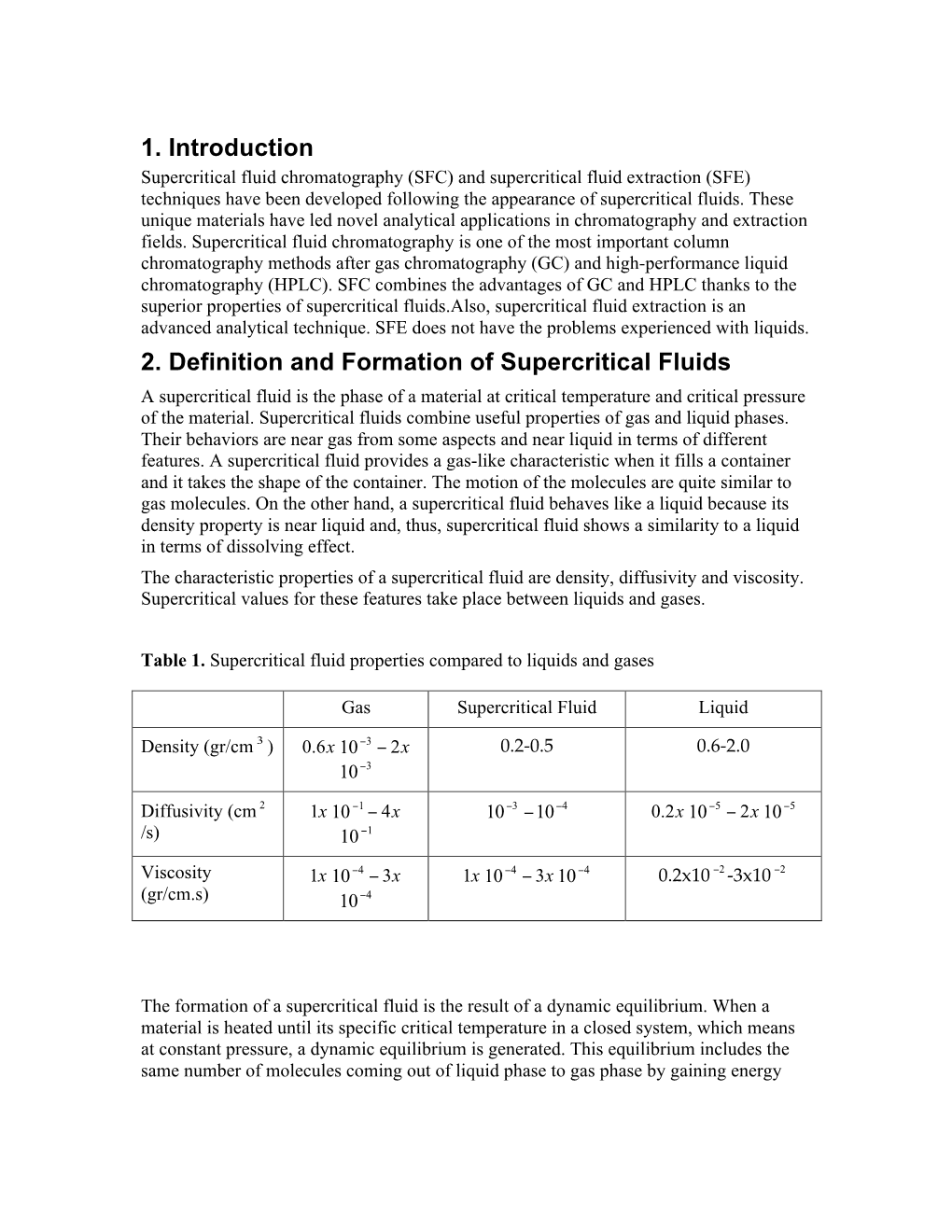

1. Introduction 2. Definition and Formation of Supercritical Fluids

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Supercritical Fluid Extraction of Positron-Emitting Radioisotopes from Solid Target Matrices

