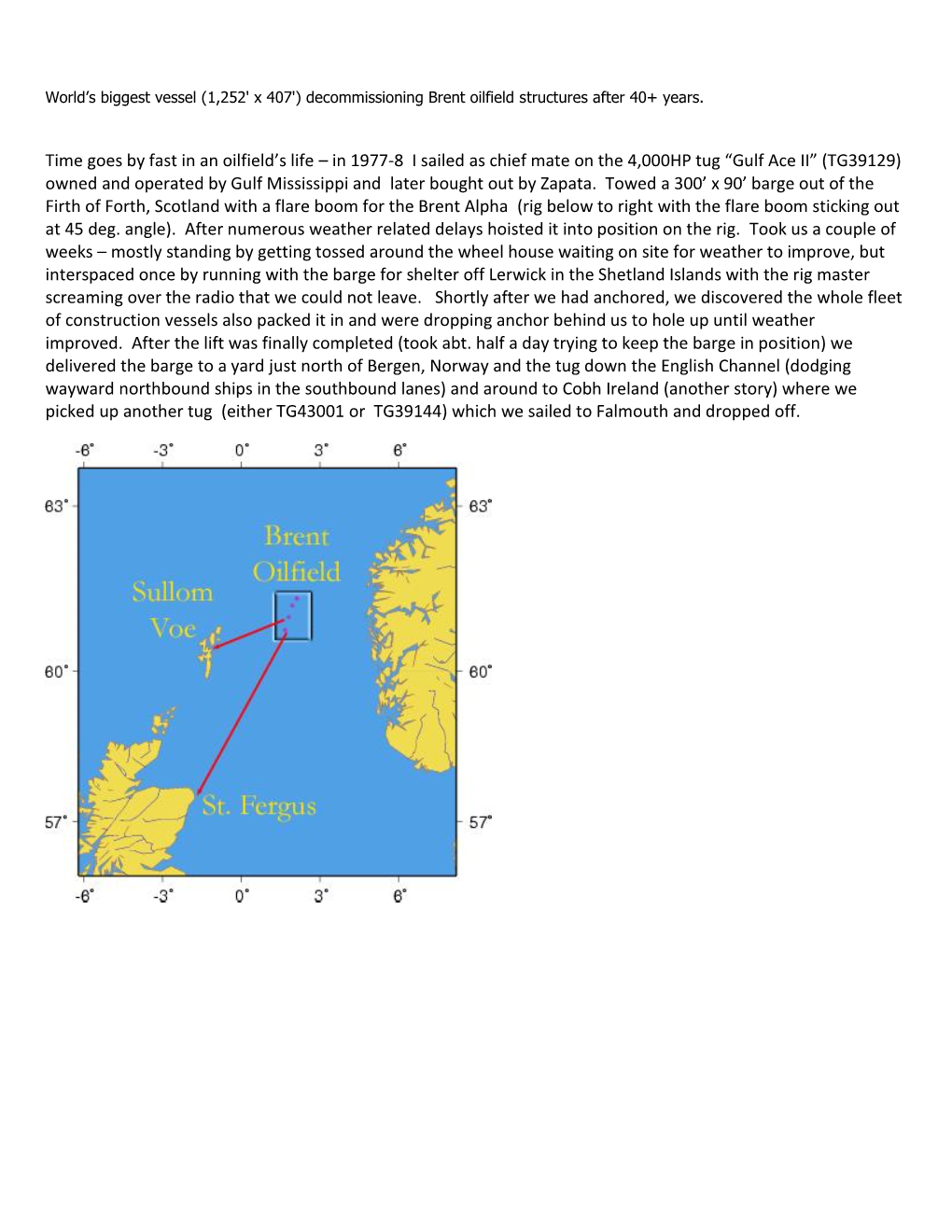

In 1977-8 I Sailed As Chief Mate on the 4000HP

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Master's Thesis

Faculty of Science and Technology MASTER’S THESIS Study program/ Specialization: Spring semester, 2013 Industrial Economics/ Project Management and Risk Management Open access Writer: Sunniva Landmark Bjørnstad ………………………………………… (Writer’s signature) Faculty supervisor: Roy Endré Dahl External supervisor: Johan Magne Sollie, Statoil ASA Title of thesis: Pricing and Risk Management of Spread Options on Brent and West Texas Intermediate Oil Futures Markets Credits (ECTS): 30 Key words: Oil Futures Markets, Spread Options, Pages: 108 Monte Carlo Simulations, Option Pricing, Delta Hedging + enclosure: 8 Stavanger, June 13th 2013 Front page for master thesis Faculty of Science and Technology Decision made by the Dean October 30th 2009 Pricing and Risk Management of Spread Options on Brent and West Texas Intermediate Oil Futures Markets Sunniva Landmark Bjørnstad June 13, 2013 Abstract This thesis investigates the price spread between futures on Brent oil from the Intercontinental Exchange and West Texas Intermediate oil from the New York Mercantile Exchange. Historical futures data is calibrated to a multi-factor forward curve model based on Clewlow and Strickland (2000), and the model is fitted, based on Sollie (2013)'s approach, to al- low for non-constant volatility. An asymmetric generalized autoregressive heteroskedastic model based on Nelson (1991), and principal component analysis is performed to find key common factor explaining the forward curve dynamics. The model is used to draw realisations of the forward curves for Brent and West Texas Intermediate (WTI) crude oils, and three selected realisations are further analysed. Sensitivity analysis is performed on the expected prices at Day 1, and options are priced on the Brent/WTI futures spread with Monte Carlo Simulations. -

A Deep-Dive Into the Ocean

360 Report $CompanySectorName$ $StoryName$$ReportType$ Blue Economy Screener Thematic & Impact Investing 31 March 2017 A deep-dive into the Ocean What’s it all about? Our in-depth assessment of the decline in ocean health shows that the tides are turning. The sectors that most jeopardise the resources provided by the sea, such as shipping, wild-catch fisheries, and offshore oil & gas, face mounting pressure to shift their model towards a more sustainable Main author trajectory, which results in a new wave of risks and opportunities, paving Samuel Mary the way to a potential recovery. Our blue economy framework looks to ESG Research identify the