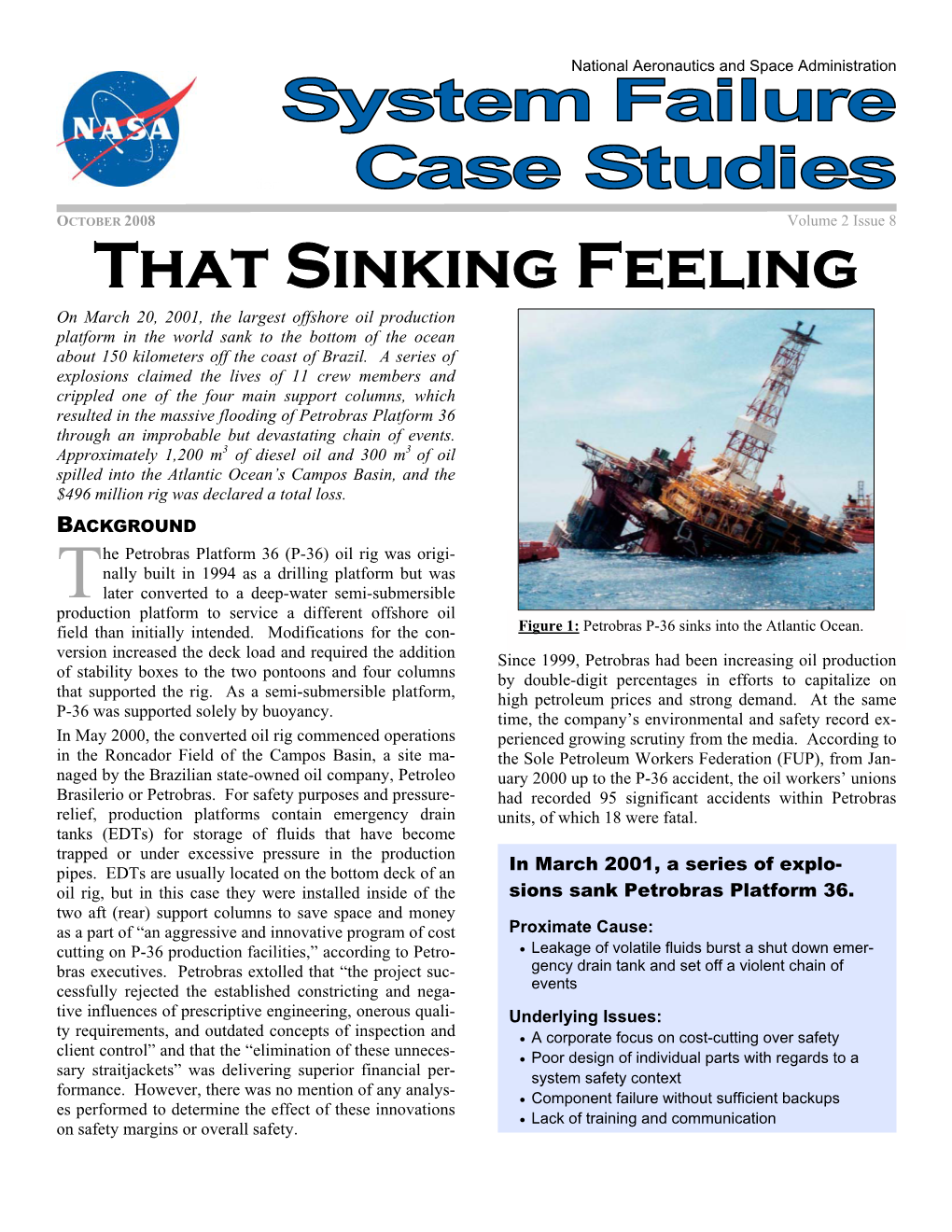

That Sinking Feeling

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Natural Gas Energy

Annual Report 2006 Contents - PROFILE, MISSION, VISION 2015, VALUES AND CONDUCT - HIGHLIGHTS - MESSAGE FROM THE CEO - OIL MARKET OVERVIEW - CORPORATE STRATEGY - BUSINESSES Exploration and Production Refining and Commercialization Petrochemicals Transportation Distribution Natural Gas Energy - INTERNATIONAL ACTIVITIES - SOCIAL AND ENVIRONMENTAL RESPONSIBILITY Human Resources Health, Safety and the Environment Social, Environmental, Cultural and Sports Sponsorship - INTANGIBLE ASSETS Technological Capital Organizational Capital Human Capital Relationship Capital - BUSINESS MANAGEMENT Business Performance Capital Markets Risk Management Corporate Governance Annual Report 2006 2 Profile Petrobras is a publicly listed company that operates on an integrated and specialized basis in the following segments of the oil, gas and energy sector: exploration and production; refining, commercialization, transportation and petrochemicals; the distribution of oil products; natural gas and energy. Founded in 1953, Petrobras is now the world’s 14 th largest oil company, according to the publication Petroleum Intelligence Weekly . The leader in the Brazilian hydrocarbons sector, the company has been expanding, in order to become an integrated energy business with international operations, and the leader in Latin America. Mission To operate safely and profitably, in a socially and environmentally responsible manner, within the oil, gas and energy sector, both domestically and abroad, supplying products and services that meet the needs of the customers, thereby -

UT2 2009 March

