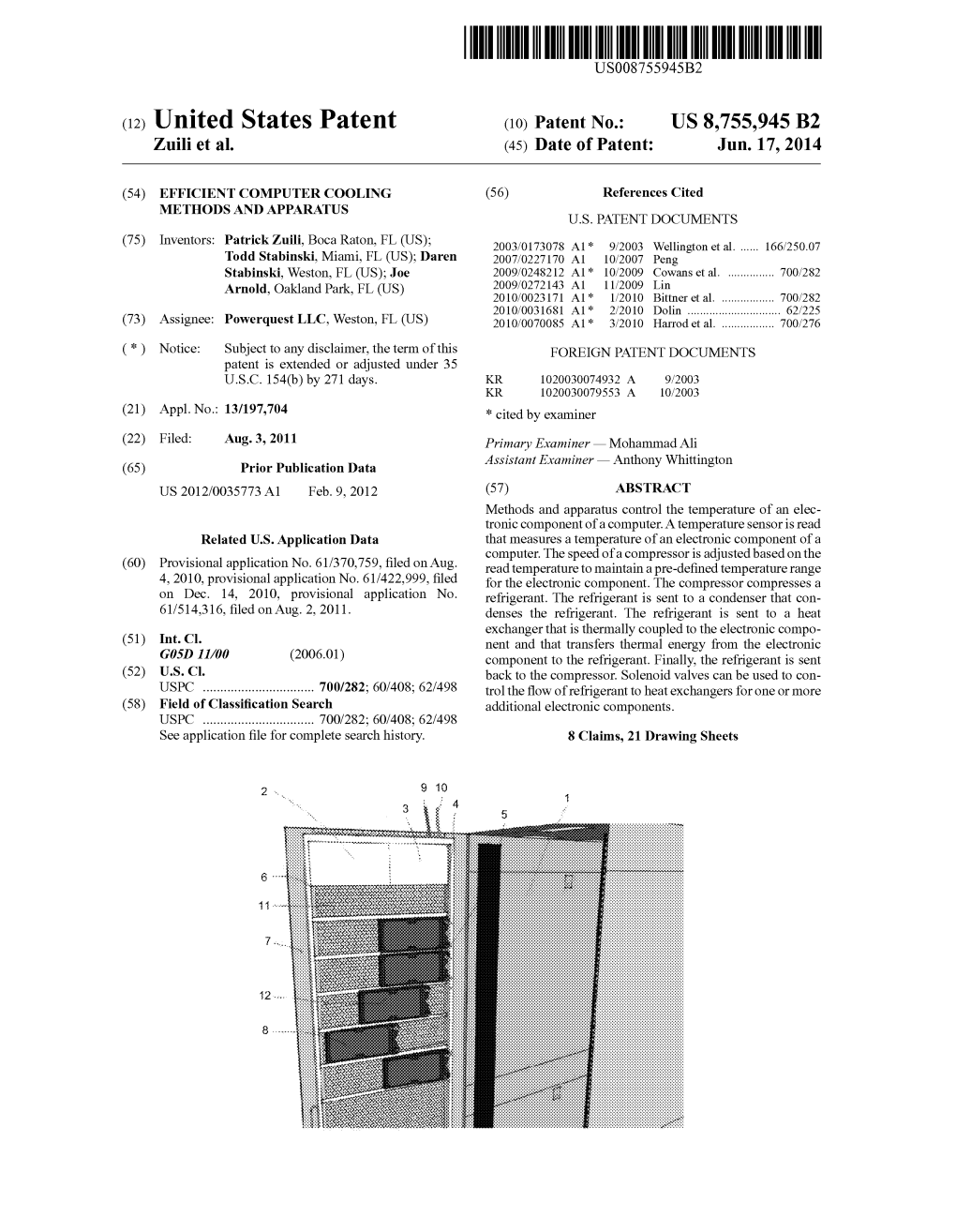

(12) United States Patent (10) Patent No.: US 8,755,945 B2 Zuili Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Icue QL140 RGB 140Mm PWM Single Fan SKU Sheets 1 CORSAIR Icue QL140 RGB 140Mm PWM Single Fan