best practices among fast-growing ocean-related industries [email protected] and likely winners and losers across our universe. Offshore-wind, +44 207 621 5190 aquaculture and ship-equipment plays are well placed to provide resource- efficient and climate-friendly solutions, while emerging themes such as ESG research team the reduction of plastic pollution are gathering steam. Biographies at the end of the report IMPORTANT. Please refer to the last page of this report for keplercheuvreux.com “Important disclosures” and analyst(s) certifications. This research is the product of Kepler Cheuvreux, which is authorised and regulated by the Autorité des Marché Financiers in France. Thematic & Impact Investing 360 in 1 minute A sea change for the ocean The swift rise of innovation-driven and renewable resource-based sectors, such as offshore wind and aquaculture, coincides with a policy clampdown on the negative environmental impact of ocean-based industries, such as seaborne trade and wild-catch fisheries. -

Copyright by Sandra Milena Wiegand 2011

Copyright by Sandra Milena Wiegand 2011 The Thesis Committee for Sandra Milena Wiegand Certifies that this is the approved version of the following thesis: An Analysis to the Main Economic Drivers for Offshore Wells Abandonment and Facilities Decommissioning APPROVED BY SUPERVISING COMMITTEE: Supervisor: Steve Nichols Manas Gupta An Analysis to the Main Economic Drivers for Offshore Wells Abandonment and Facilities Decommissioning by Sandra Milena Wiegand, B.S. Thesis Presented to the Faculty of the Graduate School of The University of Texas at Austin in Partial Fulfillment of the Requirements for the Degree of Master of Science in Engineering The University of Texas at Austin August 2011 Dedication This thesis is dedicated to the two most important people in my life: my wonderful father, Hugo Torres and my dear husband, Michael Wiegand. To my father who taught me the meaning of unconditional love. Thank you for giving me the best you had and helping me succeed in life and instilling in me the confidence that I am capable of doing anything I put my mind to. I love you Daddy !. And to my husband, my soul mate and confidant, for always being there for me. Thank you for you endless love, support and patience as I went through this journey. I could not have made it through without you by my side. Acknowledgements I would like to express my gratitude to the following people: Dr. Robert Duvic, for his guidance throughout the first stage of my thesis process. To Dr. Farid Shecaira and Mr. Dalmo Barros for all their support as my managers during these last two years. -