XA0101188 11. United States of America Supercritical Fluid Extraction of Positron-Emitting Radioisotopes From Solid Target Matrices D. Schlyer, Brookhaven National Laboratory, Chemistry Department, Upton, Bldg. 901, New York 11973-5000, USA Project Description Supercritical fluids are attractive as media for both chemical reactions, as well as process extraction since their physical properties can be manipulated by small changes in pressure and temperature near the critical point of the fluid. What is a supercritical fluid? Above a certain temperature, a vapor can no longer be liquefied regardless of pressure critical temperature - Tc supercritical fluid r«gi on solid a u & temperature Fig. 1. Phase diagram depicting regions of solid, liquid, gas and supercritical fluid behavior. The critical point is defined by a critical pressure (Pc) and critical temperature (Tc) for a particular substance. Such changes can result in drastic effects on density-dependent properties such as solubility, refractive index, dielectric constant, viscosity and diffusivity of the fluid[l,2,3]. This suggests that pressure tuning of a pure supercritical fluid may be a useful means to manipulate chemical reactions on the basis of a thermodynamic solvent effect. It also means that the solvation properties of the fluid can be precisely controlled to enable selective component extraction from a matrix. In recent years there has been a growing interest in applying supercritical fluid extraction to the selective removal of trace metals from solid samples [4-10]. Much of the work has been done on simple systems comprised of inert matrices such as silica or cellulose. Recently, this process as been expanded to environmental samples as well [11,12]. -

Ionic Liquid and Supercritical Fluid Hyphenated Techniques for Dissolution and Separation of Lanthanides, Actinides, and Fission Products

Project No. 09-805 Ionic Liquid and Supercritical Fluid Hyphenated Techniques for Dissolution and Separation of Lanthanides, Actinides, and Fission Products ItIntegrat tdUied Universit itPy Programs Dr. Chien Wai University of Idaho In collaboration with: Idaho National Laboratory Jack Law, Technical POC James Bresee, Federal POC 1 Ionic Liquid and Supercritical Fluid Hyphenated Techniques For Dissolution and Separation of Lanthanides and Actinides DOE-NEUP Project (TO 00058) Final Technical Report Principal Investigator: Chien M. Wai Department of Chemistry, University of Idaho, Moscow, Idaho 83844 Date: December 1, 2012 2 Table of Contents Project Summary 3 Publications Derived from the Project 5 Chapter I. Introduction 6 Chapter II. Uranium Dioxide in Ionic Liquid with a TP-HNO3 Complex – Dissolution and Coordination Environment 9 1. Dissolution of UO2 in Ionic Liquid with TBP(HNO3)1.8(H2O)0.6 2. Raman Spectra of Dissolved Uranyl Species in IL 13 3. Transferring Uranium from IL Phase to sc-CO2 15 Chapter III. Kinetic Study on Dissolution of Uranium Dioxide and Neodymium Sesquioxide in Ionic Liquid 19 1. Rate of Dissolution of UO2 and Nd2O3 in RTIL 19 2. Temperature Effect on Dissolution of UO2 and Nd2O3 24 3. Viscosity Effect on Dissolution of UO2 in IL with TBP(HNO3)1.8(H2O)0.6 Chapter IV. Separation of UO2(NO3)2(TBP)2 and Nd(NO3)3(TBP)3 in Ionic Liquid Using Diglycolamide and Supercritical CO2 Extraction 30 1. Complexation of Uranyl with Diglycolamide TBDGA in Ionic Liquid 31 2. Complexation of Neodymium(III) with TBDGA in Ionic Liquid 35 3. Solubility and Distribution Ratio of UO2(NO3)2(TBP)2 and Nd(NO3)3(TBP)3 in Supercritical CO2 Phase 38 4. -

Extraction Methods and Their Influence on Yield When Extracting Thermo-Vacuum-Modified Chestnut Wood