CORSAIR iCUE QL140 RGB 140mm PWM Single Fan Embargo Date 14-Nov-19 First Customer Ship Date 8-Nov-19 Product Etail Title CORSAIR QL140 RGB 140mm Fan RGB Product Title CORSAIR iCUE QL140 RGB 140mm PWM Single Fan Product Name CORSAIR QL Series, QL140 RGB, 140mm RGB LED Fan, Single Pack Pre Order Option No Product Imagery Image Asset Overview 25 Word Product Description Give your PC spectacular lighting from any angle with a CORSAIR iCUE QL140 RGB PWM fan, equipped with 34 individually addressable RGB LEDs across four distinct light loops. Overview 50 Word Product Description Give your PC spectacular lighting from any angle with a CORSAIR iCUE QL140 RGB PWM fan, equipped with 34 individually addressable RGB LEDs across four distinct light loops. Pair with an existing QL140 RGB Dual Fan Kit or a CORSAIR iCUE RGB lighting controller (sold separately) to control and synchronize your RGB lighting through CORSAIR iCUE software. Keep your system cool with PWM speeds up to 1,250 RPM. OverviewOverview 100 Word Product Description Give your PC spectacular lighting from any angle with a CORSAIR iCUE QL140 RGB PWM fan, equipped with 34 individually addressable RGB LEDs across four distinct light loops. Pair with an existing QL140 RGB Dual Fan Kit or a CORSAIR iCUE RGB lighting controller (sold separately) to control and synchronize your RGB lighting through CORSAIR iCUE software. Keep your system cool with PWM speeds up to 1,250 RPM with a 140mm fan blade engineered to ensure both low noise operation and outstanding lighting. Complete with front and back-facing metal logos on the hub and anti-vibration rubber dampers to reduce vibration noise, QL140 RGB fans create spectacular lighting that doesn’t choose sides. -

Hardware Components and Internal PC Connections

Technological University Dublin ARROW@TU Dublin Instructional Guides School of Multidisciplinary Technologies 2015 Computer Hardware: Hardware Components and Internal PC Connections Jerome Casey Technological University Dublin, [email protected] Follow this and additional works at: https://arrow.tudublin.ie/schmuldissoft Part of the Engineering Education Commons Recommended Citation Casey, J. (2015). Computer Hardware: Hardware Components and Internal PC Connections. Guide for undergraduate students. Technological University Dublin This Other is brought to you for free and open access by the School of Multidisciplinary Technologies at ARROW@TU Dublin. It has been accepted for inclusion in Instructional Guides by an authorized administrator of ARROW@TU Dublin. For more information, please contact [email protected], [email protected]. This work is licensed under a Creative Commons Attribution-Noncommercial-Share Alike 4.0 License Higher Cert/Bachelor of Technology – DT036A Computer Systems Computer Hardware – Hardware Components & Internal PC Connections: You might see a specification for a PC 1 such as "containing an Intel i7 Hexa core processor - 3.46GHz, 3200MHz Bus, 384 KB L1 cache, 1.5MB L2 cache, 12 MB L3 cache, 32nm process technology; 4 gigabytes of RAM, ATX motherboard, Windows 7 Home Premium 64-bit operating system, an Intel® GMA HD graphics card, a 500 gigabytes SATA hard drive (5400rpm), and WiFi 802.11 bgn". This section aims to discuss a selection of hardware parts, outline common metrics and specifications -

HP 17 Laptop PC Maintenance and Service Guide

HP 17 Laptop PC Maintenance and Service Guide © Copyright 2018 HP Development Company, Product notice Software terms L.P. This user guide describes features that are By installing, copying, downloading, or AMD and AMD Radeon are trademarks of common to most models. Some features may otherwise using any software product Advanced Micro Devices, Inc. Bluetooth is a not be available on your computer. preinstalled on this computer, you agree to be trademark owned by its proprietor and used by bound by the terms of the HP End User License HP Inc. under license. Intel and Core are Not all features are available in all editions of Agreement (EULA). If you do not accept these trademarks of Intel Corporation in the U.S. and Windows. This computer may require upgraded license terms, your sole remedy is to return the other countries. Microsoft and Windows are and/or separately purchased hardware, drivers entire unused product (hardware and software) trademarks of the Microsoft group of and/or software to take full advantage of within 14 days for a full refund subject to the companies. Windows functionality. Go to refund policy of your seller. http://www.microsoft.com for details. The information contained herein is subject to For any further information or to request a full change without notice. The only warranties for refund of the price of the computer, please HP products and services are set forth in the contact your seller. express warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein. -

