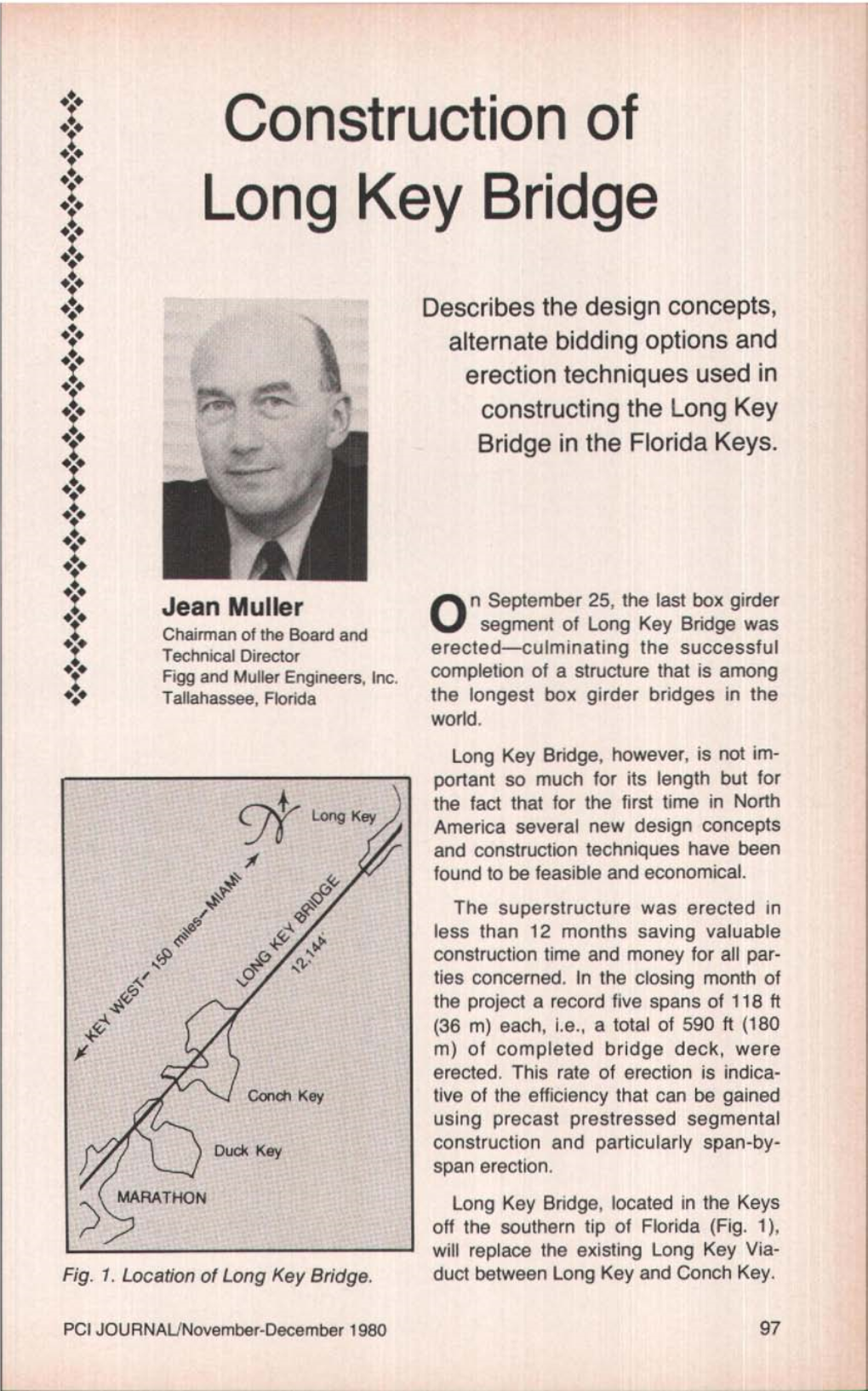

Construction of Long Key Bridge

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Repurposing the East Coast Railway: Florida Keys Extension a Design Study in Sustainable Practices a Terminal Thesis Project by Jacqueline Bayliss

