Soft Matter PAPER

Total Page:16

File Type:pdf, Size:1020Kb

Load more

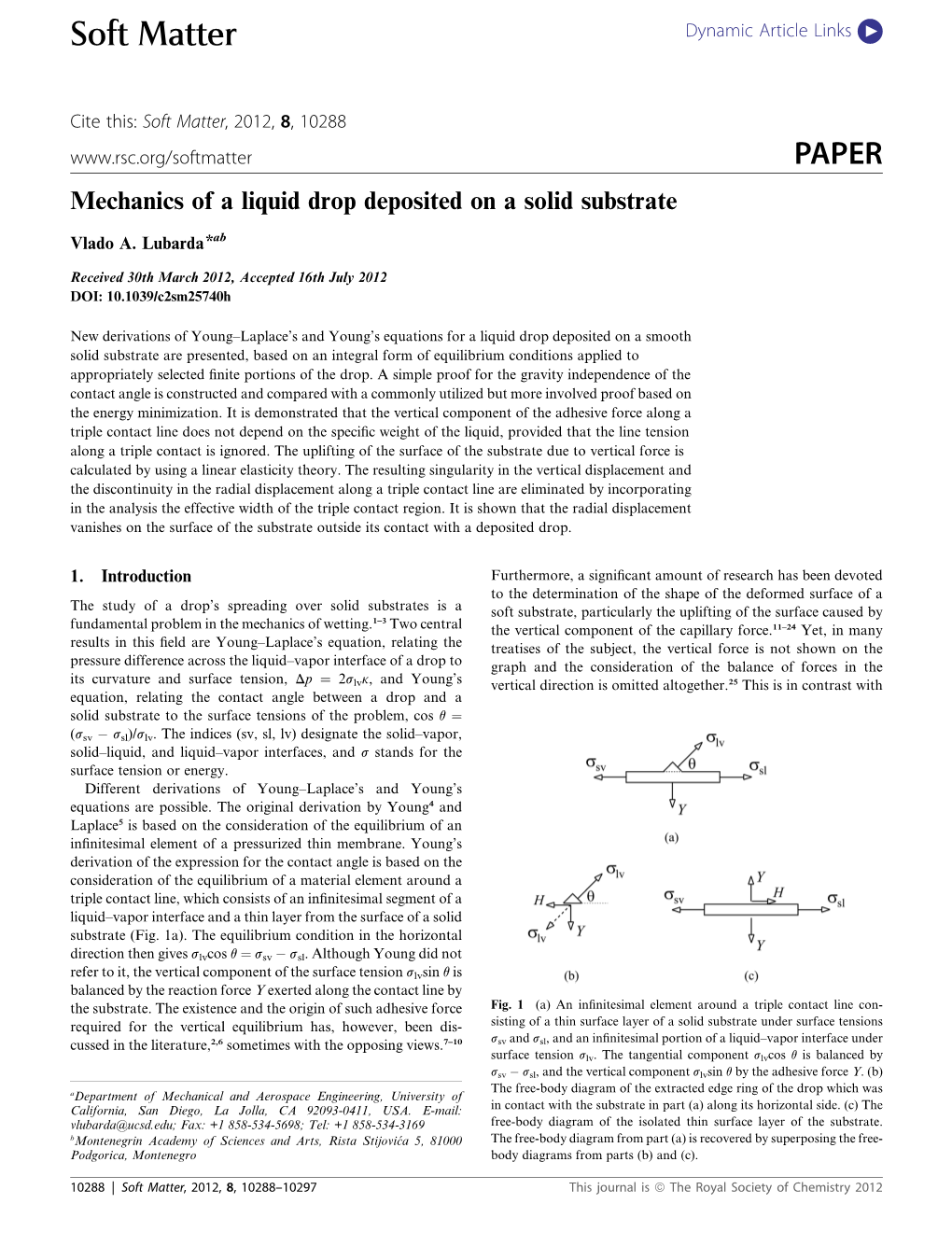

Recommended publications

-

Bioinspired Inner Microstructured Tube Controlled Capillary Rise

Bioinspired inner microstructured tube controlled capillary rise Chuxin Lia, Haoyu Daia, Can Gaoa, Ting Wanga, Zhichao Donga,1, and Lei Jianga aChinese Academy of Sciences Key Laboratory of Bio-inspired Materials and Interfacial Sciences, Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, 100190 Beijing, China Edited by David A. Weitz, Harvard University, Cambridge, MA, and approved May 21, 2019 (received for review December 17, 2018) Effective, long-range, and self-propelled water elevation and trans- viscosity resistance for subsequent bulk water elevation but also, port are important in industrial, medical, and agricultural applica- shrinks the inner diameter of the tube. On turning the peristome- tions. Although research has grown rapidly, existing methods for mimetic tube upside down, we can achieve capillary rise gating water film elevation are still limited. Scaling up for practical behavior, where no water rises in the tube. In addition to the cap- applications in an energy-efficient way remains a challenge. Inspired illary rise diode behavior, significantly, on bending the peristome- by the continuous water cross-boundary transport on the peristome mimetic tube replica into a “candy cane”-shaped pipe (closed sys- surface of Nepenthes alata,herewedemonstratetheuseof tem), a self-siphon is achieved with a high flux of ∼5.0 mL/min in a peristome-mimetic structures for controlled water elevation by pipe with a diameter of only 1.0 mm. bending biomimetic plates into tubes. The fabricated structures have unique advantages beyond those of natural pitcher plants: bulk wa- Results ter diode transport behavior is achieved with a high-speed passing General Description of the Natural Peristome Surface. -

The Life of a Surface Bubble

molecules Review The Life of a Surface Bubble Jonas Miguet 1,†, Florence Rouyer 2,† and Emmanuelle Rio 3,*,† 1 TIPS C.P.165/67, Université Libre de Bruxelles, Av. F. Roosevelt 50, 1050 Brussels, Belgium; [email protected] 2 Laboratoire Navier, Université Gustave Eiffel, Ecole des Ponts, CNRS, 77454 Marne-la-Vallée, France; fl[email protected] 3 Laboratoire de Physique des Solides, CNRS, Université Paris-Saclay, 91405 Orsay, France * Correspondence: [email protected]; Tel.: +33-1691-569-60 † These authors contributed equally to this work. Abstract: Surface bubbles are present in many industrial processes and in nature, as well as in carbon- ated beverages. They have motivated many theoretical, numerical and experimental works. This paper