Article Extraction Methods and Their Influence on Yield When Extracting Thermo-Vacuum-Modified Chestnut Wood Maurizio D’Auria 1 , Marisabel Mecca 1, Maria Roberta Bruno 2 and Luigi Todaro 2,* 1 Department of Science, University of Basilicata, Viale dell’Ateneo Lucano 10, 85100 Potenza, Italy; [email protected] (M.D.); [email protected] (M.M.) 2 School of Agricultural Forestry, Food, and Environmental Science, University of Basilicata, Viale dell’Ateneo Lucano 10, 85100 Potenza, Italy; [email protected] * Correspondence: [email protected]; Tel.: +39-3478782534 Abstract: Improvements in the yield and solubility of chestnut wood extractives, by using different extraction methods and molybdenum catalysts as support, have rarely been reported in literature. Many studies focus on the different parts of trees, except for the chemical characteristics of the remaining extractives achieved from thermally modified (THM) chestnut (Castanea sativa Mill) wood. This research seeks to better understand the effects of extraction techniques and catalysts on the yield and solubility of extractives. GC-MS analysis of the chloroform soluble and insoluble fractions was also used. Accelerated Solvent Extraction (ASE) 110 ◦C, Soxhlet, and autoclave extraction techniques were used to obtain extractives from untreated and thermally modified (THM) chestnut ◦ wood (170 C for 3 h). Ethanol/H2O, ethanol/toluene, and water were the solvents used for each technique. A polyoxometalate compound (H3PMo12O40) and MoO3 supported on silica were used as catalysts. The THM induced a change in the wood’s surface color (DE = 21.5) and an increase in mass loss (5.9%), while the equilibrium moisture content (EMC) was reduced by 17.4% compared to the control wood. -

Liquid-Liquid Transition in Supercooled Aqueous Solution Involving a Low-Temperature Phase Similar to Low-Density Amorphous Water

Liquid-liquid transition in supercooled aqueous solution involving a low-temperature phase similar to low-density amorphous water * * # # Sander Woutersen , Michiel Hilbers , Zuofeng Zhao and C. Austen Angell * Van 't Hoff Institute for Molecular Sciences, University of Amsterdam, Science Park 904,1098 XH Amsterdam, The Netherlands # School of Molecular Sciences, Arizona State University, Tempe, AZ, 85287-1604, USA The striking anomalies in physical properties of supercooled water that were discovered in the 1960-70s, remain incompletely understood and so provide both a source of controversy amongst theoreticians1-5, and a stimulus to experimentalists and simulators to find new ways of penetrating the "crystallization curtain" that effectively shields the problem from solution6,7. Recently a new door on the problem was opened by showing that, in ideal solutions, made using ionic liquid solutes, water anomalies are not destroyed as earlier found for common salt and most molecular solutes, but instead are enhanced to the point of precipitating an apparently first order liquid-liquid transition (LLT)8. The evidence was a spike in apparent heat capacity during cooling that could be fully reversed during reheating before any sign of ice crystallization appeared. Here, we use decoupled-oscillator infrared spectroscopy to define the structural character of this phenomenon using similar down and upscan rates as in the calorimetric study. Thin-film samples also permit slow scans (1 Kmin-1) in which the transition has a width of less than 1 K, and is fully reversible. The OH spectrum changes discontinuously at the phase- transition temperature, indicating a discrete change in hydrogen-bond structure. -

Application of Supercritical Fluids Review Yoshiaki Fukushima

1 Application of Supercritical Fluids Review Yoshiaki Fukushima Abstract Many advantages of supercritical fluids come Supercritical water is expected to be useful in from their interesting or unusual properties which waste treatment. Although they show high liquid solvents and gas carriers do not possess. solubility solutes and molecular catalyses, solvent Such properties and possible applications of molecules under supercritical conditions gently supercritical fluids are reviewed. As these fluids solvate solute molecules and have little influence never condense at above their critical on the activities of the solutes and catalysts. This temperatures, supercritical drying is useful to property would be attributed to the local density prepare dry-gel. The solubility and other fluctuations around each molecule due to high important parameters as a solvent can be adjusted molecular mobility. The fluctuations in the continuously. Supercritical fluids show supercritical fluids would produce heterogeneity advantages as solvents for extraction, coating or that would provide novel chemical reactions with chemical reactions thanks to these properties. molecular catalyses, heterogenous solid catalyses, Supercritical water shows a high organic matter enzymes or solid adsorbents. solubility and a strong hydrolyzing ability. Supercritical fluid, Supercritical water, Solubility, Solvation, Waste treatment, Keywords Coating, Organic reaction applications development reached the initial peak 1. Introduction during the period from the second half of the 1960s There has been rising concern in recent years over to the 1970s followed by the secondary peak about supercritical fluids for organic waste treatment and 15 years later. The initial peak was for the other applications. The discovery of the presence of separation and extraction technique as represented 1) critical point dates back to 1822. -

