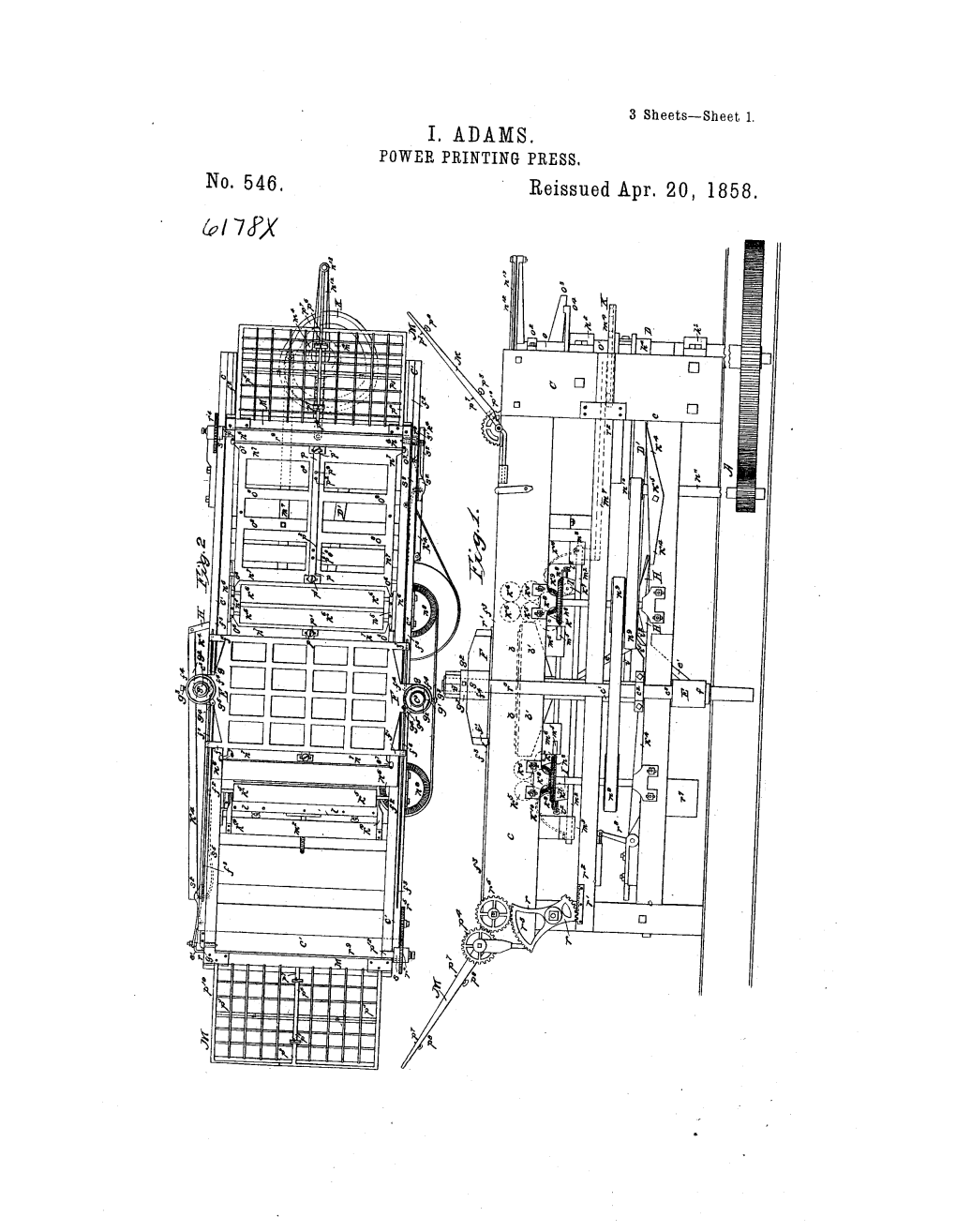

I, Adams. Power Printing Press

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Typesetting Old German: Fraktur, Schwabacher, Gotisch and Initials Yannis Haralambous