Contents Contents News Mussel Power 4 Subsea Report 5 UT2 March 2009 The magazine of the Seismic Society for Underwater Technology Seismic Coil Shooting 6-8 Towed Streamer Technology 8-9 Oceans Projects Seafl oor Laboratory 10, Life on MARS 12 Oceans News Hydroid for Geomar 14, Ice Profi lers 14 Tsunami Detection Remote Vehicles Offshore 15, Google Earth 15, Seabed Visualisation 16, Depth Measurement 16, Pressure Sensor 16, Swedish Tracking 17, Waterside security 18, Contour Generator 18, Seabed Cover: Using mussels as a pollution biosensor Scanning 18, Training Courses 19, Software Enhancement Photo by Vidar Skålevik 20, Deepwater Acoustic release 21, Seabed Classifi cation Cables and Software 22, Glass Ceiling 22, Current Profi ler 22 Umbilicals Usan and Skarv 24, Airgun Umbilicals 24, Jade 24 Digital Digital Controlled Manipulator, Digital Pan and Tilt 26, Revolution March 2009 Vol 4 No 1 ROVs & Off shore ROVs Aircraft Crash 28, Icy Ise Hysub 28, Buoyant Market 30, Going East 30, Rock Trencher 30, ISS ROV Control System 2 31, Tracking Jason 31, Wet Mate Connector 31 UT Subsea Perdido 32, Tupi 33, Yttergryta 28, Frigg 34 Asgard 34 Society for Underwater Projects ABS Rules 35, Cascacde Chinook 35, Roncador 36, Girassol Technology 36, Gudrun 36 Machar 37, Tahiti 37 80 Coleman St, Underwater The Lost Arc 40, Friction Stitch Welding 40, Cold Tee 41, London EC25 5BJ Welding and Deeper Welding 42, Future 43, Chamber of Secrets 43, Pipelines EHPIP 44 +44 (1) 480 370007 Births, Marriages and Separations 47 Editor: John Howes [email protected] SUT London SUT AGM 48, Aberdeen SUT AGM 49, Award of Merit 49, Carbon Capture and Storage 50, SUT YP 50 Sub Editor: Mariam Pourshoushtari [email protected] Advertising: Joe Sinfi eld Published by UT2 Publishing Ltd for and on behalf of the Society for Underwater Technology. -