presents the current knowledge on the physics of surface bubbles lifetime and shows the diversity of mechanisms at play that depend on the properties of the bath, the interfaces and the ambient air. In particular, we explore the role of drainage and evaporation on film thinning. We highlight the existence of two different scenarios depending on whether the cap film ruptures at large or small thickness compared to the thickness at which van der Waals interaction come in to play. Keywords: bubble; film; drainage; evaporation; lifetime 1. Introduction Bubbles have attracted much attention in the past for several reasons. First, their ephemeral Citation: Miguet, J.; Rouyer, F.; nature commonly awakes children’s interest and amusement. Their visual appeal has raised Rio, E. The Life of a Surface Bubble. interest in painting [1], in graphism [2] or in living art. -

Equilibria of Pendant Droplets: Spatial Variation and Anisotropy of Surface Tension

Equilibria of Pendant Droplets: Spatial Variation and Anisotropy of Surface Tension by Dale G. Karr Department of Naval Architecture and Marine Engineering University of Michigan Ann Arbor, MI 48109-2145 USA Email: [email protected] 1 Abstract An example of capillary phenomena commonly seen and often studied is a droplet of water hanging in air from a horizontal surface. A thin capillary surface interface between the liquid and gas develops tangential surface tension, which provides a balance of the internal and external pressures. The Young-Laplace equation has been historically used to establish the equilibrium geometry of the droplet, relating the pressure difference across the surface to the mean curvature of the surface and the surface tension, which is presumed constant and isotropic. The surface energy per unit area is often referred to as simply surface energy and is commonly considered equal to the surface tension. The relation between the surface energy and the surface tension can be established for axisymmetric droplets in a gravitational field by the application of the calculus of variations, minimizing the total potential energy. Here it is shown analytically and experimentally that, for conditions of constant volume of the droplet, equilibrium states exist with surface tensions less than the surface energy of the water-air interface. The surface tensions of the interface membrane vary with position and are anisotropic. Keywords: capillary forces, droplets, surface energy, surface tension 2 Background For droplets of water in air with negligible inertia forces, the water mass is influenced by gravity and surface tension. These forces dominate at length scales of approximately 2mm, the characteristic capillary length (1-3). -