Typesetting Old German: Fraktur, Schwabacher, Gotisch and Initials Yannis Haralambous To cite this version: Yannis Haralambous. Typesetting Old German: Fraktur, Schwabacher, Gotisch and Initials. Tugboat, TeX Users Group, 1991, Proceedings of TeX90, 12 (1), pp.129-138. hal-02099292 HAL Id: hal-02099292 https://hal.archives-ouvertes.fr/hal-02099292 Submitted on 23 Apr 2019 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. Typesetting Old German: Fraktur, Schwabacher, Gotisch and Initials Yannis Haralambous U. F. R. de MathCmatiques, UniversitC de Lille - Flandres - Artois, 59655 Villeneuve d'Ascq, France. Abstract Typesetting in the old style, with the corresponding types, besides being an art, is also a real pleasure. METAFONT allows the creation of faithful copies of these types and T&K gives the possibility of using them in the most traditional manner. In this spirit, the necessary fonts and macros to typeset in the Old German types: Gotisch (also called Textur), Schwabacher and F'raktur are presented in this paper, together with an historical introduction to each of them. Also, a set of initials is described. Rules for typesetting in these types are given, together with extracts from the original sources. -

Tv38bigelow.Pdf

Histoire de l’Ecriture´ Typographique — le XXi`eme si`ecle (The History of Typographic Writing—The 20th century). Jacques Andr´e, editorial direction. Atelier Perrousseaux, Gap, France, 2016. http://www.adverbum.fr/atelier-perrousseaux Review and summaries by Charles Bigelow (TUGboat vol.38, 2017). https://tug.org/books/#andre vol.1 TUGboat38:1,pp.18–22 vol.2, ch.1–5 TUGboat 38:2, pp.274–279 vol.2, ch.6–8+ TUGboat 38:3, pp.306–311 The original publication, as reviewed, was in two volumes: Tome I/II, de 1900 `a1950. ISBN 978-2-36765-005-0, tinyurl.com/ja-xxieme. 264 pp. Tome II/II, de 1950 `a2000. ISBN 978-2-36765-006-7, tinyurl.com/ja-xxieme-ii. 364 pp. These are the last two volumes in the series The History of Typographical Writing, comprised of seven volumes in all, from the beginning of printing with Gutenberg through the 20th century. All are in French. The individual volumes and the series as a whole are available in various electronic and print formats; please see the publisher’s web site for current offerings. ❧ ❧ ❧ 18 TUGboat, Volume 38 (2017), No. 1 Review and summaries: The History of phy had begun to supplant print itself, because text Typographic Writing — The 20th century display and reading increasingly shifted from paper Volume 1, from 1900 to 1950 to computer screen, a phenomenon now noticed by nearly all readers and publishers. Charles Bigelow In the 20th century, typography was also trans- Histoire de l’Ecriture´ Typographique — le XXi`eme formed by cultural innovations that were strikingly si`ecle; tome I/II, de 1900 `a1950. -

Historical Technological Impacts on the Visual Representation of Language with Reference to South Asian Typeforms

Historical technological impacts on the visual representation of language with reference to South Asian typeforms Article Accepted Version Ross, F. (2018) Historical technological impacts on the visual representation of language with reference to South Asian typeforms. Philological Encounters, 3 (4). ISSN 2451-9189 doi: https://doi.org/10.1163/24519197-12340054 Available at http://centaur.reading.ac.uk/66725/ It is advisable to refer to the publisher’s version if you intend to cite from the work. See Guidance on citing . To link to this article DOI: http://dx.doi.org/10.1163/24519197-12340054 Publisher: Brill All outputs in CentAUR are protected by Intellectual Property Rights law, including copyright law. Copyright and IPR is retained by the creators or other copyright holders. Terms and conditions for use of this material are defined in the End User Agreement . www.reading.ac.uk/centaur CentAUR Central Archive at the University of Reading Reading’s research outputs online Fiona Ross Historical technological impacts on the visual representation of language with reference to South-Asian typeforms. The scripts of South Asia, which mainly derive from the Brahmi script, afford a visible voice to the numerous linguistic communities that form over one fifth of the world’s population. However, the transition of these visually diverse scripts from chirographic to typographic form has been determined by historical processes that were rarely conducive to accurately rendering non-Latin scripts. This essay provides a critical evaluation of the historical technological impacts on typographic textual composition in South-Asian languages. It draws on resources from relevant archival collections to consider within a historical context the technological constraints that have been crucial in determining the textural appearance of South-Asian typography. -

