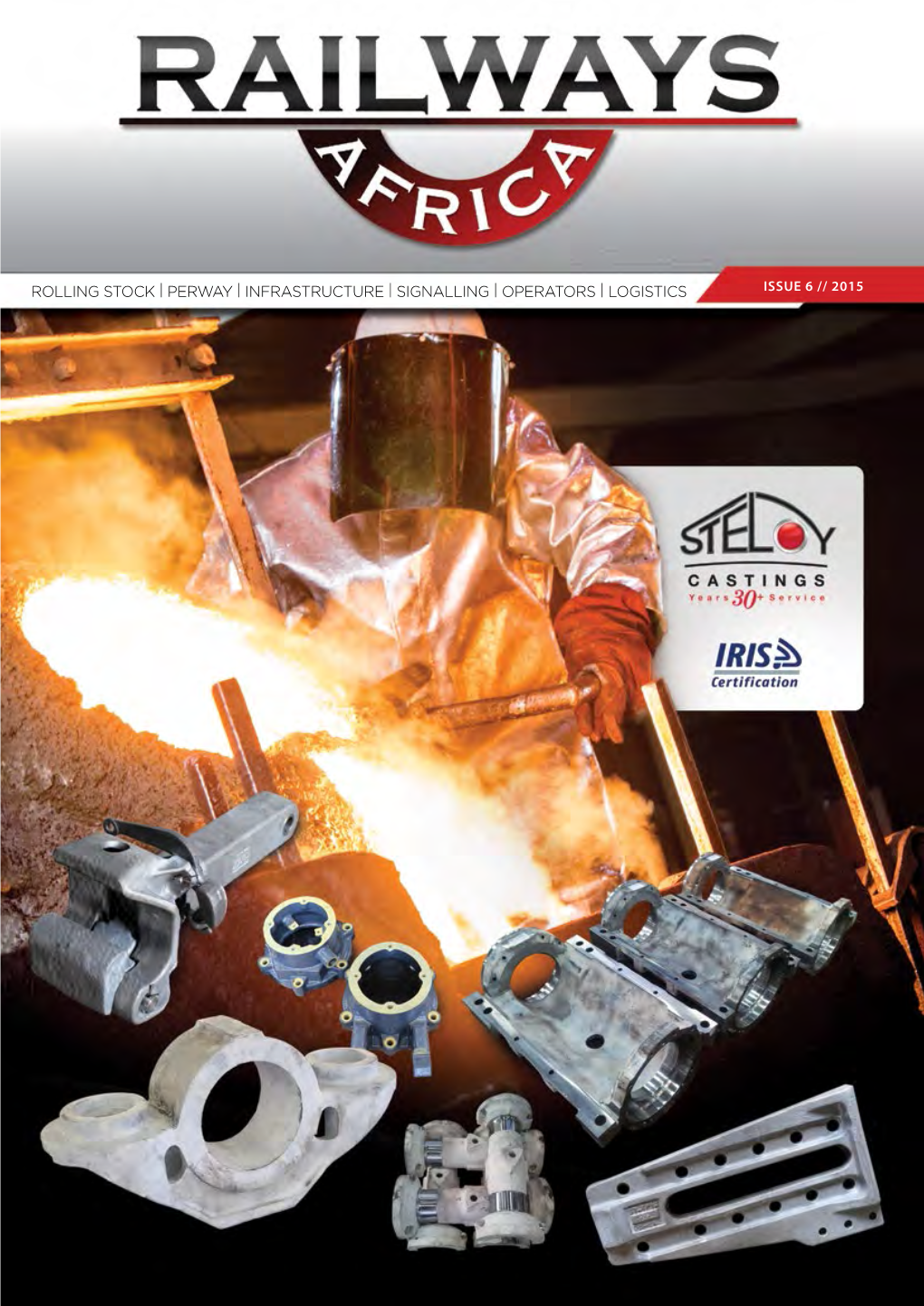

Rolling Stock | Perway | Infrastructure | Signalling | Operators | Logistics Issue 6 // 2015

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Review of the Effectiveness of Rail Concessions in the SADC Region