Directional Water Wicking on a Metal Surface Patterned by Microchannels

materials Article Directional Water Wicking on a Metal Surface Patterned by Microchannels Nima Abbaspour 1,*, Philippe Beltrame 1,* , Marie-Christine Néel 1 and Volker P. Schulz 2 1 UMR1114 EMMAH INRAE—Avignon Université, F-84914 Avignon, France; [email protected] 2 Department of Mechanical Engineering, Baden-Württemberg Cooperative State University Mannheim, Coblitzallee 1-9, D-68163 Mannheim, Germany; [email protected] * Correspondence: [email protected] (N.A.); [email protected] (P.B.) Abstract: This work focuses on the simulation and experimental study of directional wicking of water on a surface structured by open microchannels. Stainless steel was chosen as the material for the structure motivated by industrial applications as fuel cells. Inspired by nature and literature, we designed a fin type structure. Using Selective Laser Melting (SLM) the fin type structure was manufactured additively with a resolution down to about 30 µm. The geometry was manufactured with three different scalings and both the experiments and the simulation show that the efficiency of the water transport depends on dimensionless numbers such as Reynolds and Capillary numbers. Full 3D numerical simulations of the multiphase Navier-Stokes equations using Volume of Fluid (VOF) and Lattice-Boltzmann (LBM) methods reproduce qualitatively the experimental results and provide new insight into the details of dynamics at small space and time scales. The influence of the static contact angle on the directional wicking was also studied. The simulation enabled estimation of the contact angle threshold beyond which transport vanishes in addition to the optimal contact angle for transport. Keywords: directional wicking; patterned surface; wetting dynamics; capillarity, 3D simulation; Citation: Abbaspour, N.; Beltrame, Volume of Fluid; Lattice Boltzmann Method; Selective Laser Melting Manufacturing; microstructure B.; Néel, M.-C.; Schulz, V. -

![Arxiv:1805.07608V3 [Cond-Mat.Soft] 29 Aug 2018 Rsafreta Ihrdasteclne Noo Expels Or Into Cylinder the Ex- Drags Meniscus Either the That 17]](https://docslib.b-cdn.net/cover/9099/arxiv-1805-07608v3-cond-mat-soft-29-aug-2018-rsafreta-ihrdasteclne-noo-expels-or-into-cylinder-the-ex-drags-meniscus-either-the-that-17-3119099.webp)

Arxiv:1805.07608V3 [Cond-Mat.Soft] 29 Aug 2018 Rsafreta Ihrdasteclne Noo Expels Or Into Cylinder the Ex- Drags Meniscus Either the That 17]

The Meniscus on the Outside of a Circular Cylinder: From Microscopic to Macroscopic Scales Yanfei Tang (唐雁飞) and Shengfeng Cheng (程胜峰)∗ Department of Physics, Center for Soft Matter and Biological Physics, and Macromolecules Innovation Institute, Virginia Polytechnic Institute and State University, Blacksburg, Virginia 24061, USA (Dated: August 30, 2018) We systematically study the meniscus on the outside of a small circular cylinder vertically im- mersed in a liquid bath in a cylindrical container that is coaxial with the cylinder. The cylinder has a radius R much smaller than the capillary length, κ−1, and the container radius, L, is varied − from a small value comparable to R to ∞. In the limit of L ≪ κ 1, we analytically solve the general Young-Laplace equation governing the meniscus profile and show that the meniscus height, − ∆h, scales approximately with R ln(L/R). In the opposite limit where L ≫ κ 1, ∆h becomes inde- − pendent of L and scales with R ln(κ 1/R). We implement a numerical scheme to solve the general Young-Laplace equation for an arbitrary L and demonstrate the crossover of the meniscus profile be- − − tween these two limits. The crossover region has been determined to be roughly 0.4κ 1 . L . 4κ 1. An approximate analytical expression has been found for ∆h, enabling its accurate prediction at any values of L that ranges from microscopic to macroscopic scales. I. INTRODUCTION it from the liquid depending on if the contact angle is acute or obtuse. A recent study of the meniscus rise on a A liquid meniscus as a manifestation of capillary action nanofiber showed that the force on the nanofiber highly is ubiquitous in nature and our daily life. -