REPURPOSING THE EAST COAST RAILWAY: FLORIDA KEYS EXTENSION A DESIGN STUDY IN SUSTAINABLE PRACTICES A terminal thesis project by Jacqueline Bayliss College of Design Construction and Planning University of Florida Spring 2016 University of Florida Spring 2016 Terminal Thesis Project College of Design Construction & Planning Department of Landscape Architecture A special thanks to Marie Portela Joan Portela Michael Volk Robert Holmes Jen Day Shaw Kay Williams REPURPOSING THE EAST COAST RAILWAY: FLORIDA KEYS EXTENSION A DESIGN STUDY IN SUSTAINABLE PRACTICES A terminal thesis project by Jacqueline Bayliss College of Design Construction and Planning University of Florida Spring 2016 Table of Contents Project Abstract ................................. 6 Introduction ........................................ 7 Problem Statement ............................. 9 History of the East Coast Railway ...... 10 Research Methods .............................. 12 Site Selection ............................... 14 Site Inventory ............................... 16 Site Analysis.................................. 19 Case Study Projects ..................... 26 Limitations ................................... 28 Design Goals and Objectives .................... 29 Design Proposal ............................ 30 Design Conclusions ...................... 40 Appendices ......................................... 43 Works Cited ........................................ 48 Figure 1. The decommissioned East Coast Railroad, shown on the left, runs alongside the Overseas -

Florida Keys Vessel Pumpout Facilities Marine Sanitation Device

Marine Sanitation Device Discharge Regulations Effective: December 27, 2010 Activities prohibited Sanctuary-Wide: q Discharge of sewage incidental to vessel use and generated by a marine sanitation device in accordance with the Federal Water Pollution Control Act (also called the Clean Water Act). q Having a marine sanitation device that is not secured in a manner that prevents discharges or deposits of treated and untreated sewage. Acceptable methods include, but are not limited to, all methods that have been approved by the U.S. Coast Guard. Pumpout facilities are located throughout the Keys to assist boat operators in complying with this rule. For a list of pumpout facilities, visit http://www.dep.state.fl.us/cleanmarina/about.htm. Florida Keys Vessel Pumpout Facilities * Designated Clean Marina Facility Key West Duck Key Mobile Pumpout Services • A & B Marina • Hawk’s Cay Resort Marina Free pumpout services for vessels • Conch Harbor Marina* anchored within unincorporated Long Key • City Marina at Garrison Bight* Monroe County (Key Largo, • Key West Bight Marina* • Fiesta Key KOA Tavernier, Cudjoe, Big Pine, Stock Stock Island Upper Matecumbe Key Island, etc.) and the Village of • Stock Island Marina Village • Bayside Marina- World Wide Sportsman* Islamorada. • Sunset Marina • Coral Bay Marina • Pumpout USA at 305-900-0263 or visit www.po-keys.com. Lower Keys Plantation Key • Plantation Yacht Harbor* • Bahia Honda State Park* • City of Key West 305-292-8167 • Sunshine Key RV Resort & Marina • Treasure Harbor Marine* • Stock Island, Mark LPS 305-587-2787 Marathon Tavernier • City of Marathon 305-289-8877 • Boot Key Harbor City Marina • Mangrove Marina • Key Colony Beach 305-289-1310 • Burdines Waterfront • Marathon Yacht Club Key Largo • Panchos Fuel Dock & Marina • All Keys Portalet Tips: • Sombrero Marina Dockside* • John Pennekamp Coral Reef State Park* • Check with marina ahead of time on • Manatee Bay Marina status of pumpout equipment. -