View Annual Report

Contents PROFILE, MISSION, 2020 VISION MAIN INDICATORS MESSAGE FROM THE CEO RESULTS AND BUSINESS - Analysis of the oil market - Corporate strategy - Stock performance - Exploration and production - Refining and marketing - Petrochemicals - Transportation - Distribution - Natural Gas - Electric Power - Biofuels - International Research & Development SOCIAL AND ENVIRONMENTAL RESPONSIBILITY - Social Responsibility - Health, Safety, Environment and Energy Efficiency MANAGEMENT & ORGANIZATIONAL STRUCTURE - Financing - Risk management - Human resources - Corporate governance FINANCIAL ANALYSIS - Economic-Financial Summary Consolidated - Consolidated Results - Net Income by Business Segment - Added Value Distributed - Liquidity and Capital Resources - Debt - Taxes and Production Taxes - Assets and Liabilities subject to Exchange Variation 2 Profile Founded in 1953 and the Brazilian oil sector leader, Petrobras is a publicly-held corporation which closed 2012 as the seventh largest energy company in the world in terms of market capitalization, according to the ranking published by the Consulting firm PFC Energy. It was also ranked 12th by Petroleum Intelligence Weekly (PIW), which, in addition to market cap, considers six operational criteria. In the oil, gas and energy industry, Petrobras operates in an integrated and specialized manner in the exploration and production, refining, marketing, transportation, petrochemical, oil product distribution, natural gas, electric power, gas-chemical and biofuel segments. Mission To operate in a safe and -

Technip Brazil: Solid Local Foundations for Profitable Growth

Technip Brazil: Solid Local Foundations for Profitable Growth Paulo Veronesi, Subsea Commercial Director, Brazil Investor Day in Brazil, October 4, 2011 Key Aspects of Brazil’s Economy One of the world’s largest economies 193 million inhabitants over 8.5 million km² 2010 nominal GDP: US$2.1 trillion (Ranked 8th globally) World’s seventh-largest oil consumer(1) Driven by natural resources ~40% of stock market capitalization (IBOVESPA index) 2.1 mb/d oil production US$74 billion of agricultural exports(2) Forthcoming sports events trigger significant investments Soccer World Cup in 2014 and Olympic Games in 2016 Source: Brazilian National Petroleum Agency (ANP), CIA World Factbook, IHS Global Insight, MDIC (1) Domestic oil demand of ~2 mb/d (2) From November 2009 to October 2010 2 Investor Day in Brazil, October 4, 2011 Focus on the Oil Industry Expected oil production Diversified customer base (Thousand barrels per day) 5 000 National company: 4 900 CAGR: 8.7% 98.5% of Brazilian production 4 000 ~14 billion boe of proved oil reserves 3 000 CAGR: Other operators 5.3% 2 000 2 137 1 716 1 268 1 000 … 2000 2005 2010 2020 Brazil’s oil production is estimated to double by 2020 Source: BP Statistical Review of World Energy 2011, Bradesco Corretora, Petrobras, PFC Energy. 3 Investor Day in Brazil, October 4, 2011 Brazil’s Leadership in Deepwater Worldwide new discoveries 2005 - 2010 Deepwater discoveries (33,989 million bbl) (300 - 1,500 meters) Deepwater accounts for 50% of worldwide discoveries over the last 5 years Development -

Brazilian Achievements 2010 Your Best Choice for Business and Investment

BRAZILA BRAND OF EXCELLENCE BRAZILIAN ACHIEVEMENTS 2010 YOUR BEST CHOICE FOR BUSINESS AND INVESTMENT PAC 1: A Long Cycle of Expansion Growth in Industrial Output Floating Exchange Rate and International Reserves Annual GDP growth Data in % annual change International reserves allow secure exchange rate fluctuation PAC 1 PAC 2 8 250 US$ billions Mar 03 - 241.7 6 6 Ago 08 - 205.1 Average 200 5 5.5% 4 4 2 150 Average 3 4.2% 0 100 2 - 2 50 1 - 4 Average 1.7% 0 0 - 6 Jan Jan Jan Jan Jan Jan Jan Jan Jan 1998 2000 2002 2004 2006 2008 2010* 2012* 2014* 1995 1997 1999 2001 2003 2005 2007 2009*10* 02 03 04 05 06 07 08 09 10 *Government forecast Source: IBGE *Forecast Source: FGV Source: Central Bank of Brazil Investment Has Strong Growth Path Job Creation Inflation Targeting Forecast of investment ratio 2009-2012 (% of GDP) Net Creation of Jobs Six consecutive years of inflation on target 22.0 10 MILLION JOBS IN THE FORMAL ECONOMY 8 1600 Market 21.0 7 forecast Forecast 20.0 1200 6 2010 4.91% 19.0 800 5 4 18.0 400 3 17.0 0 2 16.0 -400 1 15.0 0 1 2006 2007 2008 2009 2010 2011 2012 95 96 97 98 99 00 01 02 03 04 05 06 07 08 09 10* Jan/04 Jan/05 Jan/06 Jan/07 Jan/08 Jan/09 Jan/10 Jan/11 Source: APE/BNDES *Government forecast Source: MTE/CAGED Source: Central Bank of Brazil Brazil is awash with optimism, thanks to a booming economy, huge new oil fields, the 2014 World Cup and the 2016 Olympic Games Achievements.indd 1 4/17/10 1:22 AM BRAZIL Contents APRIL / MAY / 2010 DIRECTOR AND EDITOR Dirceu Brisola ENGLISH EDITOR Brian Nicholson ASSISTANT EDITOR Luiz Gonzaga S. -