Printing History News 31

Printingprinting History history news 31 News 1 The Newsletter of the National Printing Heritage Trust, Printing Historical Society and Friends of St Bride Library Number 31 Summer 2011 PHS Journal Editor and ST BRIDE EVENTS OTHER EVENTS Web-Editor Book History Research John Trevitt will retire as Editor of the Printing Historical Society Journal at Network the next AGM. Catherine Armstrong, who has been reviews editor of the The Book History Research Network Journal since 2007, will also retire will hold twice yearly events. There is shortly. John has edited the journal for information about these and a register four years, and Catherine the reviews of interests on their new website at: for five, and the Society is very grateful Print workshops www.bookhistory.org.uk. Please visit for their excellent work during this the website to register and to sign up St Bride Foundation is bringing letter- for the next free event. period. The PHS is delighted to wel- press printing back to Fleet Street. The come Dr Victoria Gardner as the new exhibition room has been transformed reviews editor to replace Catherine. into a printing workshop, where prac- PRINT NETWORKS However, we are still seeking an Editor tical teaching and hands-on experience for the Journal, and would be most can take place. A series of courses and CONFERENCES grateful for any suggestions or, better workshops is now on offer. Through- still, volunteers. If you would like to out 2011 the range of classes will be Religion and the book trade discuss the role with the current Editor, developed and expanded to include do please contact John Trevitt on kindred trades and techniques, in This, the twenty-ninth Print Networks [email protected]. -

The Bookseller 1861 a AB (16 High Street, Tunstall, Staffordshire)

The Bookseller 1861 A A.B. (16 High Street, Tunstall, Staffordshire), books wanted 150 A'Beckett, T.T., article on Punch and his progenitors 397 Abel & Sons (Northampton), books wanted 87, 384 Aberdeen, Adam, John, books wanted 384, 466 Aberdeen, Duffus, John, books wanted 151, 263, 327, 514 Aberdeen, King, G. & R., publications advertised 576 Aberdeen, Milne, A. & R., books wanted 566, 653, 936 Aberdeen, Smith, John, new and forthcoming publications 476 Aberdeen, Walker, J. (34 Upper Kirkgate Street), books wanted 567 Aberdeen, Wilson, R. & Son (Schoolhill), books wanted 467, 654 Aberdeen, Wyllie, D. & Son, books announced 163 Aberdeen, Wyllie, D. & Son, books wanted 88, 467, 515 Aberdeen, Wyllie, D. & Son, James Wyllie gives share of business to assistant 664 Abergavenny, Hancocks, George, bookseller, stationer and printer, assignment 392 Abergavenny, Hancocks, George, bookseller, stationer and printer, business sold to Mr. Meredith 472 Abergavenny, Meredith, J.S. (formerly of Burford, Oxfordshire), commences business at Abergavenny 521 Accrington, Bowker, E., bookseller, etc., business for sale advertised 864 Accrington, Maysh, Nathan, stationer, insolvency 520 Acts of Parliament, collections, William Salt seeks information on collections to help him improve list he is compiling 136 Acts of Parliament, collections, Salt asks person who bought Acts at sale to communicate with him 535 Acts of Parliament, see also Bankruptcy Act 1861 Adam, John (Aberdeen), books wanted 384, 466 Adams, Frederick, stationer, etc. (Peterborough), bankruptcy -