FWC Division of Law Enforcement South Region

FWC Division of Law Enforcement South Region – Bravo South Region B Comprised of: • Major Alfredo Escanio • Captain Patrick Langley (Key West to Marathon) – Lieutenants Roy Payne, George Cabanas, Ryan Smith, Josh Peters (Sanctuary), Kim Dipre • Captain David Dipre (Marathon to Dade County) – Lieutenants Elizabeth Riesz, David McDaniel, David Robison, Al Maza • Pilot – Officer Daniel Willman • Investigators – Carlo Morato, John Brown, Jeremy Munkelt, Bryan Fugate, Racquel Daniels • 33 Officers • Erik Steinmetz • Seth Wingard • Wade Hefner • Oliver Adams • William Burns • John Conlin • Janette Costoya • Andy Cox • Bret Swenson • Robb Mitchell • Rewa DeBrule • James Johnson • Robert Dube • Kyle Mason • Michael Mattson • Michael Bulger • Danielle Bogue • Steve Golden • Christopher Mattson • Steve Dion • Michael McKay • Jose Lopez • Scott Larosa • Jason Richards • Ed Maldonado • Adam Garrison • Jason Rafter • Marty Messier • Sebastian Dri • Raul Pena-Lopez • Douglas Krieger • Glen Way • Clayton Wagner NOAA Offshore Vessel Peter Gladding 2 NOAA near shore Patrol Vessels FWC Sanctuary Officers State Law Enforcement Authority: F. S. 379.1025 – Powers of the Commission F. S. 379.336 – Citizens with violations outside of state boundaries F. S. 372.3311 – Police Power of the Commission F. S. 910.006 – State Special Maritime Jurisdiction Federal Law Enforcement Authority: U.S. Department of Commerce - National Marine Fisheries Service U.S. Department of the Interior - U.S. Fish & Wildlife Service U.S. Department of the Treasury - U.S. Customs Service -

Sea Level Rise Impacts in the Florida Keys

Past and future impacts of sea level rise on terrestrial ecosystems of the Florida Keys Sugarloaf Key, Spring 2006 Mike Ross Florida International University Department of Earth & Environment/Southeast Environmental Research Center Tidal wetlands Fresh water- dependent ecosystems (restricted to the lower Keys, due to its peculiar geology) Tropical hardwood hammocks White-crowned pigeon returning to its Florida Bay nest after feeding in an Upper Keys hammock Elevation: Low --------------------------------------------------------------------------High GW Salinity: l-------Saline-----l-----Brackish--------l----Fresh----l----Brackish----l Species/Site: l—5---5-----5-----13-----15------14---16---29----35---29---24---23---23-l Keys habitat mosaic Within-island habitat mosaic is relatively simple, determined by elevation and salinity. Lower Keys islands have fresher ground water, lower elevations, and a drier climate. Keys ecosystems differ spatially in vulnerability to sea level rise; risk depends greatly on rate of SLR high e.g., Upper Keys hammocks vulnerable e.g., protected shorelines vulnerable e.g., Lower Keys hammocks vulnerable Pine forests & freshwater wetlands Hardwood low hammocks e.g., exposed shorelines vulnerable Mangroves & coastal wetlands 1 ft per 1-2 m per Probability of ecosystem (%) ecosystem loss of Probability century century Rate of sea level rise Pine Forests – doubly vulnerable due to dependence on both fire and fresh groundwater Evidence of environmental change on Sugarloaf Key– pine snags in Ross et al. buttonwood woodland 1994 Recession of Sugarloaf pine forest (toward the interior of the island, toward higher elevations) Projected habitat change with sea level rise on Sugarloaf Key Ross et al. 2009 Hurricane Wilma, October 24th, 2005 Storm Surge in the lower Keys Wilma-related mortality: Sugarloaf Key, 70-100%; Big Pine Key Big Pine Key, 10-90%; Sugarloaf Key - North Sugarloaf Key - South concentrated at elevations < 1m Ross et al. -