P-36 Report-R

OCS Study MMS 2008-052 Benefits and Burdens of OCS Activities on States, Labor Market Areas, Coastal Counties, and Selected Communities Supplemental Study Component Social and Economic Impacts of the Sinking of Petrobras-36 (P-36) Deepwater Oil Platform Author John S. Petterson, PhD Prepared under MMS Contracts 1435-01-98-CT-30899 1435-01-00-CT-31066 (M98PC0001) Submitted to New Orleans November 2008 Background Information Petrobras Petrobras was founded in 1953 as a state-owned company after the government decided that all natural resources were the property of the state. Previously, all petroleum products had been imported into Brazil. At the beginning of Petrobras’ establishment, there were not many new reserves that were found. This problem compounded the national debt that already existed as a result of the absence of private oil companies investing in the country (Deloitte Touche Tohmatsu, 2002). Since Petrobras was the only oil company in Brazil, it incurred all the exploration risk. The two international oil crises of 1973 and 1979 severely affected Brazil’s economy- mainly due to an increase in import costs. Petrobras was ordered to find more oil. An extensive exploration program began in the late 70’s and early 80’s that included moving exploration activity into deepwater areas. The discoveries made particularly in the Campos Basin produced lucrative oil fields. In 1988, Article 177 of Brazil’s constitution was passed, prohibiting foreign investment in the hydrocarbon industry. This secured Petrobras’ monopoly, which in turn secured the state’s monopoly on the oil industry (ibid). In 1997, the 44 year monopoly that Petrobras had held effectively ended when Brazil opened the industry to outside private companies through a series of licensing rounds. -

Subsea Onshore/Offshore

Growing Use of Natural Gas Driving Opportunities for Technip Philip Hagyard, Senior Vice President LNG/GTL Business Unit SGCIB Oil & Oil Services: LNG Conference, London, April 3, 2012 Safe Harbor This presentation contains both historical and forward-looking statements. These forward-looking statements are not based on historical facts, but rather reflect our current expectations concerning future results and events and generally may be identified by the use of forward-looking words such as “believe”, “aim”, “expect”, “anticipate”, “intend”, “foresee”, “likely”, “should”, “planned”, “may”, “estimates”, “potential” or other similar words. Similarly, statements that describe our objectives, plans or goals are or may be forward- looking statements. These forward-looking statements involve known and unknown risks, uncertainties and other factors that may cause our actual results, performance or achievements to differ materially from the anticipated results, performance or achievements expressed or implied by these forward-looking statements. Risks that could cause actual results to differ materially from the results anticipated in the forward-looking statements include, among other things: our ability to successfully continue to originate and execute large services contracts, and construction and project risks generally; the level of production-related capital expenditure in the oil and gas industry as well as other industries; currency fluctuations; interest rate fluctuations; raw material (especially steel) as well as maritime freight price fluctuations; the timing of development of energy resources; armed conflict or political instability in the Arabian-Persian Gulf, Africa or other regions; the strength of competition; control of costs and expenses; the reduced availability of government-sponsored export financing; losses in one or more of our large contracts; U.S. -