1 Thomas Hvid Kromann “Montages Wrapped in Flong: a Material–Archaeological Investigation of Asger Jorn and Guy Debord'

Thomas Hvid Kromann “Montages wrapped in flong: a material–archaeological investigation of Asger Jorn and Guy Debord’s Fin de Copenhague” (2015) Extended English summary "Montager svøbt i matricepap. En materialearkæologisk undersøgelse af Asger Jorn og Guy Debords Fin de Copenhague" was published in the Danish peer-reviewed journal Fund & Forskning, no. 54, 2015, pp. 587–625. Published by The Royal Library in Copenhagen. Thomas Hvid Kromann (b. 1974), PhD Researcher at the Center for Manuscripts and Rare Books, The Royal Library, Copenhagen, Denmark. [email protected] and [email protected] Aim of the article The making of Fin de Copenhague took place a couple of months before the foundation of the Situationist International movement (1957–72) and is closely linked to it. In an increasingly politicized situationist movement, Fin de Copenhague and its sequel, Mémoires, were instrumentalized as“documents” – not as art works in a book format, but rather as anti- art works. As was stated in the first issue of the bulletin Internationale Situationniste, no situationist art form could exist, only a situationist use of artistic methods. This self- perception, primarily influenced by Debord, has subsequently influenced the way the two books have been critically received. In the decades that followed their creation, relatively little attention was paid to them in the increasing amount of research into the art of Jorn, the political-avantgardist activism of Debord and the situationist movement. The “concept” behind the books was reduced to the theoretical framework of the situationist movement (corresponding to key situationist strategies such as “détournement”), while the material dimension of the concrete artefacts themselves was neglected. -

The Widening World of Books & Readers

Treasures of the Library THE WIDENING WORLD OF BOOKS &READERS Examining how printing revolutionized society by the rapid dissemination of ideas thereby opening the way for wider public participation in political, social, and economic life. Grade 7 World History and Geography: Medieval and Early Modern Times The Huntington Library, Art Collections, and Botanical Gardens This project is generously made possible through a grant from The Los Angeles Times/Times Mirror Foundation. I. Introduction rinting began a technological revolution that facilitated the communication of Pideas and the preservation of knowledge. It would be hard to imagine society, as we know it today, without unlimited access to ideas. Without the communication and preservation of ideas made possible by the invention of printing and the technological advances that have improved the process over the past five centuries, public knowledge would largely depend on what institutions dictated scribes to record. II. Objectives ♦ To explain the impact of printing on the communication of ideas. ♦ To give examples of religious themes in literature and explain how the literature of Medieval Europe reflected religious teachings. ♦ To explain how printing broadened readership and promoted literacy. ♦ To explain how the spread of ideas advanced Renaissance humanism, the Reformation, and the Scientific Revolution. The Huntington Library, Art Collections, and Botanical Gardens 1 Treasures of the Library The Widening World of Books and Readers III. History-Social Science Standards Addressed 7.6 Students analyze the geographic, political, economic, religious, and social structures of the civilizations of Medieval Europe. 8 Understand the importance of the Catholic Church as a political, intellectual, and aesthetic institution. -

Principles of Typesetting

h e H T a p p y T PREPARE y p e s e t t 1. Determine the longest line to be set. Keep in mind that if lines are staggered left e r or right, your line must run the entire length from most left to most right. 2. To determine the length of leading to use: add at least 48pts to the line length (to give room for large spacing on the ends of each line) and round up to the nearest convenient furniture length. 3. Set up your work area. Pull your type tray out carefully and set it on one of the work counters. Set a good amount of the leading length and thickness that you’ve chosen next to the type tray. Check your leading to make sure it is all the same length (no oddballs). 4. Clear out the spacing compartments in your tray. The spacing in these trays are often a bit jumbled. Sort them out before you begin. 5. Retrieve some word-spacers, ems, and quads from the appropriate spacing drawer, and sort them into the appropriate compartments in your type tray. If necessary, you may want to pull out the spacing drawer and set it along-side your type tray. 6. Hold the composing stick so that your wrist is as straight and relaxed as possible. Have your thumb or forefinger poised to hold type as you set it in the stick. BEGIN SETTING 1. Lay in a piece of leading. If the leading is too long to fit easily, check the leading length and check the placement of the “stop” on the composing stick. -