Polyhipes MORPHOLOGY, SURFACE MODIFICATION and TRANSPORT

POLYHIPEs MORPHOLOGY, SURFACE MODIFICATION AND TRANSPORT PROPERTIES by BORAN ZHAO Submitted in partial fulfillment of the requirements for the degree of DOCTOR OF PHILOSOPHY Dissertation Advisers: Dr. Donald L. Feke and Dr. Ica Manas-Zloczower Department of Chemical and Biomolecular Engineering CASE WESTERN RESERVE UNIVERSITY January 2019 CASE WESTERN RESERVE UNIVERSITY SCHOOL OF GRADUATE STUDIES We hereby approve the thesis/dissertation of Boran Zhao candidate for the degree of Doctor of Philosophy *. Committee Chair Donald L. Feke Committee Members Ica Manas-Zloczower Jay Adin Mann Jr. Uziel Landau David Schiraldi Date of Defense September 18th, 2018 *We also certify that written approval has been obtained for any proprietary material contained therein. DEDICATION To faith in truth, who carries me in seeking answers; To faith in consciousness, who drives me in the right directions; To my beloved family, who are the source of my happiness; To myself, for not yielding in pressure and not being satisfied in absorbing knowledge. i TABLE OF CONTENTS Dedication ............................................................................................................................ i Table of Contents ................................................................................................................ ii List of Tables ................................................................................................................... viii List of Figures ................................................................................................................... -

Dripping Faucet in Extreme Spatial and Temporal Resolution

Dripping faucet in extreme spatial and temporal resolution Achim Sack and Thorsten Poschel€ Institute for Multiscale Simulations, Friedrich-Alexander-Universitat€ Erlangen-Nurnberg,€ Erlangen 91052, Germany (Received 5 February 2016; accepted 22 March 2017) Besides its importance for science and engineering, the process of drop formation from a homogeneous jet or at a nozzle is of great aesthetic appeal. In this paper, we introduce a low-cost setup for classroom use to produce quasi-high-speed recordings with high temporal and spatial resolution of the formation of drops at a nozzle. The visualization of the process can be used for quantitative analysis of the underlying physical phenomena. VC 2017 American Association of Physics Teachers. [http://dx.doi.org/10.1119/1.4979657] I. INTRODUCTION depending on the parameters of the experiment, one or more much smaller satellite drops may appear for each drop (see The formation of drops of liquids is an everyday phenom- Fig. 1 below); and (ii) small perturbations of the surface of a enon, yet obtaining a detailed understanding of the process fluid cylinder grow over time if the wavelength of the pertur- is not straightforward from an experimental or a theoretical bation exceeds a certain value. The latter observation allowed point of view. In engineering, drop formation is of impor- for the systematic investigation of the instability of fluid surfa- tance for a number of processes such as ink jet printing, ces and gave rise to a large body of related experimental work spray drying, spray coating, and others. by Hagen,8,9 Magnus,10 Rayleigh,11,12 and many others. -