Technical Report: Review of the Effectiveness of Rail Concessions in the SADC Region Larry Phipps, Short-term Consultant Submitted by: AECOM Submitted to: USAID/Southern Africa Gaborone, Botswana March 2009 USAID Contract No. 690-M-00-04-00309-00 (GS 10F-0277P) P.O. Box 602090 ▲Unit 4, Lot 40 ▲ Gaborone Commerce Park ▲ Gaborone, Botswana ▲ Phone (267) 390 0884 ▲ Fax (267) 390 1027 E-mail: [email protected] TABLE OF CONTENTS 1. EXECUTIVE SUMMARY............................................................................................. 4 2. INTRODUCTION......................................................................................................... 8 2.1 Background .......................................................................................................... 8 2.2 Objectives of Study .............................................................................................. 9 2.3 Study Methodology .............................................................................................. 9 2.4 Report Structure................................................................................................. 10 3. BEITBRIDGE BULAWAYO RAILWAY CONCESSION ............................................. 11 3.1 Objectives of Privatization .................................................................................. 11 3.2 Scope of Railway Privatization ........................................................................... 11 3.3 Mode of Privatization......................................................................................... -

Rolling Stock | Perway | Infrastructure | Signalling | Operators | Logistics Issue 1 // 2016

ROLLING STOCK | PERWAY | INFRASTRUCTURE | SIGNALLING | OPERATORS | LOGISTICS ISSUE 1 // 2016 EDITOR’S COMMENT RAILWAYS AFRICA 1-2016 Luck Of The Irish A guy called Murphy has this well-known law: if anything can go wrong, it will. For instance, if a train from East London hits a cow early in January, damaging the locomotive, a 17-coach express heading for the coast with anything up to 1,200 passengers on-board won’t be able to get past. If the passenger train has already spent five hours in a heatwave at Burgersdorp, standing face-to-face with another train in the middle of nowhere, it will have run out of water and the toilets will be overflowing. Not all that far away, Murphy seems to have had his hands full, with a train from Port Elizabeth that was Photographed this in the municipal transport supposed to take 20 hours to Johannesburg. It was workshops at Seattle. battling with binding brakes, overflowing toilets and no water. In the end it was to take 33 hours to complete its journey. Attempts to contact Shosholoza Meyl offices were unsuccessful. Nobody answered (Murphy again). The train manager said there was nothing she could do. Eastern Cape area operations manager for Shosholoza Meyl, Nosipho Mancotywa wasn't aware of any complaints regarding the lack of water but she confirmed the lengthy delays with News24. Mancotywa said the signals were not working at Cradock because the electricity was off. Murphy can be a real devil where electricity is involved and he is a dab hand with cockroaches. -

Tender Advert -Tc 1015-19/20

BOTSWANA RAILWAYS PUBLIC TENDER NOTICE ENGAGEMENT OF CONSULTANTS FOR THE EVALUATION OF BIDS FOR THE CONSULTANCY SERVICES TO CONDUCT A BANKABLE FEASIBILITY STUDY FOR THE TWO RAIL LINKS OF MOSETSE-KAZUNGULA-LIVINGSTONE AND MMAMABULA LEPHALALE-TC 1015-19/20 Telex or facsimile tender submissions will not be The Procuring Entity is Botswana Railways and considered. Zambia Railways Limited. One (1) original tender document marked Botswana Railways (BR) is a Government Enterprise ORIGINAL and Four (4) duplicate copies of the given a mandate as sole Rail operator since original Document marked copy in one sealed establishment in 1987 (BR Act 1986; Amended in envelope clearly marked: “Tender Reference No. 2004). The act was amended to allow BR to form TC 1015 19/20 ENGAGEMENT OF CONSULTANTS FOR Joint Ventures, Subsidiary companies and to THE EVALUATION OF BIDS FOR THE CONSULTANCY exploit other business opportunities. SERVICES TO CONDUCT A BANKABLE FEASIBILITY BR is mandated to provide transportation of goods STUDY FOR THE TWO RAIL LINKS OF MOSETSE- and passengers within Botswana, effi ciently, safely KAZUNGULA-LIVINGSTONE AND MMAMABULA- and cost-effectively, along sound commercial LEPHALALE” shall be delivered to: lines. The Supply Chain Manager Botswana Railways Zambia Railways Limited (ZRL) is a parastatal Head Quarters railway of Zambia mandated to operate both Along A1 Road passenger and freight trains by an Act of Parliament Mowana Ward Mahalapye, Botswana with company registration number 12780. It is a The name and address of the bidder should be public company with the Industrial Development clearly marked on the envelope. Corporation (IDC) as its sole shareholder. -