Using Supercritical Fluid Technology As a Green Alternative During the Preparation of Drug Delivery Systems

pharmaceutics Review Using Supercritical Fluid Technology as a Green Alternative During the Preparation of Drug Delivery Systems Paroma Chakravarty 1, Amin Famili 2, Karthik Nagapudi 1 and Mohammad A. Al-Sayah 2,* 1 Small Molecule Pharmaceutics, Genentech, Inc. So. San Francisco, CA 94080, USA; [email protected] (P.C.); [email protected] (K.N.) 2 Small Molecule Analytical Chemistry, Genentech, Inc. So. San Francisco, CA 94080, USA; [email protected] * Correspondence: [email protected]; Tel.: +650-467-3810 Received: 3 October 2019; Accepted: 18 November 2019; Published: 25 November 2019 Abstract: Micro- and nano-carrier formulations have been developed as drug delivery systems for active pharmaceutical ingredients (APIs) that suffer from poor physico-chemical, pharmacokinetic, and pharmacodynamic properties. Encapsulating the APIs in such systems can help improve their stability by protecting them from harsh conditions such as light, oxygen, temperature, pH, enzymes, and others. Consequently, the API’s dissolution rate and bioavailability are tremendously improved. Conventional techniques used in the production of these drug carrier formulations have several drawbacks, including thermal and chemical stability of the APIs, excessive use of organic solvents, high residual solvent levels, difficult particle size control and distributions, drug loading-related challenges, and time and energy consumption. This review illustrates how supercritical fluid (SCF) technologies can be superior in controlling the morphology of API particles and in the production of drug carriers due to SCF’s non-toxic, inert, economical, and environmentally friendly properties. The SCF’s advantages, benefits, and various preparation methods are discussed. Drug carrier formulations discussed in this review include microparticles, nanoparticles, polymeric membranes, aerogels, microporous foams, solid lipid nanoparticles, and liposomes. -

Glossary of Terms

GLOSSARY OF TERMS For the purpose of this Handbook, the following definitions and abbreviations shall apply. Although all of the definitions and abbreviations listed below may have not been used in this Handbook, the additional terminology is provided to assist the user of Handbook in understanding technical terminology associated with Drainage Improvement Projects and the associated regulations. Program-specific terms have been defined separately for each program and are contained in pertinent sub-sections of Section 2 of this handbook. ACRONYMS ASTM American Society for Testing Materials CBBEL Christopher B. Burke Engineering, Ltd. COE United States Army Corps of Engineers EPA Environmental Protection Agency IDEM Indiana Department of Environmental Management IDNR Indiana Department of Natural Resources NRCS USDA-Natural Resources Conservation Service SWCD Soil and Water Conservation District USDA United States Department of Agriculture USFWS United States Fish and Wildlife Service DEFINITIONS AASHTO Classification. The official classification of soil materials and soil aggregate mixtures for highway construction used by the American Association of State Highway and Transportation Officials. Abutment. The sloping sides of a valley that supports the ends of a dam. Acre-Foot. The volume of water that will cover 1 acre to a depth of 1 ft. Aggregate. (1) The sand and gravel portion of concrete (65 to 75% by volume), the rest being cement and water. Fine aggregate contains particles ranging from 1/4 in. down to that retained on a 200-mesh screen. Coarse aggregate ranges from 1/4 in. up to l½ in. (2) That which is installed for the purpose of changing drainage characteristics. -