Weierstrass' Variational Theory for Analysing Meniscus Stability

Weierstrass' variational theory for analysing meniscus stability in ribbon growth processes Eyan P. Noronha∗1, German A. Oliveros1, and B. Erik Ydstis1 1Department of Chemical Engineering Carnegie Mellon University November 7, 2020 Abstract We use the method of free energy minimization to analyse static meniscus shapes for crystal ribbon growth systems. To account for the possibility of multivalued curves as solutions to the minimization problem, we choose a parametric representation of the meniscus geometry. Using Weierstrass' form of the Euler-Lagrange equation we derive analytical solutions that provide explicit knowledge on the behavior of the meniscus shapes. Young's contact angle and Gibbs pinning conditions are analysed and shown to be a consequence of the energy minimization prob- lem with variable end-points. For a given ribbon growth configuration, we find that there can exist multiple static menisci that satisfy the boundary conditions. The stability of these solu- tions is analysed using second order variations and are found to exhibit saddle node bifurcations. We show that the arc length is a natural representation of a meniscus geometry and provides the complete solution space, not accessible through the classical variational formulation. We provide a range of operating conditions for hydro-statically feasible menisci and illustrate the transition from a stable to spill-over configuration using a simple proof of concept experiment. Keywords: Interfaces; Edge defined film fed growth; Growth from melt; Solar cells 1 Introduction These investigations, which have found their confirmation in striking agreement with careful ex- periments, are among the most beautiful enrichments of natural science that we owe to the great mathematician. -

Mugele: Wetting Basics

FriederMugele Physics of Complex Fluids University of Twente coorganizers: JaccoSnoeier Physics of Fluids / UT Anton Darhuber MesoscopicTransport Phenomena / Tu/e speakers: JoséBico (ESPCI Paris) Daniel Bonn (UvA) MichielKreutzer (TUD) Ralph Lindken (TUD) 1 program Monday: 12:00 –13:00h registration + lunch 13:00h welcome: FriederMugele 13:15h –14:00h FriederMugele: Wetting basics (Young-Laplace equation; Young equation; examples) 14:10-15:25h JaccoSnoeijer: Wetting flows: the lubrication approximation 15:25-15:50h coffee break 15:50-16:35h JaccoSnoeijer: Coating flows: the Landau-Levichproblem and its solution using asymptotic matching 16:45-17:30h Anton Darhuber: Surface tension, capillary forces and disjoining pressure I Tuesday: 9:00h-9:45h FriederMugele: Dewetting 9:5510:40 Anton Darhuber: Surface tension, capillary forces and disjoining pressure II 10:40-11:05h coffee break 11:05h-11:50h Anton Darhuber: Surface tension-gradient-driven flows 12:00h-12:45h Daniel Bonn: Evaporating drops 12:45-14:00h lunch 14:00h-14:45h Daniel Bonn: Drop impact 15:55h-15:40h JoséBico: Elastocapillarity (I) 15:40-16:05h coffee break 16:05h –16:50h JoséBico: Elasticity & Capillarity (II) 18:30 -... joint dinner & get together 2 program Wednesday: 9:00h-9:45h MichielKreutzer: Two-phase flow in microchannels: the Brethertonproblem 9:55h-10:40h Michiel Kreutzer: Drop generation& emulsificationin microchannels 10:40h-11:05h coffeebreak 11:05h-11:50h Michiel Kreutzer: Jet instabilitiesin microchannels 12:00h-12:45h Ralph Lindken: PiVcharacterization of capillarity-driven -

Stability of Constrained Capillary Surfaces

FL47CH22-Steen ARI 1 December 2014 20:31 Stability of Constrained Capillary Surfaces J.B. Bostwick1 and P.H. Steen2 1Department of Engineering Science and Applied Mathematics, Northwestern University, Evanston, Illinois 60208 2School of Chemical and Biomolecular Engineering and Center for Applied Mathematics, Cornell University, Ithaca, New York 14853; email: [email protected] Annu. Rev. Fluid Mech. 2015. 47:539–68 Keywords First published online as a Review in Advance on surface tension, wetting, drops, bridges, rivulets, contact line, common line September 29, 2014 Annu. Rev. Fluid Mech. 2015.47:539-568. Downloaded from www.annualreviews.org The Annual Review of Fluid Mechanics is online at Abstract fluid.annualreviews.org A capillary surface is an interface between two fluids whose shape is deter- Access provided by Northwestern University - Evanston Campus on 01/06/15. For personal use only. This article’s doi: mined primarily by surface tension. Sessile drops, liquid bridges, rivulets, and 10.1146/annurev-fluid-010814-013626 liquid drops on fibers are all examples of capillary shapes influenced by con- Copyright c 2015 by Annual Reviews. tact with a solid. Capillary shapes can reconfigure spontaneously or exhibit All rights reserved natural oscillations, reflecting static or dynamic instabilities, respectively. Both instabilities are related, and a review of static stability precedes the dynamic case. The focus of the dynamic case here is the hydrodynamic sta- bility of capillary surfaces subject to constraints of (a) volume conservation, (b) contact-line boundary conditions, and (c) the geometry of the supporting surface. 539 FL47CH22-Steen ARI 1 December 2014 20:31 1. OVERVIEW Capillary surfaces are at once a modern and classical topic. -