Results of Railway Privatization in Africa

36005 THE WORLD BANK GROUP WASHINGTON, D.C. TP-8 TRANSPORT PAPERS SEPTEMBER 2005 Public Disclosure Authorized Public Disclosure Authorized Results of Railway Privatization in Africa Richard Bullock. Public Disclosure Authorized Public Disclosure Authorized TRANSPORT SECTOR BOARD RESULTS OF RAILWAY PRIVATIZATION IN AFRICA Richard Bullock TRANSPORT THE WORLD BANK SECTOR Washington, D.C. BOARD © 2005 The International Bank for Reconstruction and Development/The World Bank 1818 H Street NW Washington, DC 20433 Telephone 202-473-1000 Internet www/worldbank.org Published September 2005 The findings, interpretations, and conclusions expressed here are those of the author and do not necessarily reflect the views of the Board of Executive Directors of the World Bank or the governments they represent. This paper has been produced with the financial assistance of a grant from TRISP, a partnership between the UK Department for International Development and the World Bank, for learning and sharing of knowledge in the fields of transport and rural infrastructure services. To order additional copies of this publication, please send an e-mail to the Transport Help Desk [email protected] Transport publications are available on-line at http://www.worldbank.org/transport/ RESULTS OF RAILWAY PRIVATIZATION IN AFRICA iii TABLE OF CONTENTS Preface .................................................................................................................................v Author’s Note ...................................................................................................................... -

Compendium on Deliberations of Electrical Standards Committee

COMPENDIUM ON DELIBERATIONS OF ELECTRICAL STANDARDS COMMITTEE (1935-2014) ISSUED ON 26-10-2015 BY ELECTRICAL DIRECTORATE RESEARCH DESIGNS AND STANDARDS ORGANISATION MANAK NAGAR, LUCKNOW-226 011 Compendium of ESC 1935-2014 Page 1 INDEX S. No. DETAILS PAGE No. 1. FORWARD 3 2. OBJECTIVE OF ESC 4 3. DELIBERATIONS: 1st to 5th 7-53 4. DELIBERATIONS: 6th to 10th 54-104 5. DELIBERATIONS:11th to 15th 105-157 6. DELIBERATIONS:16th to 20th 158-200 7. DELIBERATIONS:21st to 25th 201-252 8. DELIBERATIONS:26th to 30th 253-301 9. DELIBERATIONS:31st to 35th 302-351 10. DELIBERATIONS:36th to 40th 352-382 11. DELIBERATIONS:41st to 45th 383-411 12. DELIBERATIONS:46th to 50th 412-445 13. DELIBERATIONS:51st to 55th 446-485 14. DELIBERATIONS:56th to 59th 486-525 Compendium of ESC 1935-2014 Page 2 FOREWORD Electrical Standards Committee (ESC) is a highest forum for Railway Electrical Engineers to discuss various issues pertaining to Electrical Department for efficient and economical train operation. This compendium will provide a glimpse of the events and technological upgradation over last 80 years since inception of this committee. As very old records were not available easily, efforts have been made to collect as much records for the ESC, particularly for pre-independence period. Initially separate ESC meetings used to be held for General Services and Traction. From 49th ESC onward, which was held in January’1999 at Pune, a decision was taken to convene a common ESC meeting for all items of Electrical department. This compendium will be updated regularly so that all the records are available at one place. -

FERRMED LOCOMOTIVE CONCEPT STUDY 1 2.Pdf

FERRMED FREIGHT LOCOMOTIVE CONCEPT STUDY By: TABLE OF CONTENTS 1 INTRODUCTION .................................................................................................................... 4 1.1 What is FERRMED? ....................................................................................................... 4 1.2 FERRMED Objectives .................................................................................................... 5 1.3 The FERRMED Standards.............................................................................................. 5 2 EXECUTIVE SUMMARY ....................................................................................................... 7 3 EUROPEAN NETWORK CHARACTERISTICS .................................................................... 9 4 INTEROPERABILITY AND CROSS-ACCEPTANCE .......................................................... 12 4.1 Interoperability .............................................................................................................. 12 4.2 ERTMS.......................................................................................................................... 18 4.3 Cross-Acceptance ......................................................................................................... 21 5 STATE-OF-THE-ART WORLDWIDE LOCOMOTIVES ....................................................... 23 6 REQUIRED STARTING TRACTIVE EFFORT AND POWER TO HAUL “FERRMED TRAINS” ..................................................................................................................................... -