Worldwide Oil and Gas Platform Decommissioning: a Review of Practices and T Reefing Options ∗ Ann Scarborough Bull , Milton S

Ocean and Coastal Management 168 (2019) 274–306 Contents lists available at ScienceDirect Ocean and Coastal Management journal homepage: www.elsevier.com/locate/ocecoaman Worldwide oil and gas platform decommissioning: A review of practices and T reefing options ∗ Ann Scarborough Bull , Milton S. Love Marine Science Institute, University of California, Santa Barbara, CA, 93016, USA ARTICLE INFO ABSTRACT Keywords: Consideration of whether to completely remove an oil and gas production platform from the seafloor or to leave Decommissioning the submerged jacket as a reef is an imminent decision for California, as a number of offshore platforms in both Offshore platforms state and federal waters are in the early stages of decommissioning. Laws require that a platform at the end of its Rigs-to-reefs production life be totally removed unless the submerged jacket section continues as a reef under state spon- Artificial reefs sorship. Consideration of the eventual fate of the populations of fishes and invertebrates beneath platforms has led to global reefing of the jacket portion of platforms instead of removal at the time of decommissioning. The construction and use of artificial reefs are centuries old and global in nature using a great variety ofmaterials. The history that led to the reefing option for platforms begins in the mid-20th century in an effort forgeneral artificial reefs to provide both fishing opportunities and increase fisheries production for a burgeoning U.S. population. The trend toward reefing platforms at end of their lives followed after the oil and gas industry installed thousands of standing platforms in the Gulf of Mexico where they had become popular fishing desti- nations. -

International Ccs Technology Survey, Issue 5, July 2009

INTERNATIONAL CCS TECHNOLOGY SURVEY, ISSUE 5, JULY 2009 International CCS (Carbon Capture and Storage) technology survey Report prepared for Gassnova by Innovation Norway. Issue 5 - July 2009. Contact: Per Christer Lund, IN Tokyo. [email protected], +81-3-3440-2611 INTERNATIONAL CCS TECHNOLOGY SURVEY, ISSUE 5, JULY 2009 Table of Contents TABLE OF CONTENTS 3 INTRODUCTION 5 EXECUTIVE SUMMARY 6 CANADA AND USA 6 GERMANY 8 UK 11 FRANCE AND ITALY 12 JAPAN 14 AUSTRALIA 16 CHINA 19 CANADA AND USA 21 GOVERNMENTAL PROGRAMS AND STRATEGIES 21 CURRENT CCS PROJECTS IN CANADA 37 CURRENT CCS PROJECTS IN US 42 CCS TECHNOLOGY COMPANIES IN CANADA 51 CCS RESEARCH AND DEVELOPMENT 51 BRAZIL 59 GERMANY 60 GOVERNMENTAL PROGRAMS AND STRATEGIES 60 CURRENT CCS PROJECTS IN GERMANY 64 CCS TECHNOLOGY COMPANIES IN GERMANY 69 CCS RESEARCH AND DEVELOPMENT 70 UK 75 GOVERNMENTAL PROGRAMS AND STRATEGIES 75 CCS PROJECTS IN UK 82 THE CCS INDUSTRY IN UK 90 USEFUL UK REFERENCES 92 FRANCE 94 GOVERNMENTAL PROGRAMS AND STRATEGIES 94 CURRENT CCS PROJECTS IN FRANCE 94 CCS TECHNOLOGY COMPANIES IN FRANCE 96 ITALY 98 GOVERNMENTAL PROGRAMS AND STRATEGIES 98 CCS TECHNOLOGY COMPANIES AND INSTITUTES IN ITALY 98 CCS INITIATIVES IN ITALY 99 THE NETHERLANDS 101 CCS PROJECTS IN THE NETHERLANDS 101 JAPAN 103 Page 3 of 144 INTERNATIONAL CCS TECHNOLOGY SURVEY, ISSUE 5, JULY 2009 GOVERNMENTAL PROGRAMS AND STRATEGIES 103 CURRENT CCS PROJECTS IN JAPAN 107 CCS TECHNOLOGY COMPANIES IN JAPAN 112 CCS RESEARCH AND DEVELOPMENT 115 AUSTRALIA 118 GOVERNMENTAL PROGRAMS AND STRATEGIES 118 CURRENT CCS PROJECTS IN AUSTRALIA 122 COMPANIES ENGAGED IN CCS ACTIVITIES IN AUSTRALIA 132 CCS RESEARCH AND DEVELOPMENT 134 CHINA 137 GOVERNMENTAL PROGRAMS AND STRATEGIES 137 PROJECTS IN CHINA 139 OTHER PROJECTS AND INTERNATIONAL COLLABORATION 140 INTERNATIONAL COLLABORATION. -