Kinetics of Molten Metal Capillary Flow in Non- Reactive and Reactive Systems

University of Kentucky UKnowledge Theses and Dissertations--Mechanical Engineering Mechanical Engineering 2016 KINETICS OF MOLTEN METAL CAPILLARY FLOW IN NON- REACTIVE AND REACTIVE SYSTEMS Hai Fu University of Kentucky, [email protected] Digital Object Identifier: http://dx.doi.org/10.13023/ETD.2016.163 Right click to open a feedback form in a new tab to let us know how this document benefits ou.y Recommended Citation Fu, Hai, "KINETICS OF MOLTEN METAL CAPILLARY FLOW IN NON-REACTIVE AND REACTIVE SYSTEMS" (2016). Theses and Dissertations--Mechanical Engineering. 79. https://uknowledge.uky.edu/me_etds/79 This Doctoral Dissertation is brought to you for free and open access by the Mechanical Engineering at UKnowledge. It has been accepted for inclusion in Theses and Dissertations--Mechanical Engineering by an authorized administrator of UKnowledge. For more information, please contact [email protected]. STUDENT AGREEMENT: I represent that my thesis or dissertation and abstract are my original work. Proper attribution has been given to all outside sources. I understand that I am solely responsible for obtaining any needed copyright permissions. I have obtained needed written permission statement(s) from the owner(s) of each third-party copyrighted matter to be included in my work, allowing electronic distribution (if such use is not permitted by the fair use doctrine) which will be submitted to UKnowledge as Additional File. I hereby grant to The University of Kentucky and its agents the irrevocable, non-exclusive, and royalty-free license to archive and make accessible my work in whole or in part in all forms of media, now or hereafter known. -

DYNAMIC and STATIC EFFECTS in WETTING of CAPILLARIES and FIBERS Taras Andrukh Clemson University, [email protected]

Clemson University TigerPrints All Dissertations Dissertations 12-2012 DYNAMIC AND STATIC EFFECTS IN WETTING OF CAPILLARIES AND FIBERS Taras Andrukh Clemson University, [email protected] Follow this and additional works at: https://tigerprints.clemson.edu/all_dissertations Part of the Materials Science and Engineering Commons Recommended Citation Andrukh, Taras, "DYNAMIC AND STATIC EFFECTS IN WETTING OF CAPILLARIES AND FIBERS" (2012). All Dissertations. 1013. https://tigerprints.clemson.edu/all_dissertations/1013 This Dissertation is brought to you for free and open access by the Dissertations at TigerPrints. It has been accepted for inclusion in All Dissertations by an authorized administrator of TigerPrints. For more information, please contact [email protected]. DYNAMIC AND STATIC EFFECTS IN WETTING OF CAPILLARIES AND FIBERS _______________________________________________________ A Dissertation Presented to the Graduate School of Clemson University _______________________________________________________ In Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy Material Science and Engineering _______________________________________________________ by Taras Andrukh December 2012 _______________________________________________________ Accepted by: Dr. Konstantin G. Kornev, Committee Chair Dr. M. Ellison Dr. I. Luzinov Dr. R. Groff . ABSTRACT This research is centered on the analysis of wetting and wicking phenomena. In six chapters we discuss static and dynamic effects of wetting of single capillary and fibers. In the first chapter, we review the prior work and formulate the research goals. In the second chapter, we develop a mathematical model of liquid uptake by capillaries and analyze the factors affecting liquid uptake. We derived a fundamental equation describing the dynamics of the fluid uptake by short capillaries where the effects of apparent mass, gravity and air resistance can be neglected.