Port of Maputo, Mozambique

CONFERENCE PROGRAMME Transport Evolution presents 13 - 14 May 2019 | Port of Maputo, Mozambique 25+ expert speakers, including: Osório Lucas Chief Executive Officer, Maputo Port Development Company Col. Andre Ciseau Secretary General, Port Management Association of Eastern & Southern Africa (PMAESA) Clive Smith Chief Executive Officer, Walvis Bay Corridor Group, Namibia Johny Smith Chief Executive Officer, TransNamib Holdings Limited, Namibia Boineelo Shubane Director Operations, Botswana Railways, Botswana Building the next generation of ports and rail in Mozambique Host Port Authority: Supported by: Member of: Organised by: Simultaneous conference translation in English and Portuguese will be provided Será disponibilizada tradução simultânea da conferência em Inglês e Português www.transportevolutionmz.com Welcome to the inaugural Mozambique Ports and Rail Evolution Forum Ports and railways are leading economic engines for Mozambique, providing access to import and export markets, driving local job creation, and unlocking opportunities for the development of the local blue economy. Hosted by Maputo Port Development Company, Mozambique Ports and Rail Evolution prepares the region’s ports and railways for the fourth industrial revolution. Day one of the extensive two-day conference will feature a high level keynote comprising of leading African ports and rail authorities and focus on advancing Intra-African trade. We then explore challenges, opportunities and solutions for improving regional integration and connectivity. Concluding the day, attendees will learn from local and international ports authorities and terminal operators about challenges and opportunities for ports development. Day two begins by looking at major commodities that are driving infrastructure development forward and what types of funding and investment opportunities are available. This is followed by a rail spotlight session where we will learn from local and international rail authorities and operators about maintenance and development projects. -

Case Studies

SECTION 4 Case Studies Inclusive Infrastructure and Social Equity | 129 SECTION 4 Contents Case Studies U.S. Bank Stadium, United States of America 131 El Metropolitano Bus Rapid Transit, Peru 141 Regional Communications Infrastructure Program (RCIP), Malawi 151 Water Sector Trust Fund, Kenya 161 Mi Teleférico Cable Car, Bolivia 171 TransMilenio Bus Rapid Transit, Colombia 183 Cairo Metro, Egypt 199 Last Mile Connectivity Program, Kenya 215 130 | GLOBAL INFRASTRUCTURE HUB U.S. BANK STADIUM United States of America U.S. Bank Stadium Source: Image provided by Alex Tittle, Equity Director for the Minnesota Sports Facilities Authority A state-led program to encourage more The Equity Plan includes pragmatic goals to integrate women and minorities to pursue the women, minorities and low-income residents in the workforce, and women- and minority-owned businesses employment and business opportunities in the design and construction activities of the project. created by the construction of a major Specifically, the Equity Plan outlines how to provide sporting and events stadium. employment and equal access to labour market opportunities and establishes goals for contracts to be The U.S. Bank Stadium (the Stadium) is the centrepiece awarded to capable, available and willing women-owned of Minnesota’s redevelopment plan1 and has a strong and minority-owned businesses (refer to Table 1: Target social inclusion agenda aimed at benefitting local goals and additional achievements of the Equity Plan). communities. The Stadium is owned and operated by Veterans and low-income residents were also included the Minnesota Sports Facilities Authority (the Authority), in employment initiatives with much of the engagement which was also responsible for its design and build. -

Botswana Country Mining Guide

KPMG GLOBAL MINING INSTITUTE Botswana Country mining guide kpmg.com/mining KPMG INTERNATIONAL Strategy Series B | Botswana mining guide © 2014 KPMG International Cooperative (“KPMG International”). KPMG International provides no client services and is a Swiss entity with which the independent member firms of the KPMG network are affiliated. Contents Executive summary 2 New geographic expansion risk framework 3 Country snapshot 4 World Bank ranking: Ease of doing business 5 Type of government 6 Economy and fiscal policy 7 Heritage Foundation of Economic Freedom 8 Fraser Institute rankings 9 Sustainability and environment 12 Infrastructure development 17 Labor relations and employment situation 19 Inbound and outbound investment 19 Key commodities: Production and reserves 21 Major mining companies in Botswana 29 Foreign companies with operations in Botswana 29 © 2014 KPMG International Cooperative (“KPMG International”). KPMG International provides no client services and is a Swiss entity with which the independent member firms of the KPMG network are affiliated. 2 | Botswana mining guide Executive summary Since its independence in 1966, Botswana has witnessed good economic growth on the back of fiscal discipline and robust governance. The country has a strong legal framework, low prevalence of civil unrest or disorder and minimal government interference in the mining sector. Botswana also boasts infrastructure that is in better condition than several of its neighbors, which has assisted in boosting interest from international companies in the mining sector. Botswana is one of the world leaders in diamond production, with Russia competing closely. While Russia was the largest diamond producer in the world in terms of production volume in 2012, Botswana produced the most in terms of value, accounting for 23.6 percent of total global diamond production. -