Coast Guard, DHS § 100.701

Coast Guard, DHS § 100.701 TABLE TO § 100.501—ALL COORDINATES LISTED IN THE TABLE TO § 100.501 REFERENCE DATUM NAD 1983—Continued No. Date Event Sponsor Location 68 .. June 25 and 26, Thunder on the Kent Narrows All waters of Prospect Bay enclosed by the following points: 2011. Narrows. Racing Asso- Latitude 38°57′52.0″ N., longitude 076°14′48.0″ W., to lati- ciation. tude 38°58′02.0″ N., longitude 076°15′05.0″ W., to latitude 38°57′38.0″ N., longitude 076°15′29.0″ W., to latitude 38°57′28.0″ N., longitude 076°15′23.0″ W., to latitude 38°57′52.0″ N., longitude 076°14′48.0″ W. [USCG–2007–0147, 73 FR 26009, May 8, 2008, as forbid and control the movement of all amended by USCG–2009–0430, 74 FR 30223, vessels in the regulated area(s). When June 25, 2009; 75 FR 750, Jan. 6, 2010; USCG– hailed or signaled by an official patrol 2011–0368, 76 FR 26605, May 9, 2011] vessel, a vessel in these areas shall im- EFFECTIVE DATE NOTE: By USCG–2010–1094, mediately comply with the directions at 76 FR 13886, Mar. 15, 2011, the Table to given. Failure to do so may result in § 100.501 was amended by suspending lines No. expulsion from the area, citation for 13, No. 19, No. 21 and No. 23, and adding a new failure to comply, or both. heading and entries 65, 66, 67, and 68, effec- tive Apr. 1, 2011 through Sept. 1, 2011. -

Key West Attractions Association Committed to Excellence We Are Truly One the World’S Most Popular Vacation Destinations

Welcome to KEY WEST Key West Attractions Association Committed to Excellence We are truly one the world’s most popular vacation destinations. Key West vacations offer a unique The Key West Attractions Association makes Key West combination of fun and sun, land and sea, as well as vacations great. In a commitment to excellence in family excitement day and night. entertainment, the members of the Key West Attractions Come and take a stroll through historic Old Town and must meet and maintain quality standards of cleanliness, see hundreds of examples of 19th century architecture. safety, truth in advertising, hospitality and proper complaint Sail just seven miles offshore and experience North resolution. What’s your attraction to Key West? The island America’s only living coral reef. Tour the homes of lifestyle, laid-back and relaxed? Ocean views, swaying Hemingway and Harry Truman. Enjoy deep-sea and flats palms, the flavors of the sea? The excitement of watersports sports fishing, boating, diving, snorkeling and jet skiing. by day and wild life by night? The step back in time to a Join the sunset party on a pier or the water. Visit some of swashbuckling era of pirates and treasure-laden shipwrecks? the most unique museums in the U.S. And, experience Or is it the local color? The oranges and purples of our famous our heritage in art galleries, shops, hotels and restaurants sunsets, the green of banana leaves, palm designed to suit every style and taste. fronds and sea turtles, the blue According to legend, once Key West sand gets in and turquoise of the water your shoes, you’ll return again and again. -

Florida Keys Destination Guide

s y e .k a l f . The Florida Keys & Key West: 0 80 . come as you are 1 m o .c s y ke - la f fla-keys.com 1.800.fla.keys THE FLORIDA KEYS Most people know the Florida Keys and Key West as a great getaway. One of the most unique places on earth. Calm. Serene. Laid back. Just the right setting to recharge your batteries and rejuvenate your spirits. But a getaway to the Florida Keys and Key West is much more than peace and quiet. And not just because of the legendary fishing and the world’s most spectacular dive sites. The Keys mean history. Art. Theater. Museums. Shopping. Fine dining. Entertainment. And much more. All told, 120 miles of perfect balance between natural beauty and extra-ordinary excitement. Between relaxation and activities. Between the quaint and the classic. And you’ll find our accommodations just as diverse as our pleasures. From some of the best camping spots in the country to luxurious hotels. From charming bed-and-breakfasts to rustic, family-owned lodgings. In other words, we’ve got something for everyone. In the next few pages you’ll get to know what your Florida Keys vacation can and will be like. What you’d expect. And what will surprise you. Our fame and our secrets. We figured we owed it to you. After all, we wouldn’t want you to get here and wish you had booked just a few more days. For the latest on health & safety protocols in The Florida Keys, please visit our website. -

Keys Sanctuary 25 Years of Marine Preservation National Parks Turn 100 Offbeat Keys Names Florida Keys Sunsets