Catalog 296.Indd

Books About Books 1. (Alwil Press) Stevens, Thomas Wood and Alden Charles Nobel. HOLD RED- MERE, A TALE. Ridgewood, NJ: Alwil Press, 1901, 12mo., later cloth-backed boards, paper cover label. Not paginated. $ 150.00 Limited to 450 numbered copies printed on hand-made paper and initialed by the designer, Frank B. Rae, Jr. A handsome press book in the Arts & Crafts style, with hand-colored title-page and decorative initials by Elgie F. Bowen. Some offset from hand-coloring. [105380] Item 1 2. Amory, Hugh (Editor). A HISTORY OF THE BOOK IN AMERICA VOLUME 1: THE COLONIAL BOOK IN THE ATLANTIC WORLD. Cambridge: Cambridge University Press, (2000), 8vo., cloth, dust jacket. xxiv, 638 pages. $ 100.00 First edition. The first volume is organized around three major themes: the persisting colonial relationship between European settlements and the Old World; the gradual emergence of a pluralistic book trade that differentiated printers from booksellers; and the transition from a “culture of the Word” to the culture of republicanism. A History of the Book in America a five-volume, interdisciplinary series, is a collaborative history of the book in American culture from the earliest days of European settlement to modern times sponsored by The American Antiquarian Society. With 53 black and white illustrations, 16 line diagrams, 2 tables, bibliography and index. [63135] [ 1 ] 3. Annenberg, Maurice. A TYPOGRAPHICAL JOURNEY THROUGH THE INLAND PRINTER, 1883–1900. Baltimore: Maran Press, (1977), 4to., cloth, dust jacket. xx, 731 pages. $ 130.00 First edition. An excellent anthology of the early issues of America’s greatest magazine devoted to printing. -

Typesetting Techniques

NBS MONOGRAPH 99 Automatic Typographic-Quality Typesetting Techniques: A State-of-the-Art Review U.S. DEPARTMENT OF COMMERCE NATIONAL BUREAU OF STANDARDS —— THE NATIONAL BUREAU OF STANDARDS The National Bureau of Standards ' provides measurement and technical information services essential to the efficiency and effectiveness of the work of the Nation's scientists and engineers. The Bureau serves also as a focal point in the Federal Government for assuring maximum application of the physical and engineering sciences to the advancement of technology in industry- and commerce. To accomplish this mission, the Bureau is organized into three institutes covering broad program areas of research and services: THE INSTITUTE FOR BASIC STANDARDS . provides the central basis within the United States for a complete and consistent system of physical measurements, coordinates that system with the measurement systems of other nations, and furnishes essential services leading to accurate and uniform physical measurements throughout the Nation's scientific community, industry, and commerce. This Institute comprises a series of divisions, each serving a classical subject matter area: —Applied Mathematics—^Electricity—Metrology—Mechanics—-Heat—Atomic Physics Physical Chemistry—Radiation Physics—Laboratory Astrophysics ^—Radio Standards Laboratory,^ which includes Radio Standards Physics and Radio Standards Engineering- Office of Standard Reference Data. THE INSTITUTE FOR MATERIALS RESEARCH . conducts materials research and provides associated materials services including mainly reference materials and data on the properties of materials. Beyond its direct interest to the Nation's scientists and engineers, this Institute yields services which are essential to the advancement of technology in industry and commerce. This Institute is organized primarily by technical fields: —Analytical Chemistry—Metallurgy'—-Reactor Radiations—^Polymers—Inorganic Mate- rials—Cryogenics ^—Materials Evaluation Laboratory—Office of Standard Reference Materials. -