Dell Precision Workstation 350 User's Guide

Dell Precision™ Workstation 350 User's Guide Information About Your Computer Finding Information for Your Computer Specifications Your Computer Front View Back View Inside Your Computer System Board Components Cleaning Your Computer Before Cleaning Your Computer Computer, Keyboard, and Monitor Mouse Floppy Drive CDs and DVDs Advanced Features LegacySelect Technology Control Manageability Security Password Protection System Setup Jumper Settings Power Button Connecting an IEEE 1394 Device TAPI Hyper-Threading Microsoft® Windows® XP Features Overview New User Interface Files and Settings Transfer Wizard Application and Device Compatibility System Restore User Accounts and Fast User Switching Home and Small Office Networking Internet Connection Firewall Removing and Installing Computer Parts Opening the Computer Cover Drives PCI Cards AGP Card Microprocessor Memory Battery Closing the Computer Cover Solving Problems Battery Problems Card Problems Drive Problems Dropped or Damaged Computer E-Mail, Modem, and Internet Problems Error Messages General Problems IEEE 1394 Device Problems Keyboard Problems Memory Problems Mouse Problems Network Problems Power Problems Printer Problems Serial or Parallel Device Problems Sound and Speaker Problems System Board Problems Video and Monitor Problems Advanced Troubleshooting Diagnostic Lights Beep Codes Dell Diagnostics Drivers Using System Restore Resolving Software and Hardware Incompatibilities Getting Help Technical Assistance Problems With Your Order Product Information Returning Items for Warranty Repair or Credit Before You Call Contacting Dell Warranty and Return Policy Ergonomic Computing Habits Regulatory Notices Glossary NOTE: A NOTE indicates important information that helps you make better use of your computer. NOTICE: A NOTICE indicates either potential damage to hardware or loss of data and tells you how to avoid the problem. -

AIR-FI: Generating Covert Wi-Fi Signals from Air-Gapped Computers

AIR-FI: Generating Covert Wi-Fi Signals from Air-Gapped Computers Mordechai Guri Ben-Gurion University of the Negev, Israel Cyber-Security Research Center [email protected] demo video: https://www.youtube.com/watch?v=vhNnc0ln63c air-gap research page: http://www.covertchannels.com Abstract—In this paper, we show that attackers can exfiltrate deceived insiders [20][5]. These techniques allow the attackers data from air-gapped computers via Wi-Fi signals. Malware in to insert targeted malware into systems within the isolated a compromised air-gapped computer can generate signals in the environment. Wi-Fi frequency bands. The signals are generated through the memory buses - no special hardware is required. Sensitive data One of the most famous incidents in which the air-gap can be modulated and secretly exfiltrated on top of the signals. was breached involved the Stuxnet worm which targeted su- We show that nearby Wi-Fi capable devices (e.g., smartphones, pervisory control and data acquisition (SCADA) systems and laptops, IoT devices) can intercept these signals, decode them, destroyed an estimated 1,000 centrifuges at an Iranian uranium and send them to the attacker over the Internet. To extract enrichment facility [53]. In 2018, the US Department of the signals, we utilize the physical layer information exposed by the Wi-Fi chips. We implement the transmitter and receiver Homeland Security accused Russian hackers of penetrating the and discuss design considerations and implementation details. We internal network of America’s electric utilities [4]. In 2019, the evaluate this covert channel in terms of bandwidth and distance media reported that the Kudankulam Nuclear Power Plant was and present a set of countermeasures. -

Texas Instrument Essay

Texas Instruments Challenge Essay Written by Riverglades Elementary Robogators Team 2891 We took apart a Dell N5010 and found many pieces inside, including the motherboard, the processor, and the RAM memory unit. We selected this device because it was bigger and had more components than other electronic devices that we had. Here are the components we found. The motherboard is a piece that connects all the components and parts in many devices. It also allows other components to interact with each other. A wireless LAN (Local Area Network) is a piece used to contact and message others. It is used for Gmail, messages, and other ways of calling and contacting. A hard drive is the piece that stores all your documents, pictures, downloads, and more. They can be internal or external. The processor is the central processing unit and is the piece that gives instructions to the rest of the computer. It is the main and most important part of the computer. The Bluetooth chip interprets incoming Bluetooth signals and then sends them out to other devices. The computer fan’s job is to cool the computer by expelling warm air and taking in cool air from the inside. The computer fan helps keep the computer cool. The DC Jack is the part of the computer that allows something to be plugged into the computer including the charging plug, USBs, and more wires. CD player lets you insert a cd, play it, pause, rewind, forward, record, etc. The RAM memory unit keeps all the things you download, save, copy, paste, and more, into one chip. -