Commodity Option Pricing Is a Must-Read for Option Traders, Risk Managers and Quantita- Tive Analysts

“It has been very hard to find a comprehensive option pricing book cover- ing all exchange-traded commodities, until Iain Clark’s book. Commodity Option Pricing is a must-read for option traders, risk managers and quantita- tive analysts. The author combines academic rigor with real-world examples. Practitioners can find an extremely useful toolkit in option pricing andan excellent introduction to various commodities.” Joseph Y. Chen, Chief, Market Analytics, Nexen “Being himself a practitioner with a wealth of experience, Iain knows what is relevant to the daily work of commodities trading desks. He uses his remarkable pedagogical skills to develop the reader’s intuition for the mod- els and products before delving into the practicalities of the commodities markets. Many of the details covered in this book cannot be found elsewhere in the literature. I am pleased to recommend this book to quants and traders, who will soon find themselves relying on it in their daily work.” Paul Bilokon, Director, Deutsche Bank “Option pricing analytics for trading commodity derivatives can be quite different from those of equity and fixed income derivatives. This book fills a gap in current literature by presenting a comprehensive treatise on the risk characteristics associated with pricing and hedging commodity derivatives. The author strikes a fine balance between option pricing theory and financial practice in the markets. The materials are succinctly written, with clear and insightful descriptions of the features of various commodity markets and state-of-the-art pricing models. This book is destined to be a valuable prac- tical guide for practitioners and a useful academic reference for researchers in trading and understanding commodities derivatives.” Yue Kuen Kwok, Professor, Department of Mathematics, Hong Kong University of Science and Technology Commodity Option Pricing For other titles in the Wiley Finance series please see www.wiley.com/finance Commodity Option Pricing A Practitioner’s Guide Iain J. -

The Late Jurassic Biorøy Formation: a Provenance Indi

NORWEGIAN JOURNAL OF GEOLOGY The BjorøyFormation: A provenance indicator for offshore sediments 283 J F r i A The late urassic Biorøy o mat on: provenance indi cator for offshore sediments derived from SW Norway as based on single zircon (SIMS) data Trine-Lise Knudsen & Haakon Fossen Knudsen, T. -L. & Fossen, H.: The Late Jurassic Bjorøy Formation: A provenance indicator fo r offshore sediments derived from SW Norway as based on single zircon (SIMS) data. No rsk Geologisk Tidsskrift, Vo l. 81, pp. 283-292. Trondheim 2001. ISSN 029-196X. The Late Jurassic Bjorøy Formation is located in a fracturezone in granodioritic gneisses of the Øygarden Complex in the Bergen area, SW Nor way. An ion-microprobe (SIMS) U-Pb zircon study has been performed on a sand sample and the granitic basement, and the data are integrated with Nd and Sr whole rock isotopes in order to identify the provenance components to the Bjorøy Fm. The detrital zircons reflect a source area that was dominated by rocks with zircon ages in Caledonian (450 and 520 Ma), Sveconorwegian (900 to 1010 Ma) and mid-Proterozoic (ca. 1450 Ma) times. One Archaean zircon at ca. 2700 Ma is recorded. The sand sample has a relatively low Nd model age of 0.5 Ga, which can be connected to an important sediment source in Caledonian rocks of intermediate and mafic compositions. These were probably derived from units related to the Min or and Major Bergen Arcs. Thus, rocks of the Upper Allochthon of the Caledonides were probably important in the sediment source area together with Proterozoic gneisses and late-Proterozoic platform sediments, which appear as tectonically intercalated slivers in the upper alloch thonous units. -