Investigations of Liquid Steel Viscosity and Its Impact As the Initial Parameter on Modeling of the Steel Flow Through the Tundish

materials Article Investigations of Liquid Steel Viscosity and Its Impact as the Initial Parameter on Modeling of the Steel Flow through the Tundish Marta Sl˛ezak´ 1,* and Marek Warzecha 2 1 Department of Ferrous Metallurgy, Faculty of Metals Engineering and Industrial Computer Science, AGH University of Science and Technology, Al. Mickiewicza 30, 30-059 Kraków, Poland 2 Department of Metallurgy and Metal Technology, Faculty of Production Engineering and Materials Technology, Cz˛estochowaUniversity of Technology, Al. Armii Krajowej 19, 42-201 Cz˛estochowa,Poland; [email protected] * Correspondence: [email protected] Received: 14 September 2020; Accepted: 5 November 2020; Published: 7 November 2020 Abstract: The paper presents research carried out to experimentally determine the dynamic viscosity of selected iron solutions. A high temperature rheometer with an air bearing was used for the tests, and ANSYS Fluent commercial software was used for numerical simulations. The experimental results obtained are, on average, lower by half than the values of the dynamic viscosity coefficient of liquid steel adopted during fluid flow modeling. Numerical simulations were carried out, taking into account the viscosity standard adopted for most numerical calculations and the average value of the obtained experimental dynamic viscosity of the analyzed iron solutions. Both qualitative and quantitative analysis showed differences in the flow structure of liquid steel in the tundish, in particular in the predicted values and the velocity profile distribution. However, these differences are not significant. In addition, the work analyzed two different rheological models—including one of our own—to describe the dynamic viscosity of liquid steel, so that in the future, the experimental stage could be replaced by calculating the value of the dynamic viscosity coefficient of liquid steel using one equation. -

Method 3520C: Continuous Liquid-Liquid Extraction, Part of Test

METHOD 3520C CONTINUOUS LIQUID-LIQUID EXTRACTION 1.0 SCOPE AND APPLICATION 1.1 This method describes a procedure for isolating organic compounds from aqueous samples. The method also describes concentration techniques suitable for preparing the extract for the appropriate determinative steps described in Sec. 4.3 of Chapter Four. 1.2 This method is applicable to the isolation and concentration of water-insoluble and slightly soluble organics in preparation for a variety of chromatographic procedures. 1.3 Method 3520 is designed for extraction solvents with greater density than the sample. Continuous extraction devices are available for extraction solvents that are less dense than the sample. The analyst must demonstrate the effectiveness of any such automatic extraction device before employing it in sample extraction. 1.4 This method is restricted to use by or under the supervision of trained analysts. Each analyst must demonstrate the ability to generate acceptable results with this method. 2.0 SUMMARY OF METHOD 2.1 A measured volume of sample, usually 1 liter, is placed into a continuous liquid-liquid extractor, adjusted, if necessary, to a specific pH (see Table 1), and extracted with organic solvent for 18 - 24 hours. 2.2 The extract is dried, concentrated (if necessary), and, as necessary, exchanged into a solvent compatible with the cleanup or determinative method being employed (see Table 1 for appropriate exchange solvents). 3.0 INTERFERENCES 3.1 Refer to Method 3500. 3.2 The decomposition of some analytes has been demonstrated under basic extraction conditions required to separate analytes. Organochlorine pesticides may dechlorinate, phthalate esters may exchange, and phenols may react to form tannates. -