Ground Engineering

Ground Engineering Headquaters Main Offices VSL International Ltd. North Asia South Asia Saegestrasse 76 Intrafor Hong Kong Ltd. VSL Singapore Pte Ltd. CH - 3098 Köniz Tel: +852 2590 2288 Tel: +65 6559 1222 Switzerland Fax: +852 2590 0290 Fax: +65 6257 7751 Tel: +41 58 456 3000 Fax: +41 58 456 3095 Middle East Australia & New Zealand Intrafor HK Ltd. (Dubai Branch) VSL - Intrafor Australia - NZ Tel: +971 4 885 7225 Tel: +61 7 3327 0200 Fax: +971 4 885 7226 Fax: +61 7 3327 0299 Also present around the world through VSL local offices see website for details. www.intrafor.com www.vsl.com Subsidiary of VSL International Copyright Jan. 2014, Intrafor Ground Engineering Specialist Intrafor is a leading ground engineering specialist, providing expertise for major construction projects around the world. With a reputation for reliability and innovation, our experienced teams bring solutions to our clients’ most complex foundation and geotechnical engineering challenges. We specialise in all aspects of ground engineering works. Using specialist and innovative construction techniques, our works cover a variety of structures including foundations, deep basements, tunnels, station boxes, underground car parks, cut-off walls, reclamations and dams. Originally founded in France in 1850, Intrafor is a subsidiary of the VSL Group. We have developed into a well-established and widely recognised geotechnical specialist partner for developers, consultants and contractors worldwide. As a foundations partner, we are able to offer clients the strength of our local roots in each market, backed by the support of a large construction group. 1 Global support, local expertise Intrafor is part of the global VSL Group network and in addition to its permanent bases can call on the support of VSL’s extensive network of over 40 offices to operate worldwide. -

Moving Away from Aid the Experience of Botswana Rachael Calleja and Annalisa Prizzon

Report Moving away from aid The experience of Botswana Rachael Calleja and Annalisa Prizzon December 2019 Readers are encouraged to reproduce material for their own publications, as long as these are not being sold commercially. ODI requests due acknowledgement and a copy of the publication. For online use, we ask readers to link to the original resource on the ODI website. The views presented in this paper are those of the author(s) and do not necessarily represent the views of ODI or our partners. This work is licensed under CC BY-NC-ND 4.0. Cover photo: a pedestrian bridge in Gaborone, Botswana. Credit: Marc Shoul/Panos Pictures. Acknowledgements This report was possible only because of the generous financial contribution of Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ), which partnered with the Overseas Development Institute (ODI) to explore the theme of country experiences towards graduation from official development assistance. Julie Kolsdorf (GIZ) brilliantly and effectively coordinated our preparation and follow-up between GIZ colleagues in Germany and in Gaborone, Botswana. Special thanks go to Tshepo Ketshabile (GIZ SADC office in Gaborone) for arranging and coordinating our schedule when we were in Botswana and for helping us to organise our trip. The GIZ SADC office in Gaborone, led by Thomas Schaef, and Fabian Kyrieleis at the German Embassy in Gaborone were instrumental to our fact-finding mission in Gaborone. Thanks also to Same Baaitse at the Ministry of International Affairs and International Development of the Government of Botswana who kindly and effectively scheduled our meetings with senior government officials. We are grateful for the editing of this report by Hannah Caddick. -

Botswana Transport & Infrastructure Statistics 2012

BOTSWANA TRANSPORT & INFRASTRUCTURE STATISTICS 2012 STATISTICS BOTSWANA Copyrights C Statistics Botswana 2013 Statistics Botswana. Private Bag 0024, Gaborone. Botswana Tel: (267) 367 1300. Fax: (267) 395 2201. Email: [email protected] Website: www.cso.gov.bw BOTSWANA TRANSPORT AND INFRASTRUCTURE STATISTICS - 2012 Published by Statistics Botswana Private Bag 0024, Gaborone Telephone: +267 367 1300 Fax: +267 395 6087 Email: [email protected] Website: www.cso.gov.bw Contact Unit: Transport and Infrastructure Statistics Unit Ministry of Transport and Communications November 2013 COPYRIGHT RESERVED No part of this information shall be reproduced, stored in a retrieval system, or even transmitted in any form or by any means, whether electronically, mechanically, photocopying or otherwise, without the prior permission of Statistics Botswana TABLE OF CONTENTS PREFACE...........................................................................................................................................1 ABBREVIATIONS................................................................................................................................2 EXECUTIVE SUMMARY......................................................................................................................3 1. INTRODUCTION...........................................................................................................................3 2. ROAD TRANSPORT......................................................................................................................3