Wb/Mr/87/017

lJJB/MR. Marine Report~87/17 THE NATURE OF THE BRENT DELTA, NORTH SEA A CORE WORKS HOP Philip C Richards and Stewart Brown, Hydrocarbons Research Programme, British Geological Survey 19 Grange Terrace Edinburgh Presented at the Department of Energy Core Store, Edinburgh, 25th and 26th April 1987 This report has been generated from a scanned image of the document with any blank pages removed at the scanning stage. Please be aware that the pagination and scales of diagrams or maps in the resulting report may not appear as in the original 1 1. INTRODUCTION Since 1984 the Hydrocarbons· Research Group of the British Geological Survey has run a series of core workshops to illustrate the reservoir rocks of the UK North Sea. These workshops have made extensive use of the unique archive of North Sea core material stored at the BGS/D.En core store in Edinburgh. This workshop will provide the opportunity to examine the sediments of The Brent Group, the principal hydrocarbon reservoir in the northern North Sea. "Hands-on" examination of the core is encouraged, as is full discussion of the concepts and ideas presented at the workshop. The sequences illustrated all lie within the East Shetland Basin (Fig 1). To the west lies the East Shetland Plataform, where Tertiary strata rest on Devonian or older rocks, and to the east lies the NNE-SSW trending trough of the Viking Graben with its thick Hesozoic-Tertiary fill. Both N-S and NE-SW faults cut the Jurassic in the East Shetland Basin. They are normal faults which bound a number of tilted blocks whose geometry has a crucial influence on the location of hydrocarbon traps. -

Business Representation of Giant Corporations

Telling stories about… Business representation of giant corporations ‘A thesis submitted to the University of Manchester for the degree of Doctor of Philosophy in the Faculty of Humanities’ 2010 Adriana Vilella Nilsson School of Social Sciences Contents Abstract pp 5 Introduction Storytelling as strategy pp 11 Chapter one Business representation in a post-Keynesian capitalism pp 21 The British system of business power: mid -1970s pp 23 as the turning point Lobbying overload and the search for legitimacy pp 28 Business representation in the 21 st Century pp 36 Chapter two Financialisation and the turn to narratives pp 41 Capitalist restructuring and firms: political economy pp 43 and cultural economy approaches Business representation as a cultural process pp 49 Corporate Communications since the 1990s pp 59 Chapter three Business representation as a cultural practice pp 65 The cultural political economy of business representation pp 67 Methodology pp 80 Chapter four Diluting REACH: influencing governance at supranational level pp 94 The Legislation pp 96 Issues of agency and structure pp 100 Strategies and stories in REACH pp 109 2 Chapter five The mediated story of Herceptin pp 124 A historical perspective on actors and institutions pp 126 The battle for the drug pp 135 Chapter six Shell and the tale of shareholder activism pp 149 Oil Industry and Shell pp 152 Aligning stories pp 165 Chapter seven Order in chaos: stories as incomplete, immersed in contingency, pp 173 but not random Who told what pp 175 Stories versus stories pp 179 Stories -