Heat Transfer Characteristics of Natural Convection Within an Enclosure Using Liquid Cooling System

Heat Transfer Characteristics of Natural Convection within an Enclosure Using Liquid Cooling System Farouq Ali S. GDHAIDH Submitted for the Degree of Doctor of Philosophy School of Engineering and Informatics University of Bradford 2015 i Abstract Farouq Ali S. Gdhaidh Heat Transfer Characteristics of Natural Convection within an Enclosure Using Liquid Cooling System Keywords: Computer-cooling system, CPU fan, chips limit temperature, electronic chips, experimental study, internal heat sink, natural convection, numerical study, real boundary conditions, rectangular enclosure, single phase liquid. In this investigation, a single phase fluid is used to study the coupling between natural convection heat transfer within an enclosure and forced convection through computer covering case to cool the electronic chip. Two working fluids are used (water and air) within a rectangular enclosure and the air flow through the computer case is created by an exhaust fan installed at the back of the computer case. The optimum enclosure size configuration that keeps a maximum temperature of the heat source at a safe temperature level (85℃) is determined. The cooling system is tested for varying values of applied power in the range of 15 − 40푊. The study is based on both numerical models and experimental observations. The numerical work was developed using the commercial software (ANSYS-Icepak) to simulate the flow and temperature fields for the desktop computer and the cooling system. The numerical simulation has the same physical geometry as those used in the experimental investigations. The experimental work was aimed to gather the details for temperature field and use them in the validation of the numerical prediction. -

CORSAIR Icue QL120 RGB White 120Mm PWM Single Fan

CORSAIR iCUE QL120 RGB White 120mm PWM Single Fan Embargo Date First Customer Ship Date 30-Jan-20 Product Etail Title CORSAIR QL Series, iCUE QL120 RGB, 120mm RGB LED PWM White Fan, Single Fan Product Title CORSAIR QL Series, iCUE QL120 RGB, 120mm RGB LED PWM White Fan, Single Fan Product Name CORSAIR iCUE QL120 RGB 120mm RGB PWM White Single Fan Pre Order Option No Product Imagery Image Asset OverviewOverview 25 Word Product Description Give your PC spectacular lighting from any angle with a CORSAIR iCUE QL120 RGB PWM White fan, equipped with 34 individually addressable RGB LEDs across four distinct light loops in a brilliant white housing. Overview 50 Word Product Description Give your PC spectacular lighting from any angle with a CORSAIR iCUE QL120 RGB PWM White fan, equipped with 34 individually addressable RGB LEDs across four distinct light loops in a brilliant white housing. Pair with an existing QL120 RGB White Triple Fan Kit or a CORSAIR iCUE RGB lighting controller (sold separately) to control and synchronize your RGB lighting through CORSAIR iCUE software. Keep your system cool with PWM speeds up to 1,500 RPM. OverviewOverview 100 Word Product Description Give your PC spectacular lighting from any angle with a CORSAIR iCUE QL120 RGB PWM White fan, equipped with 34 individually addressable RGB LEDs across four distinct light loops in a brilliant white housing. Pair with an existing QL120 RGB White Triple Fan Kit or a CORSAIR iCUE RGB lighting controller (sold separately) to control and synchronize your RGB lighting through CORSAIR iCUE software. -

Computer Hardware: Hardware Components and Internal PC Connections Jerome Casey Dublin Institute of Technology, [email protected]

Dublin Institute of Technology ARROW@DIT Instructional Guides School of Multidisciplinary Technologies 2015 Computer Hardware: Hardware Components and Internal PC Connections Jerome Casey Dublin Institute of Technology, [email protected] Follow this and additional works at: http://arrow.dit.ie/schmuldissoft Part of the Engineering Education Commons Recommended Citation Casey, J. (2015). Computer Hardware: Hardware Components and Internal PC Connections. Guide for undergraduate students. Dublin Institute of Technology This Other is brought to you for free and open access by the School of Multidisciplinary Technologies at ARROW@DIT. It has been accepted for inclusion in Instructional Guides by an authorized administrator of ARROW@DIT. For more information, please contact [email protected], [email protected], [email protected]. This work is licensed under a Creative Commons Attribution-Noncommercial- Share Alike 3.0 License Higher Cert/Bachelor of Technology – DT036A Computer Systems Computer Hardware – Hardware Components & Internal PC Connections: You might see a specification for a PC 1 such as "containing an Intel i7 Hexa core processor - 3.46GHz, 3200MHz Bus, 384 KB L1 cache, 1.5MB L2 cache, 12 MB L3 cache, 32nm process technology; 4 gigabytes of RAM, ATX motherboard, Windows 7 Home Premium 64-bit operating system, an Intel® GMA HD graphics card, a 500 gigabytes SATA hard drive (5400rpm), and WiFi 802.11 bgn". This section aims to discuss a selection of hardware parts, outline common metrics and specifications used to describe -

