and opened for research in 1972. The UAW Studebaker - Packard Department was organized shortly after the merger of the two companies in 1954 when economic factors, including automation, were making it necessary for small plants and corporations to combine in order to successfully compete with the larger automobile manufacturers. Locals included in the UAW Studebaker - Packard Department were Packard Local 190, Detroit, Studebaker Local 5, South Bend, Studebaker Local 255, Los Angeles, Local 125, Minneapolis, Local 1555 in Chicago, and Local 525 in Canada. In 1955, prior to the opening date of negotiations, several locals met to discuss the best course for bargaining with the corporation and were successful in attempting joint negotiations for pensions, SUB, Cost of Living Allowance, and wage increases for skilled trades. Other matters were negotiated separately by each local. In 1956, Studebaker - Packard Corporation, still in financial difficulties, entered an "advisory management agreement" with the Curtiss - Wright Corporation which resulted in halting production and the laying off of employees in the Detroit Packard plant. A few Packards were built at the South Bend plant, but that was discontinued in 1958. The company, still experiencing losses in 1958, cancelled its "advisory management agreement" with Curtiss - Wright and initiated a program of diversification. The introduction of the Lark in 1959 was a great success, but the gains made were lost when the Big Three introduced compact cars in 1960. -

"The Most Glorious Story of Failure in the Business": the Studebaker-Packard Corporation and the Origins of ERISA

University at Buffalo School of Law Digital Commons @ University at Buffalo School of Law Journal Articles Faculty Scholarship Spring 2001 "The Most Glorious Story of Failure in the Business": The Studebaker-Packard Corporation and the Origins of ERISA James A. Wooten University at Buffalo School of Law Follow this and additional works at: https://digitalcommons.law.buffalo.edu/journal_articles Part of the Retirement Security Law Commons Recommended Citation James A. Wooten, "The Most Glorious Story of Failure in the Business": The Studebaker-Packard Corporation and the Origins of ERISA, 49 Buff. L. Rev. 683 (2001). Available at: https://digitalcommons.law.buffalo.edu/journal_articles/148 This Article is brought to you for free and open access by the Faculty Scholarship at Digital Commons @ University at Buffalo School of Law. It has been accepted for inclusion in Journal Articles by an authorized administrator of Digital Commons @ University at Buffalo School of Law. For more information, please contact [email protected]. "The Most Glorious Story of Failure in the Business": The Studebaker-Packard Corporation and the Origins of ERISA JAMES A. WOOTENt The Studebaker-Packard Corporation occupies a special place in the lore of the Emlloyee Retirement Income Security Act of 1974 (ERISA). No single event is more closely associated with ERISA than the shutdown of the Studebaker plant in South Bend, Indiana.2 When Studebaker-Packard closed the facility in December 1963 t Associate Professor of Law, University at Buffalo School of Law. I have benefited from conversations or interviews with a number of participants in the events recounted here. Thanks to Frank Cummings, Lester Fox, Vance Hartke, Ken Morris, Robert Paul, the late Leonard Woodcock, and Howard Young for sharing their recollections with me. -

Studebaker-Bendix Heritage Trail

SOUTH BEND’S TITANS OF There are few better ways to learn TheINDUSTRY Bend’s history than traveling the Studebaker- Learning more is simple. You can navigate the trail by referencing the map in this Bendix Trail. It highlights two companies that shaped South Bend and the surrounding brochure or by utilizing the addresses under each destination. Driving the entire trail area through the factories and homes they built and the churches they funded. takes approximately 90 minutes. Allow additional time for visiting museums. STUDEBAKER BLACKSMITH SHOP HIGHWAY MARKER & CARRIAGE FACTORY SITE SW. CORNER OF W. WASHINGTON & MICHIGAN ST. CORNER OF S. MICHIGAN ST. JMS BUILDING & E. JEFFERSON BLVD. 108 N. MAIN ST. 2 Emigrating from Gettysburg, Transportation and the Pennsylvania, via Ashland, movement of goods played an Ohio, the Studebaker brothers important role in South Bend’s constructed their first blacksmith growth. As car traffic increased, shop and carriage, factory on this major highways intersected here. site in 1852. Located in the heart of These included Lincoln and Dixie South Bend’s growing business district Highways and the Michigan Road. near the St. Joseph River (look to the east), John M. Studebaker constructed the 1 the Studebakers’ business grew rapidly as JMS office building (pictured) in 1909. a supplier of wagons during the Civil War. It was South Bend’s tallest building at the They remained on this site until the late 1880s. time of its construction and was connected Production then moved to Studebaker’s newer to other nearby buildings by tunnels. plant south of downtown. STUDEBAKER ADMINISTRATION BUILDING 635 S.