Geology of the Brent Group: Introduction

Downloaded from http://sp.lyellcollection.org/ by guest on September 25, 2021 Geology of the Brent Group: Introduction A. C. MORTON 1, R. S. HASZELDINE 2, M. R. GILES 3 & S. BROWN 4 1 British Geological Survey, Keyworth, Nottingham NG12 5GG, UK 2 Department of Geology and Applied Geology, The University of Glasgow, Glasgow G12 8QQ, UK 3 KoninkIi]ke/Shell Exploratorie en Produktie Laboratorium, Volmerlaan 6, 2280 AB Rijswi]k, Netherlands 4 The Petroleum Science and Technology Institute, Research Park, Riccarton, Edinburgh EH14 4AS, UK The Middle Jurassic Brent Group sediments Province, and to discuss future exploration po- and their correlatives on the Norwegian shelf tential. Although the Brent Group was orig- are, in economic terms, the most important inally interpreted to have been deposited during hydrocarbon reservoir in NW Europe. In 1971 a period of active rifting and basin subsidence, the Brent Field was discovered by Shell/Esso Yielding et al. show that the major phase of and tested in 1972 with 1.8 billion barrels of rifting occurred earlier, with the Brent deposited recoverable oil; nine major Brent sandstone during a thermal subsidence phase. fields were discovered by the end of 1973 Several papers deal with the sedimentological (Brennand et al. 1990). In 1980 the northern framework of the Brent Group, beginning with North Sea (overwhelmingly comprising fields the review by Riehards. Although the original with Brent Group reservoirs) was ranked as the interpretation of the sequence as 'deltaic' 13th largest petroleum province in the world, (Bowen 1975) is still broadly acceptable, the containing 1.6% of produced and recoverable book illustrates the controversy over the precise oil equivalent reserves (Ivanhoe 1980). -

Abstract This Thesis Analyzes the Effect of Crude Oil on the Prices of Commodities

Abstract This thesis analyzes the effect of crude oil on the prices of commodities. The thesis provides an overview of the oil market and of its participants, as well as how the price of crude oil and the commodities is determined and how they are traded. Using a Vector Autoregressive Model (VAR), we were able to analyze the causation relationships between the variables and compare the effect on the different industries and sectors. In order to analyze the effects from the financial crisis we made use of two sample periods, one going from 1994 through June 2008: (1) and the other from 1994 up until today: (2). What we found was that the correlations between the price of crude oil and the commodities were higher in (2) for all but natural gas and iron ore, which decreased severely through the financial crisis. We further found that leading up to the financial crisis most of the agricultural commodities, coal and gold all shared a delayed but significant causation relationship with the crude oil price. In (2) however, only soybeans and rubber of the agricultural commodities proved to have a significant causation relationship with the crude oil price whereas both the metal sector and the energy sector as well as salmon proved to have a significant causation relationship with the crude oil price. In addition, we have analyzed how economic growth affects the price of the commodities to be able to compare this to how the crude oil price affects the price of the commodities. 1 Preface This thesis is written as a finalization of our Master’s degree in Industrial Economics at the University of Stavanger. -

0135 North Sea Petroleum Provinces Report RR 03 001.Qxp

Middle Jurassic, Upper Jurassic and Lower Cretaceous of the UK Central and Northern North Sea Continental Shelf and Margins Programme Research Report RR/03/001 BRITISH GEOLOGICAL SURVEY RESEARCH REPORT RR/03/001 Middle Jurassic, Upper Jurassic and Lower Cretaceous of the UK Central and Northern North Sea The National Grid and other Ordnance Survey data are used with the permission of the Authors Controller of Her Majesty’s Stationery Office. Licence No: 100017897/2005. H Johnson, A B Leslie, C K Wilson, I J Andrews and R M Cooper Keywords Contributors Central and Northern North Sea, Middle Jurassic, Upper Jurassic, P Egerton, E Gillespie, A F Henderson, S Jones, M F Quinn and J B Wild Lower Cretaceous Front cover Glacial till overlying Oxfordian sedimentary rocks at Filey Brigg, North Yorkshire. Bibliographical reference JOHNSON, H, LESLIE, A B, WILSON, C K, ANDREWS, I J, and COOPER, R M. 2005. Middle Jurassic, Upper Jurassic and Lower Cretaceous of the UK Central and Northern North Sea. British Geological Survey Research Report, RR/03/001. 42pp. ISBN 0 85272 509 4 Copyright in materials derived from the British Geological Survey’s work is owned by the Natural Environment Research Council (NERC) and/or the authority that commissioned the work. You may not copy or adapt this publication without first obtaining permission. Contact the BGS Intellectual Property Rights Section, British Geological Survey, Keyworth, e-mail [email protected]. You may quote extracts of a reasonable length without prior permission, provided a full acknowledgement is given of the source of the extract. Maps and diagrams in this book use topography based on Ordnance Survey mapping.