Comparison of Analytical and Numerical Solutions of the Heat

Interconnect Thermal Management of High Power Packaged Electronic Architectures A Thesis Presented to The Academic Faculty By Jason Todd Cook In Partial Fulfillment of the Requirements for the Degree Master’s of Science in Mechanical Engineering Georgia Institute of Technology June 2004 Interconnect Thermal Management of High Power Packaged Electronic Architectures Approved: Yogendra Joshi, Ph.D., Chair Ravi Doraiswami, Ph.D. S. Mostafa Ghiaasiaan, Ph.D. Date Approved: June 29, 2004 ii DEDICATION To my wife Megan M. Cook & To my parents Roy and Mary Ann Cook iii ACKNOWLEDGEMENTS The author would like to thank Jesus Christ the Lord and Savior, without whom none of this would have been possible. Next, the author would like to thank Roy and Mary Ann Cook for their encouragement and support over the years. The author would like to thank Dr. Yogendra Joshi and Dr. Ravi Doraiswami for their advice, direction, and serving on the thesis committee for this project. The author would also like to thank Dr. Mostafa Ghiaasiaan for participating in the thesis reading committee. The author also acknowledges financial support for this study from the National Science Foundation and Packaging Research Center at Georgia Institute of Technology. Finally, the author would like to thank the Woodruff School of Mechanical Engineering at Georgia Institute of Technology. iv TABLE OF CONTENTS DEDICATION.................................................................................................................III ACKNOWLEDGEMENTS ...........................................................................................IV -

® A7v266-E User's Manual

® A7V266-E JumperFree™ DDR DRAM 266MHz FSB AGP Pro/4X Socket A Motherboard USER’S MANUAL USER'S NOTICE No part of this manual, including the products and software described in it, may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language in any form or by any means, except documentation kept by the purchaser for backup purposes, without the express written permission of ASUSTeK COMPUTER INC. (“ASUS”). ASUS PROVIDES THIS MANUAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL ASUS, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES (INCLUDING DAMAGES FOR LOSS OF PROFITS, LOSS OF BUSINESS, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS AND THE LIKE), EVEN IF ASUS HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES ARISING FROM ANY DEFECT OR ERROR IN THIS MANUAL OR PRODUCT. Product warranty or service will not be extended if: (1) the product is repaired, modified or altered, unless such repair, modification of alteration is authorized in writing by ASUS; or (2) the serial number of the product is defaced or missing. Products and corporate names appearing in this manual may or may not be registered trademarks or copyrights of their respective companies, and are used only for identification or explanation and to the owners’ benefit, without intent to infringe. • Intel and Pentium are registered trademarks of Intel Corporation. • VIA is a registered trademark of VIA Technologies, Inc. -

® A7m266-D User's Manual

® A7M266-D Dual Socket A Motherboard USER’S MANUAL USER'S NOTICE No part of this manual, including the products and software described in it, may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language in any form or by any means, except documentation kept by the purchaser for backup purposes, without the express written permission of ASUSTeK COMPUTER INC. (“ASUS”). ASUS PROVIDES THIS MANUAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EI- THER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WAR- RANTIES OR CONDITIONS OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL ASUS, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUEN- TIAL DAMAGES (INCLUDING DAMAGES FOR LOSS OF PROFITS, LOSS OF BUSINESS, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS AND THE LIKE), EVEN IF ASUS HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES ARISING FROM ANY DEFECT OR ERROR IN THIS MANUAL OR PRODUCT. Product warranty or service will not be extended if: (1) the product is repaired, modified or al- tered, unless such repair, modification of alteration is authorized in writing by ASUS; or (2) the serial number of the product is defaced or missing. Products and corporate names appearing in this manual may or may not be registered trademarks or copyrights of their respective companies, and are used only for identification or explanation and to the owners’ benefit, without intent to infringe. • AMD, Athlon™ are trademarks of Advanced Micro Devices, Inc. • VIA is a trademark of VIA Technologies, Inc.