A Review of Supercritical Fluid Extraction

NAT'L INST. Of, 3'«™ 1 lY, 1?f, Reference NBS PubJi- AlllDb 33TA55 cations /' \ al/l * \ *"»e A U O* * NBS TECHNICAL NOTE 1070 U.S. DEPARTMENT OF COMMERCE / National Bureau of Standards 100 LI5753 No, 1070 1933 NATIONAL BUREAU OF STANDARDS The National Bureau of Standards' was established by an act of Congress on March 3, 1901. The Bureau's overall goal is to strengthen and advance the Nation's science and technology and facilitate their effective application for public benefit. To this end, the Bureau conducts research and provides: (1) a basis for the Nation's physical measurement system, (2) scientific and technological services for industry and government, (3) a technical basis for equity in trade, and (4) technical services to promote public safety. The Bureau's technical work is per- formed by the National Measurement Laboratory, the National Engineering Laboratory, and the Institute for Computer Sciences and Technology. THE NATIONAL MEASUREMENT LABORATORY provides the national system ot physical and chemical and materials measurement; coordinates the system with measurement systems of other nations and furnishes essential services leading to accurate and uniform physical and chemical measurement throughout the Nation's scientific community, industry, and commerce; conducts materials research leading to improved methods of measurement, standards, and data on the properties of materials needed by industry, commerce, educational institutions, and Government; provides advisory and research services to other Government agencies; develops, -

Plasma Discharge in Water and Its Application for Industrial Cooling Water Treatment

Plasma Discharge in Water and Its Application for Industrial Cooling Water Treatment A Thesis Submitted to the Faculty of Drexel University by Yong Yang In partial fulfillment of the Requirements for the degree of Doctor of Philosophy June 2011 ii © Copyright 2008 Yong Yang. All Rights Reserved. iii Acknowledgements I would like to express my greatest gratitude to both my advisers Prof. Young I. Cho and Prof. Alexander Fridman. Their help, support and guidance were appreciated throughout my graduate studies. Their experience and expertise made my five year at Drexel successful and enjoyable. I would like to convey my deep appreciation to the most dedicated Dr. Alexander Gutsol and Dr. Andrey Starikovskiy, with whom I had pleasure to work with on all these projects. I feel thankful for allowing me to walk into their office any time, even during their busiest hours, and I’m always amazed at the width and depth of their knowledge in plasma physics. Also I would like to thank Profs. Ying Sun, Gary Friedman, and Alexander Rabinovich for their valuable advice on this thesis as committee members. I am thankful for the financial support that I received during my graduate study, especially from the DOE grants DE-FC26-06NT42724 and DE-NT0005308, the Drexel Dean’s Fellowship, George Hill Fellowship, and the support from the Department of Mechanical Engineering and Mechanics. I would like to thank the friendship and help from the friends and colleagues at Drexel Plasma Institute over the years. Special thanks to Hyoungsup Kim and Jin Mu Jung. Without their help I would not be able to finish the fouling experiments alone. -

2.1.2 Extractive Crystallization

EUROPEAN ROADMAP OF PROCESS INTENSIFICATION - TECHNOLOGY REPORT - TECHNOLOGY: EXTRACTIVE CRYSTALLIZATION TECHNOLOGY CODE: 2.1.2 AUTHOR: Mark Roelands, TNO Science & Industry, Delft, Netherlands Table of contents 1. Technology 1.1 Description of technology / working principle 1.2 Types and “versions” 1.3 Potency for Process Intensification: possible benefits 1.4 Stage of development 2. Applications 2.1 Existing technology (currently used) 2.2 Known commercial applications 2.3 Known demonstration projects 2.4 Potential applications discussed in literature 3. What are the development and application issues? 3.1 Technology development issues 3.2 Challenges in developing processes based on the technology 4. Where can information be found? 4.1 Key publications 4.2 Relevant patents and patent holders 4.3 Institutes/companies working on the technology 5. Stakeholders 5.1 Suppliers/developers 5.2 End-users 6. Expert’s brief final judgment on the technology 1 1. Technology 1.1 Description of technology / working principle (Feel free to modify/extend the short technology description below) Extractive crystallization is a hybrid process in which crystallization and extraction are combined. There are several process configurations possible. Either the solute or the solvent can be extracted from a solution. In case the solute is extracted, the solute accumulates in the extractant until this phase becomes supersaturated and crystallization starts. In one configuration a reactive extractant is applied. Subsequently the crystals are separated from the mother liquor. In this case the crystal are the desired product. In a second configuration absorption of a compound from a gas stream into a reactive extractant takes place, followed by crystallization of one of the compounds.