An Economic Comparison of Hot Metal and Cold Type Composition of Display Advertising

AN ABSTRACT OF THE THESIS OF JULIE LATHAM VINCENTfor the M. S. (Name of student) (Degree) in Industrial Engineering presented on May 29, 1968 (Major) (Date) Title: AN ECONOMIC COMPARISON OF HOT METAL AND COLD TYPE COMPOSITION OF DISPLAY ADVERTISING Abstract approved: Redacted for privacy William Engesser / The objective of this thesis is to examine and compare hot metal and cold type production of display advertising for newspapers. The classical hot metal system uses a lead alloy as its basic build- ing material while modern cold type production uses photographic means. Some advantages of using cold type are the improved qual- ity of the final product, increased versatility in ad composition, possibilities for major labor savings, the lower skills required for the compositor and less production space required for the machinery. Some disadvantages of cold type production are the major investment required for new equipment, higher materials costs, difficulty in producing proofs, labor relations and retraining difficulties, and the durability of the press plates. The data for the hot metal method consisted of a sample of 195 ads.The eight major operations studied were Markup Time, Type Slips Time, Stereotype Time, Typesetting Time, Composing Time, Proof Pulling Time, and Correction Time. Thirty-seven fac- tors, such as the size of the ad and the number of lines of type, were hypothesized to effect the operation times.These operation times and factors were analyzed by multiple linear regression analysis to formulate a mathematical model of the hot metal system.For this cold type system, circumstances prevented making a complete model but data for a sample of 15 ads was collected. -

Imposing Tables and Lock-Up Appliances

This is a reproduction of a library book that was digitized by Google as part of an ongoing effort to preserve the information in books and make it universally accessible. http://books.google.com Set No. 1 The Stone Printing & Mfg. Co., Return to Mr. Edward L. Stone »e Office. FROM THE LIBRARY OF 2terd t. £tone, printer, of "Roanoke, Virginia. ABUNDANT IN PUBLIC SERVICE, RICH IN HIS FRIENDSHIPS, ASSID UOUS IN THE PRACTICE OF THE ART HE LOVED, HE DEVOTED HIS LEISURE TO ASSEMBLING ITS NOTABLE EXAMPLES. FULFILLING A PLAN INTERRUPTED BY HIS DEATH, THE ALUMNI BOARD OF TRUSTEES HAS ACQUIRED FOR THE LIBRARY OF THE ftntoersltg of Virginia THESE VOLUMES, WHICH EX HIBIT THE DEVELOPMENT OF THE PRINTING ART, AND MIRROR THE PERSONALITY OF HIM WHO BROUGHT THEM TOGETHER / / TYPOGRAPHIC TECHNICAL SERIES FOR APPRENTICES PART I, NO. 4 IMPOSING TABLES AND LOCK UP APPLIANCES DESCRIBING THE TOOLS AND MATERIALS USED IN LOCKING UP FORMS FOR THE PRESS, INCLUDING SOME MODERN UTILITIES FOR SPECIAL PURPOSES COMPILED BY A. A. STEWART PUBLISHED BY THE COMMITTEE ON EDUCATION UNITED TYPOTHETAE OF AMERICA 1918 A^T8 Copyright, 1918 Untted Typothetac of America Chicago, III. Composition and electrotypes contributed by Franklin Printing Company Philadelphia CONTENTS PAGE Introductory 3 Imposing Tables and Lock-Up Appliances ... 9 Imposing Table Frames 10 Special Make-up Tables 11 Chases 12 Sizes of Chases 13 Crossbar Chases 14 Accuracy or Chases 15, The Angle Chase 17 Screw Chases 18 Wood Furniture 19 Metal Furniture 20 Steel Furniture 22 Wooden and Mechanical Quoins 23 Mallet and Planer 28 Some Necessary Tools 29 Roller Bearers in the Chase 30 Register Points and Folding Marks ....