Technip & Refining

Technip & Refining: Taking Our Track Record Further Marie-Christine Charrier, Vice President Refining Product Line UBS European Mid-Cap Oil Conference, March 21, 2013 Safe Harbor his presentation contains both historical and forward-looking statements. These forward-looking statements are not based on historical facts, but Trather reflect our current expectations concerning future results and events and generally may be identified by the use of forward-looking words such as “believe”, “aim”, “expect”, “anticipate”, “intend”, “foresee”, “likely”, “should”, “planned”, “may”, “estimates”, “potential” or other similar words. Similarly, statements that describe our objectives, plans or goals are or may be forward-looking statements. These forward-looking statements involve known and unknown risks, uncertainties and other factors that may cause our actual results, performance or achievements to differ materially from the anticipated results, performance or achievements expressed or implied by these forward-looking statements. Risks that could cause actual results to differ materially from the results anticipated in the forward-looking statements include, among other things: our ability to successfully continue to originate and execute large services contracts, and construction and project risks generally; the level of production-related capital expenditure in the oil and gas industry as well as other industries; currency fluctuations; interest rate fluctuations; raw material, especially steel as well as maritime freight price fluctuations; the timing of development of energy resources; armed conflict or political instability in the Arabian-Persian Gulf, Africa or other regions; the strength of competition; control of costs and expenses; the reduced availability of government-sponsored export financing; losses in one or more of our large contracts; U.S. -

Tanzania Ultra-Deepwater Exploration*

Tanzania Ultra-Deepwater Exploration* Lino Teixeira1, Veronica Martinez1, and Salvador Chrispim1 Search and Discovery Article #10189 (2009) Posted April 20, 2009 *Adapted from extended abstract prepared for AAPG International Conference and Exhibition, Cape Town, South Africa, October 26-29, 2008 1Petrobras, International Exploration Department , Rio de Janeiro, RJ, Brazil ([email protected]) Abstract Petrobras’ ultra-deepwater technology is internationally recognized for its innovative approach. In 2001 Petrobras received OTC’s award for the development of the ultra-deepwater Roncador Field in Campos Basin, Brazil, and recently, it discovered Tupi oil Field in Santos Basin, the 2nd largest oil field discovered in the last 20 years worldwide. Petrobras has the proficiency of producing at water depths up to 2000m and now is going even farther, improving the knowledge and expertise that should lead to a capability to produce at 3000m water depths (Figure 1). Eastern Africa is becoming a challenging but encouraging area for petroleum and gas exploration. The Eastern Africa margin, inclusive of six countries (Mozambique, Tanzania, Kenya, Somalia, Madagascar, and Seychelles), was subjected to different tectonic regimes. Its structural framework evolution started with Eastern Gondwana’s break-up, during the Juro-Triassic, and it is still active at the present time. Extensional and compressional periods controlled by strike-slip movement of the David Fracture Zone, created many sedimentary basins and multiple petroleum systems. Tanzania is considered an exploratory frontier area with only 35 wells drilled, mainly onshore and shallow water (including the islands). The presence of oil slicks suggest the existence of active petroleum systems, which encourage ultra-deepwater exploration, even though of no well has been drilled in such an environment. -

Master's Thesis

UNIVERSITY OF STAVANGER MASTER'S THESIS STUDY PROGRAM: THESIS IS WRITTEN IN THE FOLLOWING SPECIALIZATION/SUBJECT: MASTER OF SCIENCE IN PETROLEUM ENGINEERING RESERVOIR ENGINEERING IS THE ASSIGNMENT CONFIDENTIAL? (NB! Use the red form for confidential theses) TITLE: SMART WATER EOR POTENTIAL IN BRAZILIAN OIL FIELDS AUTHORS SUPERVISORS: Candidate number: Name: TINA PUNTERVOLD AND 243888 ELIANE FERREIRA SKULE STRAND ………………… ……………………………………. i | Page SUMMARY The fact that the petroleum industry still invest a lot of money on different oil recovery techniques indicates that there is an increasing demand for oil that needs to be met. Water flooding is a common secondary oil recovery method that involves the injection of water to maintain reservoir pressure and sweep oil to the producer. Studies have proven that the efficiency of a water flood depends on many factors, wettability being one of them. Injection of smart water can help alter wettability of reservoir making it favourable to overcome capillary forces that trap oil in the reservoir. In the research, we investigate the potential of smart water in the Brazilian pre-salt fields. Due to lack of significant literature for fluids and rocks from the Brazilian pre-salts, we consider the potential of smart water for oil recovery done on studies with rocks similar to the Brazilian pre-salts. The results from these studies will answer if there is at potential for smart water in the Brazilian pre-salt oil fields. A review of the historical stages and production magnitudes will be carried out to determine the current state of the oil industry within Brazil. It will be established that Brazil has numerous oilfields that are distributed mainly in offshore oil reservoirs. -