Keys TravelerThe Magazine Keys Sanctuary 25 Years of Marine Preservation National Parks Turn 100 Offbeat Keys Names Florida Keys Sunsets fla-keys.com Decompresssing at Bahia Honda State Park near Big Pine Key in the Lower Florida Keys. ANDY NEWMAN MARIA NEWMAN Keys Traveler 12 The Magazine Editor Andy Newman Managing Editor 8 4 Carol Shaughnessy ROB O’NEAL ROB Copy Editor Buck Banks Writers Julie Botteri We do! Briana Ciraulo Chloe Lykes TIM GROLLIMUND “Keys Traveler” is published by the Monroe County Tourist Development Contents Council, the official visitor marketing agency for the Florida Keys & Key West. 4 Sanctuary Protects Keys Marine Resources Director 8 Outdoor Art Enriches the Florida Keys Harold Wheeler 9 Epic Keys: Kiteboarding and Wakeboarding Director of Sales Stacey Mitchell 10 That Florida Keys Sunset! Florida Keys & Key West 12 Keys National Parks Join Centennial Celebration Visitor Information www.fla-keys.com 14 Florida Bay is a Must-Do Angling Experience www.fla-keys.co.uk 16 Race Over Water During Key Largo Bridge Run www.fla-keys.de www.fla-keys.it 17 What’s in a Name? In Marathon, Plenty! www.fla-keys.ie 18 Visit Indian and Lignumvitae Keys Splash or Relax at Keys Beaches www.fla-keys.fr New Arts District Enlivens Key West ach of the Florida Keys’ regions, from Key Largo Bahia Honda State Park, located in the Lower Keys www.fla-keys.nl www.fla-keys.be Stroll Back in Time at Crane Point to Key West, features sandy beaches for relaxing, between MMs 36 and 37. The beaches of Bahia Honda Toll-Free in the U.S. -

The Florida Keys 10 Days

THE FLORIDA KEYS 10 DAYS Home to presidents and poets who sought inspiration from the beautiful, fragile eco-system that surrounded them, the Florida Keys are truly unique. The drive, with the Gulf of Mexico on one side and the Atlantic Ocean on the other, is certainly breathtaking and will take you across 43 bridges from Key Largo to Key West. The famous ‘Seven Mile Bridge’ at Mile Marker 47 is more than 35,000 feet in length. DAY 1 –2 DAY 3 –4 DAY 7 –8 Miami Miami – Key West Duck Key – Islamorada Fly into Miami and enjoy 2 nights in South (155 miles) (30 miles) Beach before starting your journey down to Depart Miami and start your journey Islamorada has a reputation for the best the Florida Keys. south along the Florida Keys Overseas sport fishing in Florida. Explore wrecks and Offering a lively and funky atmosphere Scenic Highway US-1, across the Seven Mile coral gardens, or enjoy the nature trails in combined with a latin vibe, Miami attracts Bridge and travelling the length of the Keys Long Key State Park. to Key West, right at the very end on Mile visitors from all over the world. Famous Stay Marker 0. From here you will start your drive South Beach has some stunning sandy 4# Cheeca Lodge and Spa beaches, trendy designer shops and back up the Florida Keys towards Miami . glamorous boutique hotels. In the evening, Spend two nights in Key West where you ensure you experience the great nightlife will find relaxing beaches, a great choice of DAY 9 – 10 South Beach has to offer. -

BAHIA HONDA STATE PARK Bahia Honda Key Is Home to One of Florida’S 36850 Overseas Highway Southernmost State Parks

HISTORY BAHIA HONDA STATE PARK Bahia Honda Key is home to one of Florida’s 36850 Overseas Highway southernmost state parks. The channel Big Pine Key, FL 33043 between the old and new Bahia Honda bridges 305-872-2353 is one of the deepest natural channels in the Florida Keys. The subtropical climate has created a natural environment found nowhere else in the continental U.S. Many plants and PARK GUIDELINES animals in the park are rare and unusual, Please remember these tips and guidelines, and including marine plant and animal species of enjoy your visit: Caribbean origin. • Hours are 8 a.m. until sunset, 365 days a year. BAHIA HONDA The park has one of the largest remaining • An entrance fee is required. stands of the threatened silver palms. • The collection, destruction or disturbance of STATE PARK Specimens of the silver palm and the yellow plants, animals or park property is prohibited. satinwood, found in the park, have been • Pets are permitted in designated areas only. certified as national champion trees. The rare, Pets must be kept on a leash no longer than small-flowered lily thorn may also be found in six feet and well-behaved at all times. the park. • Fishing, boating, swimming and fires are The geological formation of Bahia Honda is Key allowed in designated areas only. A Florida Largo limestone. It is derived from a pre-historic fishing license may be required. Use diver- coral reef similar to the present-day living reefs down flags. off the Keys. Because of a drop-in sea level • Fireworks and hunting are prohibited. -

Sceniccorridorbroch-Outside (From Pdf)

Our Story The Florida Keys Scenic Highway (FKSH) corridor runs from Mile Marker 110, north of the spectacular Jewfish Creek Bridge, to Mile Marker 0 in Old Town Key West. The scenic highway corridor also extends five miles on each side of the highway. So, the FKSH truly encompasses all of the Florida Keys, its natural wonders, and its communities. Through efforts beginning in 1996 with numerous public meetings and workshops to create the Corridor Management Plan, the FDOT designated the FKSH a Florida Scenic Highway in 2001. In 2007, the Florida Keys Mission Statement Scenic Corridor Alliance (FKSCA) was To enhance the scenic image, preserve our established as the corridor management entity heritage and diversity, and promote the natural responsible for implementing the goals and beauty of the Florida Keys Scenic Corridor. objectives concerning the FKSH. The FKSCA completed its Corridor Management Plan Five- Year Update in fall of 2008 and applied for designation in the National Scenic Byways Program. The FKSCA proved our highway corridor meets the designation criteria of being considered a “destination unto itself” and “providing an exceptional travel experience.” Our scenic and recreational intrinsic qualities “are those which best represent the nation, are nationally recognized, and contain one-of-a- kind features that do not exist elsewhere.” The Florida Keys Scenic Highway is a natural fit. In October 2009, the Federal Highway Administration designated the Florida Keys Scenic Highway as an All-American Road – Florida Keys Scenic Corridor Alliance the highest status in the National Scenic P.O. Box 501930 Byways System. Marathon, FL 33050-1930 www.ScenicHighwayFlKeys.com GEOGRAPHIC AREAS OF INTEREST City of Key West Key West City Limits to 7 Mile Bridge ANNUAL MEMBERSHIP What We Do 7 Mile Bridge to Long Key Bridge The Florida Keys Scenic Corridor Alliance (FKSCA) Individual $25 is the Corridor Management Entity for the Florida Long Key Bridge to Tavernier Creek Keys Scenic Highway (FKSH). -

Fkeys-CMP.Pdf

Florida KEYS Scenic Highway corridor management plan Submitted to Florida Department of Transportation, District Six Scenic Highways Coordinator 602 South Miami Avenue Miami, FL 33130 Submitted by The Florida Keys Scenic Highway CAG June Helbling and Kathy Toribio, Co-Chairs c/o Clean Florida Keys, Inc. PO Box 1528 Key West, FL 33041-1528 Prepared by The Florida Keys Scenic Highway CAG Peggy Fowler, Planning Consultant Patricia Fontova, Graphic Designer Carter and Burgess, Inc., Planning Consultants May, 2001 This document was prepared in part with funding from the Florida Department of Transportation. This document is formatted for 2-sided printing. Some pages were left intentionally blank for that reason. Table of Contents Chapter 1: INTRODUCTION .....................................................1 Chapter 2: CORRIDOR VISION ..................................................5 Chapter 3: CORRIDOR STORY ..................................................7 Chapter 4: DESIGNATION CRITERIA .......................................13 Chapter 5: BACKGROUND CONDITONS ANALYSIS ...............27 Chapter 6: RELATIONSHIP TO COMPREHENSIVE PLAN .......59 Chapter 7: PROTECTION TECHNIQUES................................ .63 Chapter 8: COMMUNITY PARTICIPATION ..............................69 Chapter 9: PARTNERSHIPS AND AGREEMENTS.................... .79 Chapter 10: FUNDING AND PROMOTION ...............................85 Chapter 11: GOALS, OBJECTIVES AND STRATEGIES ................93 Chapter 12: ACTION PLAN .........................................................97