QUEST BRASIL DEEPWATER INSIGHT Vol

QUEST BRASIL DEEPWATER INSIGHT Vol. 9, Issue 3 December 2013 P-61 DEPARTS ANGRA DOS REIS FOR THE CAMPOS BASIN PAPA-TERRA FIELD BrasFels completed the construction of platform P-61, which departed Angra dos Reis Bay on Dec. 31, 2013. The unit will make a technical stop for diesel and water near Ilha Grande and continue on until its final location, the Papa-Terra field in the Campos Basin. The journey will take about six days after leaving the shipyard. This is the first TLWP platform (Tension Leg Wellhead Platform) to be built and operated in Brasil. The P-61 will operate together with the P-63 FPSO unit, which commenced oil production in Papa-Terra on November 11. Together, the units have the capacity to produce 140,000 BOPD via 18 wells.The TLWP has a lower range of motion compared to alternatives, allowing the use of dry trees, which are deployed on the deck of Source: Petrobras TLWP rather than on the seabed. Petrobras notes that this arrangement easier well intervention through the use of submerged centrifugal pumps. All the P-61 production will be transferred to the P-63 to process, store and offload extracted oil to shuttle tankers. The P-63 can also compress 1 million cu. m/d of natural gas and the excess gas consumed on the platforms will be injected into the reservoir. The P-61’s deck and four modules were built in Singapore, Asia.Two of the modules drive and control the submerged centrifugal pump (SCP) of the wells, while the two others distribute electricity and provide platform/accommodation control, respectively. -

Petrobras.Com/Magazine

IN DEPTH EDITION www.petrobras.com/magazine Cutting edge technology Innovations employed to enable pre-salt production ensure to Petrobras, for the third time, the OTC Distinguished Achievement Award PETROBRAS MAGAZINE EDITORIAL CONTENTS Global Connections 03 www.petrobras.com/magazine New Dimensions IN DEPTH EDITION The triumph 04 of experience Photo: Petrobras Agency Petrobras Photo: All Over Inside Story Recognized The importance Message from the president 10 competence 34 of knowledge his year, for the third time, Basin when we surpassed, for the first innovative technologies. In the subsea Petrobras is celebrating time ever, a water depth milestone: oil engineering area, we installed and the achievement of the production beyond 1,000 meters. operated the first Buoy Supporting highest international award Risers, a subsea structure weighting any petroleum company Moving forward, the company developed 2,700 tons. We have made great gains Tcan earn: the OTC Distinguished pioneer technologies with our local in achieving new water depth records Achievement Award. Granted by the and international partners. We broke for risers, and have managed to re- Energy Geek Frontiers Offshore Technology Conference – the the water depth record for offshore inject all the CO2 produced offshore Pre-salt Promising most important entity for the offshore production systems and respective into the pre-salt reservoirs of the Technology partnership industry – the distinction recognizes the subsea equipment, at the same time Santos Basin. By separating all of the 12 38 contributions the company has made as we raised our oil and gas reserves. CO2 from natural gas at our production toward developing new technologies for In 2001, we were again honored with platforms in the region, we have this industry, as a result of its efforts the OTC Distinguished Achievement prevented atmospheric emissions of 1 to explore and produce the pre-salt Award, this time for the Roncador million tons of CO2, which has brought petroleum deposits.